Multi-control intelligent wet test system

A wet test and intelligent technology, which is applied in the direction of testing dielectric strength and liquid tightness measurement using liquid/vacuum, can solve the problems of difficult control of spray volume, easy waste of spray liquid, poor spray effect, etc. Achieve the effects of improving work intensity, convenient testing, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

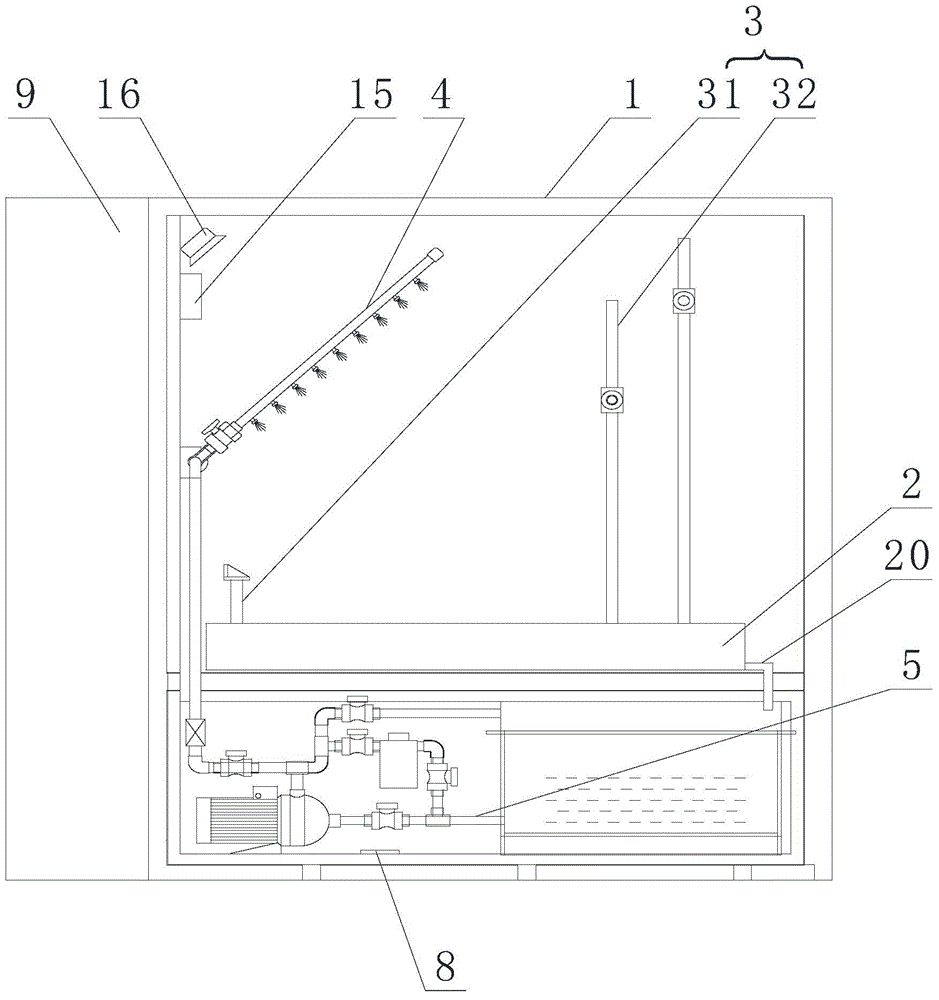

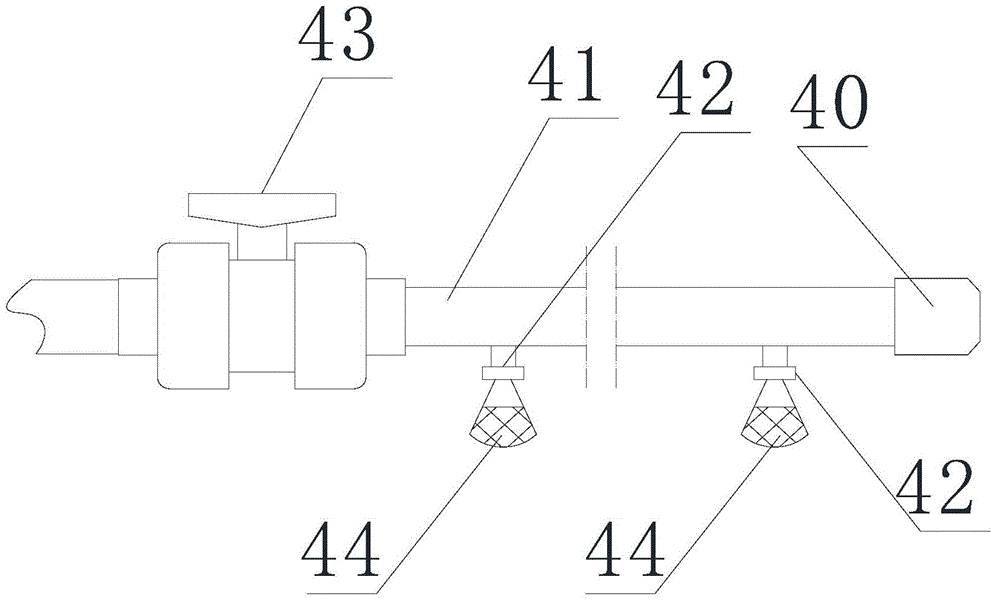

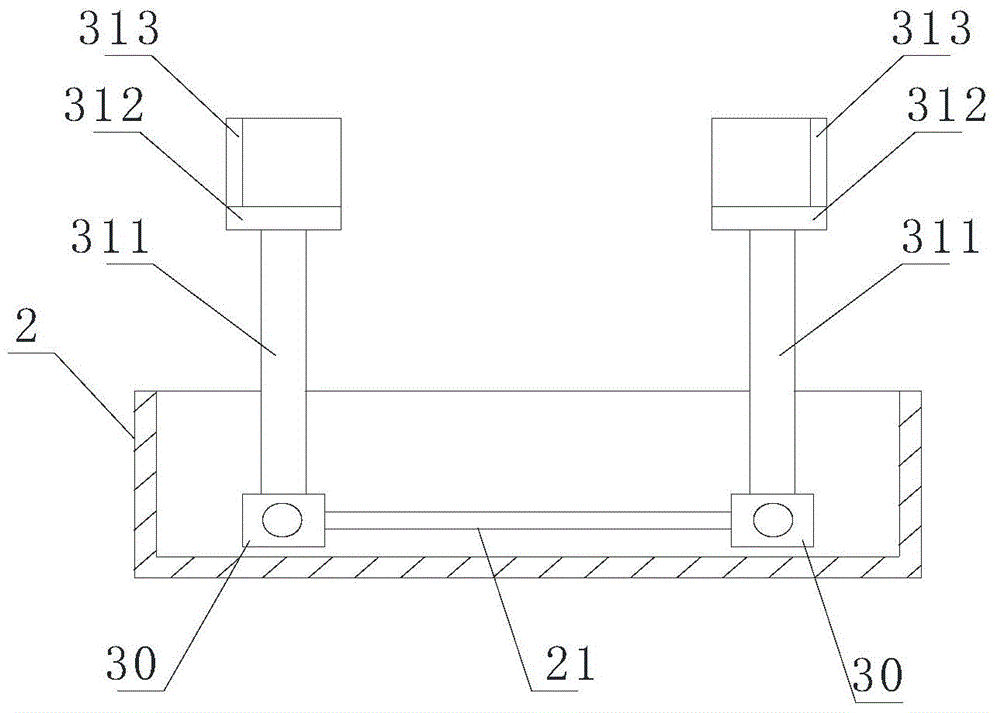

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8As shown, the multi-control intelligent wet test system includes a frame 1, and a water tank 2 is provided in the frame 1, and a support device 3 is provided in the water tank 2, and the frame 1 above the support device 3 Spray assembly 4 is rotatably connected to the top, and a water supply assembly 5 connected to spray assembly 4 is provided in the frame 1 below the water tank 2. Return to the outlet pipe 20 in the water supply assembly 5, the support device 3 includes a first support assembly 31 movably connected in the water tank 2, at least one set of second support assemblies 32 movably connected in the water tank 2, the first The connection line between the top of the support assembly 31 and the top of the second support assembly 32 forms an angle of 30-60° with the horizontal axis, which can improve the effect of the test, the quality of the spray is the bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com