Branch joint

A technology of branch joints and main pipes, which is applied in the direction of pipes/pipe joints/fittings, branch pipelines, pipes, etc., and can solve the problems of branch joint fixation and poor waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

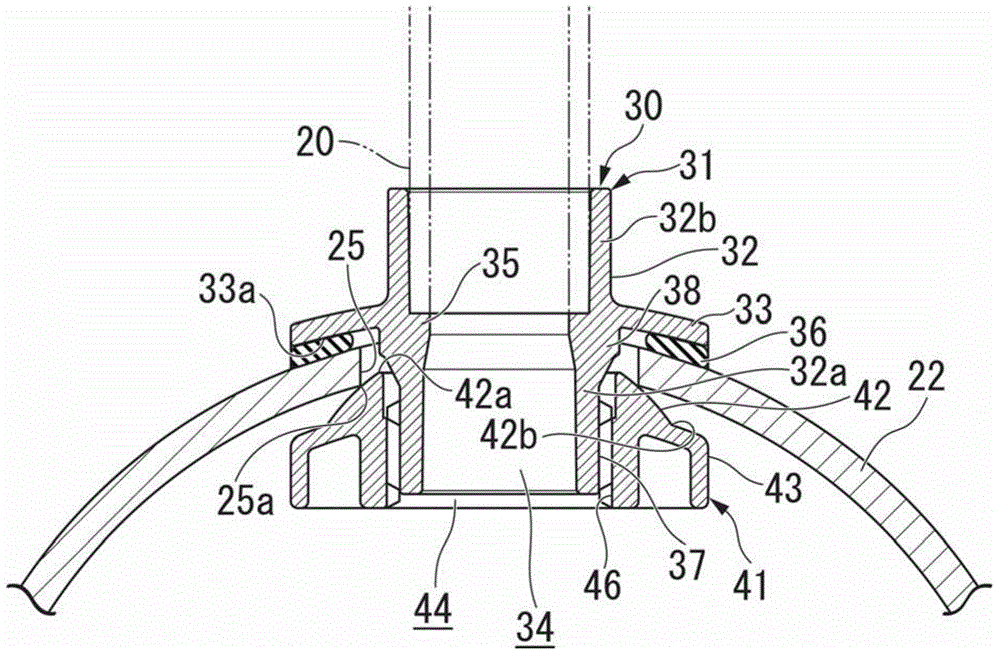

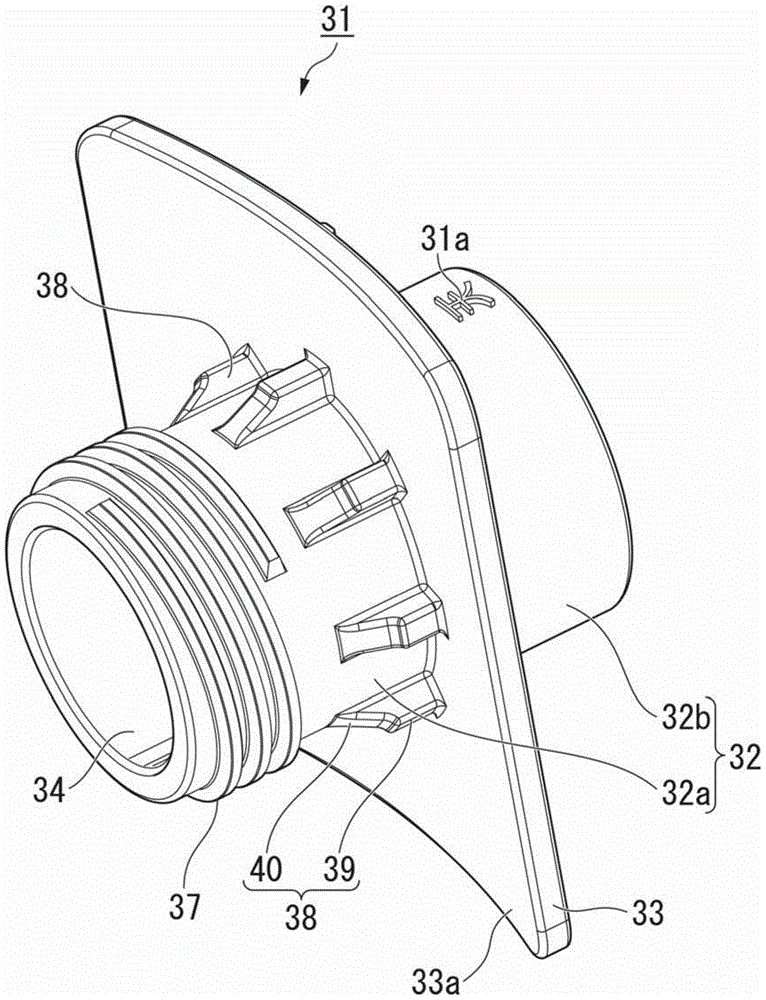

[0036] Hereinafter, a first embodiment which is an example of an embodiment to which the present invention is applied (hereinafter referred to as the present embodiment) will be described in detail using the drawings. In addition, the technical scope of this invention is not limited to this embodiment. Various changes can be made to this embodiment within the range which does not deviate from the summary of this invention.

