Working platform, monopile foundation, offshore working platform and installation method thereof

A single-pile foundation and installation method technology, which is applied in basic structure engineering, artificial island, water conservancy engineering and other directions, can solve problems such as lack of equipment, and achieve the effects of simple structure, saving construction time and reducing offshore construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

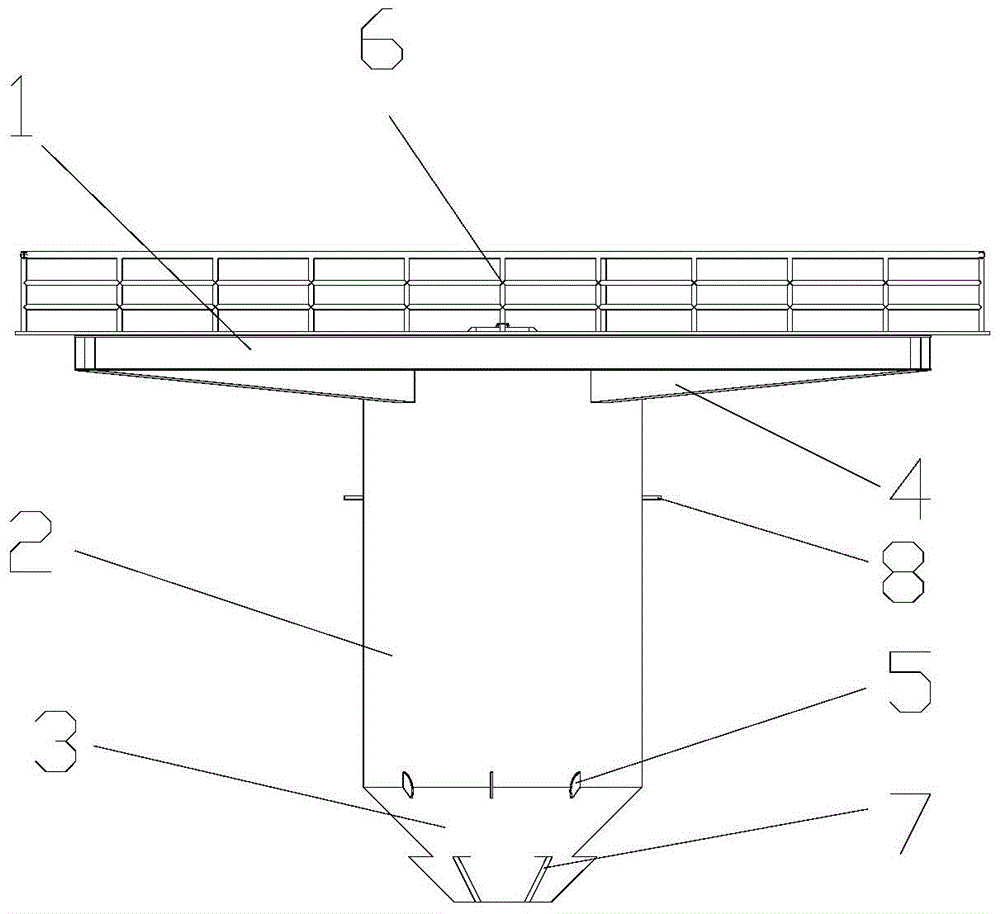

[0034] Such as figure 1 As shown, this embodiment relates to a workbench, including: a support platform 1 , a transition section 2 and a guide part 3 . The transition section 2 is columnar, and its two ends are fixedly connected to the support platform 1 and the guide part 3 respectively.

[0035] Wherein, the transition section 2 can be fixedly connected with the support platform 1 and the guide part 3 by welding, but it is not limited thereto, and other conventional connection methods such as flange connection can also be used.

[0036] The shape of the table top of the support platform 1 can be circular, square or other shapes, and is used to place the working equipment of the offshore booster station. Preferably, a protective fence can be set on the support platform 1, so that the staff can be prevented from falling into it in actual work. In the sea, the safety of personnel is guaranteed.

[0037] The transition section 2 may be cylindrical (such as a cylinder that is c...

