Copper electrode slurry for multilayer ceramic capacitor

A technology of multilayer ceramics and capacitors, applied in the direction of fixed capacitor electrodes, multilayer capacitors, fixed capacitor dielectrics, etc., can solve the problems affecting the use of screen printing, large viscosity changes, loss of fluidity, etc., to suppress cracking and delamination , Inhibition of shrinkage, good thixotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The slurry formula is according to the common method of slurry, such as weighing each formula in proportion for batching→stirring→dispersing→rolling→semi-finished product inspection→slurry mixing→finished product inspection→packaging to prepare the copper inner electrode slurry for MLCC.

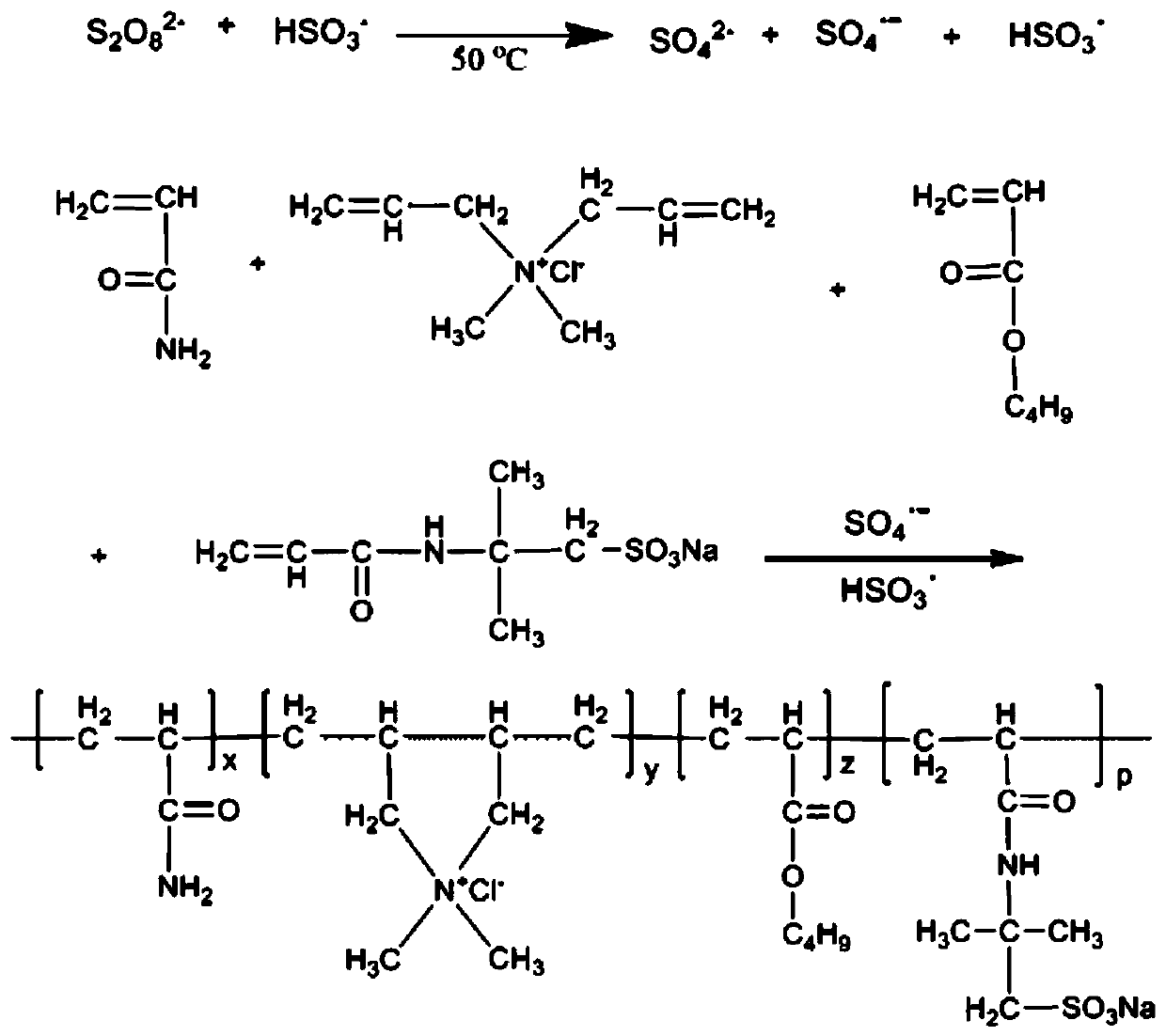

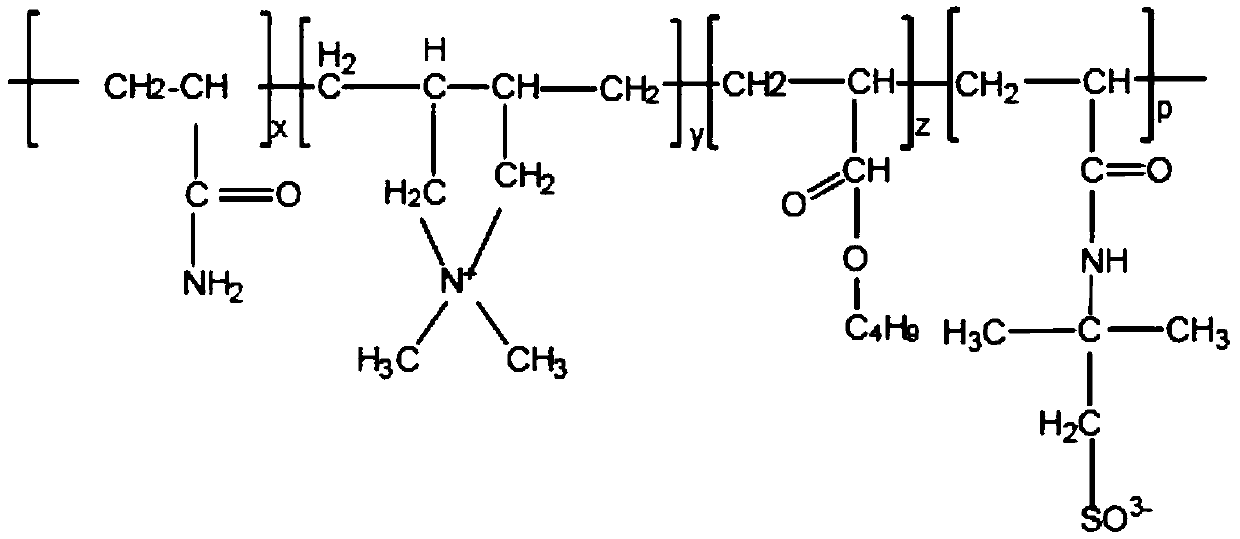

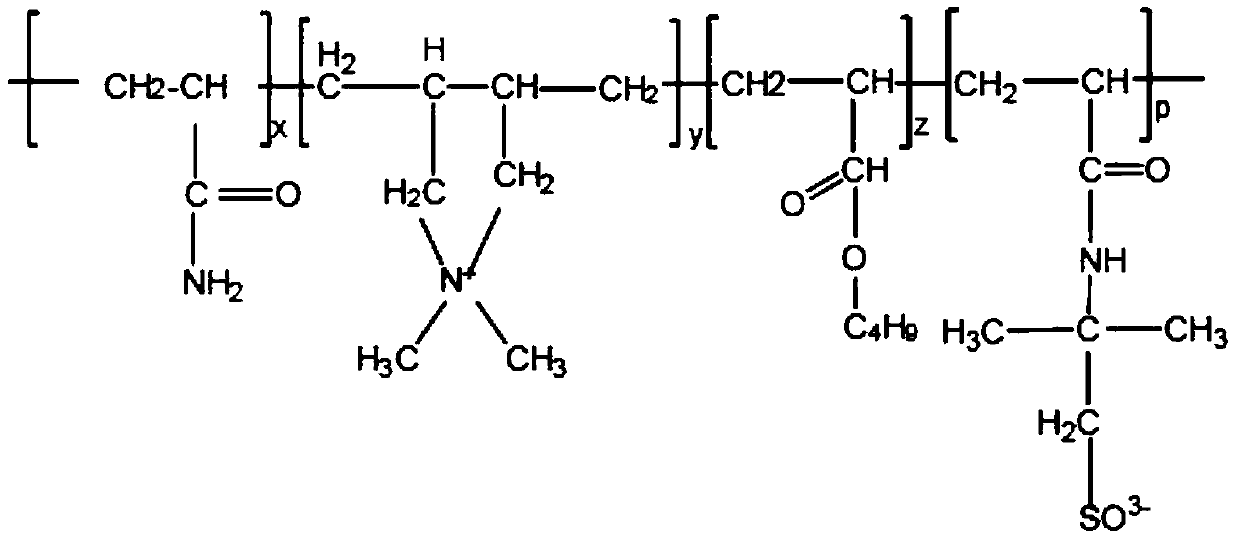

[0032] Synthesis of polyamide polyacid polymer salt: surfactant is preferably CTAB, 8.2g AMPS (2-acrylamido-2-methylpropanesulfonic acid) is dissolved in deionized water, and the pH is adjusted to be 7-8 with NaOH ; Then 21g AM (monomer acrylamide), 1.3g BA (monomer butyl acrylate) and 2.5g DMDAAC (dimethyl diallyl ammonium chloride) were dissolved in aqueous solution containing 1gCTAB, stirred to make it fully mixed dissolved; through high-purity nitrogen 30min, remove the oxygen in the solution; then add initiator 0.08g K 2 S 2 o 8 solution and 0.03g NaHSO 3 After the solution was fully mixed, the stirring was stopped. During the experiment, the amount of deionized water used was...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment is: a kind of multilayer ceramic capacitor copper electrode slurry, is made up of the raw material of following weight part:

