Instant water dispenser

A water drinker, instant heating technology, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as heater damage, product inconvenience, dry burning without water, etc., and achieve the effect of improving service life and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

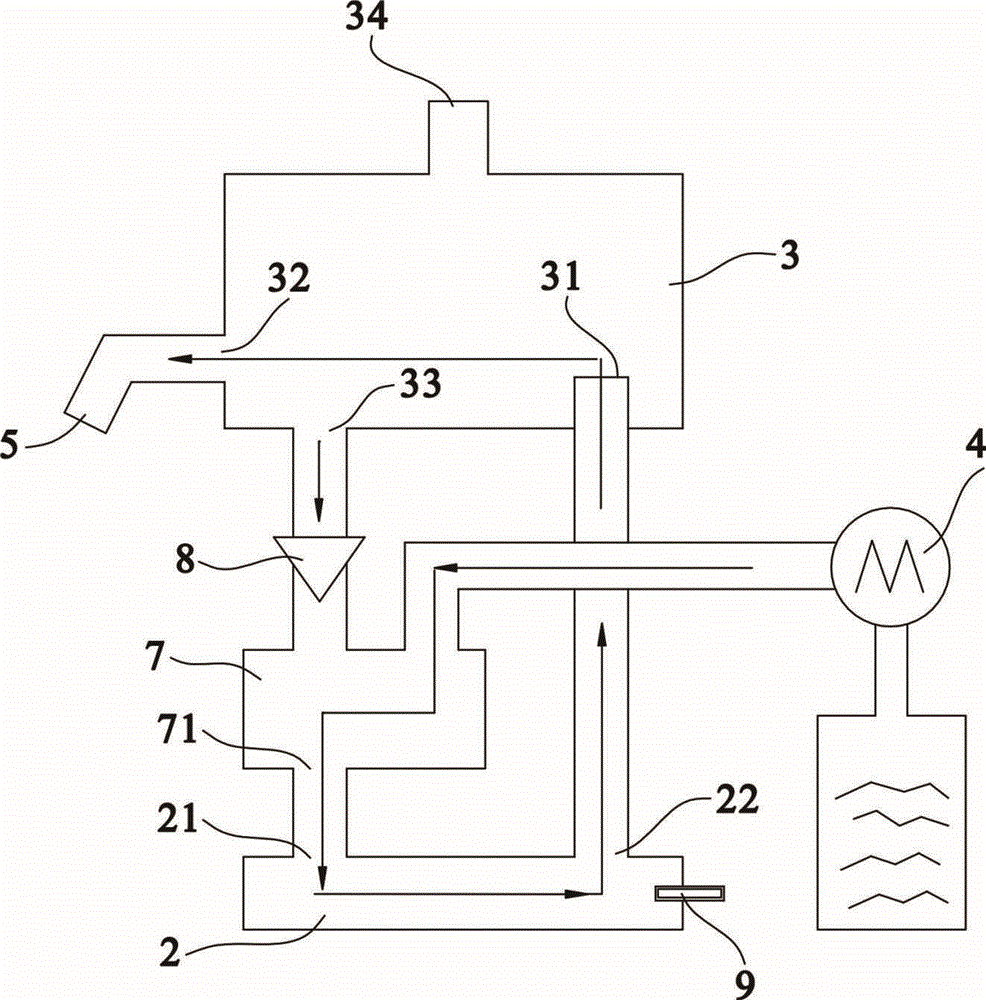

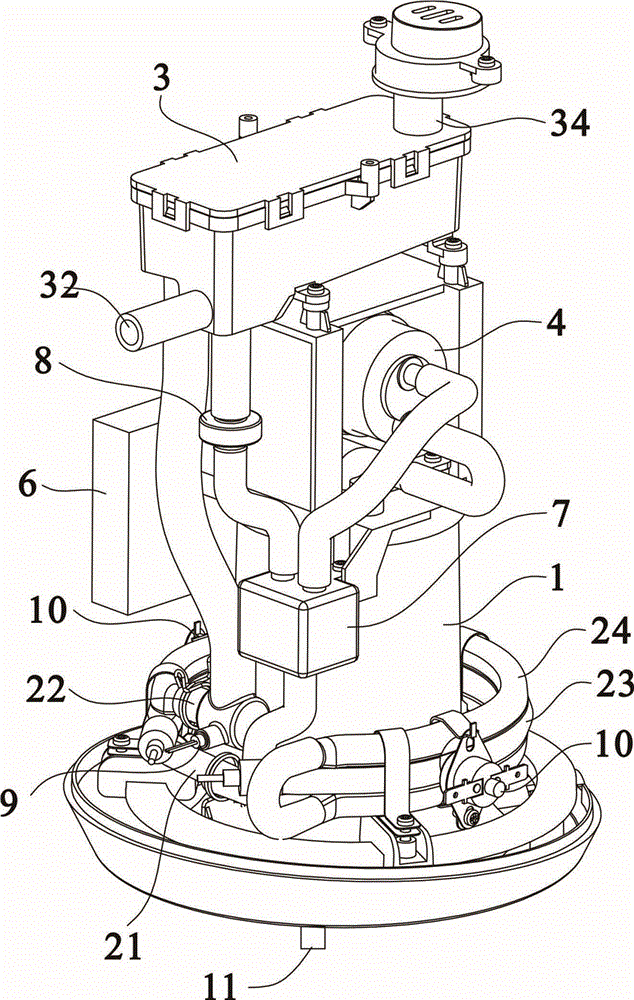

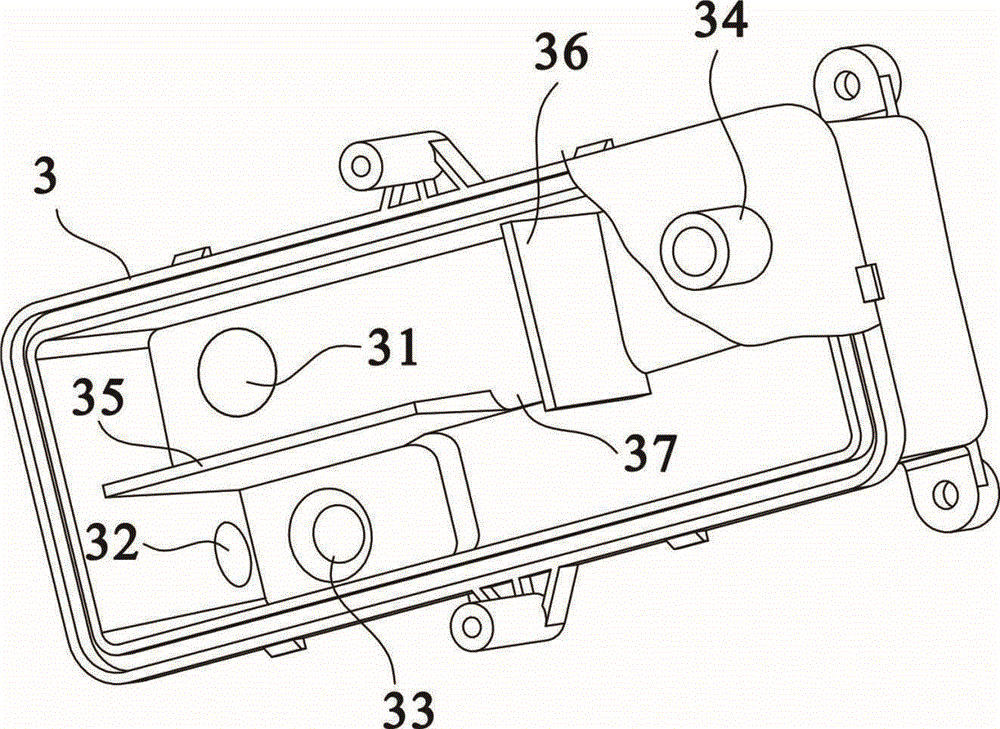

[0031] Embodiment 1: The water storage chamber and the heating device are fixedly connected together with fasteners, and the water drain hole at the bottom of the water storage chamber is attached to the water inlet end at the top of the heating device and is in airtight communication.

Embodiment approach 2

[0032] Embodiment 2: The water storage cavity and the water vapor separation box are integrally injection molded, or the water storage cavity is installed and fixed at the lower part of the water vapor separation box, and the water storage cavity is connected with the heating device through a pipe.

Embodiment approach 3

[0033] Embodiment 3, in order to make the structure of the product simpler, the water storage chamber is set as a section of pipeline that feeds water from the upper part, and the diameter of the inlet pipe of the pipeline is larger than the diameter of the outlet pipe, the water inlet pipe of this pipeline is connected with the water pump, and the pipeline The outlet pipe of the outlet pipe communicates with the water inlet end of the heating device located below it.

[0034] In the optimization scheme of this embodiment, the control valve is a one-way valve, and its working principle: when the instant water dispenser is working, the cold water is sent into the water storage chamber by the water pump through the pipeline, and a certain fluid pressure is formed in the pipeline, and the pressure in the pipeline is greater than Atmospheric pressure in the water vapor separation box, the one-way valve is closed, the cold water in the water storage chamber flows into the heating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com