Dustproof device for sewing machine

A dust-proof device and sewing machine technology, which is applied in the field of sewing machine manufacturing, can solve the problems of large space occupation and easy collision, and achieve the effects of high processing accuracy, reduced failure and low failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

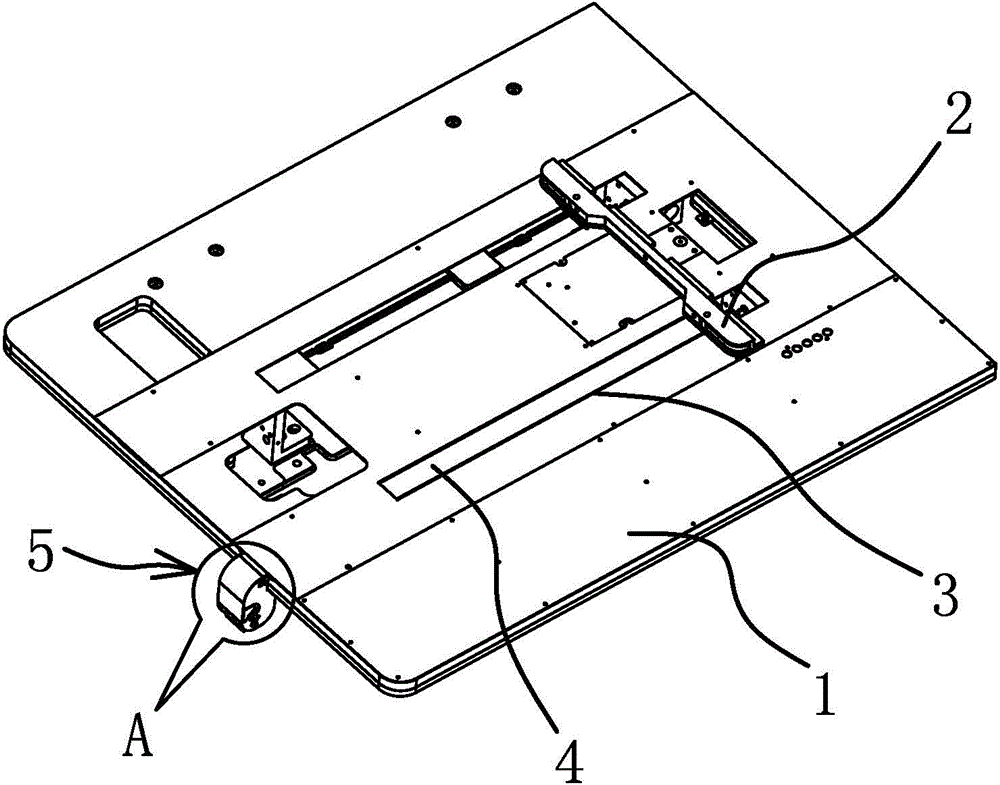

[0034] like figure 1 As shown, the sewing machine includes a workbench panel 1, a template transmission assembly 2 and a dust-proof device.

[0035] The workbench panel 1 is in the shape of a flat plate, and the formwork transmission assembly 2 is installed on the workbench panel 1. The workbench panel 1 has a long guide hole 3 that runs through the workbench panel 1. The formwork transmission assembly 2 can move along the guide hole 3. Move left and right.

