Method for extracting asiaticoside and madecassoside from centella

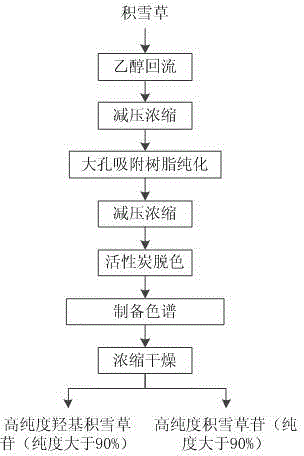

A technology of madecassoside and asiaticoside, which is applied in the field of extraction and separation of medicinal active ingredients, can solve the problems of high cost, complicated process, and complicated operation, and achieve low cost, simple process, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of the crude product of Centella asiatica: 500g of Centella asiatica is pulverized, and in the extraction tank, add 70% ethanol (v / v) of 10 times the weight of the raw material for microboiling and reflux extraction, extract for the first time for 120min, filter out the medicinal liquid, Then add 70% ethanol (v / v) of 10 times the weight of raw materials, reflux extraction for 60min, and combine the extracts;

[0026] The extract was concentrated under reduced pressure to a density of 1.05 g / ml, diluted with 4 times of water, and centrifuged to obtain the upper column solution a, which was put into a D101 macroporous resin column, washed with water until the eluate was nearly colorless, and then used for 3 columns with a volume of 20 % ethanol (v / v) and 4 column volumes of 50% ethanol (v / v) were eluted, the 50% ethanol (v / v) eluate was collected, concentrated under reduced pressure to a density of 1.03 g / ml, and 3% activated carbon was added Decolorize, and f...

Embodiment 2

[0030] Preparation of the crude product of Centella asiaticoside: 500g of Centella asiatica is pulverized, and in the extraction tank, add 70% ethanol (v / v) of 12 times the weight of the raw material for microboiling and reflux extraction, extract for the first time for 90min, filter out the medicinal liquid, Then add 70% ethanol (v / v) of 10 times the weight of raw materials, reflux extraction for 90min, and combine the extracts;

[0031] The extract was concentrated under reduced pressure to a density of 1.10 g / ml, diluted with 6 times of water, and centrifuged to obtain the upper column solution a, which was put into a D130 macroporous resin column, washed with water until the eluent was nearly colorless, and then used for 4 columns with a volume of 20 % ethanol (v / v) and 5 column volumes of 50% ethanol (v / v) were eluted, the 50% ethanol (v / v) eluate was collected, concentrated under reduced pressure to a density of 1.04 g / ml, and 3% activated carbon was added Decolorize, an...

Embodiment 3

[0035] Preparation of the crude product of Centella asiatica: 500g of Centella asiatica is pulverized, and in the extraction tank, add 70% ethanol (v / v) of 10 times the weight of the raw material for microboiling and reflux extraction, extract for the first time for 120min, filter out the medicinal liquid, Then add 70% ethanol (v / v) of 8 times the weight of raw materials, reflux extraction for 60min, and combine the extracts;

[0036] The extract was concentrated under reduced pressure to a density of 1.15 g / ml, diluted with 8 times of water, and centrifuged to obtain the upper column liquid a, which was put into a D101 macroporous resin column, washed with water until the eluate was nearly colorless, and then used for 3 columns with a volume of 20 % ethanol (v / v) and 5 column volumes of 60% ethanol (v / v) were eluted, the 60% ethanol (v / v) eluate was collected, concentrated under reduced pressure to a density of 1.05 g / ml, and 3% activated carbon was added Decolorize, and filt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap