Optimizing and fast modeling method for three-dimensional printing hole

A modeling method and three-dimensional printing technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of rapid generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation

[0014] The present invention will be described in detail below in conjunction with specific embodiments. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects.

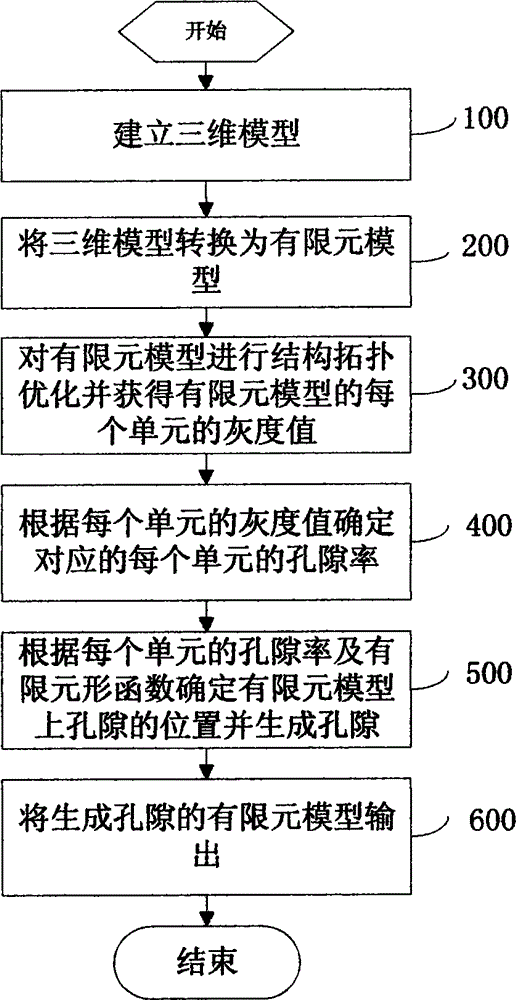

[0015] Combine below figure 1 An embodiment of the invention is described in detail, which includes:

[0016] Step 300: performing structural topology optimization on the finite element model and obtaining the gray value of each unit of the finite element model;

[0017] Step 400: a step of determining the corresponding porosity of each unit according to the gray value of each unit;

[0018] Step 500: A step of determining the positions of pores on the finite element model according to the porosity of each unit and the finite element shape function and generating pores.

[0019] The gray value in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com