Moment balance drilling machine

A torque balance and drilling machine technology, which is applied in drilling equipment, earthwork drilling, driving devices for drilling in wellbore, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

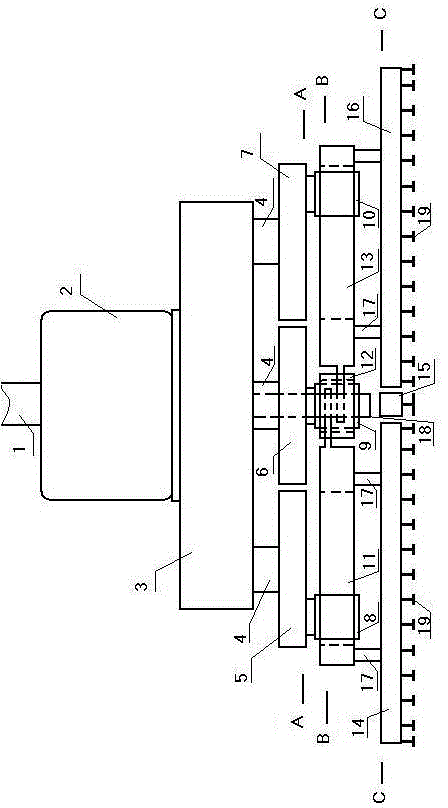

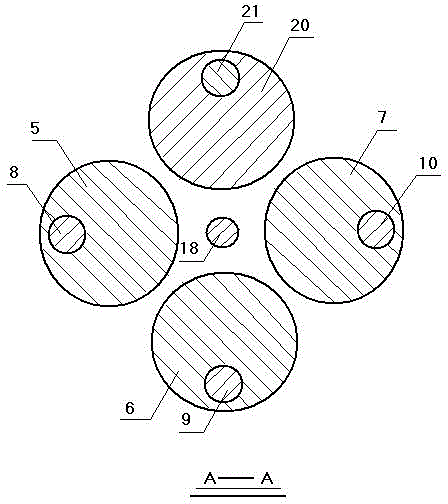

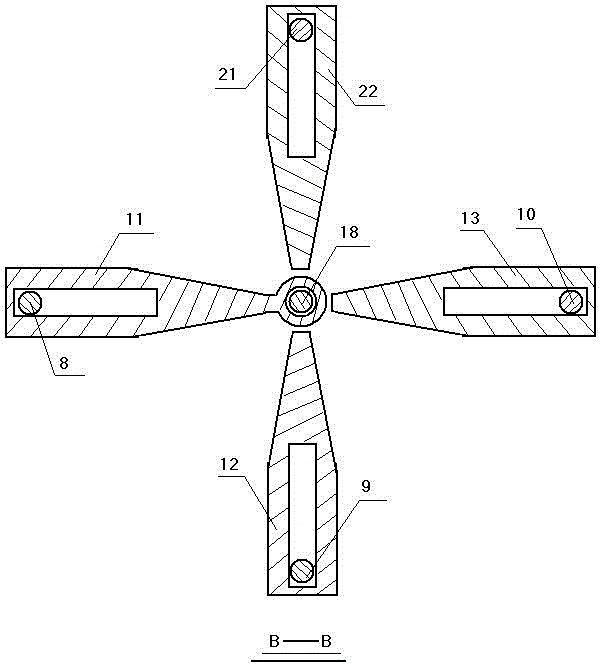

[0015] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment drilling rod 1 lower end is provided with motor 2, and motor lower end is provided with transfer case 3, and transfer case bottom outputs four five-point shafts 4, four five-point shafts A disk 5, two disks 6, three disks 7, and four disks 20 are respectively fixed at the lower end of the lower end, and a sub-axis 8 is fixed at a certain length from the center of the circle on the first disk, and a sub-axis is arranged on a rectangular hole in a rectangular arm 11. Among them, a rectangular arm is hinged to the sextant shaft by one end of the sextant shaft 18, the upper end of the sextant shaft is fixed in the middle of the lower part of the transfer case, and the lower part of a rectangular arm is fixed to a drill arm 14 through two connecting shafts 17; The two discs are fixed with a dichotomous shaft 9 at a certain length from the center of the circle, and the dichotomo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com