Method and device for removing metal impurities in polycrystalline silicon by directional solidification

A technology of directional solidification and metal impurities, applied in the direction of non-metallic elements, chemical instruments and methods, silicon compounds, etc., can solve the problems of high production cost, long reaction time, long production cycle, etc., and achieve low cost, simple equipment, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

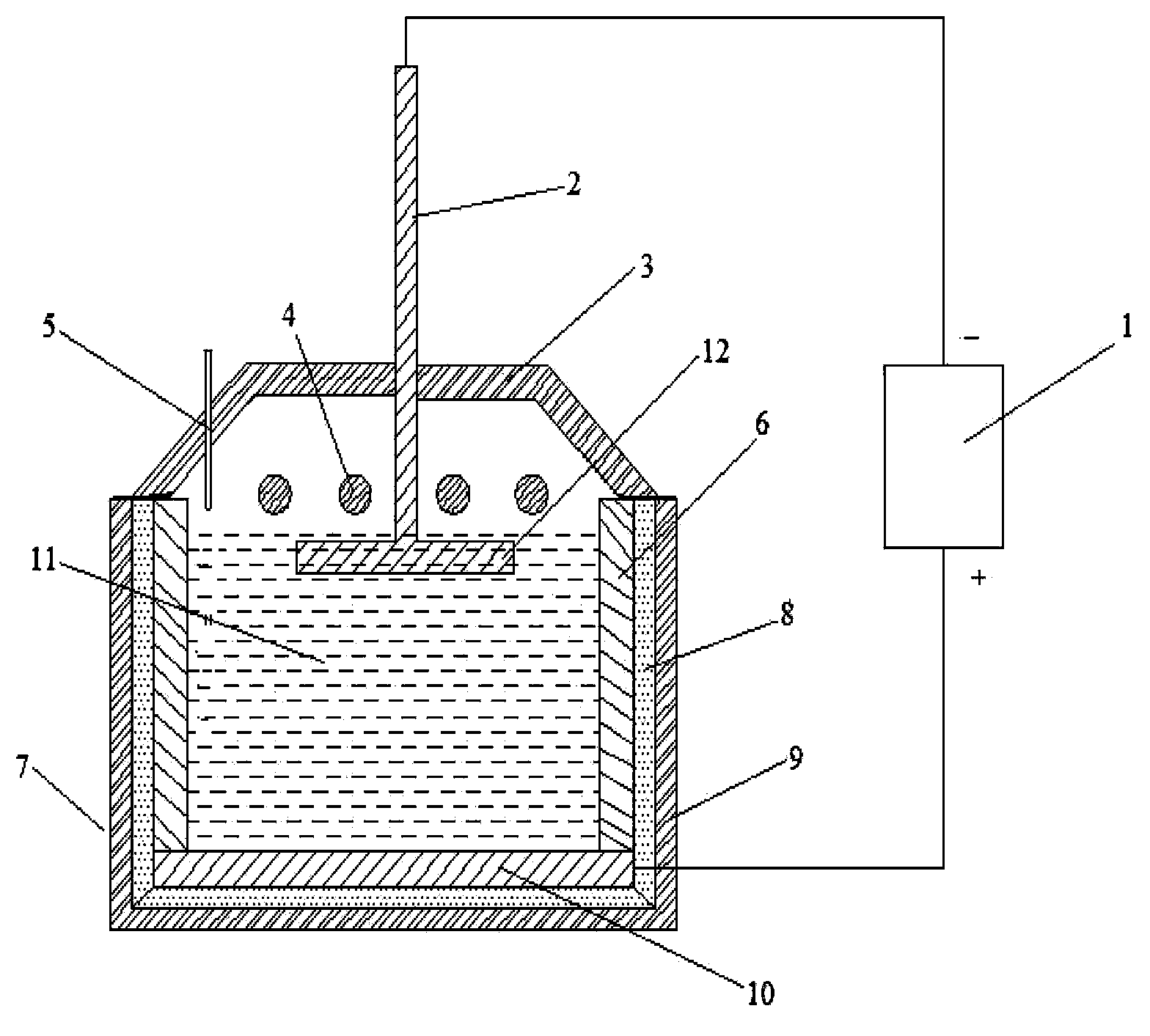

Embodiment 1

[0031] Put 100kg of raw silicon into the graphite crucible of the intermediate frequency induction furnace and heat it so that all the silicon material is melted into silicon liquid; the silicon liquid is poured into the improved directional solidification device, and the heat preservation cover is covered. The heat preservation crucible of the directional solidification furnace is characterized by a square bottom and a height equal to The bottom side length ratio is 0.8:1, start the silicon carbon rod switching power supply, realize the heating of the upper part of the silicon liquid, the heating temperature is 1450°C; place the graphite plate on the surface of the silicon liquid, the graphite rod and the graphite layer of the directional solidification furnace are respectively Connect to the negative pole and positive pole of the voltage controller, then apply a DC voltage of 10V, keep it for 2 hours, measure the temperature through a thermocouple, control the temperature of t...

Embodiment 2

[0033] Put 100kg of raw silicon into the graphite crucible of the intermediate frequency induction furnace and heat it to melt all the silicon material into silicon liquid; pour the silicon liquid into the improved directional solidification device, cover the heat preservation cover, start the silicon carbon rod switching power supply, and realize the upper part of the silicon liquid heating , the heating temperature is 1475°C; the graphite plate is placed on the surface of the silicon liquid, the graphite rod and the graphite layer of the directional solidification furnace are respectively connected to the negative pole and the positive pole of the voltage controller, and then a DC voltage of 60V is applied and kept for 3h. Even temperature measurement, control the temperature of the silicon liquid to cool down slowly, the cooling rate is 25°C / h, to achieve directional solidification; after the silicon ingot is cooled, remove the enriched impurities on the top, polish the surro...

Embodiment 3

[0035]Put 100kg of raw silicon into the graphite crucible of the intermediate frequency induction furnace and heat it to melt all the silicon material into silicon liquid; pour the silicon liquid into the improved directional solidification device, cover the heat preservation cover, start the silicon carbon rod switching power supply, and realize the upper part of the silicon liquid heating , the heating temperature is 1500°C; the graphite plate is placed on the surface of the silicon liquid, the graphite rod and the graphite layer of the directional solidification furnace are respectively connected to the negative pole and the positive pole of the voltage controller, and then a DC voltage of 100V is applied and kept for 4h. Even temperature measurement, control the temperature of silicon liquid to cool down slowly, the cooling rate is 28°C / h, to achieve directional solidification; after the silicon ingot is cooled, remove the enriched impurities on the top, polish the surroundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com