An integrated processing equipment for lotus seeds peeling, removing the core, leaving the core and grinding white

A technology for integrated processing and lotus seeds, applied in the fields of shelling, pod removal, fruit de-core devices, etc., can solve the problems of increasing processing costs, inability to meet, destroying lotus flesh, etc., to reduce the floor space, avoid intermediate links, and improve. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

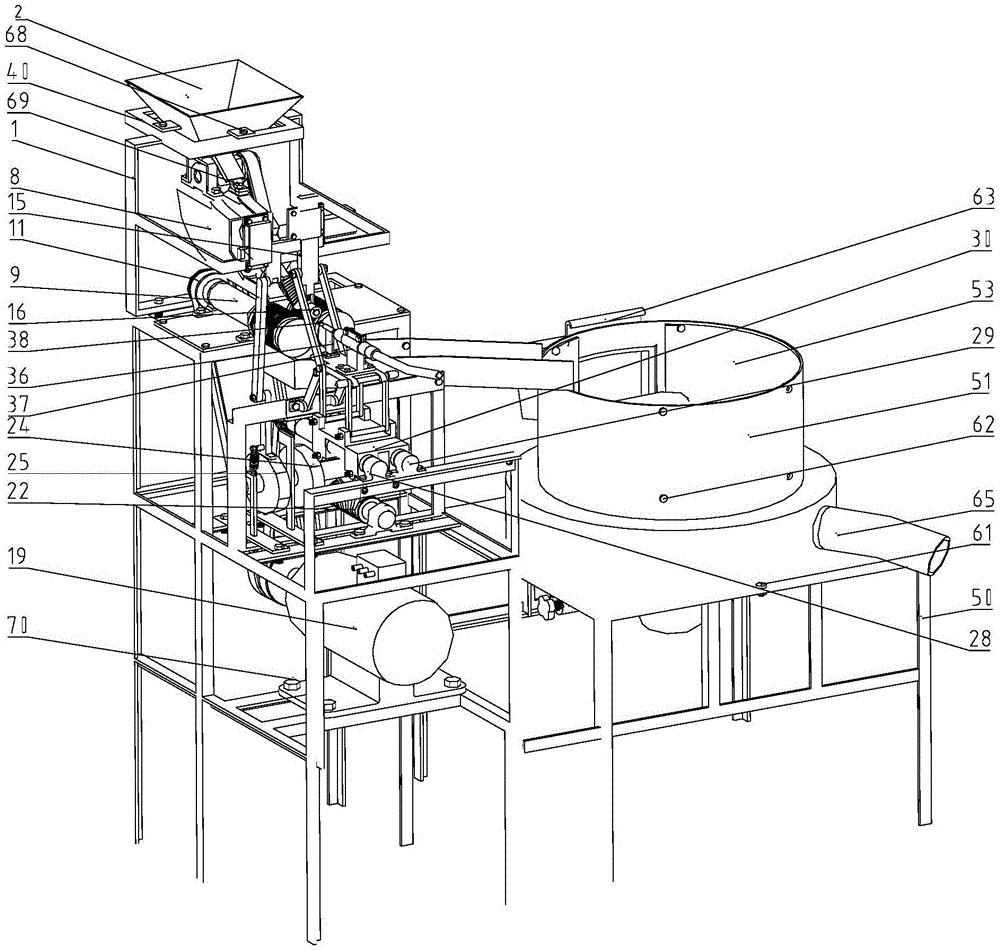

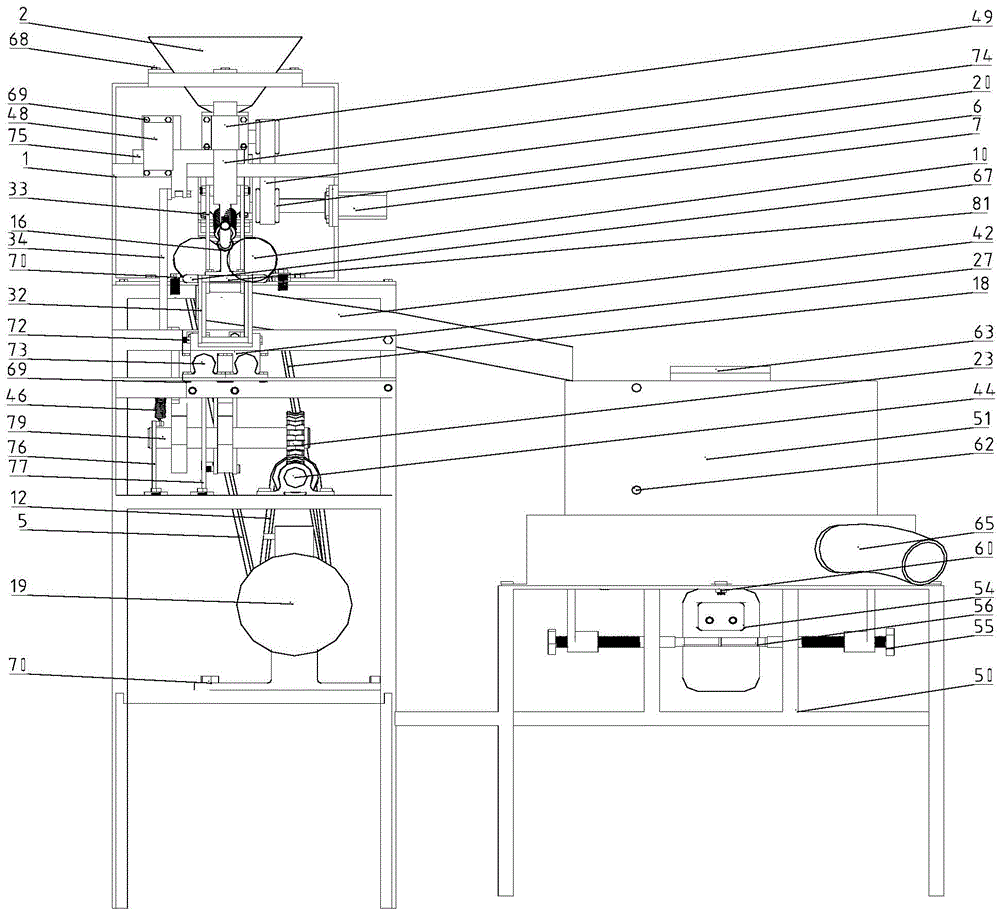

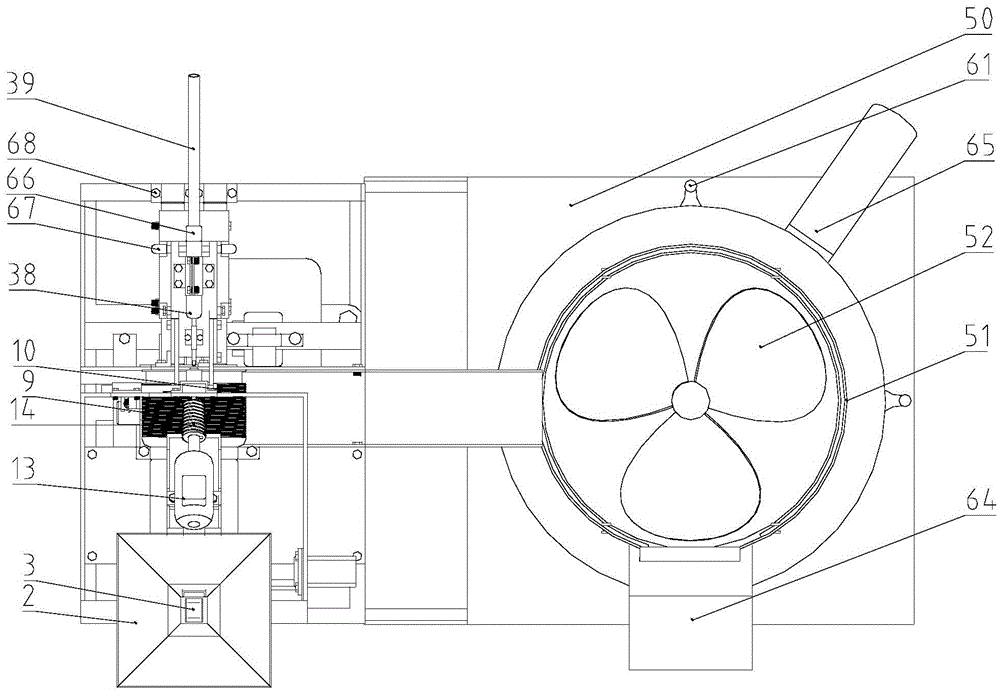

[0077] Depend on figure 1 , figure 2 , image 3 It can be seen that an integrated processing equipment for lotus seed peeling, core removal, core retention and whitening includes a material grabbing-peeling system, a core removal and core retention system, and a grinding whitening system, wherein the core removal and core retention system is installed on the material grabbing system. - the discharge end of the peeling system, the whitening system is installed at the discharge end of the core removal and core retention system.

[0078] After the lotus seeds are peeled in the grabbing-peeling system, they are removed and left in the core removal system, and then the first spiral roller driving roller 9 and the second spiral roller driving roller rotate in the same direction. Under the action of the rotating transport of the wheel 10, it enters the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com