Preform for producing plastic containers in a stretch blow moulding process

一种塑料容器、拉伸吹塑的技术,应用在不具有支承环的预制件领域,能够解决分拣系统损坏等问题,达到节省材料的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

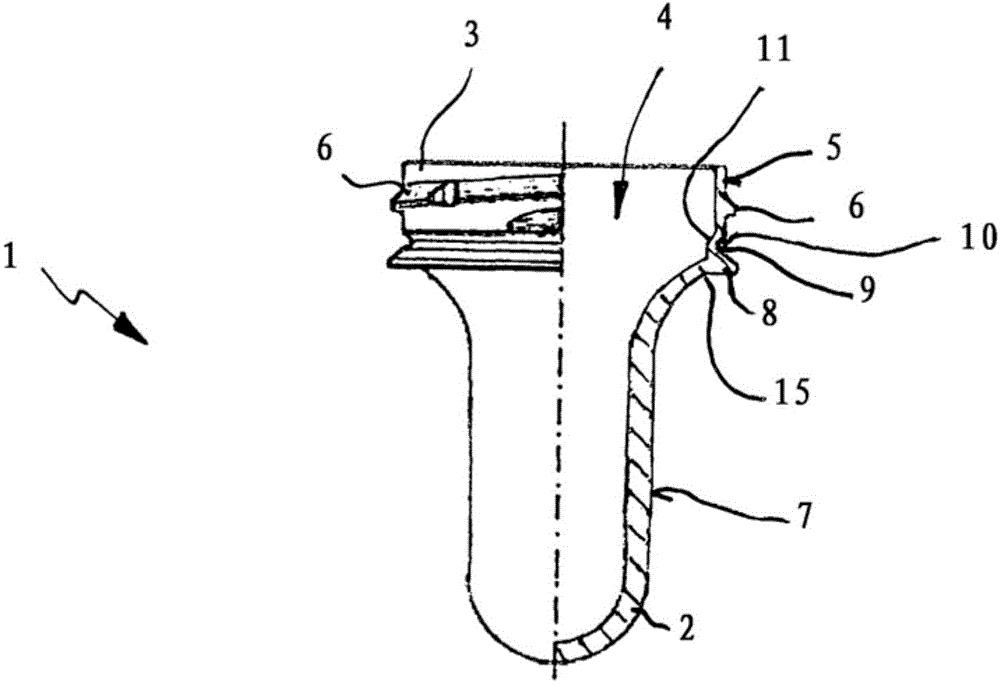

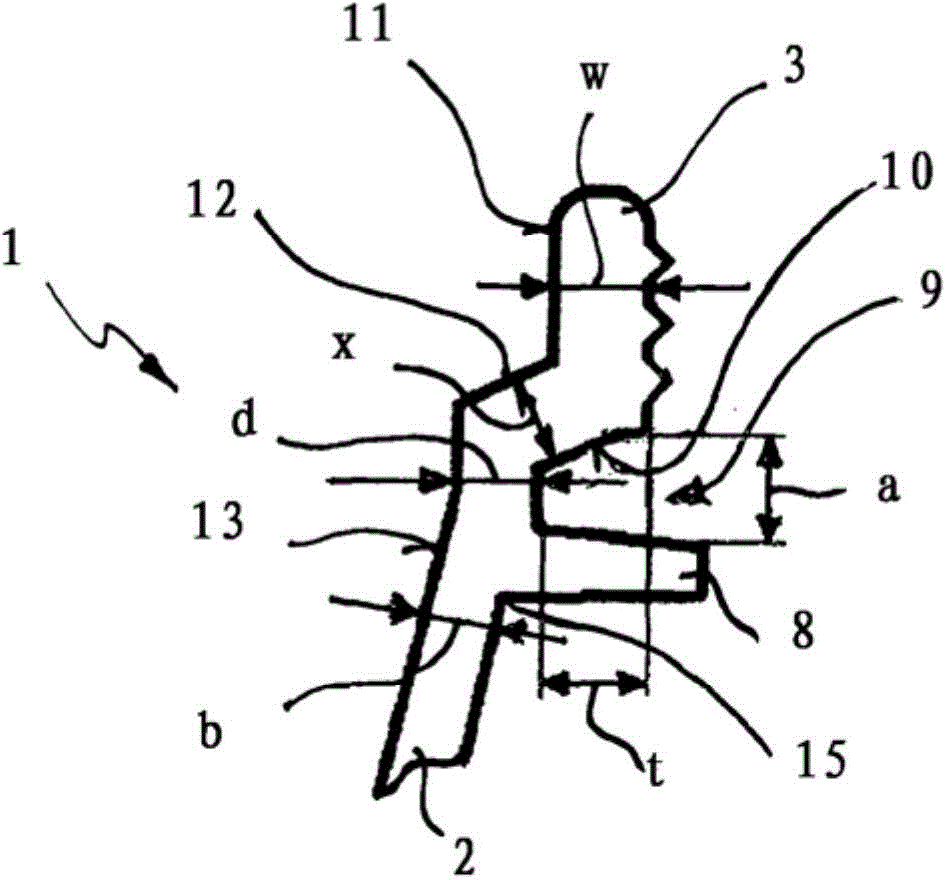

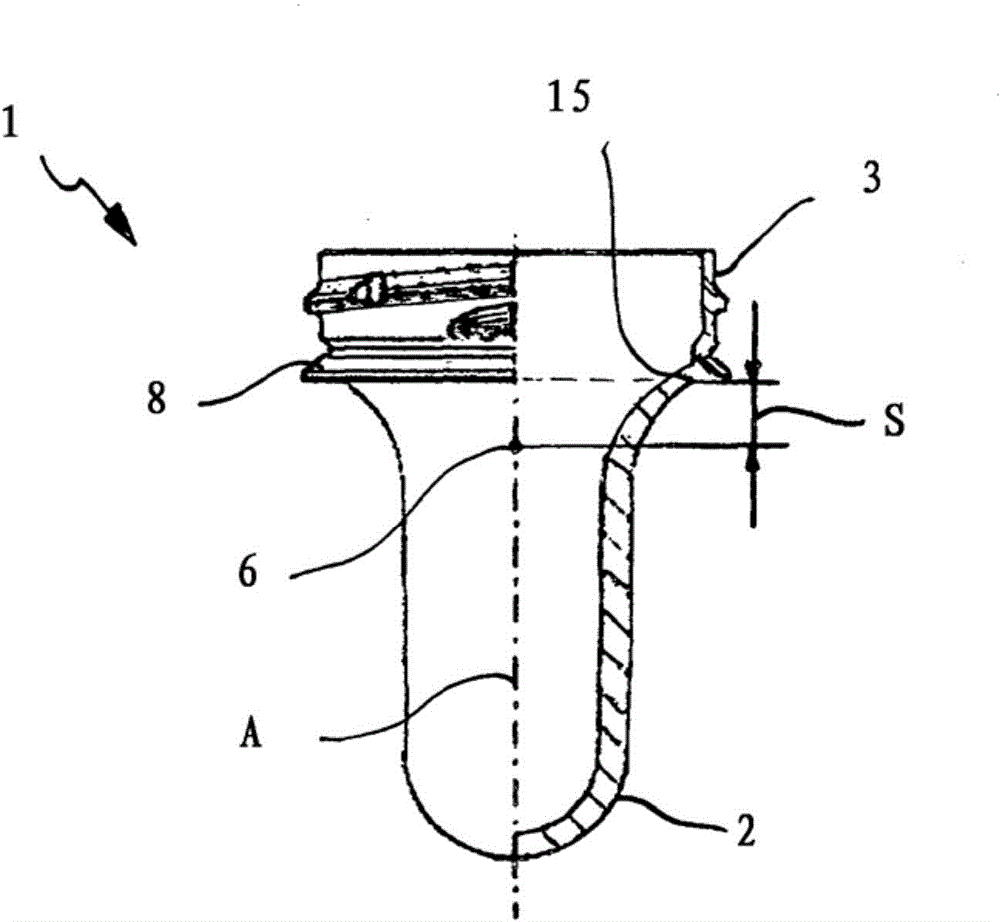

[0042] figure 1 A half-side axially sectioned preform is shown, which is assigned the reference numeral 1 in its entirety. The preform 1 has an elongated preform body 2 which is formed closed at one longitudinal end. At its opposite end, the preform body 2 is connected to a neck section 3 provided with a pouring opening 4 . The neck section 3 is provided on its outer wall 5 with a threaded section 6 for the form-fitting fastening of a threaded closure, not shown here, with an internal thread. Furthermore, it can be seen from the illustration that the preform 1 has, at the transition 15 from the preform body 2 to the neck section 3 , an annular, circumferential flange 8 which protrudes radially beyond the preform body 2 The outer side of the 7. The flange 8 serves as a support for a detachable securing strip for a screw closure for a plastic container stretch-blown from the preform 1 or, in oil bottles etc., for fastening the commonly used hinged closure. The lower part, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com