Internal electrode paste

An internal electrode and slurry technology, applied in the direction of fixed capacitor electrodes, fixed capacitor components, etc., can solve problems such as cracking and product delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing internal electrode paste according to one embodiment is used to prepare the above-mentioned internal electrode paste. The preparation method of the internal electrode slurry is as follows in step S110 and step S120.

[0041] Step S110: mixing the organic solvent and the polymer resin, heating to 80° C., and maintaining at 80° C. for 2 hours to obtain an organic vehicle.

[0042] Step S120: Mix nickel powder, ceramic powder, organic additives and organic vehicle to obtain internal electrode slurry.

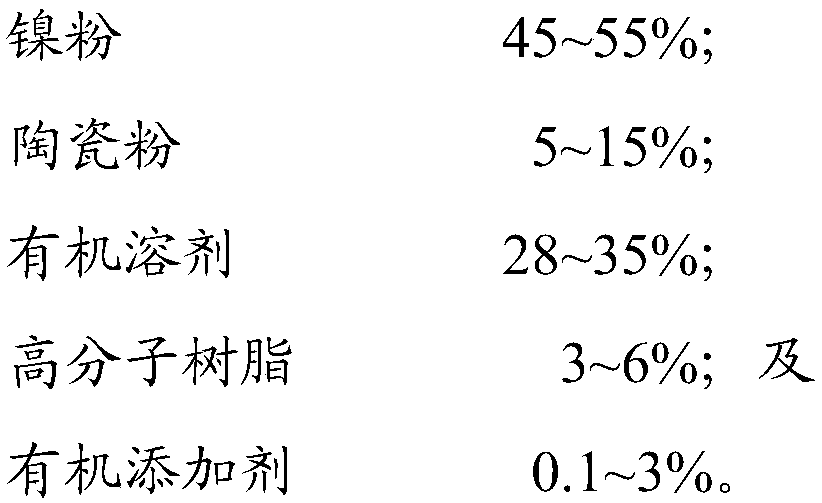

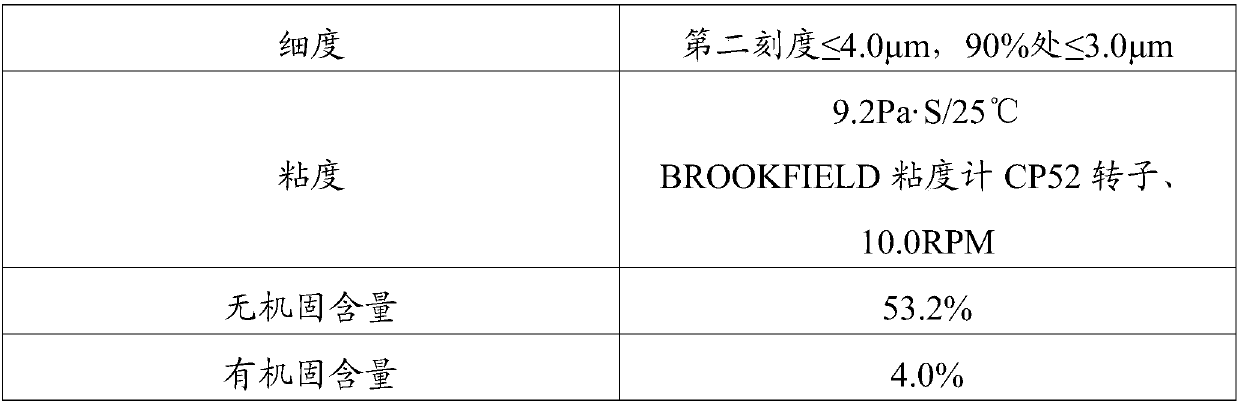

[0043] The inner electrode slurry includes the following components by mass percentage: 45-55% of nickel powder, 5-15% of ceramic powder, 28-35% of organic solvent, 3-6% of polymer resin and 0.1-3% of organic additive.

[0044] The preparation method of the above-mentioned internal electrode slurry firstly prepares an organic vehicle and then mixes nickel powder, ceramic powder, organic additives and the organic vehicle, so that the nickel powder, cer...

Embodiment 1

[0064] Preparation of internal electrode paste

[0065] 1. Preparation of ceramic powder

[0066] A, in the calcium chloride solution that concentration is 40g / L, add calcium oxide, stir while heating to boil for 25 minutes and then leave standstill for 3 hours, after the solution temperature drops to room temperature, filter the solution into the reactor; B, put Add the sodium hydroxide solution with a molar ratio of 1.3:1 into the solution obtained in step A, and circulate and stir after adding; C, feed carbon dioxide into the solution in step B under stirring to carry out carbonization reaction, and control The reaction temperature is 20° C., until the pH=6 to stop the reaction, and finally filter, wash and dry to obtain calcium carbonate powder, namely calcium carbonate ceramic powder.

[0067] 2. Preparation of organic additives

[0068] Siloxane KD-9 was dissolved in dibutanol to prepare an organic additive with a concentration of 0.15 g / L.

[0069] 3. Preparation of in...

Embodiment 2

[0082] Preparation of internal electrode paste

[0083] 1. Preparation of ceramic powder

[0084] A. Dissolve zirconium oxychloride in deionized water, control the mass ratio of zirconium oxychloride to deionized water to 4:21, and add methyl amyl alcohol to the zirconium oxychloride aqueous solution, the quality of methyl amyl alcohol is the solution quality 1‰~5‰; B. Add ammonia water dropwise to the mixed solution in step A, control the molar ratio of ammonia water to zirconium oxychloride to be 1.8:1, and control the reaction temperature to 40°C at the same time, keep the temperature after adding ammonia water dropwise Crystallize at 40°C for 0.5hr, and after the reaction is completed, a zirconium hydroxide hydrogel is generated; C, the zirconium hydroxide hydrogel in step B is washed, press-filtered or centrifuged to obtain a zirconium hydroxide gel; D, the step B The zirconium hydroxide gel of C is dried to obtain zirconium hydroxide, and then the zirconium hydroxide is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com