Embodiment 2

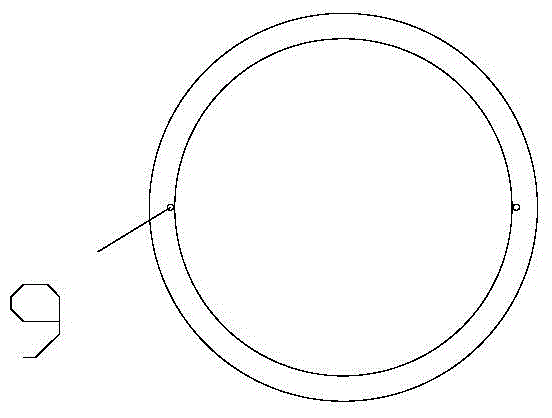

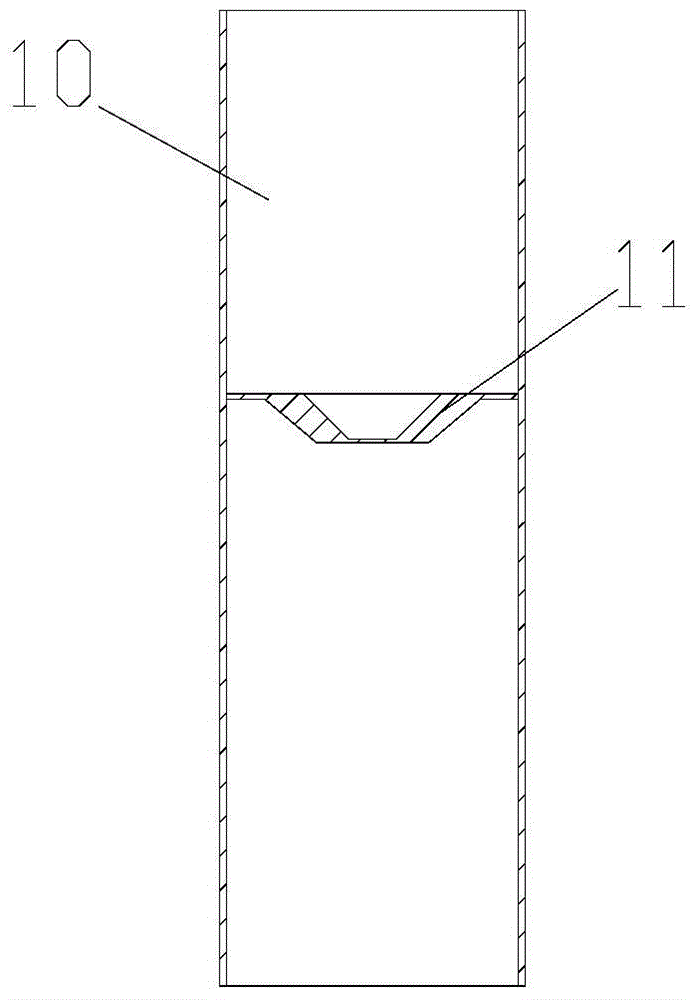

[0045] Such as image 3 As shown, a single-pile foundation, the upper part of the single-pile foundation is provided with a housing portion 10 with an upward opening, and a positioning portion 11 is provided in the housing portion 10, such as Figure 4 As shown, the positioning part 11 has a conical or frustum-shaped inner concave part 12 that matches the guide part 3 of the workbench described in Embodiment 1. The inner surface of the inner concave part 12 is provided with a The number of directional wings 7 is equal and the directional slots 13 are matched one by one with the directional wings 7 of the workbench.

[0046] Wherein, the monopile foundation may be cylindrical (such as a cylinder that is convenient for processing), but it is not limited thereto, and may also be prismatic or other columnar. The shape of the containing portion 11 may be a cylinder, or other shapes such as a prism. In this way, the manufacture of the single pile body can be made very simple, and ...

Embodiment 3

[0050] Such as Figure 5 As shown, an offshore working platform includes the workbench 16 described in the first embodiment and the monopile foundation 15 described in the second embodiment. The transition section 2 and the tapered guide part 3 of the workbench 16 are inserted into In the part 10, the orientation wing 7 is inserted into the orientation groove 13 correspondingly. Wherein, the supporting platform 1 of the working platform 16 may also be a nacelle of a wind power generating set fixedly connected with the transition section 2 .

[0051] Wherein, the monopile foundation 15 is arranged vertically, and one end is fixed in the seabed, and the other end is in a natural state, and the port of the accommodation part 10 is located at one end of the monopile foundation 15 in a natural state. The transition section 2 and the tapered guide part 3 of the workbench 16 are inserted into the housing part 10 through the port of the housing part 10. Since the guide part 3 is tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com