Pressurization controllable oil injection device and oil injection method

An oil injection device and controllable technology, which is applied in the direction of lubricating oil control valves, lubricating pumps, lubricating parts, etc., can solve problems such as the inability to adjust the pressure of the oil injection system, the inability to accurately adjust the amount of oil injection, and the complexity of the cam manufacturing process. Achieve good atomization effect, good lubrication, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

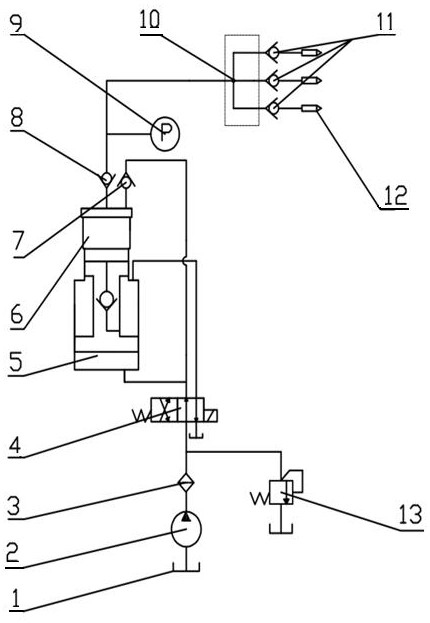

[0027] A pressurized and controllable oil injection device, which consists of: a constant pressure pump 2, the constant pressure pump is connected to the oil tank 1 and the filter 3 through pipelines, and the filter is connected to the safety valve through the pipelines 13. The two-position four-way electromagnetic reversing valve 4 is connected. The two-position four-way electromagnetic reversing valve is connected to the single-acting booster cylinder 5. The front end of the single-acting booster cylinder is connected to the front end cover 6 through threads. The front end cover is respectively connected to the one-way valve a7 and the one-way valve b8 through pipelines, the one-way valve a is connected to the two-position four-way electromagnetic reversing valve, and the one-way valve b is connected to the A pressure gauge 9 is installed between the shunts 10, and a one-way valve c11 is installed between the shunt and the oil injector 12. When the needle valve of the device ...

Embodiment 2

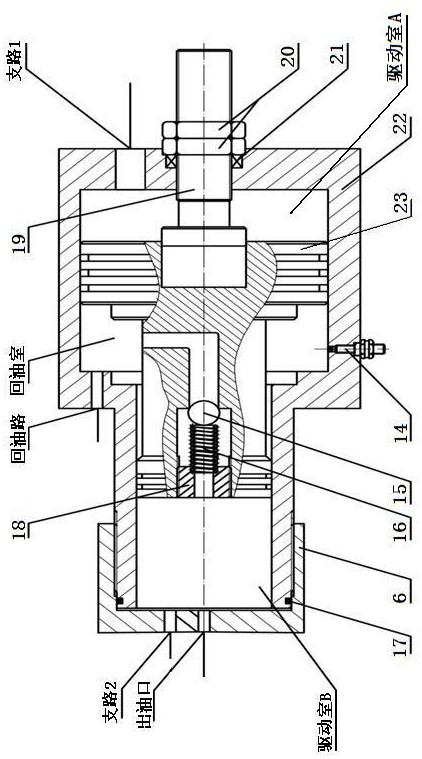

[0029] According to the pressurized controllable oil injection device described in Embodiment 1, the single-acting pressurized cylinder includes a cylinder body 22, and a piston body 23 is installed inside the cylinder body, and the piston body connects the inner part of the cylinder body. It is the driving chamber A, the oil return chamber and the driving chamber B. There are vertical intersecting holes on the circumference of the piston body, and a check valve 15 is installed at the front end of the vertical intersecting hole, and a check valve 15 is installed at the front end of the check valve. Spring 16, said spring is placed in the seam of limit sleeve 18, said piston body right end middle position is equipped with stroke adjusting screw rod 19, said stroke adjusting screw rod passes through the end face of said cylinder body, prevents The dust ring 21 is connected with the nut 20 through threads, a sealing ring 17 is installed in the groove at the front end of the cylind...

Embodiment 3

[0031] According to the pressurized controllable oil injection device described in Embodiment 1 or 2, the said splitter divides the oil circuit into a group of branches, and a group of said branches are respectively connected to the said one-way valve c, preventing The air in the oil nozzle of the oil injector enters the hydraulic circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com