Material feeding and cutting device and automatic stringing machine

A material cutting device and feeding mechanism technology, which is applied in the field of food processing, can solve the problems of food product phase influence, low degree of automation, and exposure to the outside, and achieve the effects of saving manpower, improving efficiency, and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

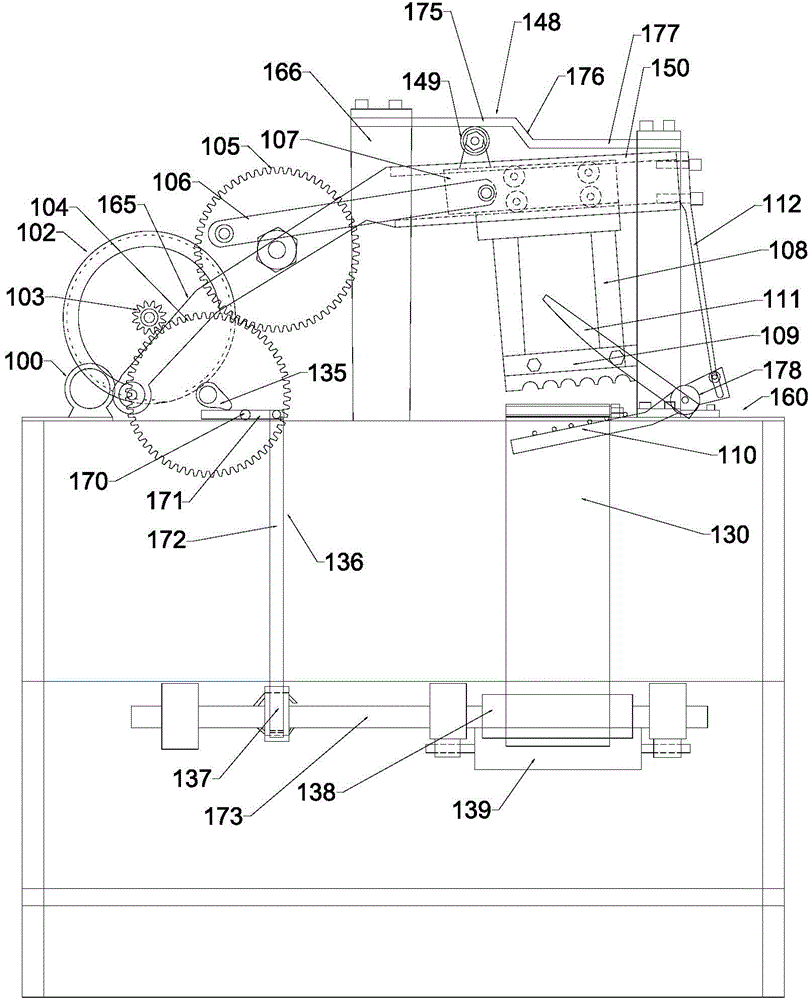

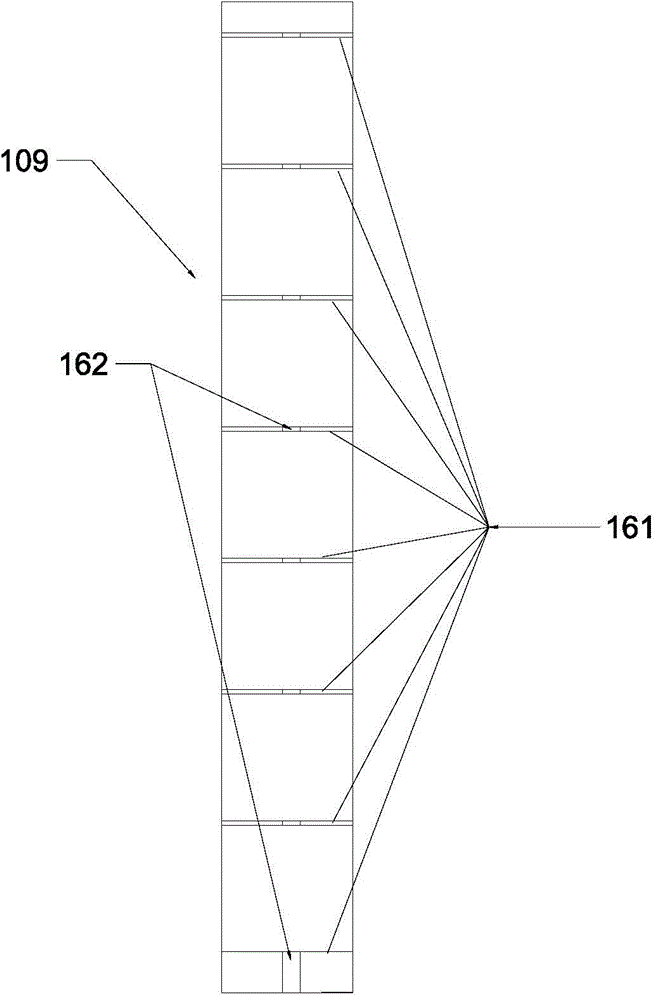

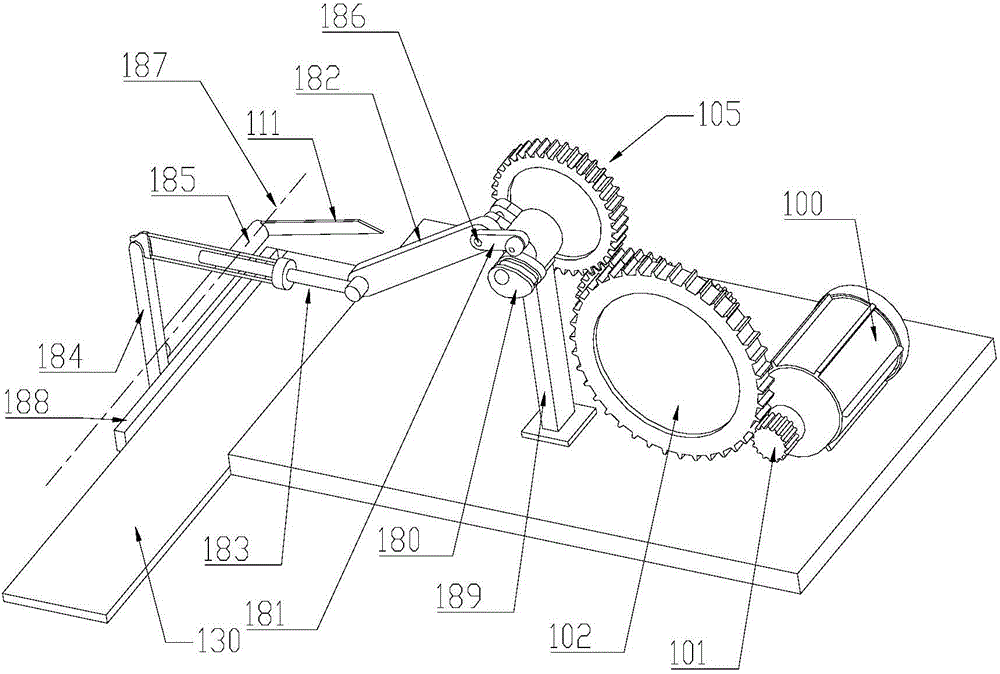

[0028] Embodiment 1, with reference to Figure 1-3 , figure 1 It is the left side view of the preferred embodiment of the feeding and cutting device of the present invention, figure 2 It is the view of the binder knife of the present invention observed toward the binder surface, image 3 It is a structural diagram of the second transverse cutter driving device in the preferred embodiment of the present invention.

[0029] The feeding and cutting device includes a driving mechanism, a feeding mechanism and a cutting mechanism.

[0030] The feeding mechanism includes a supporting conveyor belt 130 and a pinch shaft 139 , the supporting conveyor belt 130 is installed on a conveyor belt bracket not shown in the figure, and is tensioned by the pinching shaft 139 . There are also material baffles 188 on both sides of the supporting conveyor belt 130 for limiting the width of the materials placed on the supporting conveyor belt 130 .

[0031] The material cutting mechanism compr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap