Rolling bearing device having bearing retainer and method for assemling same

A bearing cage and rolling bearing technology, applied in the directions of shafts and bearings, needle roller bearings, bearing components, etc., can solve the problems of high consumption of asymmetric bearing cages, and achieve the effect of high error rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

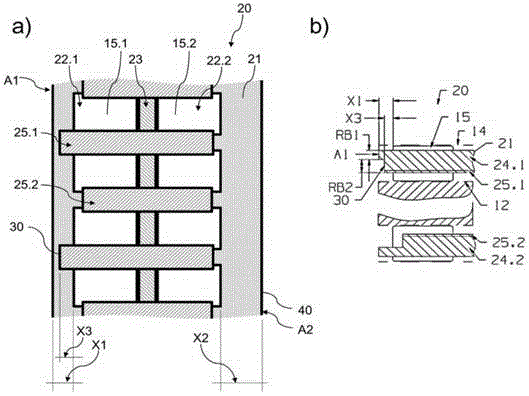

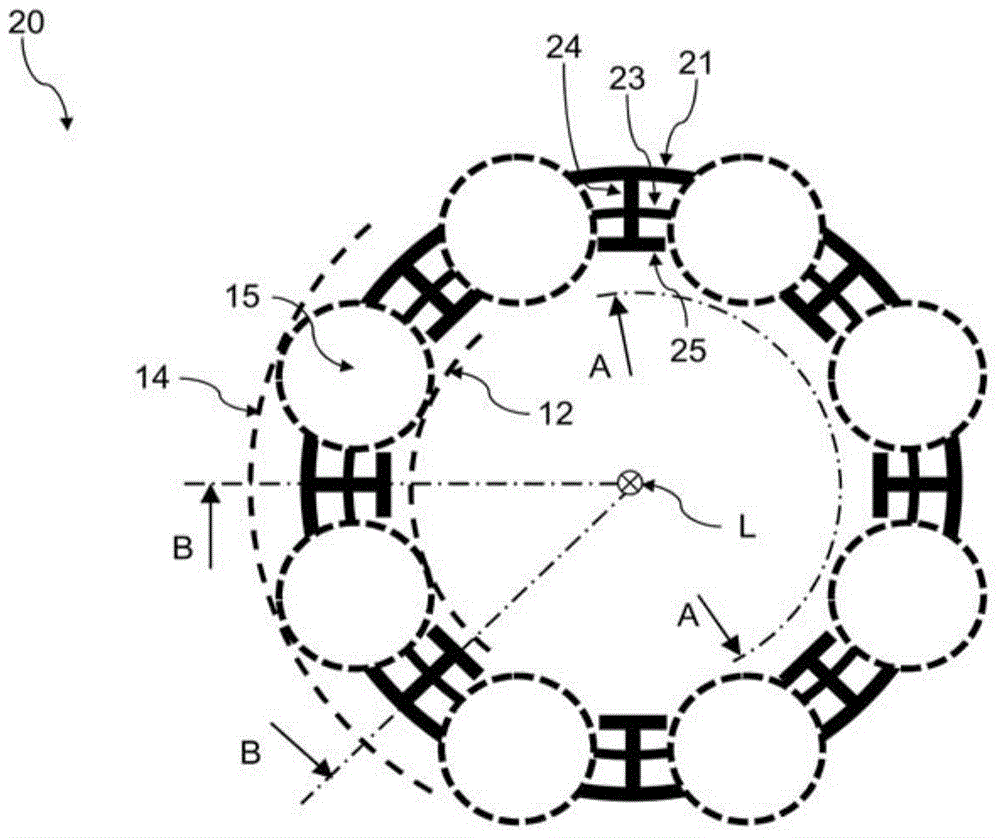

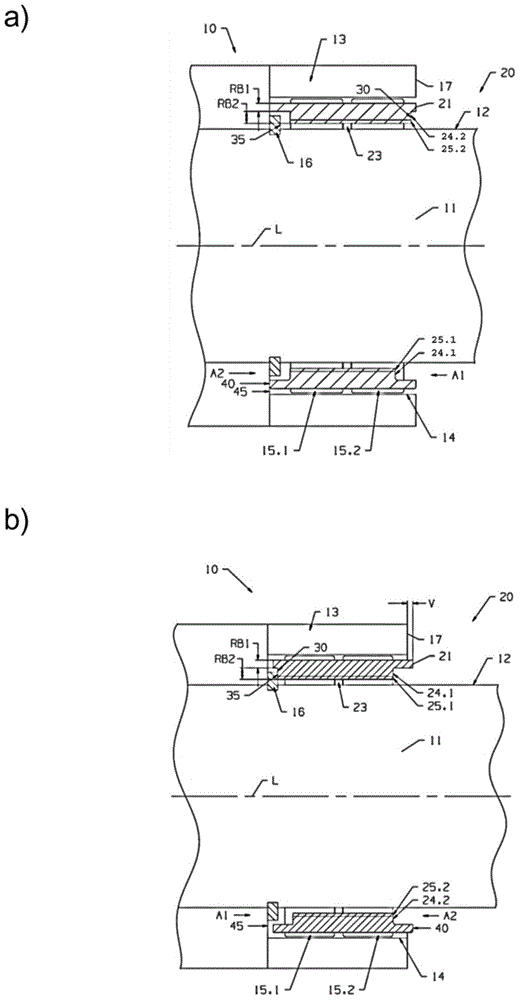

[0059] figure 1 A cross-sectional view of the bearing cage 20 of the rolling bearing device 10 according to the embodiment of the invention is shown in a radial plane with respect to the bearing axis L. As shown in FIG. exist figure 1 In this case, the rolling surfaces 12 and 14 of the rolling bearing arrangement 10 are only shown schematically with dashed lines, just like the rolling elements 15 .

[0060] The bearing cage 20 has a radially outer peripheral wall 21 . A plurality of radial strips 24 extend radially inwards from the peripheral wall 21 , wherein the number of radial strips 24 is one less than the number of rolling elements 15 arranged on one of the two rolling element rows. In this embodiment, the rolling elements 15 are designed as cylindrical rollers.

[0061] On the radial strip 24, a rolling element row partition 23 is arranged between two rolling element rows, the rolling elements 15.1 of the first rolling element row and the rolling elements 15.2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com