Experimental device and method for directional solidification of nanofluid

A nanofluid, directional solidification technology, applied in the investigation phase/state change and other directions, can solve the problem of nanofluid stability research not yet carried out, and achieve the effects of good refrigeration effect, convenient operation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

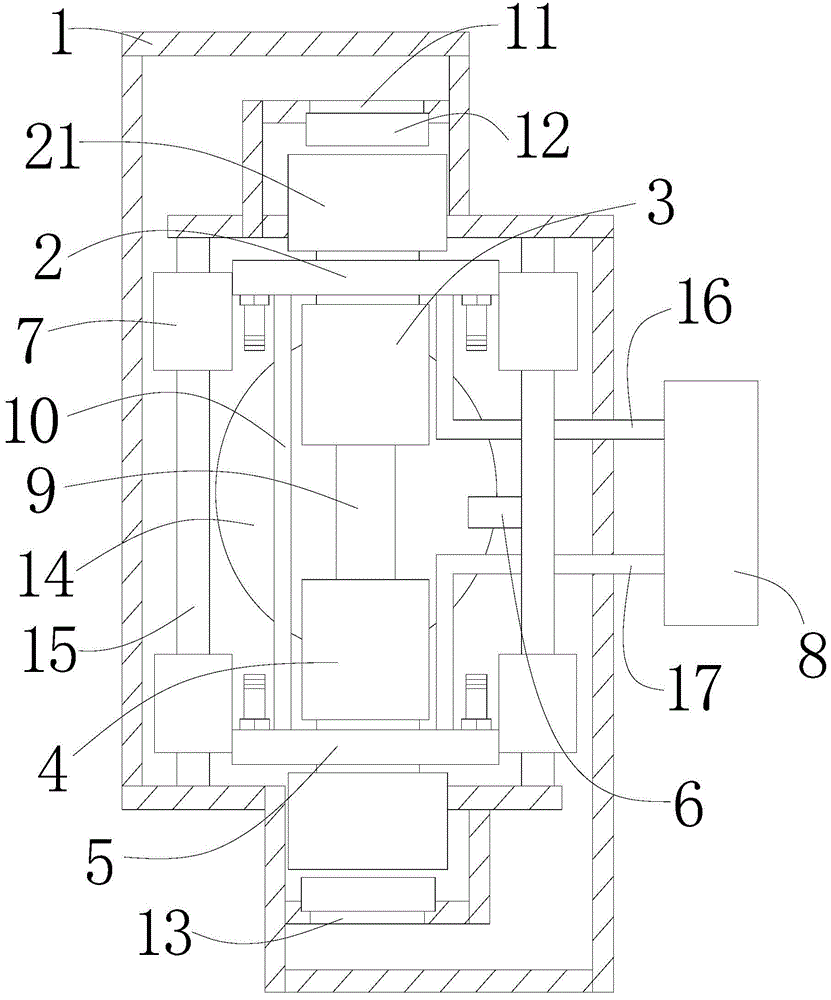

[0022] An experimental device for directional solidification of nanofluids according to the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0023] An experimental setup for directional solidification of nanofluids, such as figure 1 As shown, it includes a constant temperature and heat preservation cover 1, and the interior of the constant temperature and heat preservation cover 1 is sequentially installed with an upper cooling platform 2, an upper cooling body 3, a lower cooling body 4 and a lower cooling platform 5, and the upper cooling body 3 is fixedly installed (Welding) In the upper cooling platform 2 bottoms, the lower guide cooling body 4 is fixedly installed (welded) on the lower cooling platform 5 tops, and there is a nanofluid sample 9 to be measured between the upper guiding cooling body 3 and the lower guiding cooling body 4 The top of the upper cooling table 2 is equipped with a cooling plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com