A test method for gas-water relative permeability of tight rock core

A technology of relative permeability and test method, applied in the field of gas-water relative permeability test of tight rock cores, can solve the problems of large experimental error, low water saturation, inability to correct permeability, etc., to reduce trouble, quickly obtain, Stress-sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

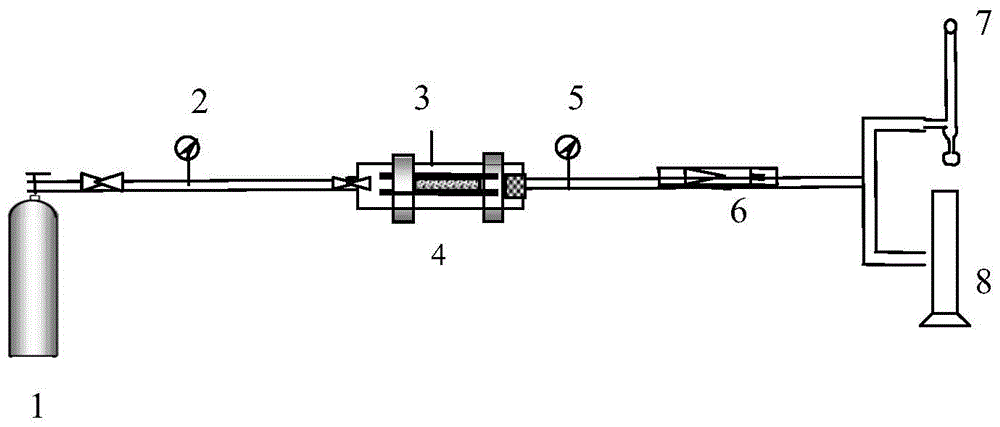

[0065] Further illustrate the present invention below by accompanying drawing.

[0066] see figure 1 .

[0067] A kind of testing method of tight rock core gas-water relative permeability of the present invention, through figure 1 Described process device is tested, and this device is mainly made up of nitrogen bottle 1, confining pressure control system 3, rock core holder 4, back pressure valve 6, gas flowmeter 7 and measuring cylinder 8, and described rock core holder 4 The inlet end is connected to the nitrogen cylinder 1 through a pressure gauge or pressure sensor 1, the outlet end is connected to the back pressure valve 6 through the pressure gauge or pressure sensor 2, the core holder 4 is connected to the confining pressure control system 3, and the back pressure valve 6 is connected to the gas cylinder respectively. Flow meter 7 and measuring cylinder 8.

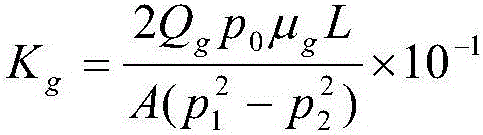

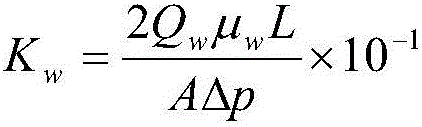

[0068] The present invention carries out gas flow experiments by applying different back pressures, determines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com