Method for designing grooving construction slurry parameters for underground diaphragm wall of water-rich sand gravel stratum based on overall stability of groove wall

An underground diaphragm wall and stability technology, applied in basic structure engineering, excavation, calculation, etc., can solve the problems of staying in the experience stage, unable to satisfy the underground diaphragm wall, and engineers can not be sure, and achieve the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

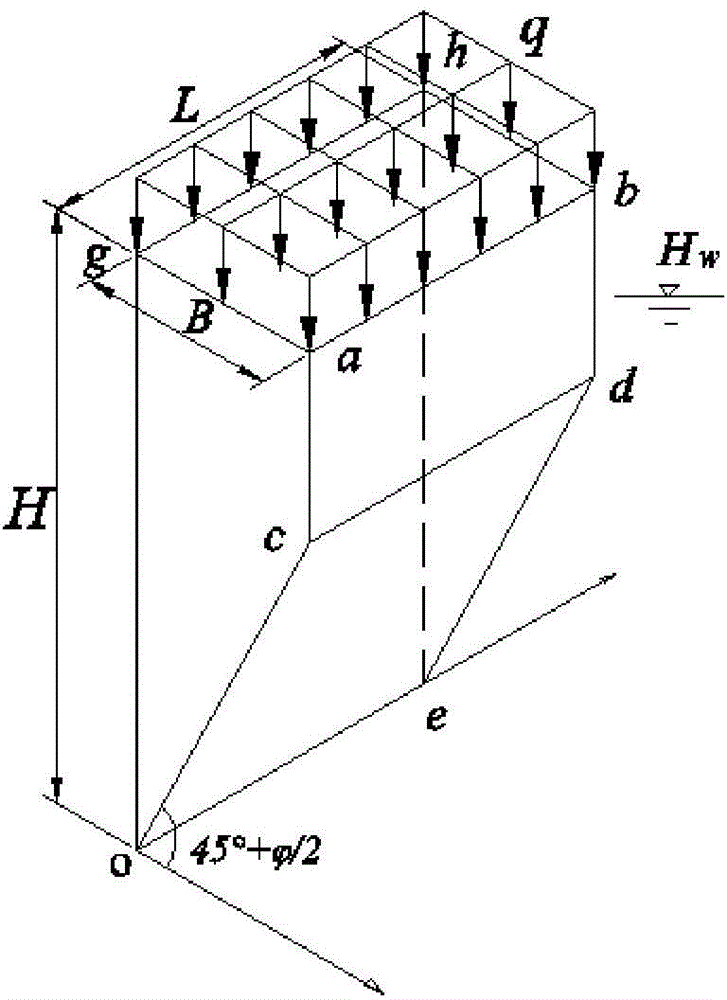

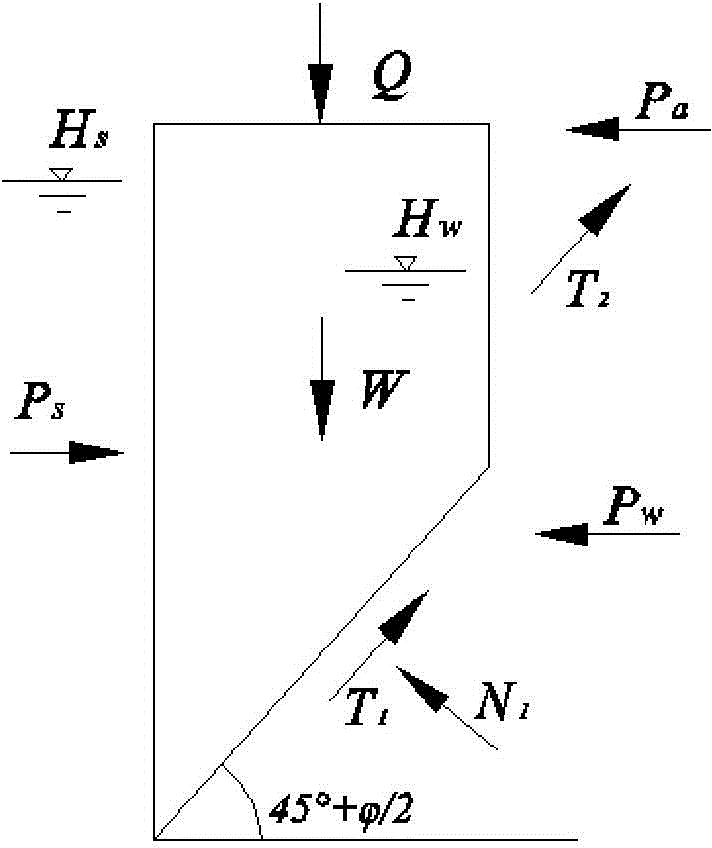

[0064] When the underground diaphragm wall in the water-rich sand egg formation is excavated into grooves, the overall instability may occur under the joint action of soil pressure, water pressure and mud pressure, and the failure mode is as follows: figure 1 , respectively calculate the sliding force and anti-sliding force acting on the sliding body along the direction of the sliding surface, based on the limit equilibrium theory, finally determine the minimum mud weight γ s .

[0065] (1) Calculation of sliding body weight W

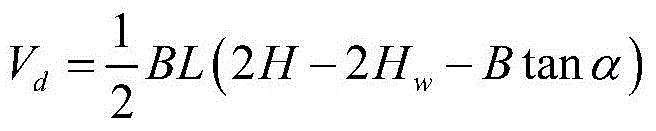

[0066] Volume V of sliding body above groundwater u :

[0067] V u =BLH w (1)

[0068] In the formula, L is the length of excavation slot; H w is the distance from the groundwater to the surface; B is the width of the sliding body, and its expression is B=(H-H t )cotα, where, H t is the burial depth of the sand egg layer; H is the depth of the sliding body; the angle between the sliding surface and the horizontal plane in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com