[0043] 45 parts of copper powder, the particle size D50 of flake copper powder is 0.3μm;

[0044] 7.5 parts of ceramic powder, ceramic powder adopts BaNd 2X (Sm (0~1 / 3) PR (0~1 / 3) ) 2(l-x) Ti 5 o 14 , 1 part of dispersant;

[0045] 2.9 parts of cellulose resin, cellulose resin adopts ethyl cellulose and polyvinyl butyral resin 4:1 blending;

[0046] 45 parts of organic solvent, organic solvent adopts dihydroterpineol;

[0047] 0.1 part of plasticizer, the plasticizer adopts dibutyl phthalate;

[0048] The main dispersant is polyamide polyacid polymer salt, 0.8 part; the auxiliary dispersant is 0.2 part of DP270.

Embodiment 3

[0050] The difference between embodiment 3 and embodiment is: a kind of multilayer ceramic capacitor copper electrode slurry, is made up of the raw material of following weight part:

[0051] 45 parts of copper powder, the particle size D50 of spherical copper powder is 0.1 μm;

[0052] 15 parts of ceramic powder, ceramic powder adopts zirconia composite ceramic powder;

[0053] 1.5 parts of dispersant;

[0054] 3 parts of cellulose resin, cellulose adopts hydroxypropyl cellulose;

[0055] 35 parts of organic solvent, organic solvent adopts butyl carbitol acetate;

[0056] 0.5 parts of plasticizer, dioctyl phthalate;

[0057] The main dispersant is polyamide polyacid polymer salt, 1.3 parts; the secondary dispersant is SILOK 70740.2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com