Double-sided textured multilayer metal texture interlaced decorative sheet and production process thereof

A multi-layer metal and production process technology, which is applied in the direction of decorative art, the process for producing decorative surface effects, special decorative structures, etc., can solve the problems of uncontrolled product quality, large cost investment, and large cumulative errors. To achieve the effect of simplifying the production process and operation difficulty, reducing the investment of human resources, and reducing the increase of accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

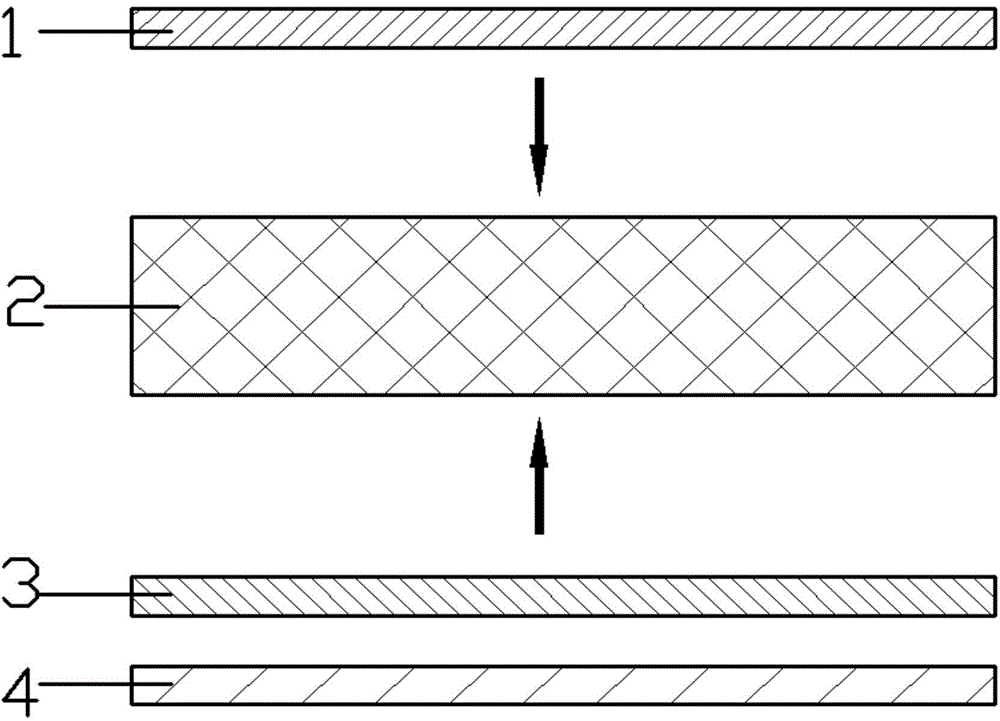

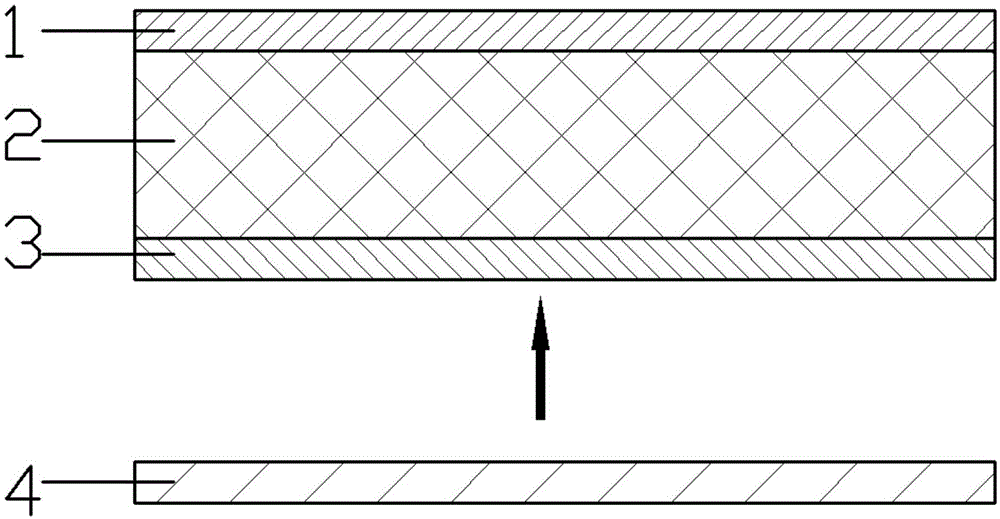

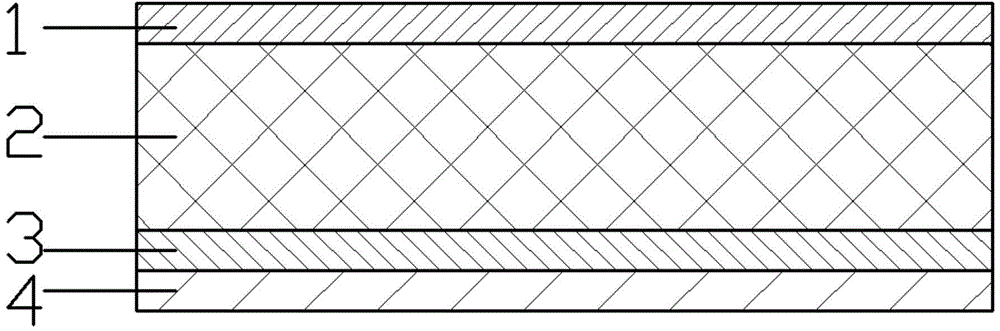

[0031] refer to Figure 1-Figure 4 As shown, a production process for a double-sided etched multi-layer metal texture interwoven decorative board, including: a first side texture 1, a transparent insulating plastic layer 2 and a second side stepped surface texture 3, characterized in that the second side The stepped surface texture 5 is composed of the second side inner layer texture 3 and the second side outer layer texture 4, the first side texture 1 and the second side inner layer texture 4 are connected with the transparent insulating plastic layer 2 at the same time, the second side The side outer layer texture 3 is covered on the second side inner layer texture 3, and the appearance shape of the second side outer layer texture 4 and the second side inner layer texture 3 is similar, but the size B2 of the second side outer laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com