Patents

Literature

44results about How to "Moment balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

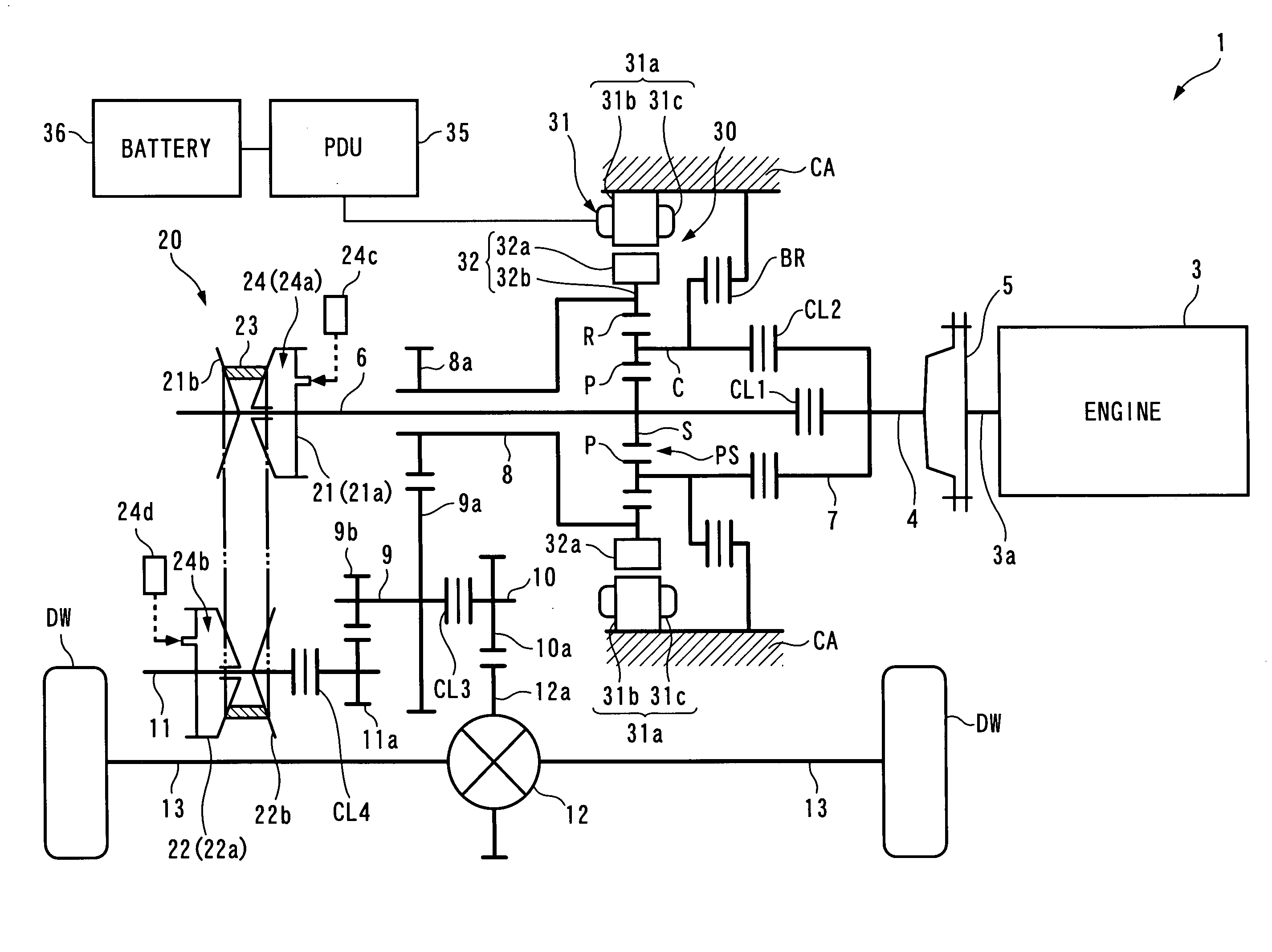

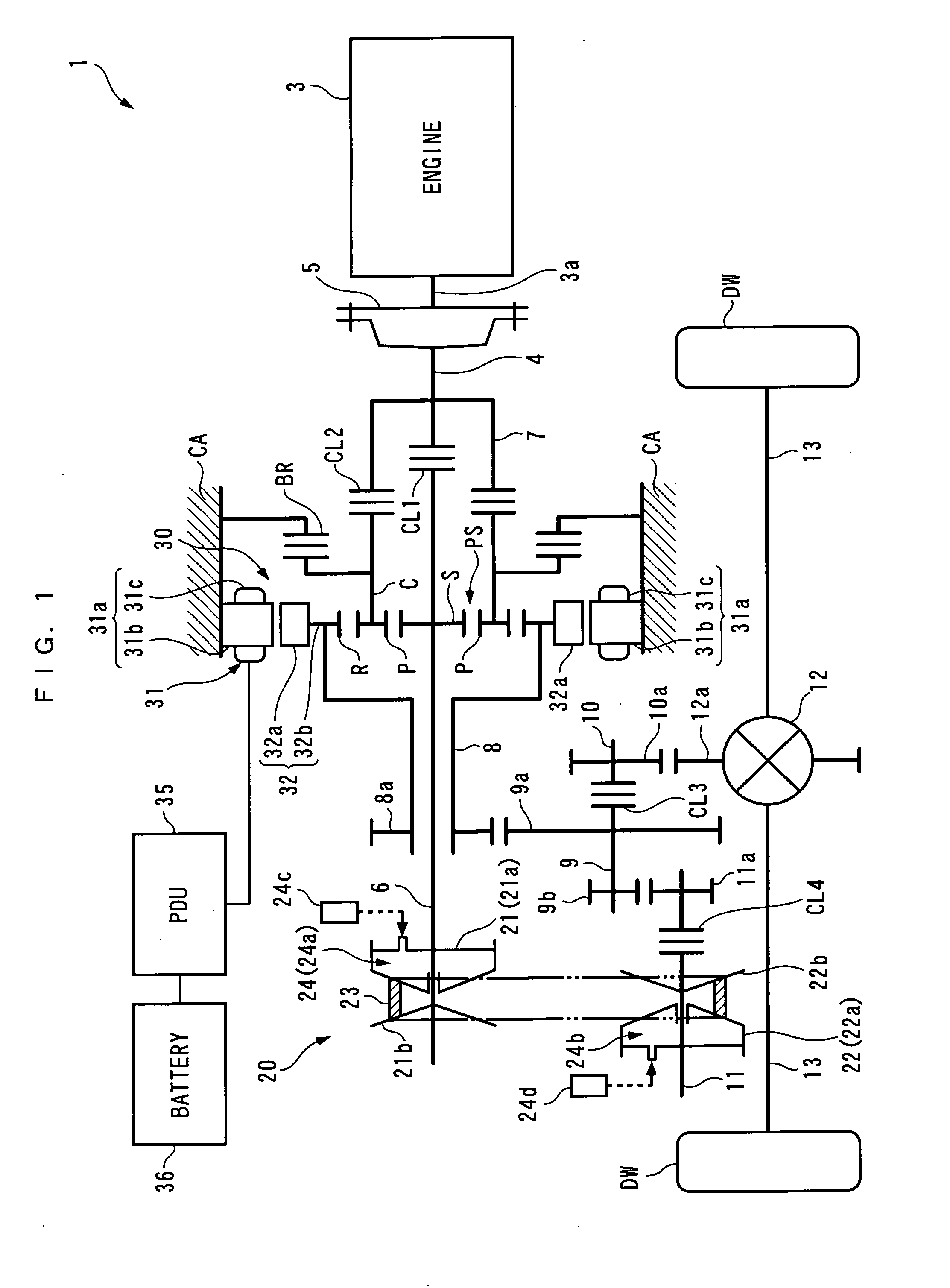

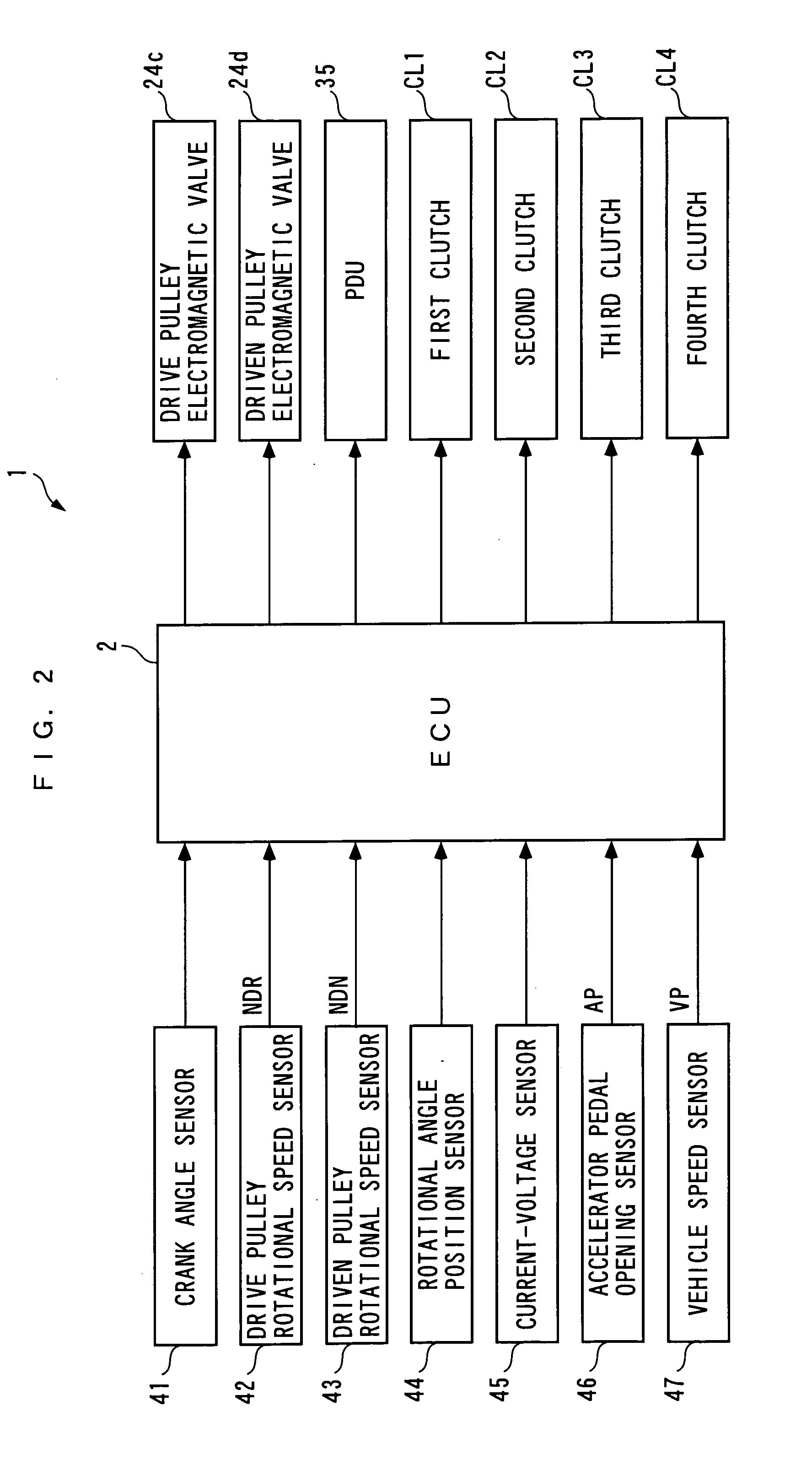

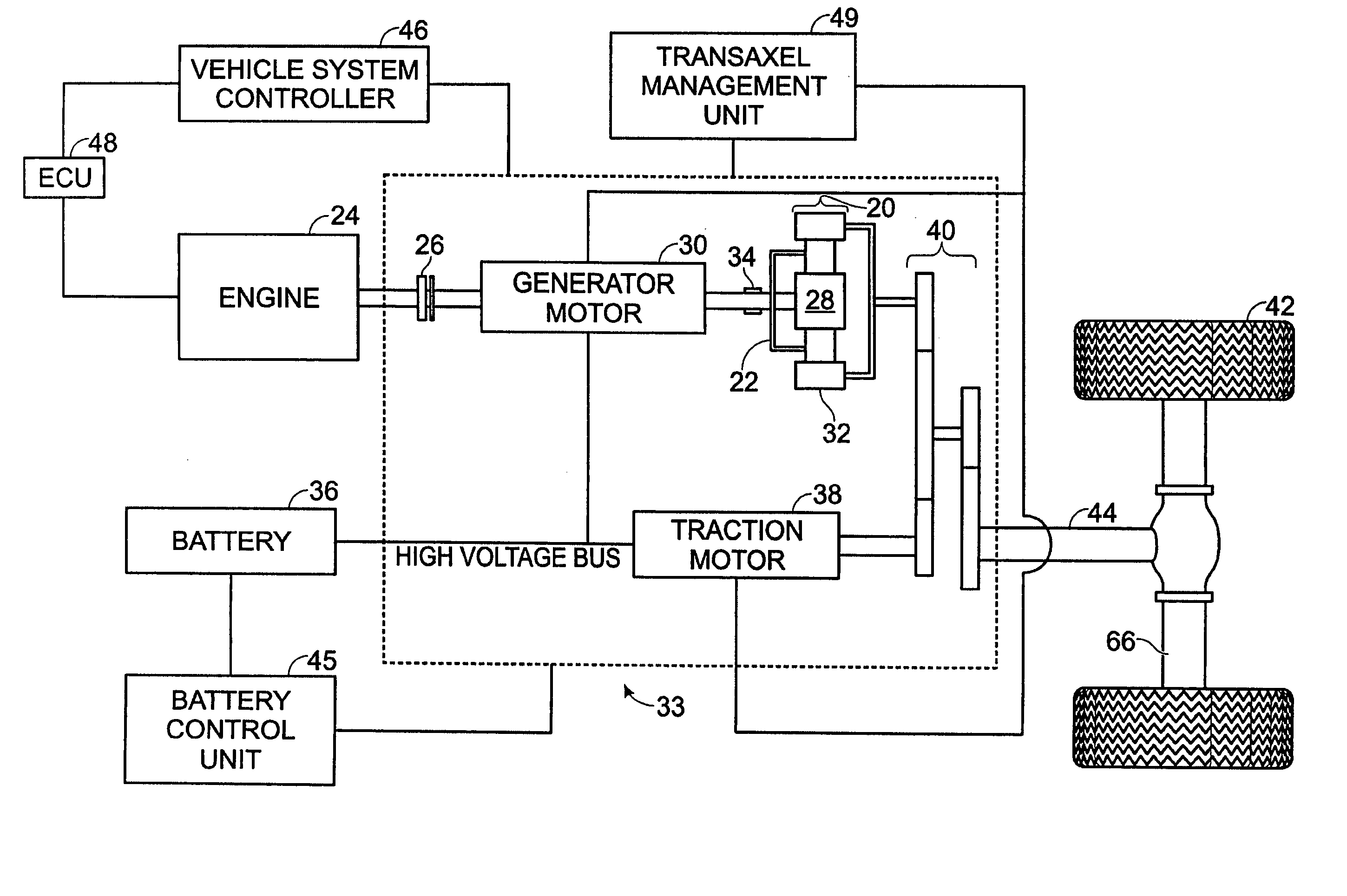

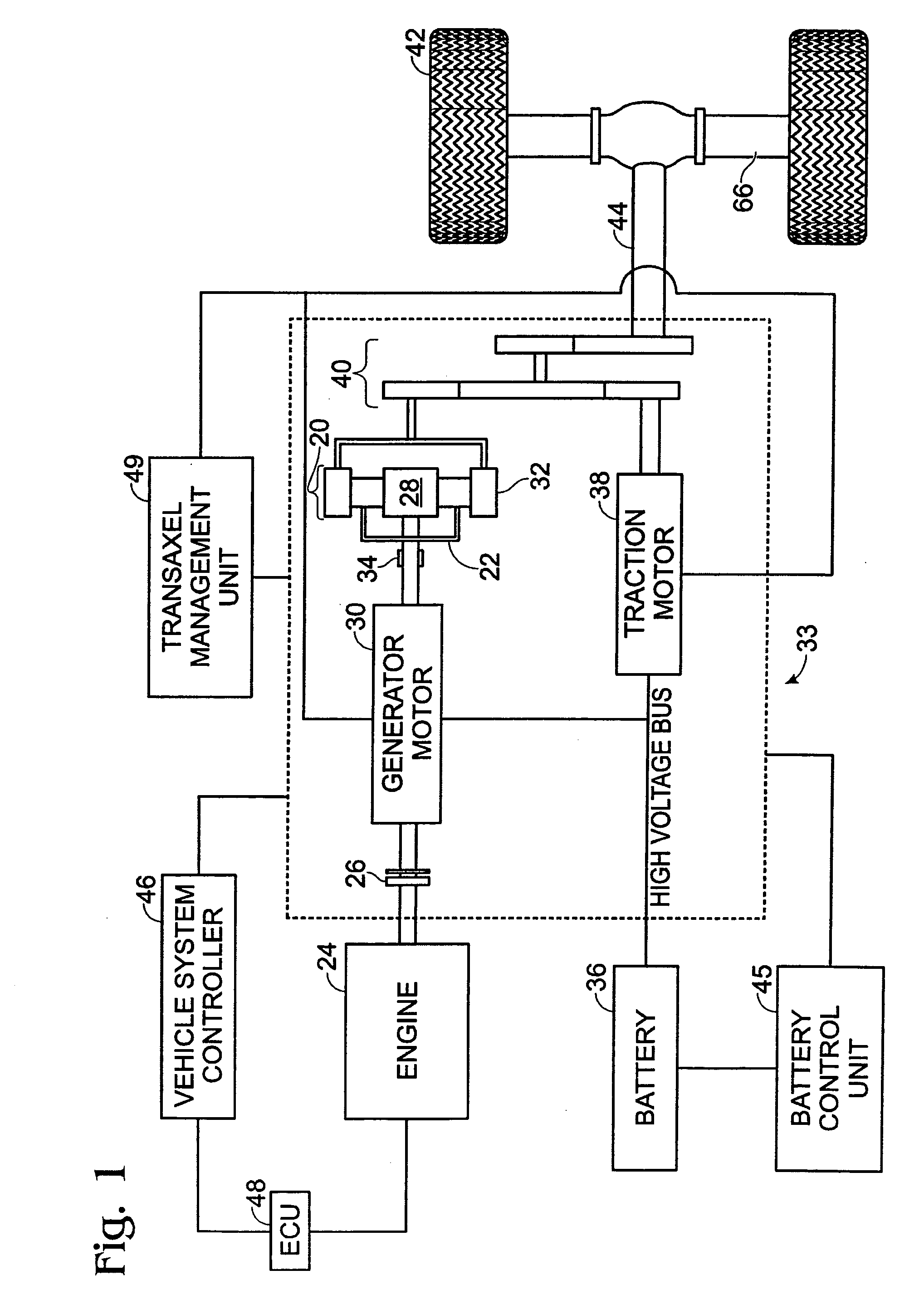

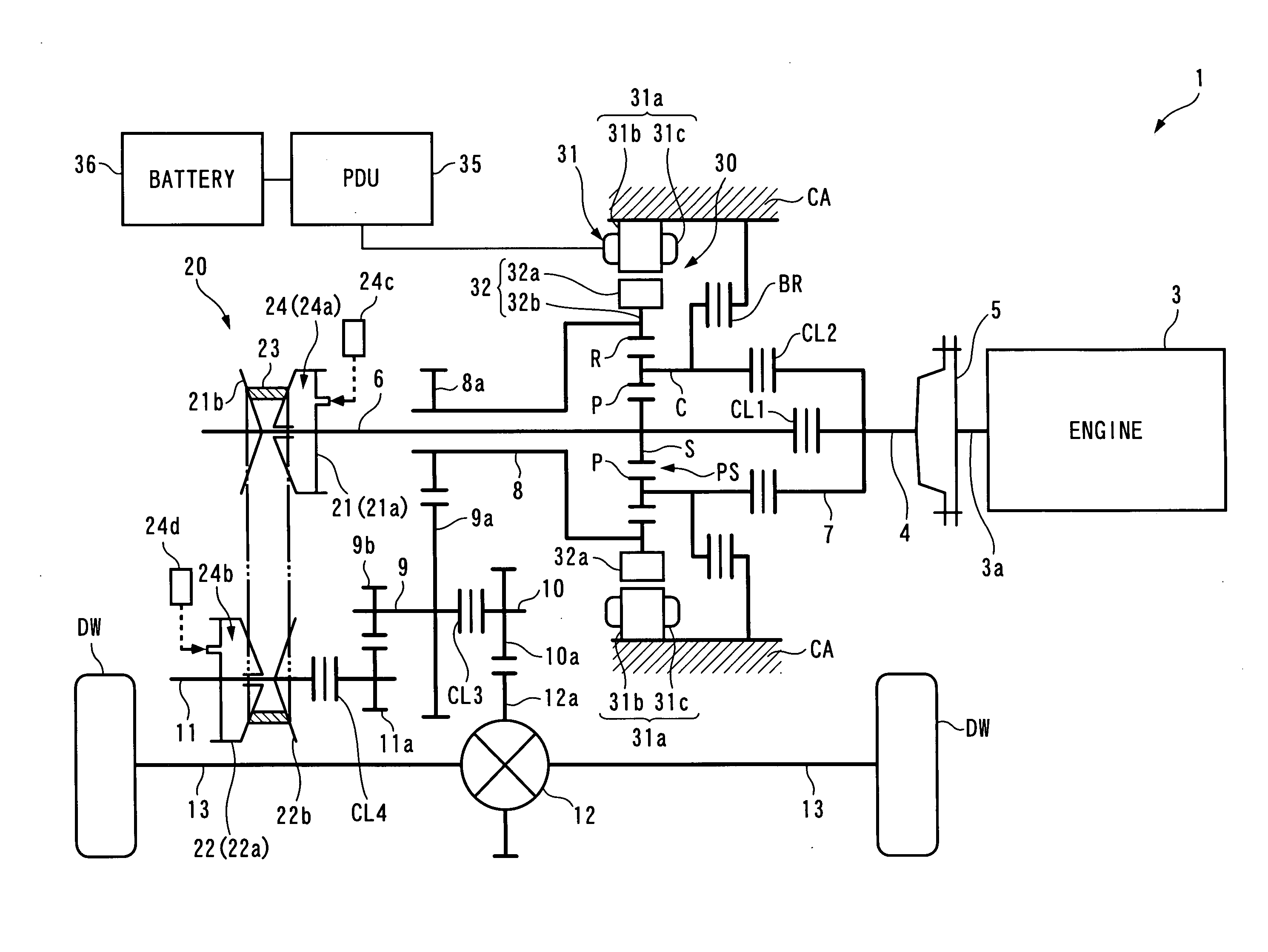

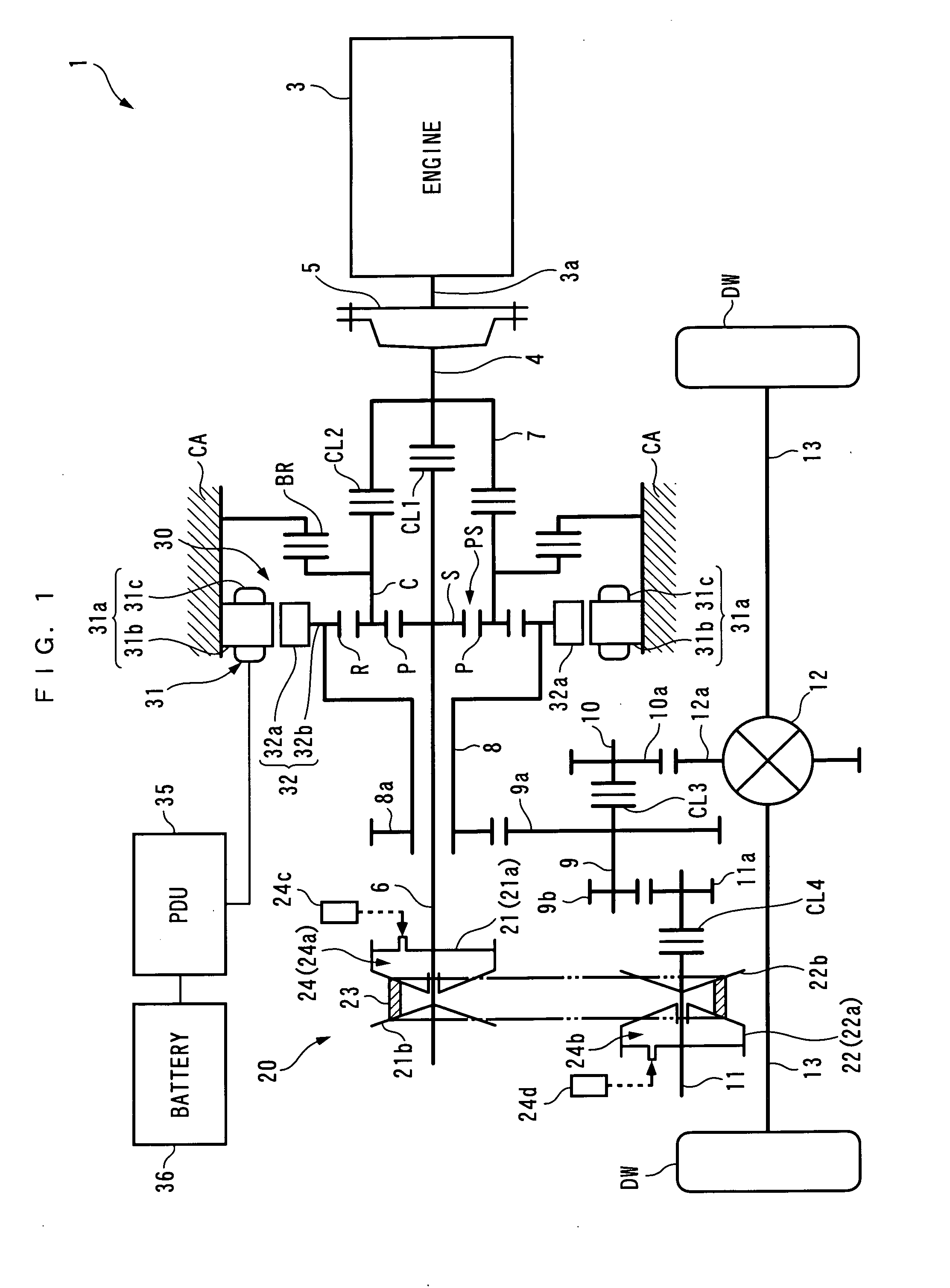

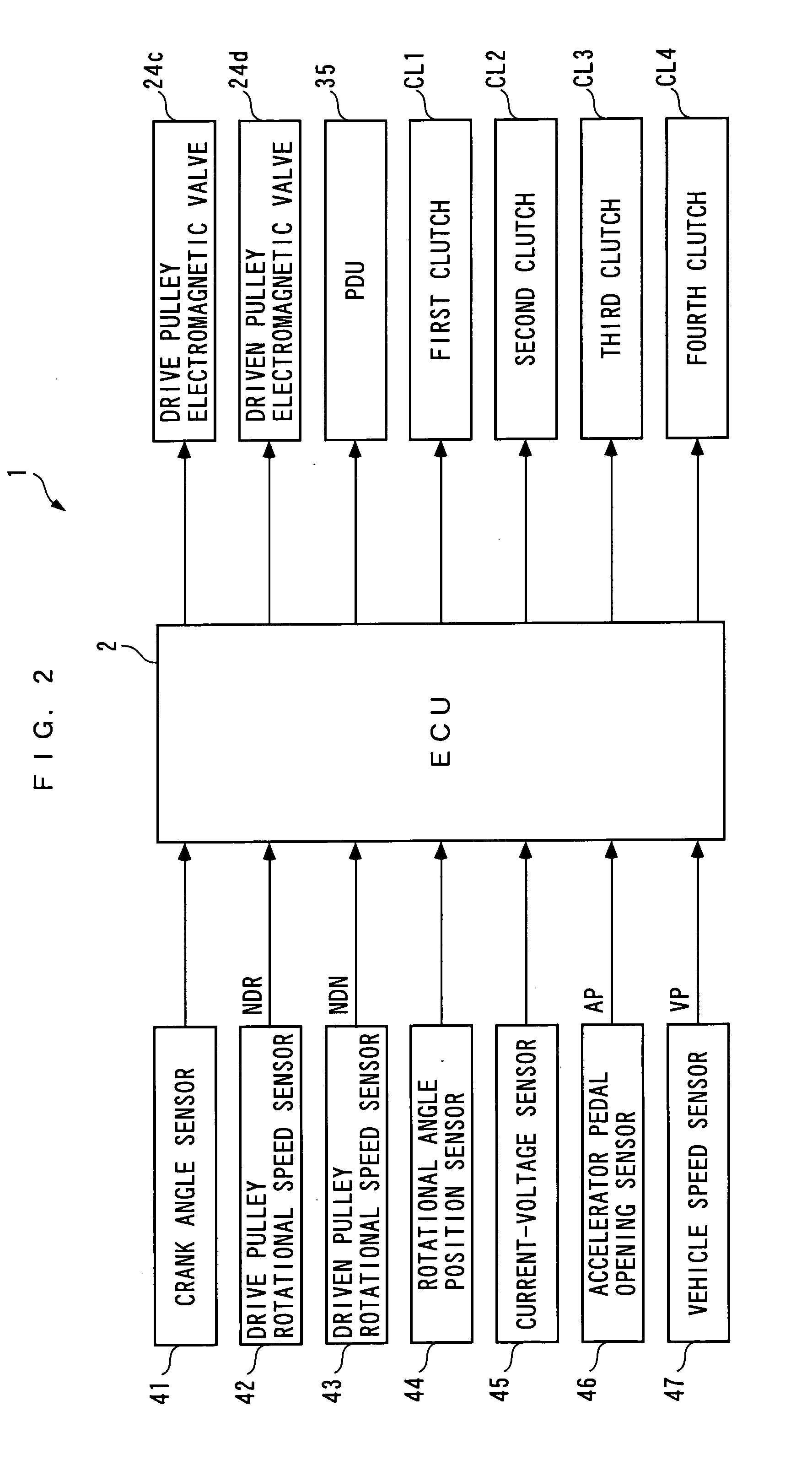

Power plant

InactiveUS20080236917A1Improve efficiencyImprove driving efficiencyElectric propulsion mountingGas pressure propulsion mountingPower stationDrive wheel

A power plant which is capable of improving the drive efficiency and the power generation efficiency thereof when the electric power is generated using the power of a driven part thereof. A power plant has an internal combustion engine having a crankshaft, and a rotary motor having a rotor. A planetary gear train includes a sun gear, a ring gear, and a carrier rotatably supporting a planetary gear in mesh with the sun gear and the ring gear. The sun gear and the ring gear are connected to drive wheels. The carrier is connected to the crankshaft. The rotor is connected between one of the sun gear and the ring gear and the drive wheels. A transmission is connected between the other of the gears and the drive wheels, for varying a speed of power of the engine and transmitting the power to the drive wheels.

