High-temperature high-pressure dry gas injection longitudinal wave and efficiency testing device and method for gas condensate reservoir

A technology for high temperature and high pressure, condensate gas reservoirs, which is applied in the fields of earthwork drilling, production of fluids, wellbore/well components, etc. It can solve problems such as inability to explore, incapable of physical simulation of gravity overlay phenomena, and inability to simulate production phenomena well. , to achieve the effect of overcoming phase change and overcoming test instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Further illustrate the present invention according to example below in conjunction with accompanying drawing.

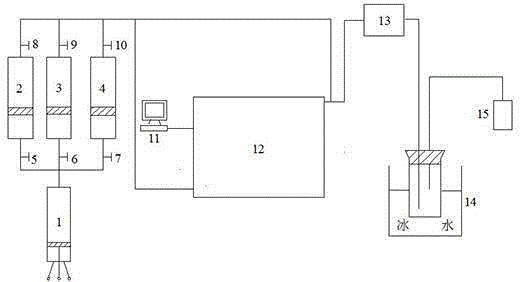

[0040] see figure 1 .

[0041] Longitudinal sweep efficiency test device for dry gas injection in high temperature and high pressure condensate gas reservoirs, mainly composed of high pressure displacement pump 1, dry gas intermediate container 2, condensate gas sample intermediate container 3, formation water sample intermediate container 4, data acquisition system 11, high temperature It consists of a high-pressure plate model system 12, a back pressure controller 13, an oil-gas separator 14, and a gas meter 15.

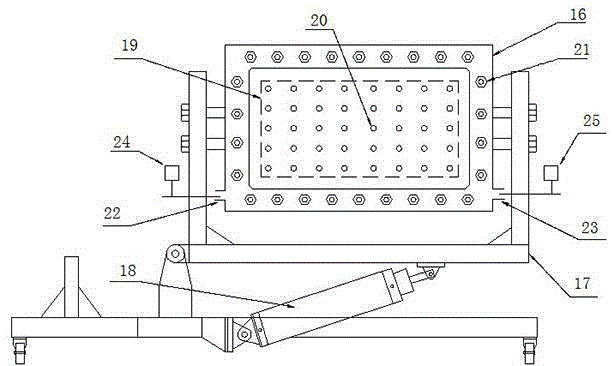

[0042] see figure 2 .

[0043]The high-temperature and high-pressure flat model system 12 is mainly composed of a flat model 16, a model frame 17, a vertical lifting mechanism 18, a temperature control system 19, fastening bolts 21, fluid physical property test points 20, pressure sensors 24 and 25, and is located in the model The flat plate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com