Analysis method for the influence of co-fired boiler operating parameter changes on the coal consumption of power generation units

A boiler operation and analysis method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as the inability to apply pulverized coal and blast furnace gas co-fired boilers, the impact of coal consumption in power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is further described below.

[0051] The specific steps of the analysis method of the influence of the change of the operating parameters of the co-fired boiler on the coal consumption of the unit for power generation of the present invention are as follows:

[0052] Regularly read the historical operation data of the past period of time from the historical database of the unit, and use the data mining method to analyze the data to obtain the continuously updated benchmark values of the main controllable operating parameters of the boiler, including the benchmark value of the exhaust gas temperature Reference value of exhaust gas oxygen Baseline value of CO content in exhaust smoke and fly ash carbon content reference value

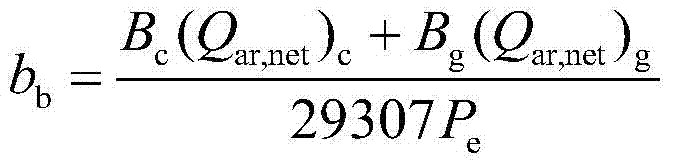

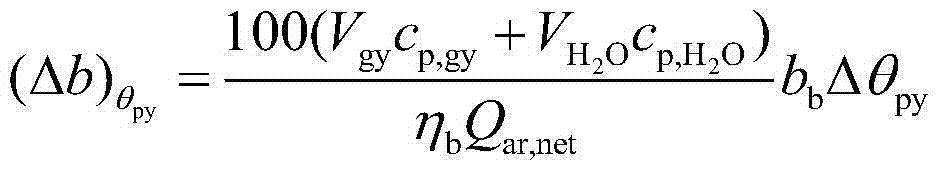

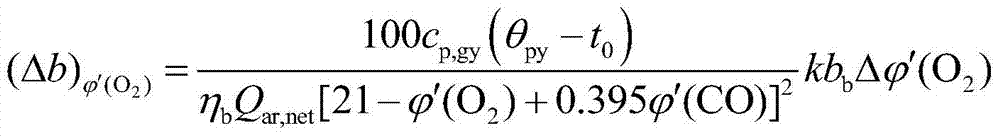

[0053] The operating data of the unit is obtained according to the instrument measurement, including the generating power P of the unit e , The actual evaporation of the boiler D, the amount of gas entering the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com