Owner:HONDA MOTOR CO LTD

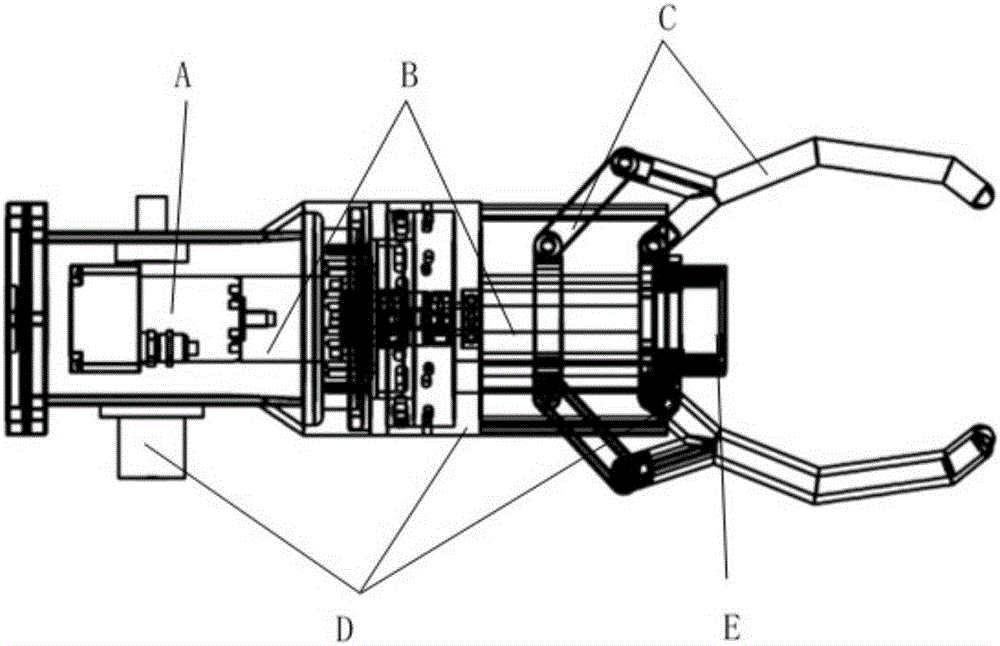

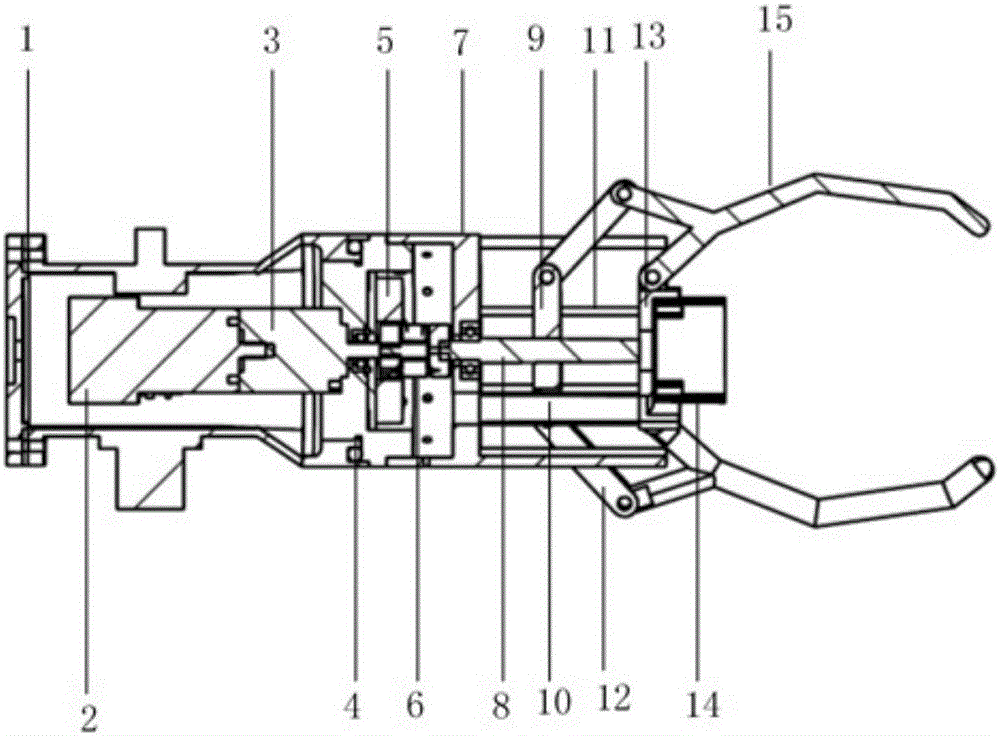

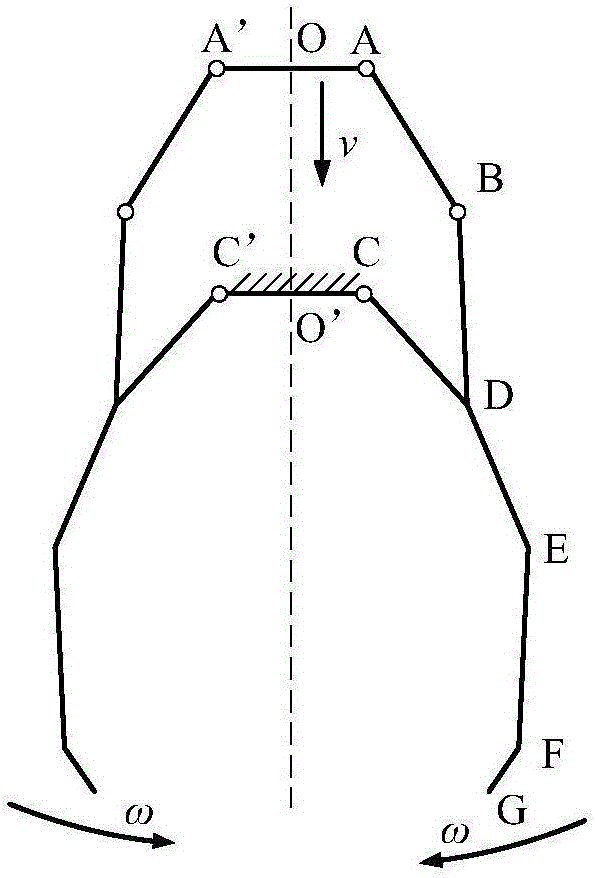

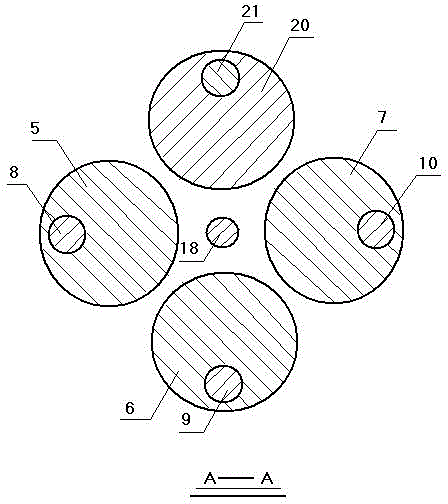

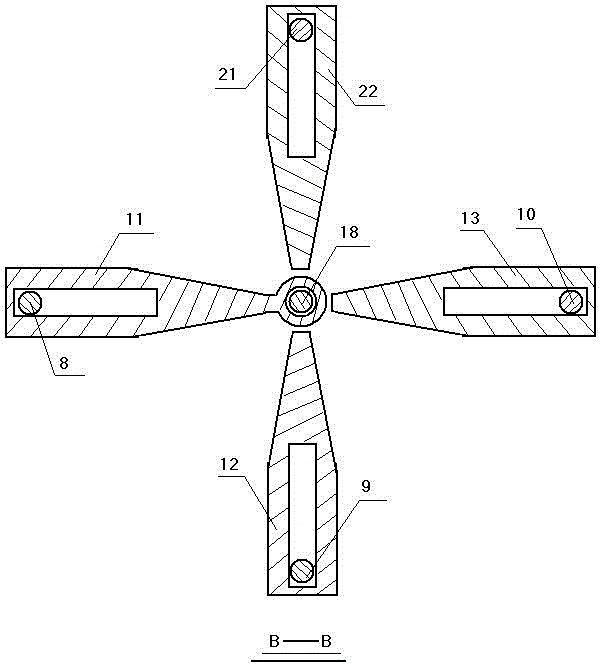

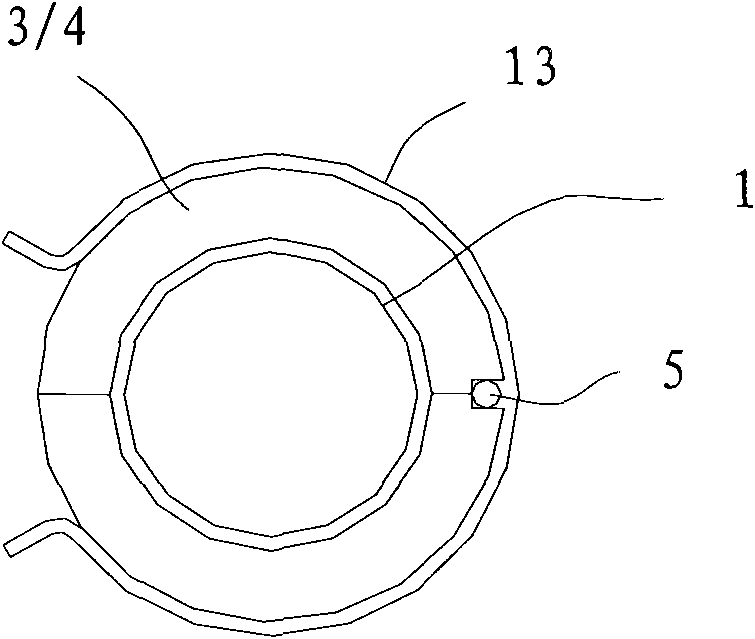

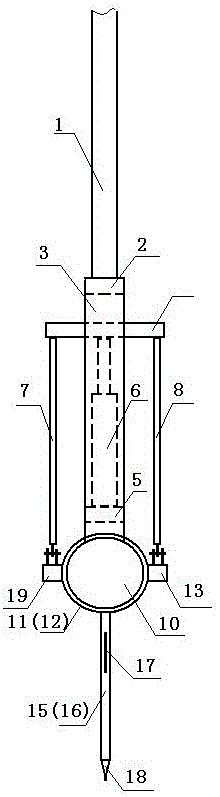

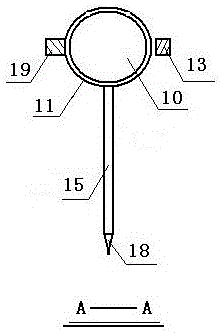

Grapping mechanism and method for spatial targets

InactiveCN106584498ABalanced gripMoment balanceCosmonautic vehiclesGripping headsIsoetes triquetraFinger structure

The invention provides a grapping mechanism and method for spatial targets. A clamp-type three-finger structure is utilized to ensure that the mechanism is as small as possible under the premise that the structure can bear loads with different kinds of specifications and sufficient strength and suitable for multiple targets. The grapping mechanism is simple in structure, easy in machining and low in manufacture cost. The grapping mechanism and method for spatial targets have following beneficial effects: the grapping mechanism for spatial targets comprises a three-finger gripper and a driving mechanism used for driving the gripper to close and open; the gripper is in the three-finger structure in which three fingers are symmetrically distributed in the form of 2 to 1 on the center surface of the grapping mechanism; the connecting lines among the central points of the sections of the fingers form an equilateral triangle so that grapping force and moment balance of the spatial targets are ensured to the maximum extent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

