Open-end spinning device

A technology of free-end and rotor, applied to open-end spinning machines, spinning machines, continuous winding spinning machines, etc., can solve the problems of complex structure design and high cost of free-end spinning devices, and achieve simple structure , Low manufacturing cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

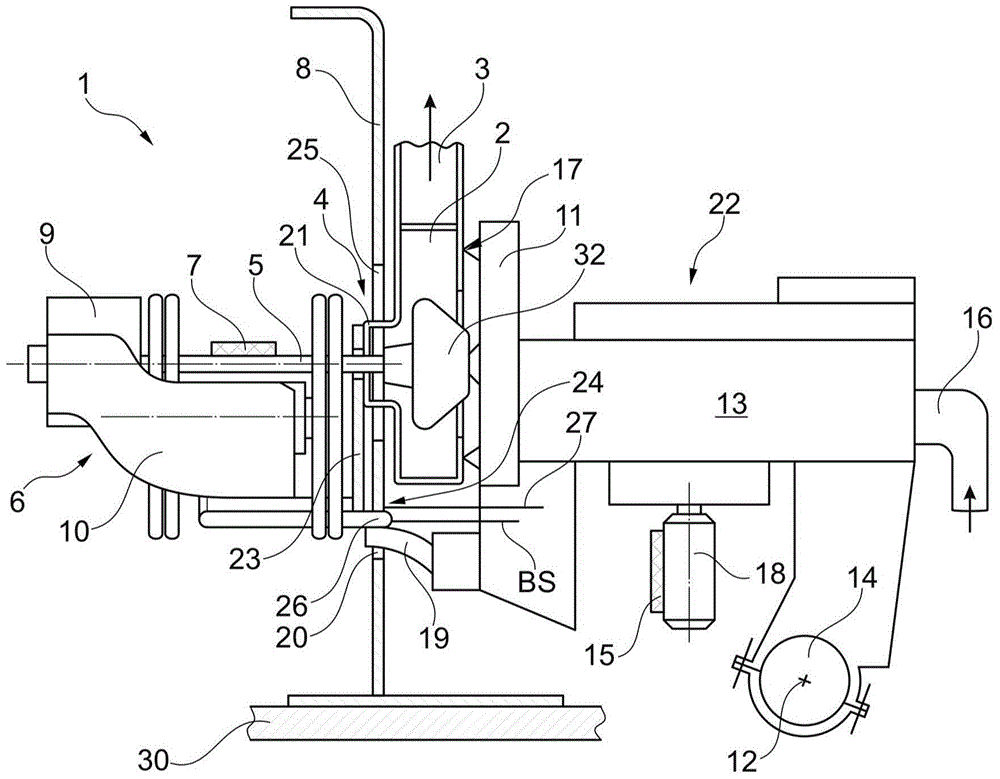

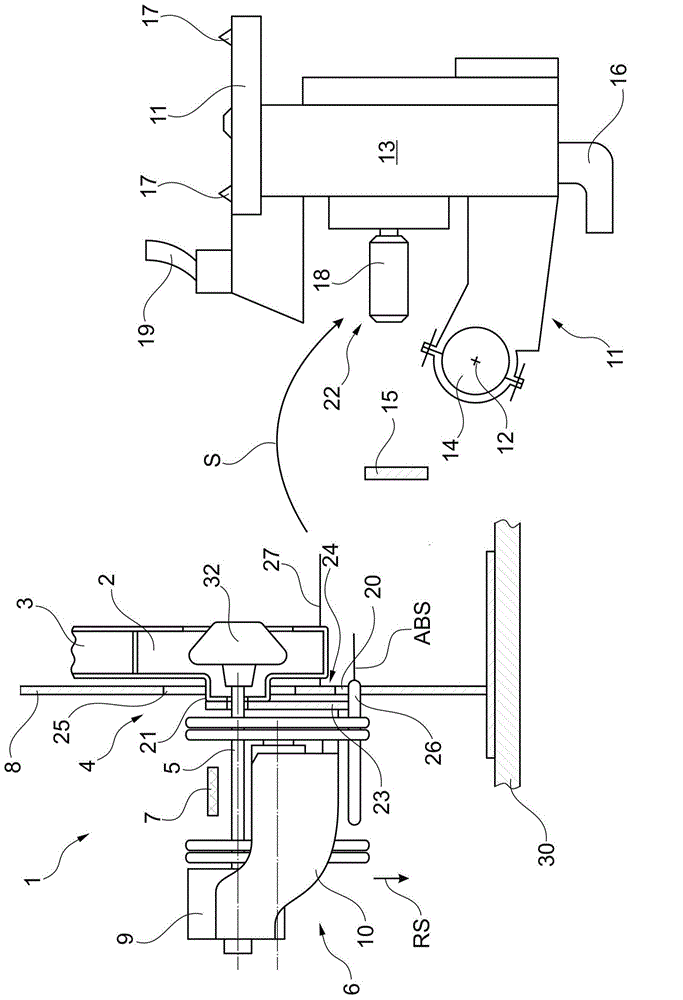

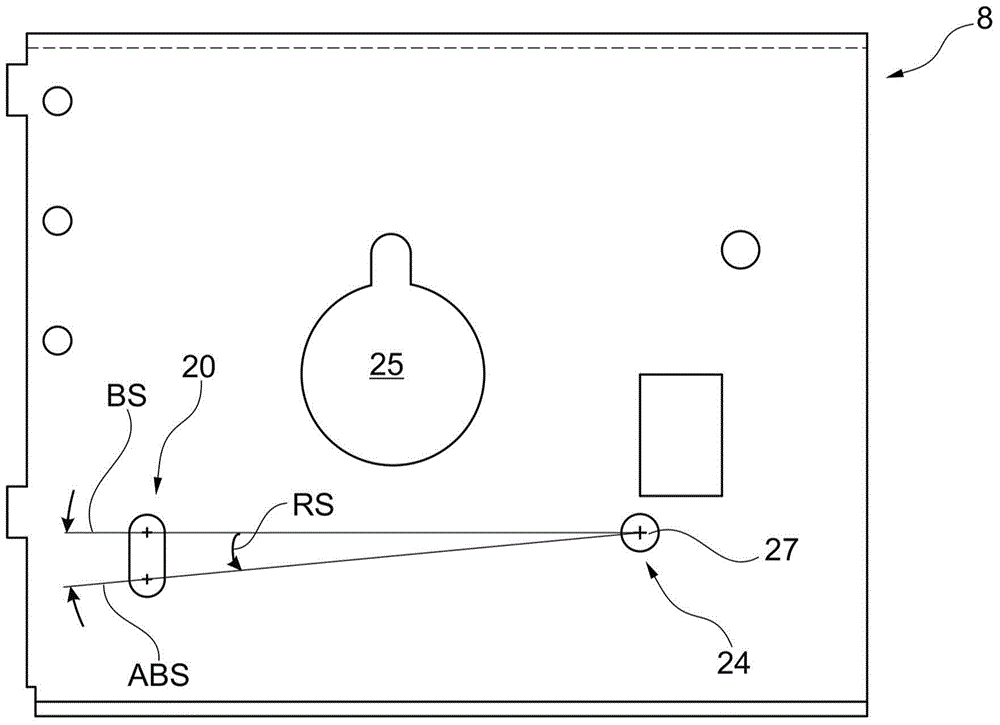

[0048] figure 1 The open-end spinning device 1 is schematically shown in its operating position BS, in which the rotor shaft bearing 10 is positioned such that the rotor shaft 5 of the spinning rotor 4 rests against the rotational edge from below. Machine length tangential drive belt7.

[0049] figure 2 The same open-end spinning device 1 is shown in the rest position ABS, that is to say in the position in which the rotor shaft bearing 10 is positioned such that the rotor of the spinning rotor 4 The cup shaft 5 is spaced from a revolving tangential drive belt 7 along the length of the machine.

[0050] As shown in the figure, the rotor housing 2 in which the rotor body 32 of the spinning rotor 4 rotates at high speed is closed by a cover 11 or by a sealing mechanism 17 and is passed through a flexible gas tube 3, for example a plastic hose Connected to a negative pressure source (not shown) for providing the negative pressure required for spinning.

[0051] In this exempl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com