Metal button switch and assembly

A button and metal technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of numerous production processes, slow welding and wiring speed, poor replaceability, etc., to improve installation speed and detachability, improve product quality, Effect of improving self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

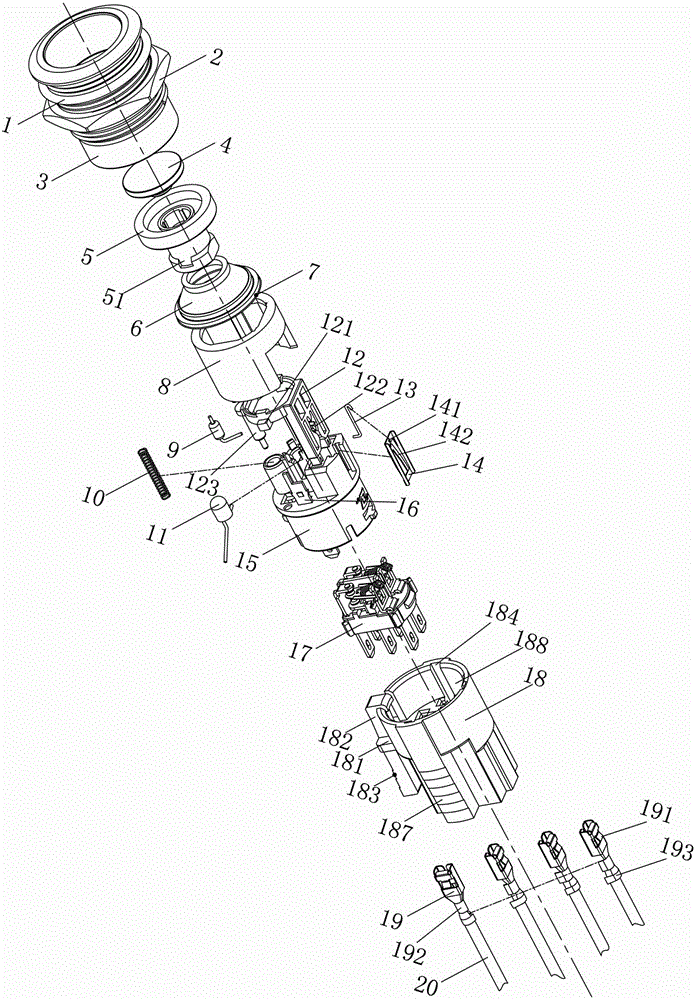

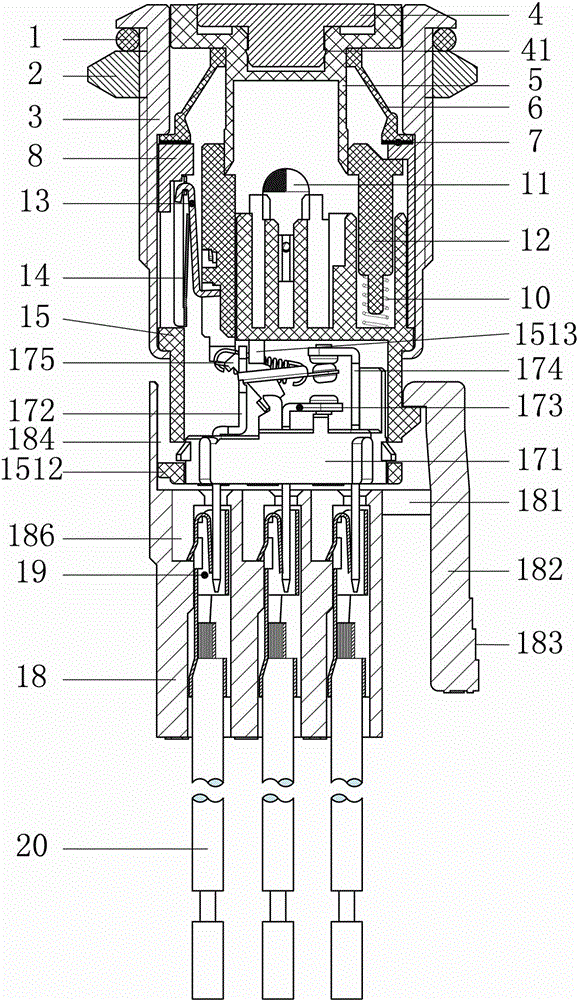

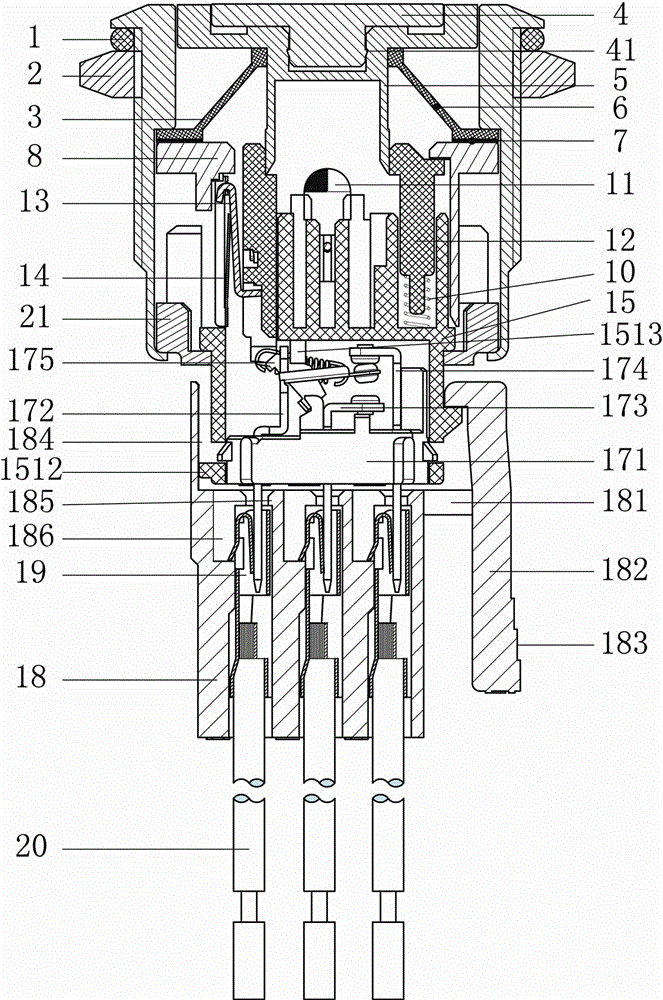

[0026] like Figures 1 to 9 As shown, the metal button switch of the present invention includes a housing 3 and a key 4 and a contact mechanism installed in the housing. The key 4 is connected in linkage with the contact mechanism 17 through a push device, and the push device and the contact mechanism A base 15 is arranged between them, two sides of the base 15 are provided with two solder pin holes 1504 for setting the solder pins 16, and a circular groove 1510 for placing the LED lamp 11 is provided at the center of the upper end of the base 15, A positioning groove 1503 for placing the resistor 9 and a square hole 1514 on the opposite side of the positioning groove 1503 are arranged on the upper end of the base 15. The contact mechanism includes a base 171, and the base 171 is inverted through the tapered bases on both sides. The hook 1713 cooperates with the barb hole 1507 provided on both sides of the lower end of the base 15, the U-shaped groove 1506 is provided at the l...

Embodiment 2

[0060] according to figure 1 , 2 . As shown in 3, the present invention is a metal button switch assembly realized according to the metal button switch described in Embodiment 1. Including the socket 18, 8 small rectangular holes are arranged inside the socket 18, the upper end of the rectangular hole is provided with a limit step of the insert spring 19, and the hanging table is arranged inside to cooperate with the V-shaped barb 191 of the insert spring 19 to be fixed in it. The upper end of the spring 19 is a rectangle compatible with the common pin 172, the normally open pin 173, and the normally closed pin 174. The S-shaped elastic sheet is arranged inside, and the A "U" shaped groove 192 is provided at the lower end to accommodate the conductor of the electric wire 20, and the B "U" The groove 193 accommodates the insulator portion of the wire 20 . A 7-shaped seesaw 182 hanging platform is arranged on one side of the outer side of the socket 18 and is interlocked with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com