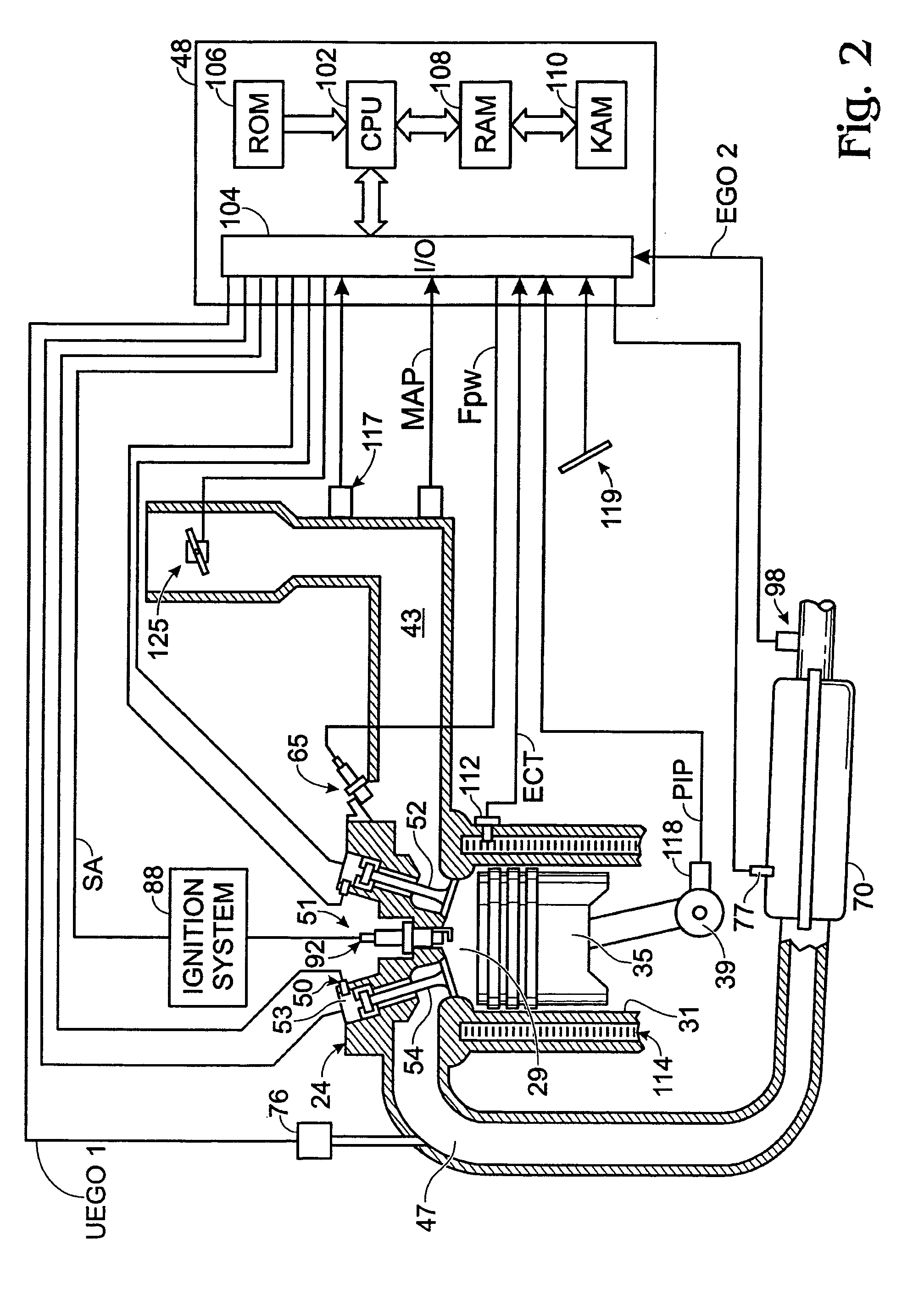

System and method to control engine during de-sulphurization operation in a hybrid vehicle

InactiveUS20070078586A1Different levelReduced fuel economyHybrid vehiclesAnalogue computers for vehiclesHybrid vehicleControl theory

A vehicle system, comprising of an engine with a first cylinder and a second cylinder operating with different engine torques, a motor coupled to said engine capable of absorbing torque and providing torque, and a controller for varying torque of said motor to compensate for said torque difference so that a total engine and motor torque operates with increased balance.

