Furnace End Face Sealing Structure for Perlite Expansion Furnace

An end face sealing and perlite technology is applied in the field of furnace end face sealing structures for perlite expansion furnaces, which can solve the problems of inconvenient disassembly and installation, inconvenient internal cleaning, economic loss, etc., and is suitable for popularization and use, and avoids the failure of sealing effect. , Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

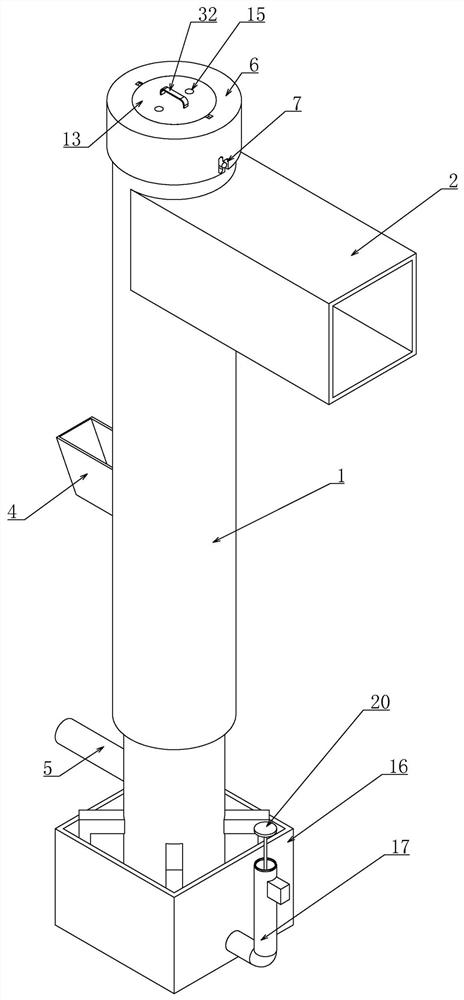

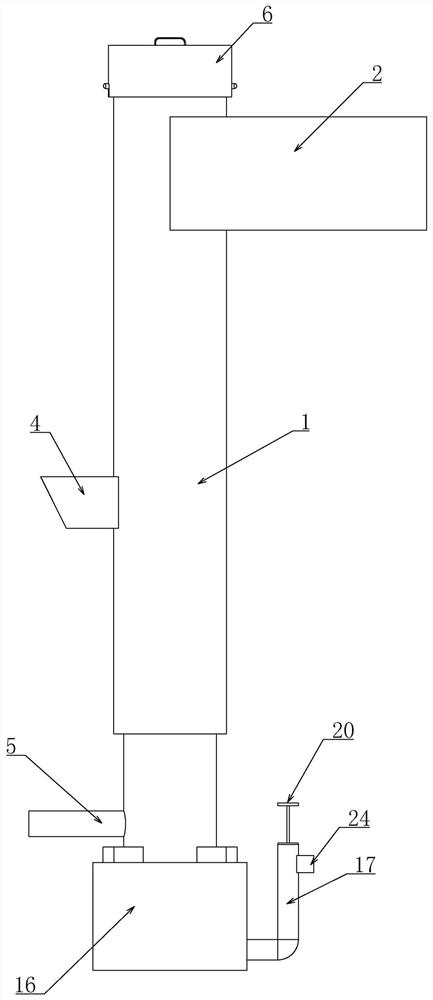

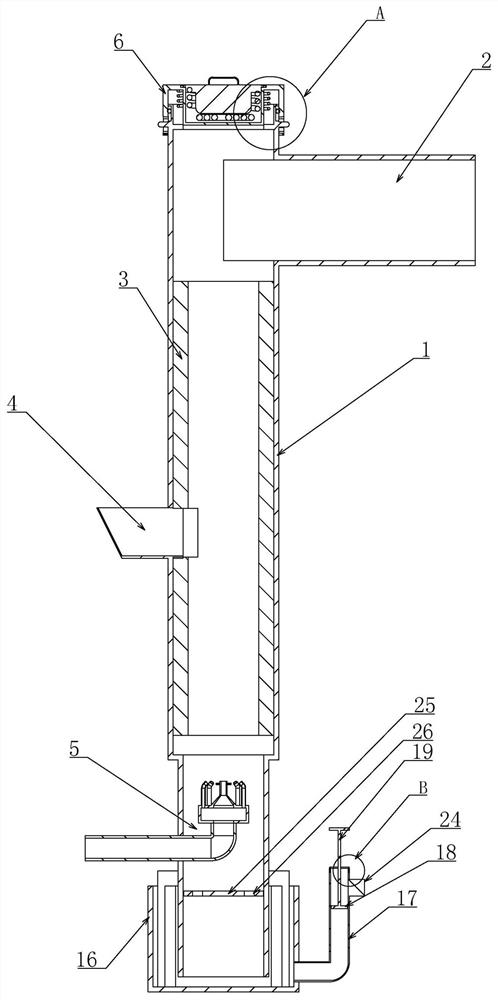

Embodiment 1

[0024]Embodiment 1, a furnace end face sealing structure for a perlite expansion furnace, comprising a furnace 1 with openings at the upper and lower ends of the furnace 1, characterized in that the upper end of the furnace 1 is connected to a discharge port 2, and the discharge port 2 is connected to a cyclone separator and After the dust collector, connect the silo, the outlet 2 is connected with an induced draft fan, and the induced draft fan is used to guide the expanded perlite to the outlet 2, and the furnace 1 is equipped with an insulation layer and Insulation layer 3, the heat insulation layer 3 blocks the high temperature in the furnace 1, and the insulation layer is to keep internal problems from being affected by the outside world, and the side wall of the furnace 1 is provided with a feed port 4, The feeding port 4 is opened at the position lower than the middle part of the side wall of the furnace 1, and the feeding port 4 is connected with a feeding hopper, and t...

Embodiment 2

[0025] Embodiment 2, on the basis of Embodiment 1 or 2, the water sealing device includes a water tank 16 connected to the lower end of the furnace 1, the inner bottom surface of the water tank 16 is not in contact with the lower bottom surface of the furnace 1, and the inside of the water tank 16 is connected to the lower end of the furnace. 1. The lower end is connected, and the lower end side wall of the water tank 16 is connected with a vertically arranged connecting pipe 17, which forms a connecting device structure with the water tank 16. The connecting pipe 17 is vertically slid to fit a float 18, and the The upper end of the buoy 18 is connected with a long connecting rod 19, and the upper end of the long connecting rod 19 is connected with a trigger plate 20. The size of the trigger plate 20 will cover the upper end of the connecting pipe 17, and the upper end of the connecting pipe 17 has an annular The accommodating groove 21, a trigger ring 22 is slid vertically in ...

Embodiment 3

[0027] Embodiment 3, on the basis of Embodiment 1 or 2, the end cap 13 includes two sets of limit pins 27 that are evenly distributed in the circumferential direction on the outer side wall of the end cap 13, and also includes two sets of stop pins 27 that are opened on the upper side wall of the accommodating cavity 12. Two groups of limit grooves 28 on the top are matched with corresponding side limit pins 27. The bottom of the limit groove 28 communicates with an arc-shaped arc groove 29 opened on the side wall of the receiving groove 21. The arc Shaped groove 29 cooperates with limit pin 27 to be used to limit the vertical relative movement of end cover 13, after end cover 13 is stuck in the bottom through the cooperation of limit groove 28 and limit pin 27, screw end cover 13, makes limit The position pin 27 snaps into the arc-shaped groove 29 to limit the vertical movement of the end cover 13 . The purpose of the movable connection of the end cover 13 is to facilitate mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com