Heavy reducer supporting body

A technology of a reducer and a support body, which is applied to shafts and bearings, mechanical equipment, transmission parts, etc., can solve the problems of reduced service life of the reducer, unbalanced transmission torque, and reduced reliability, and achieves improved transmission efficiency and torque. balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

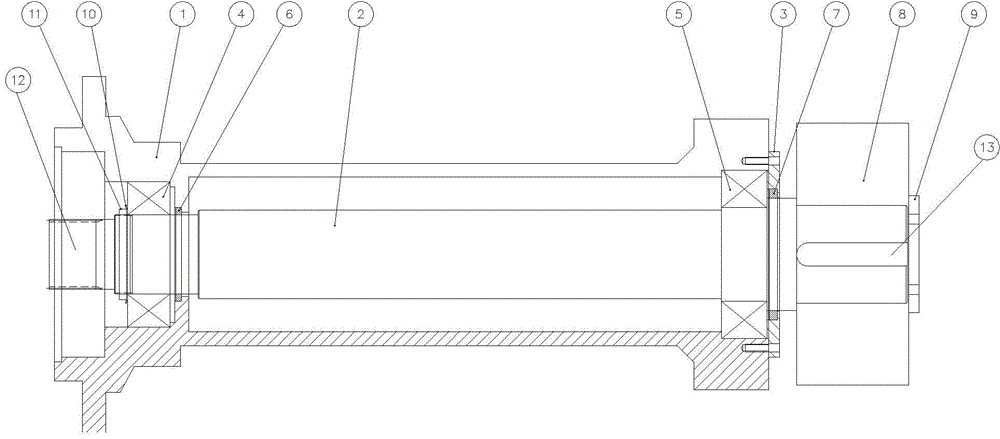

[0014] Such as figure 1 As shown, the supporting body of the heavy-duty reducer includes a housing 1 and a transmission shaft 2. The transmission shaft 2 is arranged in the housing 1 and is connected and fixed to the housing 1 through a bearing. One end of the transmission shaft 2 is provided with a gear I12, The other end is provided with a gear II8, the gear I12 is connected with the transmission shaft 2 to form an integral structure; the gear II8 is connected and fixed with the transmission shaft 2 through the key pin 13; the inner side of the gear I12 is provided with a bearing I, and the inner side of the gear II8 is provided with a bearing II.

[0015] In this embodiment, the bearing I is a tapered roller bearing 4 , and the bearing II is a spherical roller bearing 5 . The inner side of the bearing I is provided with an oil seal I6, and the outer side of the bearing I is provided with a stop washer 10 and a cap 11 in turn; the outer side of the bearing II is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com