Owner:FORD GLOBAL TECH LLC

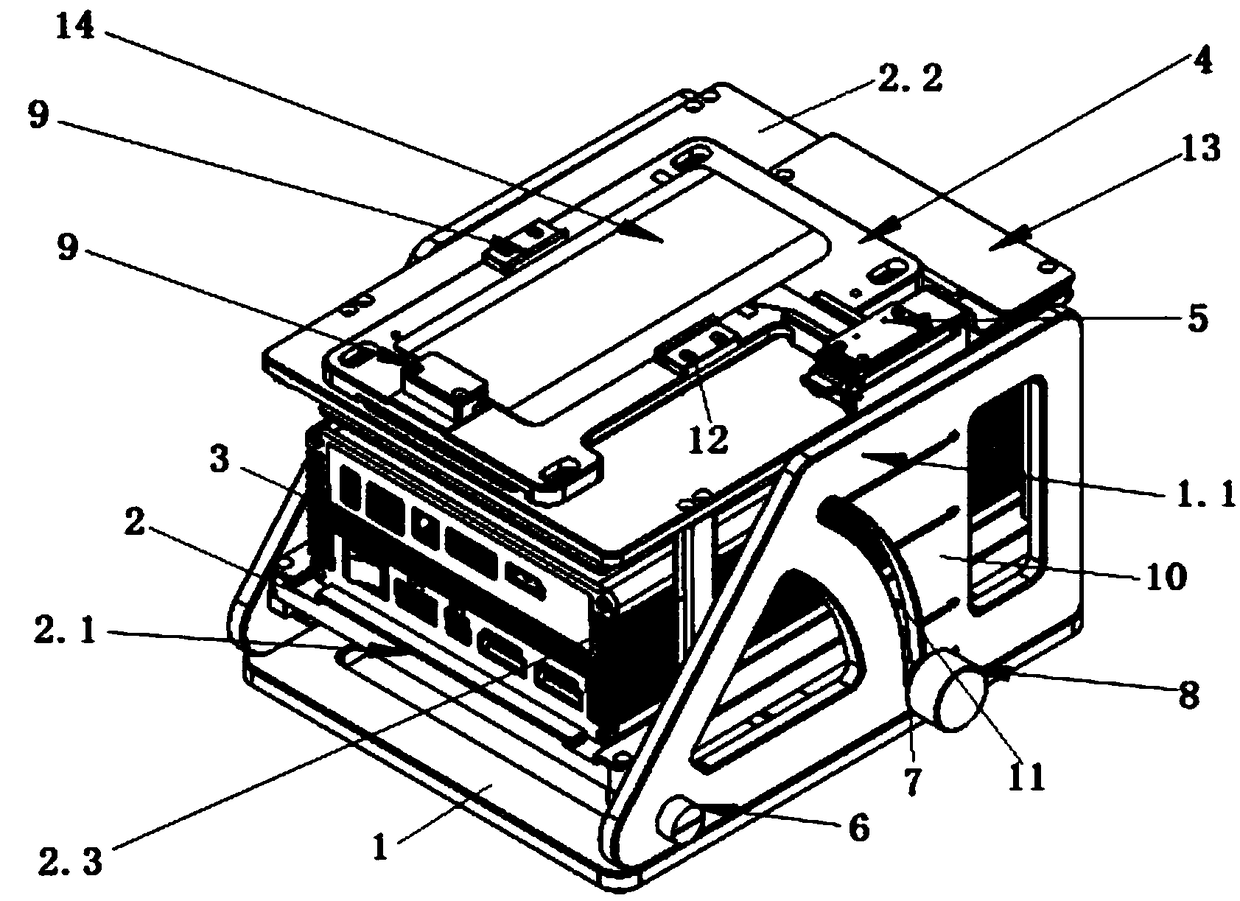

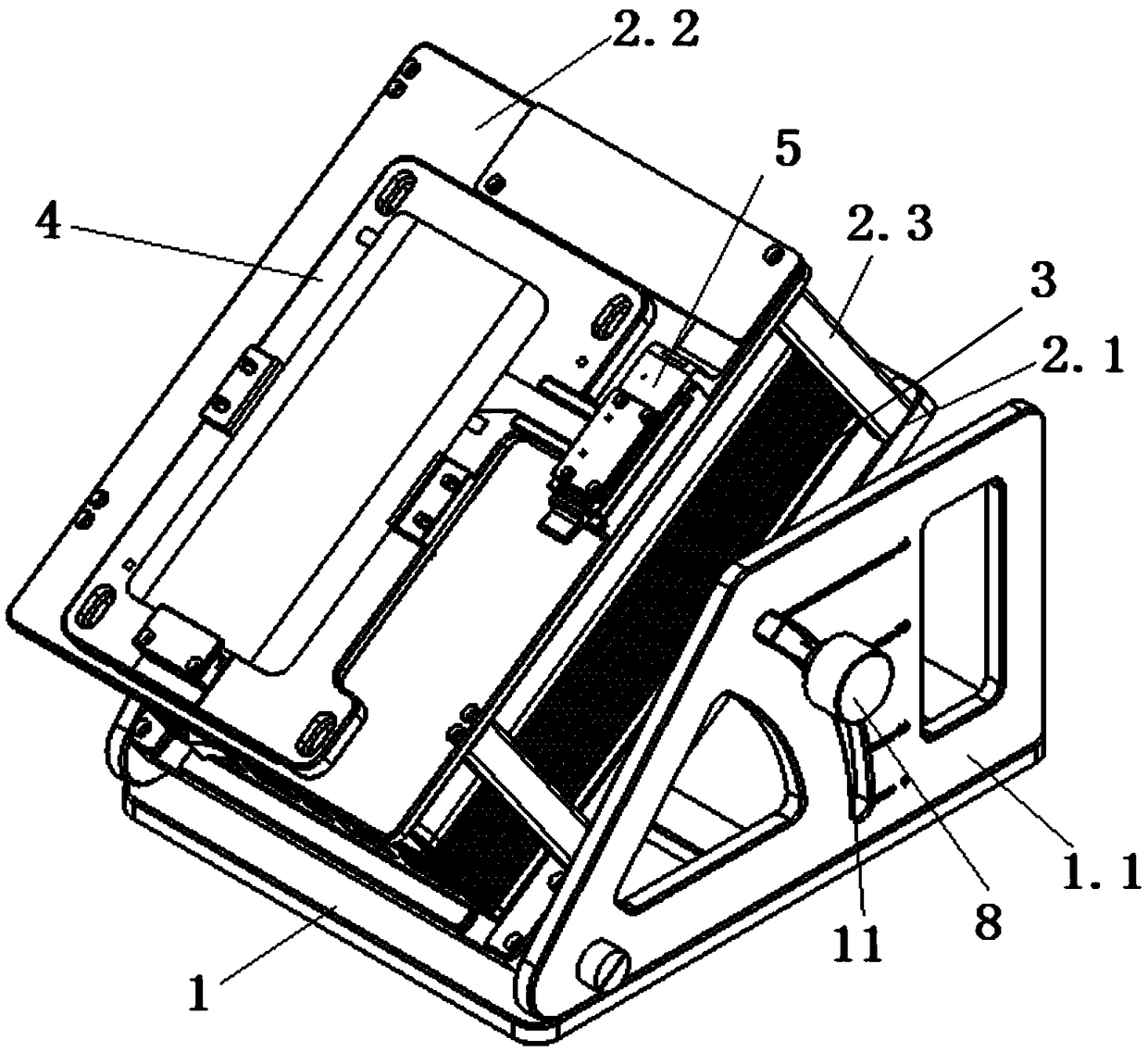

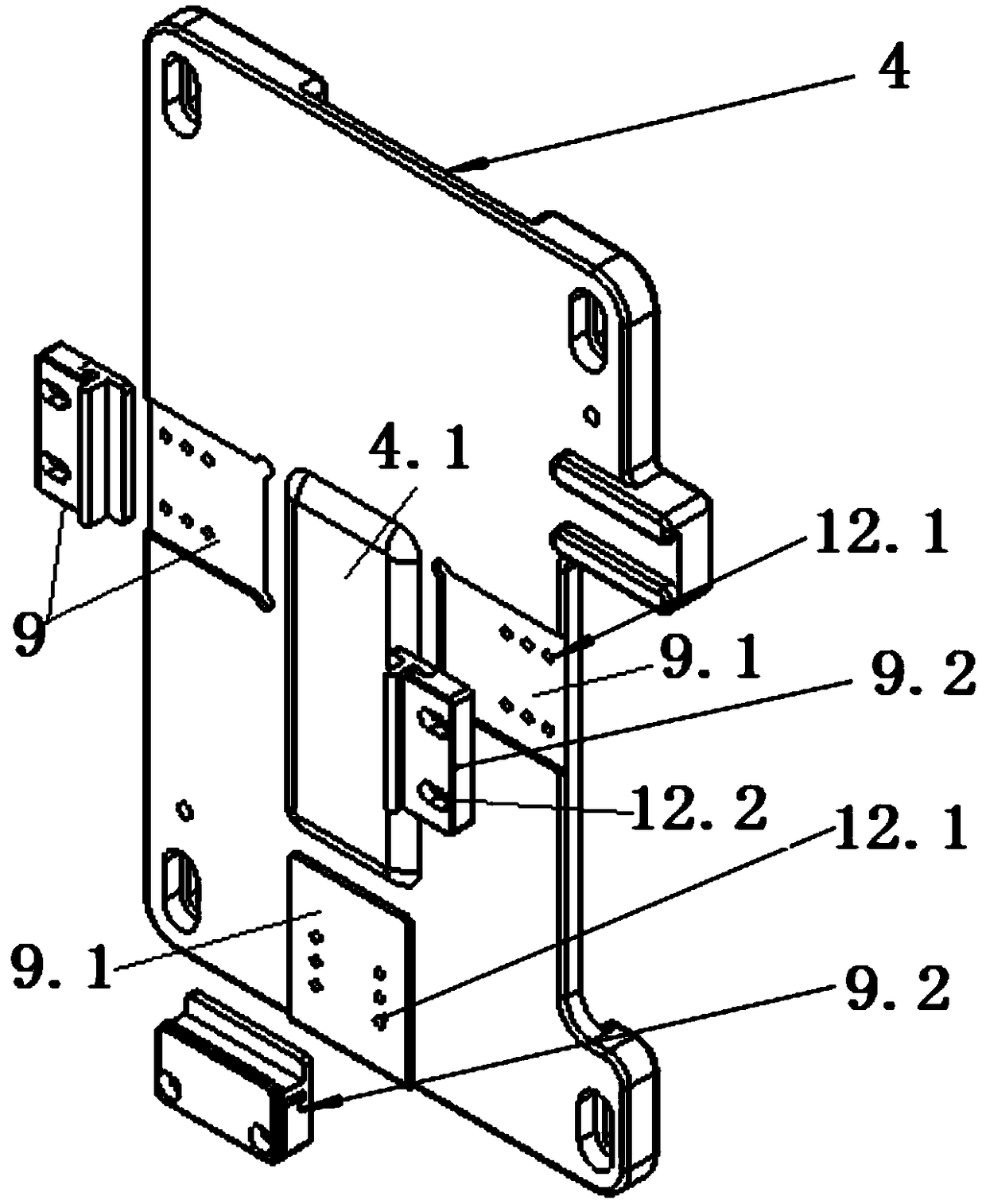

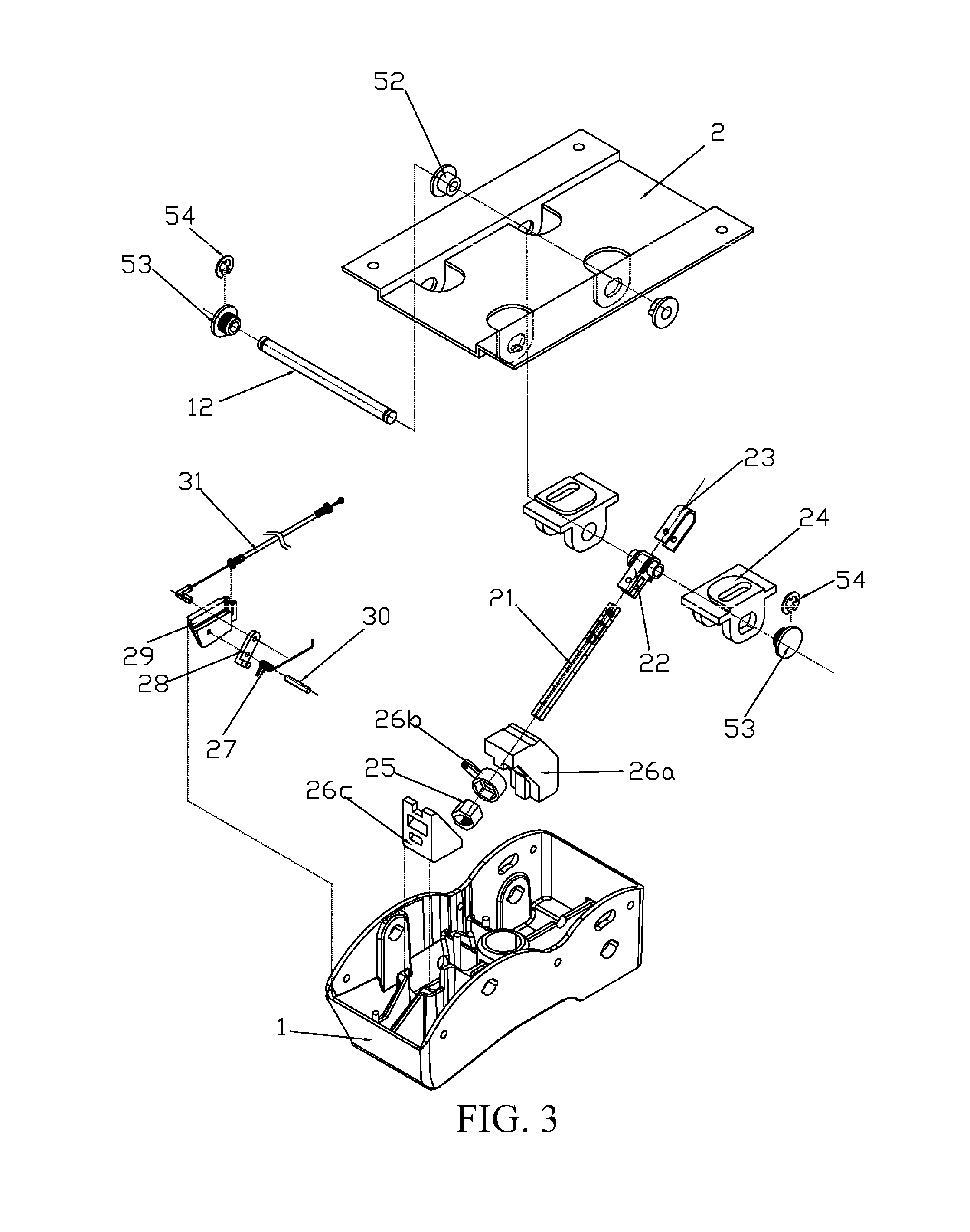

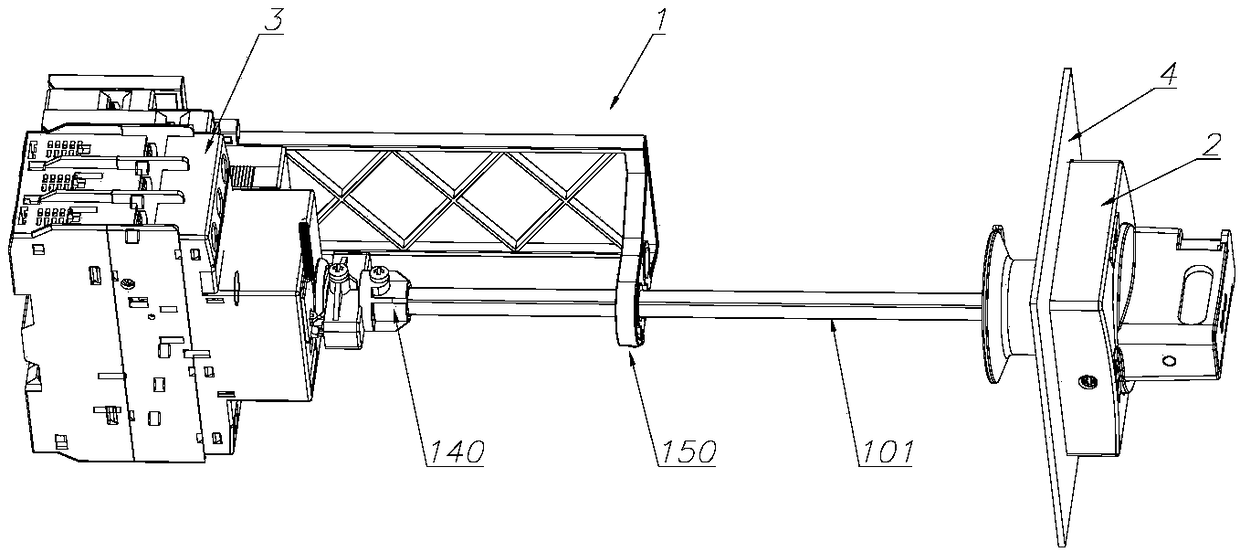

Portable angle-adjustable type electronic screen test fixture

PendingCN108776400AEasy to fixEffective positioning fixedElectrical testingNon-linear opticsEngineeringElectrical and Electronics engineering

The invention discloses a portable angle-adjustable type electronic screen test fixture. The portable angle-adjustable type electronic screen test fixture