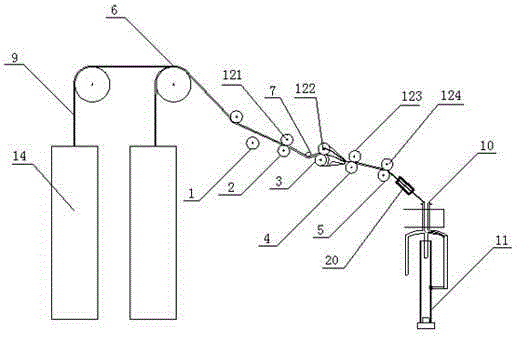

Doubling roving integrated sample weaving machine

A small prototype, roving drum technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of prolonged spinning process, high sliver quality requirements, and increased spinning costs. , to achieve the effect of reducing the spinning process, reducing the cost of proofing, and reducing the cost of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

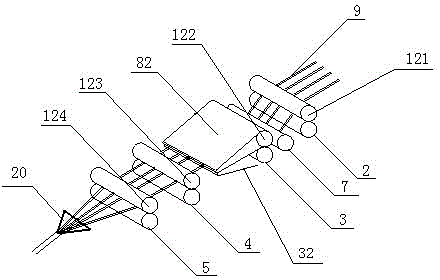

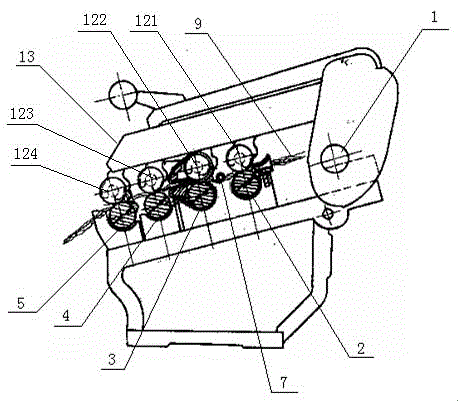

Method used

Image

Examples

Embodiment 1

[0041] After the raw cotton has gone through the opening and cleaning process, carding process, combing preparation process, and combing process, four combed cotton slivers are fed into the small integrated prototype machine of the present invention, spun into roving, and then passed through the spinning process, winding Tube process to form 18.5tex pure cotton combed yarn.

Embodiment 2

[0043] After the raw cotton goes through the opening and cleaning process and carding process, raw cotton slivers are formed; after the silver ion antibacterial polyester goes through the opening and cleaning process and carding process, silver ion antibacterial polyester slivers are formed; two carded cotton slivers and two The root silver ion antibacterial polyester raw slivers are simultaneously fed into the small integrated roughing machine of the present invention, spun into roving, and then go through the spinning process and winding process to form 28tex cotton / polyester 50 / 50 composite yarn.

Embodiment 3

[0045] After the raw cotton goes through the opening and cleaning process and the carding process, three carded cotton slivers are fed into the small integrated prototype machine of the present invention, spun into roving, and then go through the spinning process and winding process to form 28tex ordinary cotton yarn.

[0046] It can be seen from the above examples that the roving spun by the present invention not only has guaranteed quality, but also reduces the work flow and improves production efficiency.

[0047]Compared with the traditional roving frame that draws, twists, and winds a cotton sliver to form a roving, the small integrated prototype of the present invention has a greater impact on the quality of the sliver due to the use of a cotton sliver in the traditional roving frame. The requirements are relatively high, and the general sliver needs to be combined by two or three draw frames to meet the requirements. 2-4 cotton slivers are drawn and merged through the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com