A structure that highly integrates oil, water, gas and supercharger installation surface

A supercharger and mounting surface technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of adding sealing links, occupying a large volume, and high cost, so as to reduce sealing links, reduce leakage risks, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

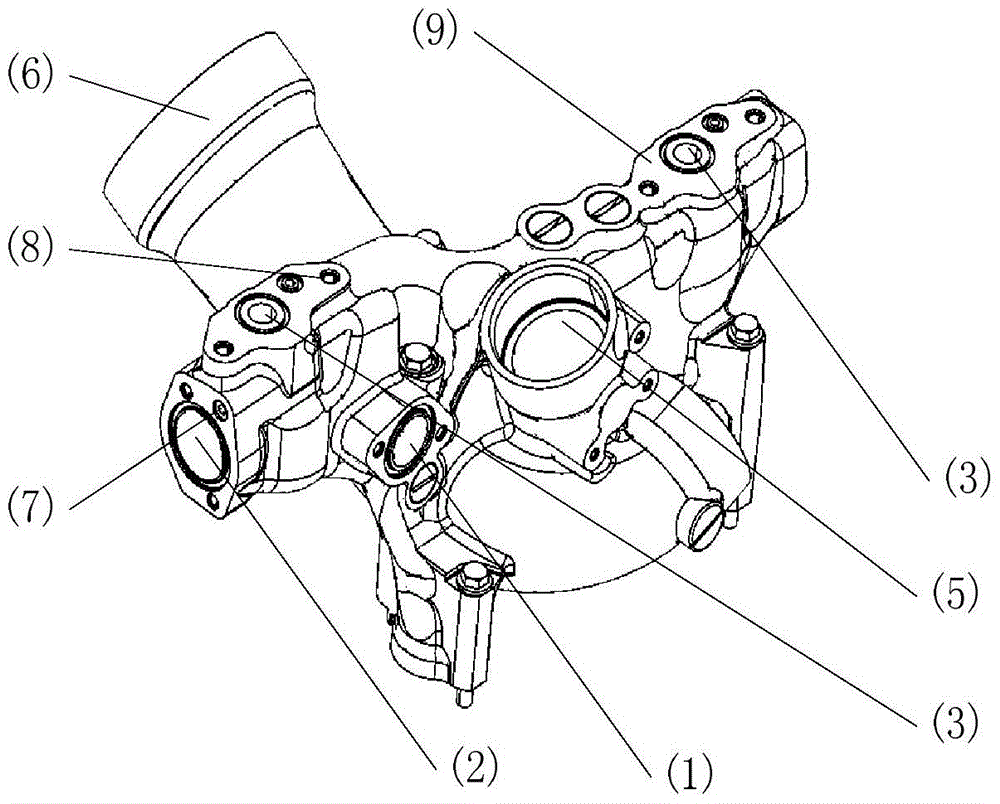

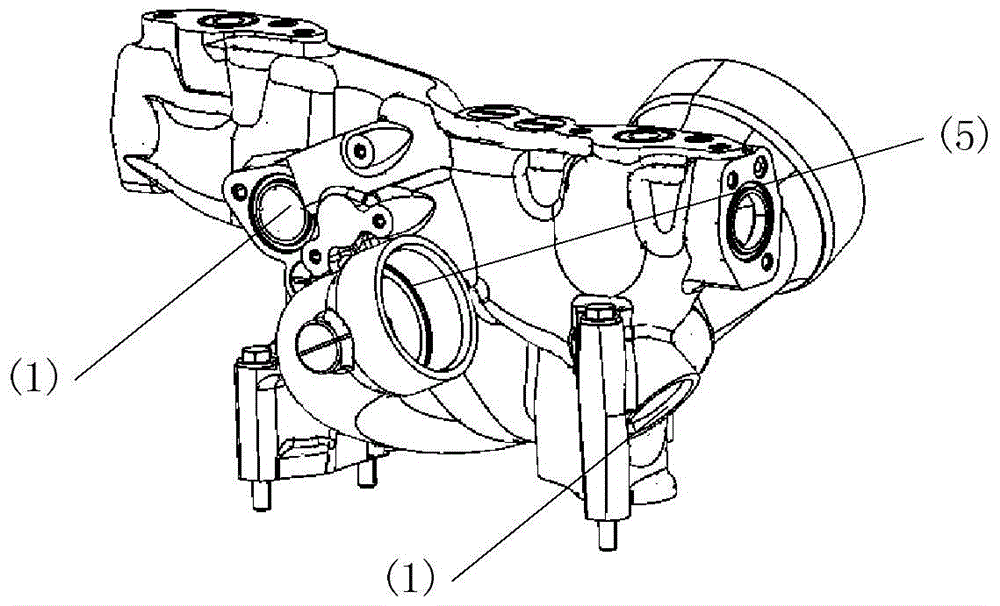

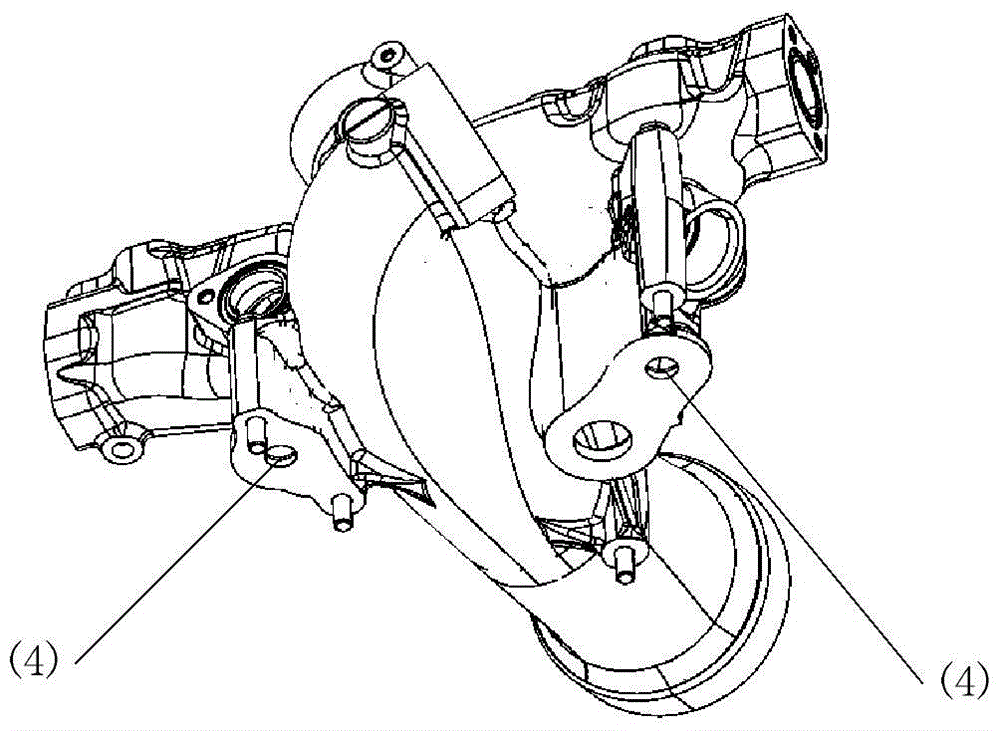

[0020] A structure that highly integrates oil, water, gas and the supercharger installation surface, including the structural body, such as Figures 1 to 3 As shown, the structural body includes two supercharger mounting surfaces 9, a lubricating oil inlet 7 and a lubricating oil outlet 8, two return water inlets 1 and one return water outlet 2, an oil return port 3 and an oil return port outlet 4 , air inlet 5 and air outlet 6;

[0021] In the preferred embodiment of the present invention, the structural body is based on a cross-shaped structure, and the front and rear passages of the cross-shaped structure of the structural body realize the air intake communication. Air port 5, the passage where the two air inlets 5 are located converges into a passage inside the structural body, which is connected to the air outlet 6 provided on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com