Nickel inner electrode slurry for MLCC

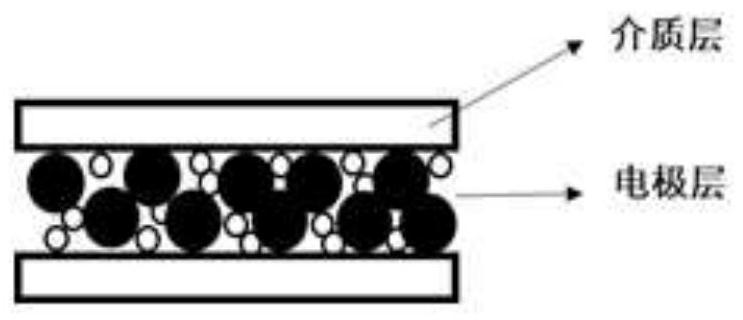

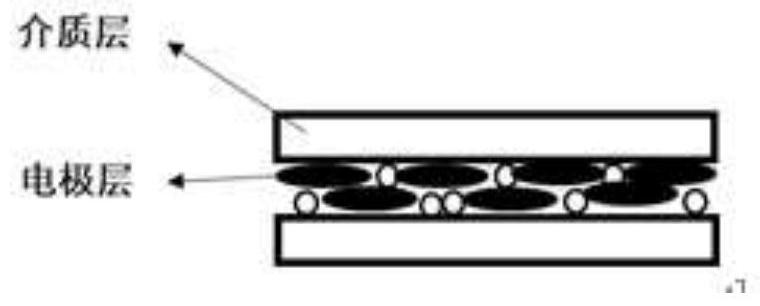

A technology of internal electrodes and pastes, which is applied to fixed capacitor electrodes, conductive materials dispersed in non-conductive inorganic materials, laminated capacitors, etc., can solve the problems that the layered arrangement of flake particles cannot be guaranteed, and achieve good flatness, Low thickness and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention relates to a nickel internal electrode slurry for MLCC. The slurry includes 55% flake nickel powder, 10% ceramic powder barium titanate powder, and the average particle diameter of the barium titanate powder is 100nm according to the mass percentage. Dispersant 2-(11-methyldodecyloxy)ethanol phosphate 0.5%, polymer resin ethyl cellulose 2%, glidant oxidized polyethylene wax 0.5%, organic solvent dihydroacetate terpinene 32 %, the length of the flaky nickel powder is 200-300nm, and the thickness of the flaky nickel powder is less than 150nm.

Embodiment 2

[0024] The difference from Example 1 is that the mass fraction of organic acid active agent 2-ethylhexanoic acid is 1%, and the organic solvent terpineol dihydroacetate is 31%.

Embodiment 3

[0026] The difference from Example 2 is that the thixotropic agent BKY-410 of BAK company is added in a mass fraction of 0.5%, and the solvent mass fraction is 30.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com