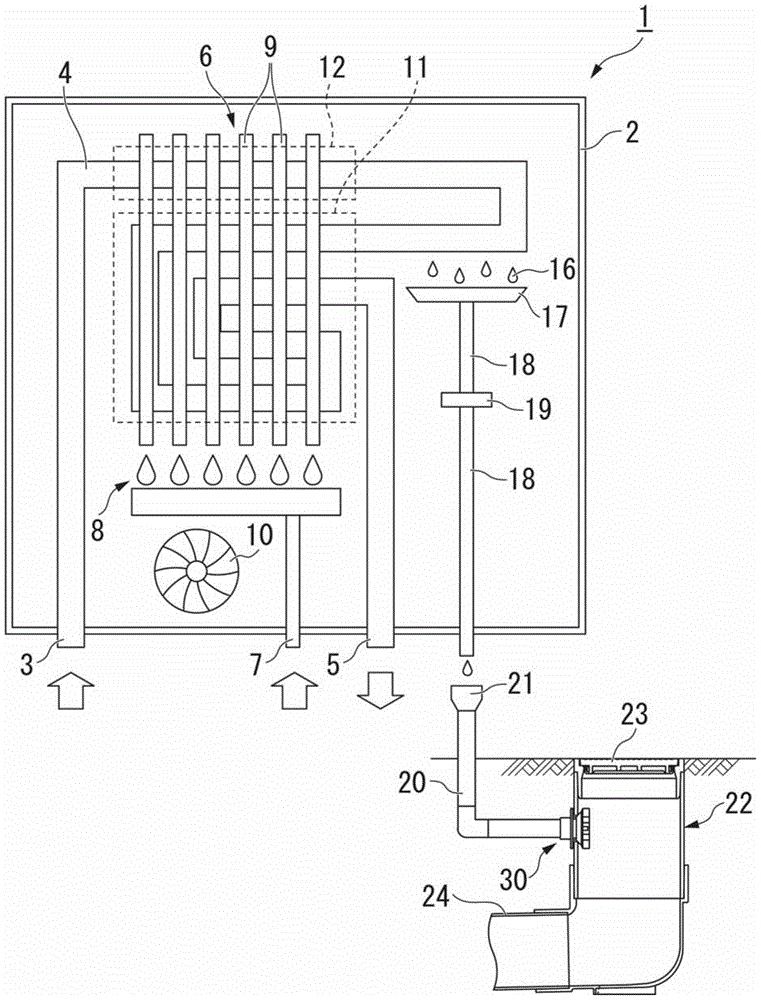

[0037] figure 1 It is a schematic diagram of applying the branch joint 30 of the first embodiment to the latent heat recovery type gas water heater 1 . figure 1 The shown latent heat recovery type gas water heater 1 is a water heater that improves the thermal efficiency of hot water by recovering the latent heat of combustion gas. The latent heat recovery type gas water heater 1 can improve the thermal efficiency of hot water of conventional water heaters by about 80% to about 95%. As a result, energy saving can be achieved, and operating costs can be g...

no. 2 approach

[0125] Next, use Figure 12 The branch joint 60 of the second embodiment will be described. In the second embodiment, the main body 31 of the branch joint 30 of the first embodiment is changed to a main body 61 (branch joint main body), and the fixing member 41 is changed to a fixing member 71 . The other structures that are the same as those in the first embodiment are assigned the same reference numerals, and description thereof will be omitted.

[0126] The branch joint 60 of the second embodiment is the same as the branch joint 30 of the first embodiment (refer to figure 2 ) In comparison, the engagement structure for fixing the main body 61 and the fixing member 71 is different. That is, the branch joint 60 of the second embodiment uses the internal thread as the locking portion 67 of the main body 61 and the external thread as the engaging portion 76 of the fixing member 71, and by screwing them, the branch joint 60 is fixed on the main pipe 22 .

[0127] The main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com