Isolated anti-theft lock structure

An anti-theft lock and isolated technology, applied in padlocks, building locks, cylinder locks, etc., can solve the problems of poor anti-theft ability, increased user cost, and poor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

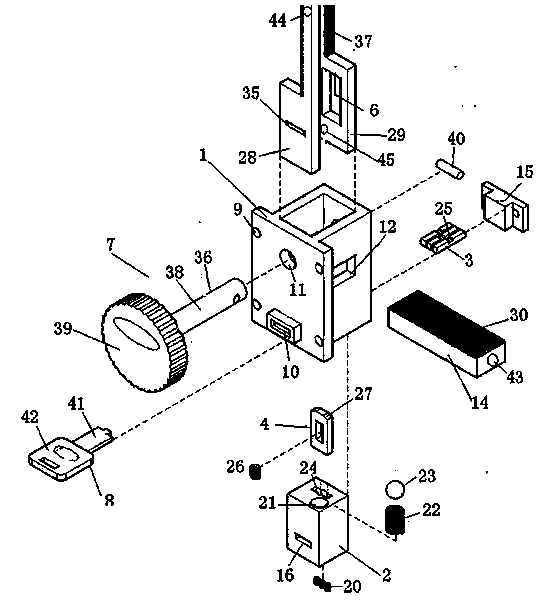

[0105] Embodiment one, with reference to the attached Figure 1-14 .

[0106] An isolated anti-theft lock structure, called a three-way output isolation lock, comprising a housing 1, a lock cylinder 2, a slider 3, a stop valve 4, a scissors body, a key 8 and a rotating rod 38; There is a keyhole 10, and the housing 1 is provided with a lock core 2 and a scissors body; the lock core 2 is provided with a rectangular hole 16 from the front face to the rear face, and the front section of the rectangular hole 16 matches the key hole 10, and the rectangular hole 16 is rectangular. The back section of the hole 16 forms 3 or 4 slider holes 18 through the grid, and a slider 3 is provided in the slider hole 18, and a slider groove 25 is provided on the slider 3; the stop valve 4 is arranged on the lock cylinder 2, the top of the stop valve 4 exposes the upper surface of the lock cylinder 2, and the bottom of the stop valve 4 is in contact with the slider 3; The upper surface of 14 is ...

Embodiment 2

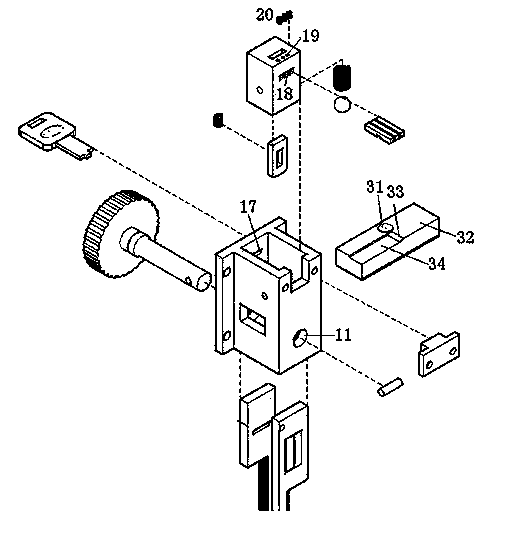

[0123] Embodiment two, referring to the attached Figure 15-23 .

[0124] An isolated anti-theft lock structure, called a rotary isolation lock, includes a housing 1, a lock cylinder 2, a slider 3, a stop valve 4, a scissor body 5, a slider return device, a key and a rotating rod 38; The housing 1 is provided with a lock cylinder 2, a stop valve 4 and a scissors body 5. The inner surface of the housing 1 is provided with a double-slope groove 33, and the double-slope groove 33 extends from the front end surface of the housing 1 to the rear end surface. There is a rear end cover 15; the rotating rod 38 and the lock cylinder 2 are in an integrated stepped shaft structure, and one end of the rotating rod 38 is provided with a key hole, which is located at the front end of the housing 1, and the other end of the rotating rod 38 is provided with a dead bolt 49, and the lock The tongue 49 passes through the rear end cover 15 of the shell 1, and the rotating rod 38 is provided with ...

Embodiment 3

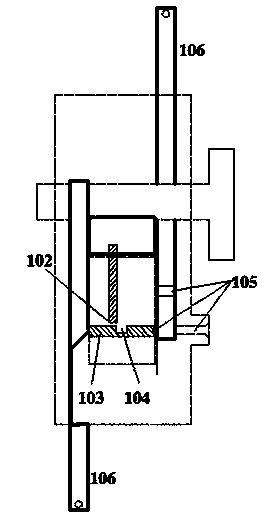

[0141] Embodiment three, with reference to the attached Figure 24-30 .

[0142]An isolated anti-theft lock structure, called an additional isolated lock, comprising a housing 1, a lock cylinder 2, a slider 3, a supporting member 51 and a key; a button 56 is provided on the front end of the housing 1, and a There is a keyhole 10, a rear end cover 15 is fixed on the rear end surface, and a cylinder 47 is arranged on the inner side of the rear end cover 15; the supporting member 51 is arranged in the casing 1, and the supporting member 51 is slidably connected with the casing 1 in the horizontal direction. A return spring 57 is provided between the supporting member 51 and the rear end cover 15; the lock core 2 and the supporting member 51 are vertically slidably connected through the vertical rib 55 on the supporting member 51, and the lock core 2 is provided with Rectangular hole 16, and rectangular hole 16 cooperates with key hole 10, constitutes variable key channel, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com