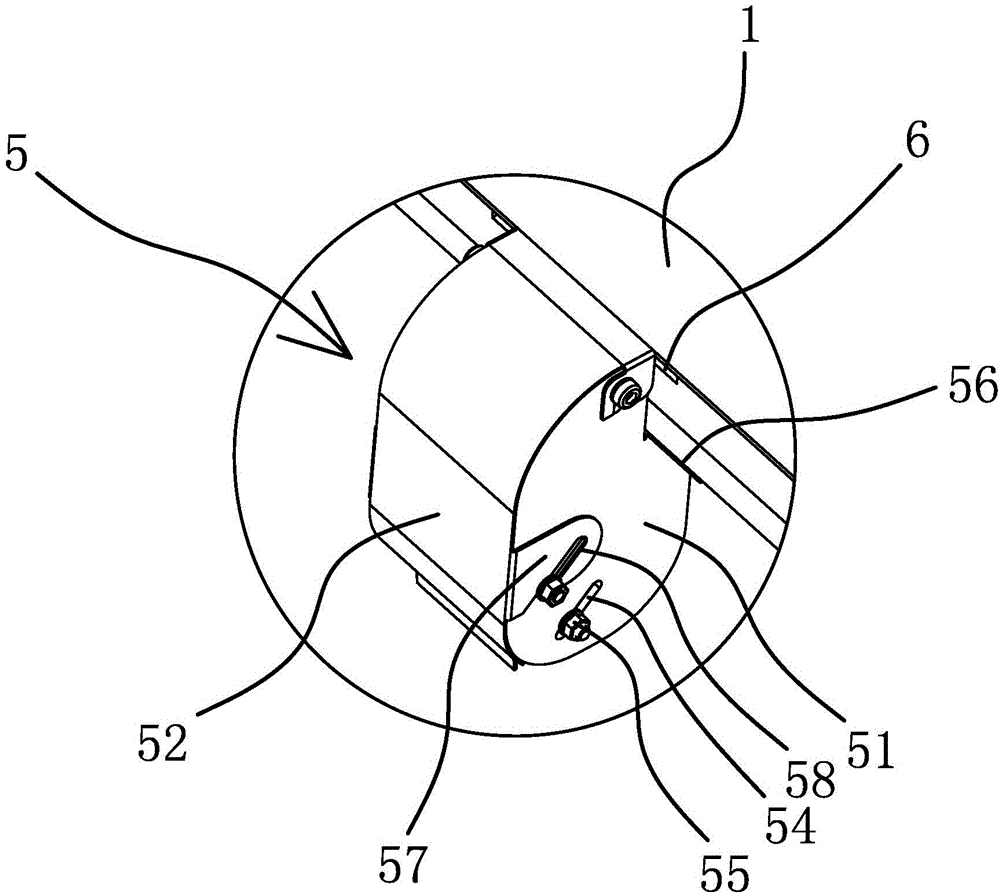

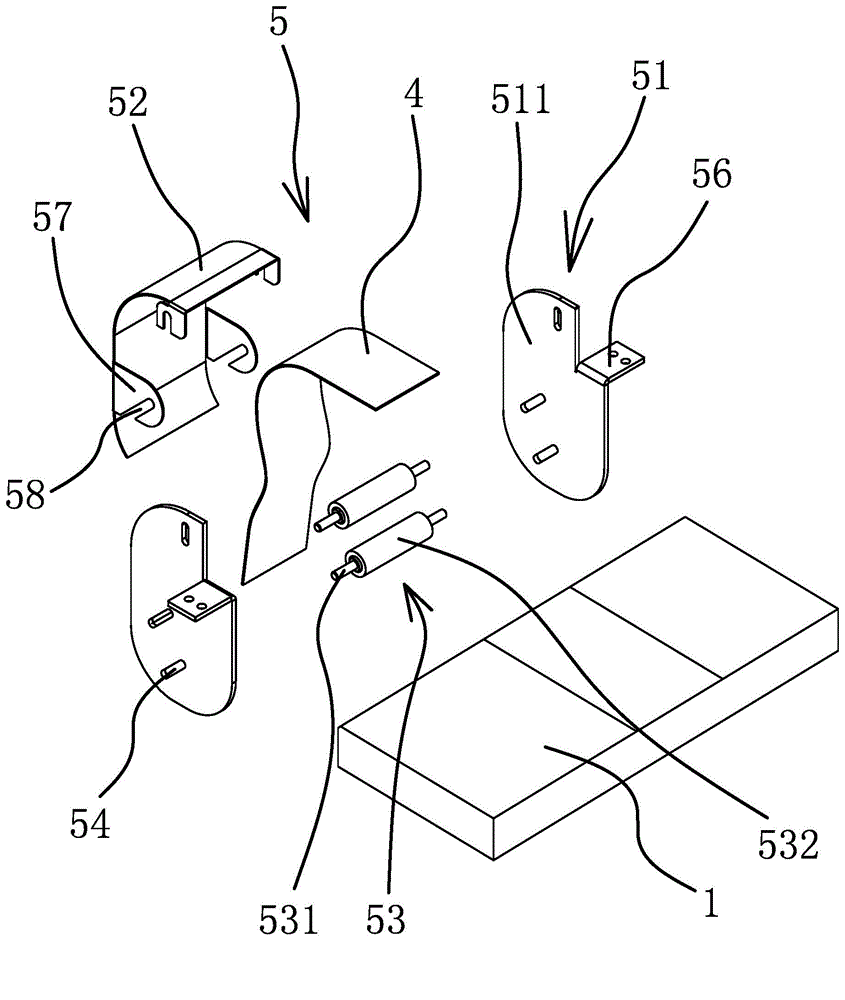

[0036] like figure 2 , image 3 , Image 6 As shown, the dustproof device includes a dustproof plate 4 and a reversing structure 5 . The dustproof plate 4 is made of plastic material and is in the shape of a sheet. The length of the dustproof plate 4 is greater than the length of the guide hole 3. The width of the dustproof plate 4 matches the width of the guide hole 3. One side of the workbench panel 1 has The positioning hole 6 matched with the dustproof plate 4, the dustproof plate 4 part is located in the positi...

Embodiment 2

[0038] like Figure 7 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the reversing structure 5 only includes the mounting seat 51 and the cover plate 52, and does not include the roller 53. The reversing structure 5 is simple in structure and low in manufacturing cost.

Embodiment 3

[0040] like Figure 8 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the reversing structure 5 includes a mounting seat 51, a cover plate 52 and a roller 53, and the roller 53 is opposite to the dustproof plate. The moving direction of 4 plays the role of adjustment to prevent the dust-proof plate 4 from deviating from the set direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com