Tooth-belt type spring buffering gear lifter

A spring buffer, lifter technology, applied in the direction of belt/chain/gear, friction transmission device, door/window accessories, etc., to achieve the effect of scattered force points, good mute effect and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

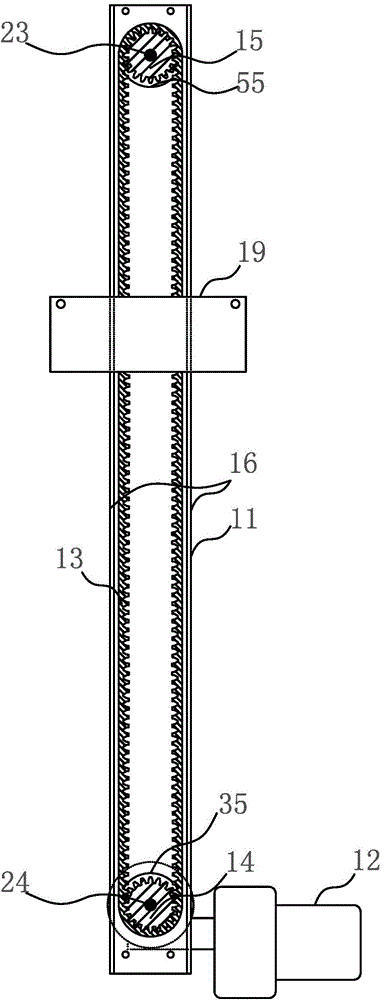

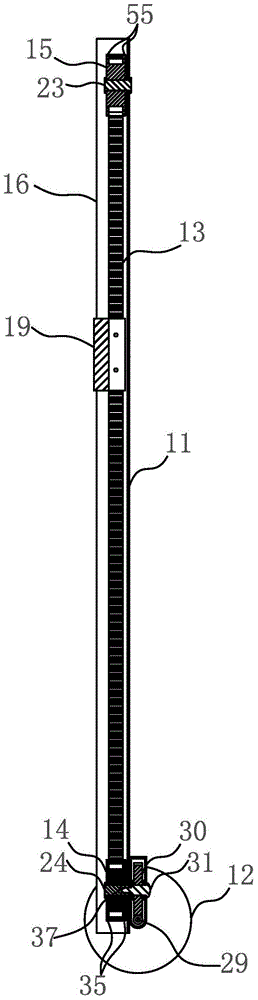

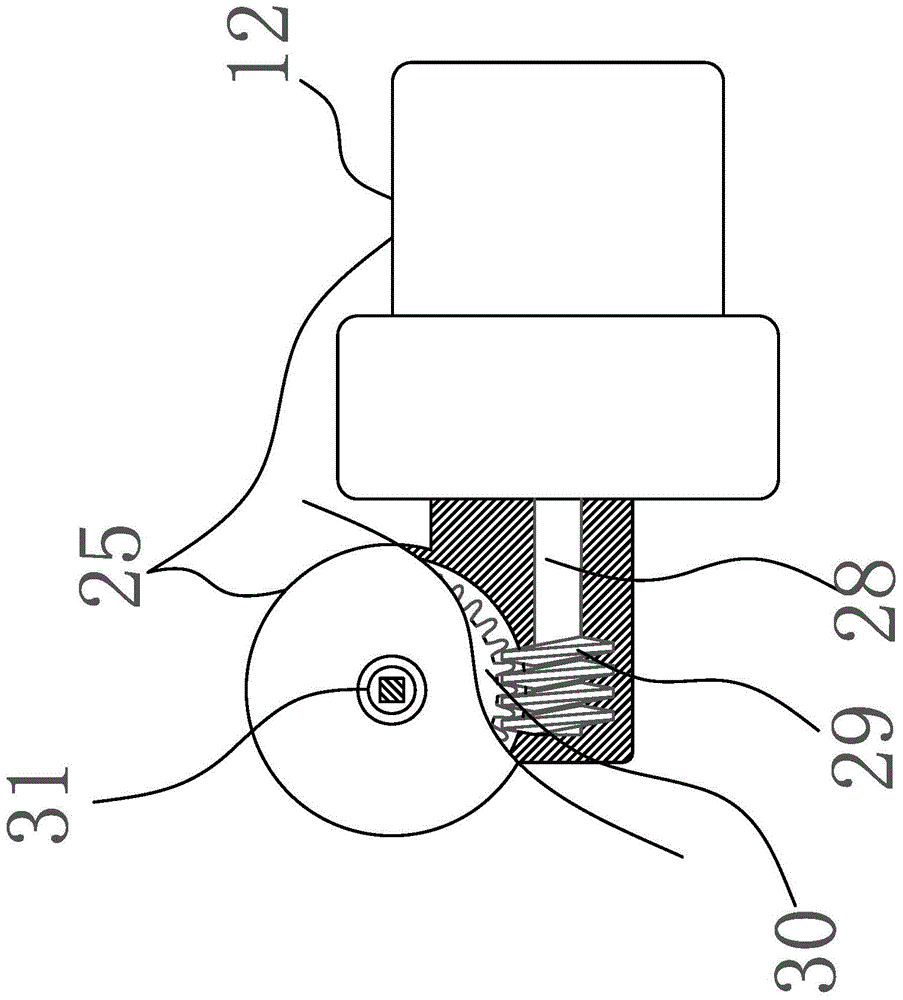

[0021] Figure 1-Figure 10 In the embodiment, a toothed belt type spring buffer gear lifter includes a driving mechanism (25) and a lifter bracket (11), and is characterized in that: Transmission belt driven gear (15) and transmission belt driving gear (14), and are connected transmission by toothed belt (13); On toothed belt (13), fix a slide block (19) that window glass is installed, the slide block (19) The chute (34) is stuck on the slide rail (16) of the lifter support (11); the transmission belt driving gear shaft (24) is connected with the driving mechanism (25).

[0022] The driving mechanism (25) is structured as follows: one end of the driving gear shaft (24) is connected to the keyway of the driving gear shaft (31), and the driving gear (30) is meshed with the worm (29) at the shaft end of the motor shaft (28) .

[0023] Described drive gear (30), comprises toothed outer wheel (1) and inner wheel (2), and outer wheel (1) is sleeved on the inner wheel (2), and on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com