A kind of silicon-based negative electrode material for lithium ion battery and preparation method thereof

A silicon-based negative electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as harsh system configuration conditions, strong toxicity and corrosion, and complex processes, so as to improve charge and discharge performance and increase Conductivity, the effect of alleviating the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of a silicon-based negative electrode material for a lithium-ion battery is as follows:

[0034] 1. Silica powder waste purification pretreatment

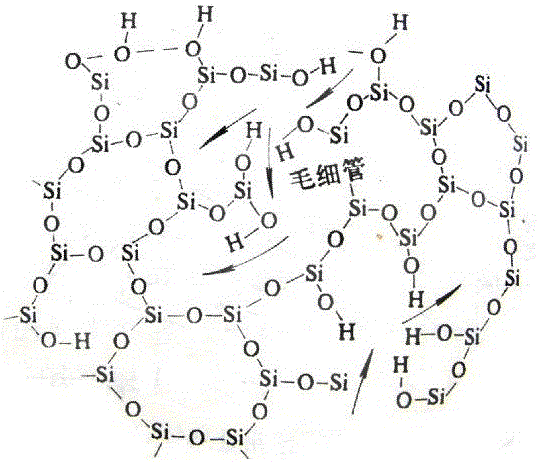

[0035] The silicon dioxide powder waste produced by the vapor deposition method in optical fiber production is pickled, soaked in hydrochloric acid, sulfuric acid or nitric acid with a concentration of 5% to 15%, stirred for 2 to 3 hours to remove impurities introduced during collection and shipment, and then used Wash and filter repeatedly with deionized water, and finally dry the filtered product.

[0036] 2. Preparation

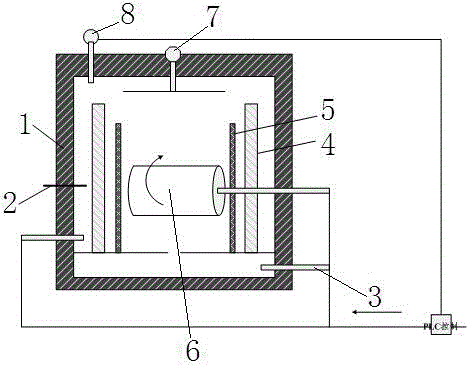

[0037] Add the silicon dioxide powder obtained by pickling and purification into deionized water to disperse, heat in a water bath, control the temperature of the water bath at 50°C~80°C, stir magnetically or ultrasonically for 3~4 hours, and wait until the silicon dioxide powder is fully dispersed , add carbon material and stir evenly, then add graphene material and stir until uni...

Embodiment 1

[0049] (1) The silicon dioxide powder waste produced by the vapor deposition method in optical fiber production is subjected to pickling pretreatment. Add it into hydrochloric acid with a concentration of 8% to soak to remove impurities, stir for 2 hours, filter with deionized water to wash and filter repeatedly, and finally dry the filtered product.

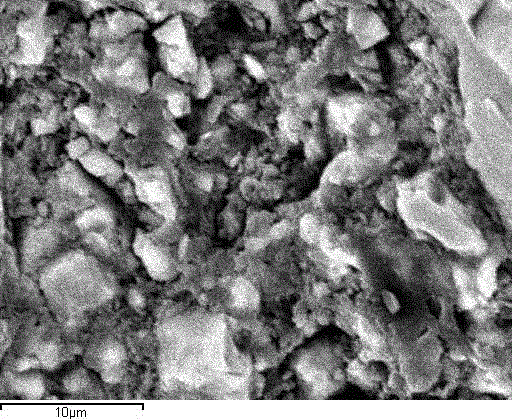

[0050] (2) Take 10g of purified silica powder and add it to deionized water for dispersion. The temperature of the water bath is controlled at 60°C. After ultrasonic vibration and dispersion for 3 hours, add 5g of artificial graphite particles, and then add 35g of graphene. After the dispersion is uniform, a And put it into an agate jar with a ball-to-material ratio of 4:1, ball mill in a planetary mill for 4 hours, wash and filter with deionized water, and dry for 5 hours.

[0051] (3) Add the above mixed powder into the sintering furnace, control the temperature at 1300°C at a heating rate of 10°C / min, and calcine at a constan...

Embodiment 2

[0053] (1) Obtain purified silica powder according to Example 1.

[0054] (2) Take 17.5g of purified silica powder and add it to deionized water to disperse. The temperature of the water bath is controlled at 60°C. After dispersing by ultrasonic vibration for 3 hours, add 10g of the mixture of mesocarbon microspheres and graphitized carbon fibers, and then add Put 22.5g of graphene into an agate jar with a ball-to-material ratio of 4:1, mill in a planetary mill for 5 hours, wash and filter with deionized water, and dry for 5 hours.

[0055] (3) Add the above mixed powder into the sintering furnace, control the temperature at 1450°C at a heating rate of 5°C / min, and calcine at a constant temperature for 7 hours. 2 Mixed with Ar, H 2 Accounting for 50%, the furnace body pressure is maintained at 100pa, and silicon, silicon carbide, carbon, graphene composite materials are obtained after natural cooling. The lithium-ion battery prepared by using this material is charged and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com