Particle three-dimensional position nanoscale resolving power measuring method under liquid state environment

A technology of three-dimensional position and measurement method, applied in measurement devices, optical devices, instruments, etc., can solve the problems of inability to measure multiple particles, complex measurement methods, and inability to meet measurement requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

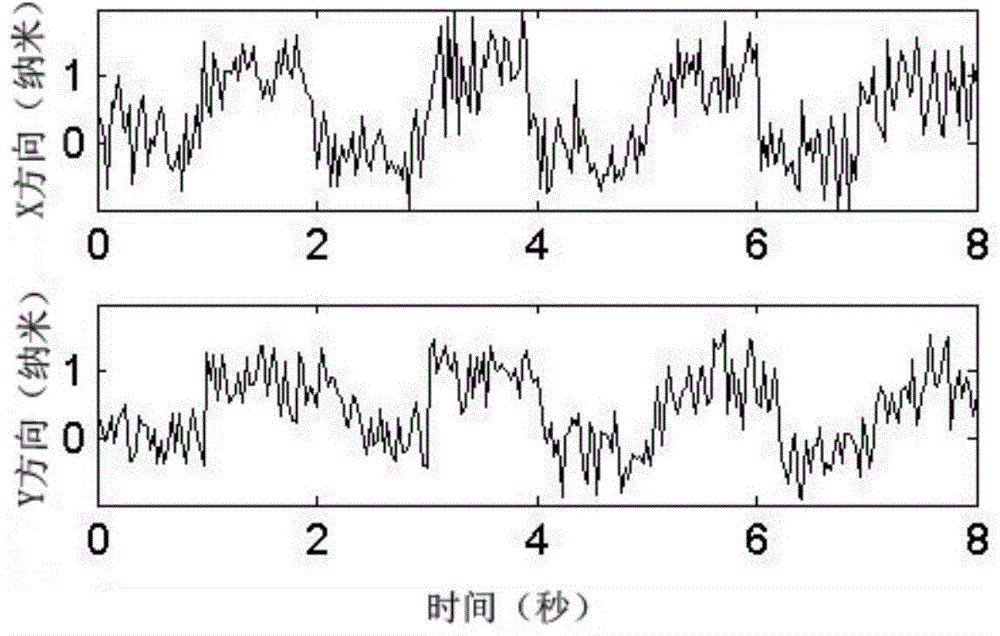

[0030] The present invention proposes a three-dimensional particle position measurement method based on coaxial digital holographic microscopy technology and image processing technology, including the following steps:

[0031] Build a coaxial digital holographic microscopic imaging system;

[0032] Place particles (including cells, viruses, magnetic beads, silicon spheres, polystyrene beads, nanorods, etc.) seal;

[0033] Use the above-mentioned imaging system to track particles in real time and record particle holographic images;

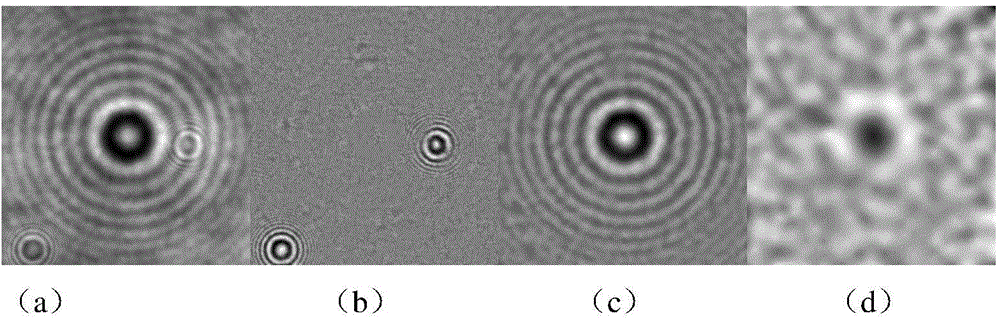

[0034] Preprocess the hologram of the particle, and use the two-dimensional integral empirical mode decomposition (BEEMD) method to eliminate the speckle noise and background noise of the particle hologram;

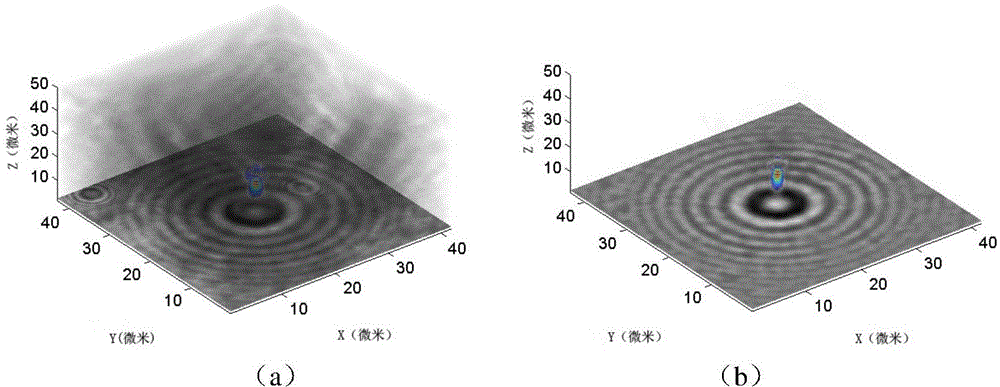

[0035] Perform holographic reconstruction on the hologram obtained from the above processing to obtain the three-dimensional reconstructed intensity distribution information of the particles;

[0036] Perform deconvolution operations on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com