Door body of roller washing machine and washing machine

A drum washing machine and door body technology, which is applied in the field of washing machines, can solve the problems of screw rust and corrosion, and achieve the effect of strong integrity, simple assembly, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

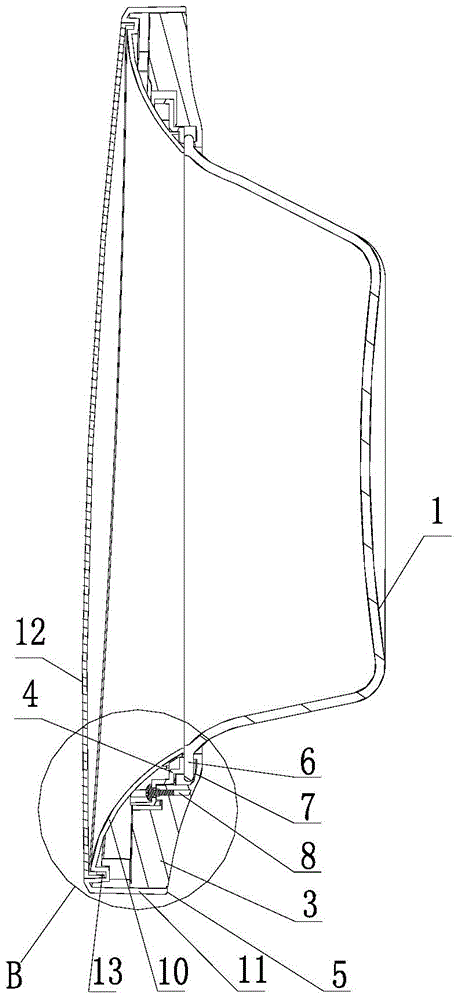

[0042] In this embodiment, the thickness of the inner circle of the inner frame 3 changes abruptly to form a recessed step, the height of the recessed step corresponds to the thickness of the ring flange 6, the middle frame 4 is a ring-shaped structure, and the The annular flange 6 extends into the recessed step, the inner circle of the middle frame 4 presses the annular flange 6, the outer circle cooperates with the inner frame 3, and the joint is screwed.

Embodiment 2

[0044] In this embodiment, the thickness of the inner ring part of the inner frame 3 changes suddenly to form a concave step, and the thickness of the inner ring part of the middle frame 4 changes suddenly to form a raised step, and the height of the recessed step is the same as the height of the raised step, The sum of the thicknesses of the ring-shaped flange 6 is corresponding, and the ring-shaped flange 6 extends into the concave step, and the raised step of the middle frame 4 presses the ring-shaped flange 6, and the outer surface of the middle frame 4 The ring part is matched with the inner frame 3, and the matching part is screwed.

Embodiment 3

[0046] The inner frame 3 described in this embodiment is annular, and the inner ring of the inner frame 3 has a flat side, which is matched with the annular flange 6, and the middle frame 4 is annular, and the inner ring has a The flat side of the flat side presses the other side of the ring-shaped flange 6, and the outer ring of the middle frame 4 matches the shape of the opposite side of the inner frame. After the two are matched, they are connected by screws, and the ring-shaped flange 6 is clamped. Between the middle frame 4 and the inner frame 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com