comprises a mounting seat and a rack, whereinthe rack is hinged with the mounting seat through a hinged shaft; an angle adjusting device is arranged between the mounting seat and the rack; a PG test box, a carrier and a POGO conduction device are arranged on the rack; the PG test box is electrically connected with the POGO conduction device; the carrier is of an integrated plate-shaped structure; a support boss and limiting structures are arranged on one side surface of the carrier; the limiting structures are arranged on the periphery of the support boss; each limiting structure comprises a guiding groove formed in the surface of the carrier and a limiting block connected into the guiding groove in a sliding fit manner, and the limiting block is connected with the carrier through a positioning structure. The fixture is simple in structure and convenient to carry, and can be applicable to lighting tests of electronic screens with various sizes on the premise that the carrier is not replaced integrally.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

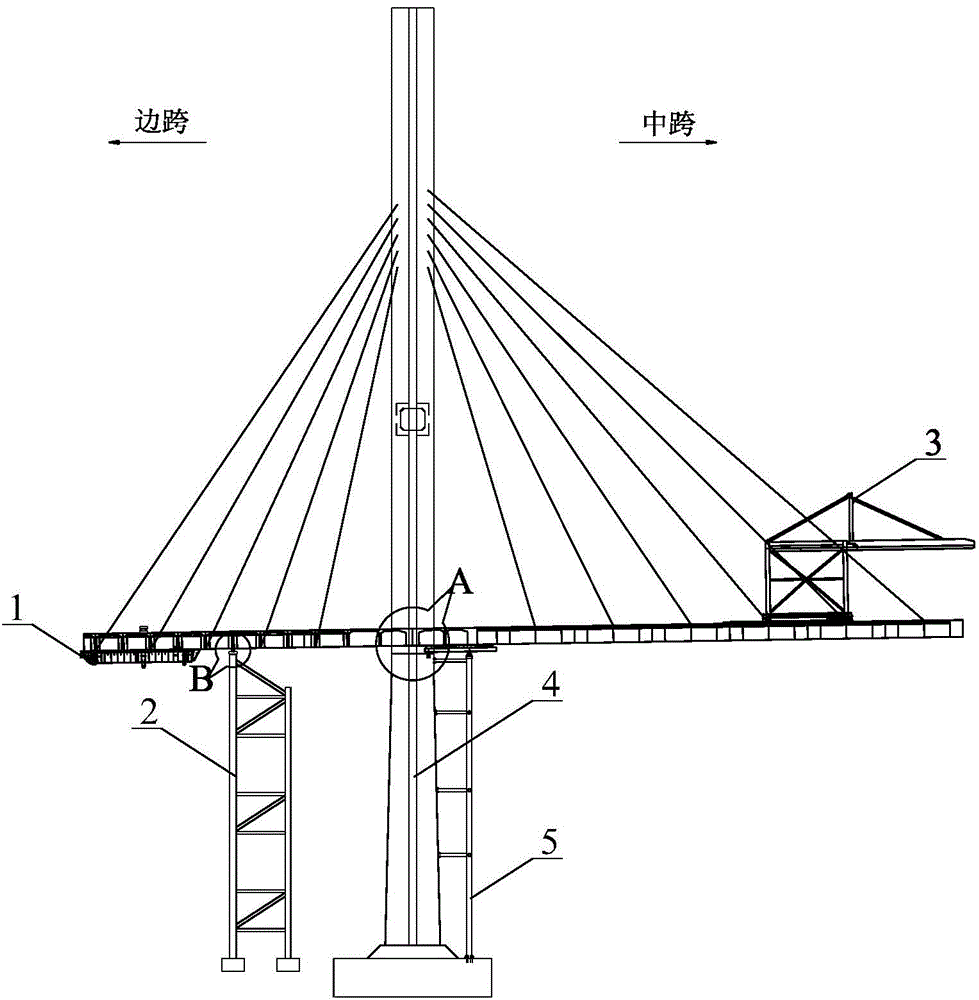

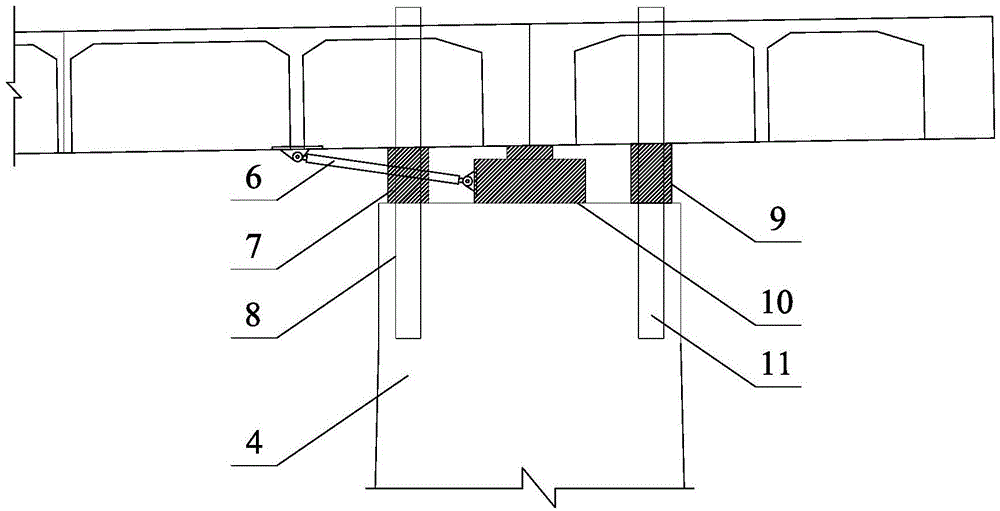

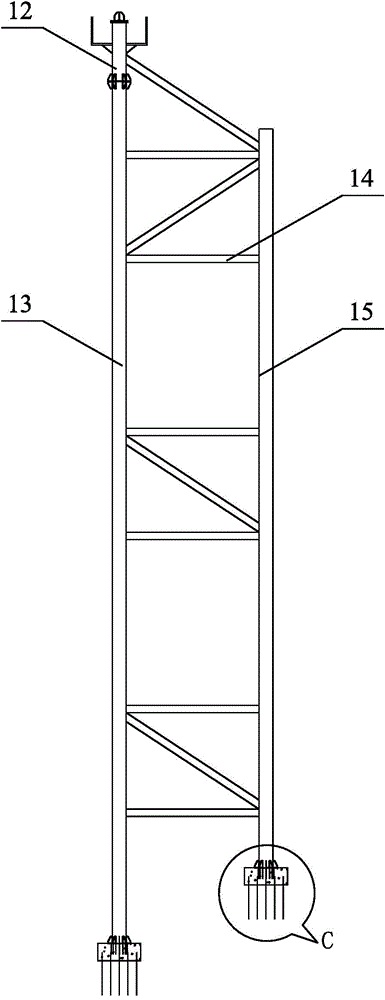

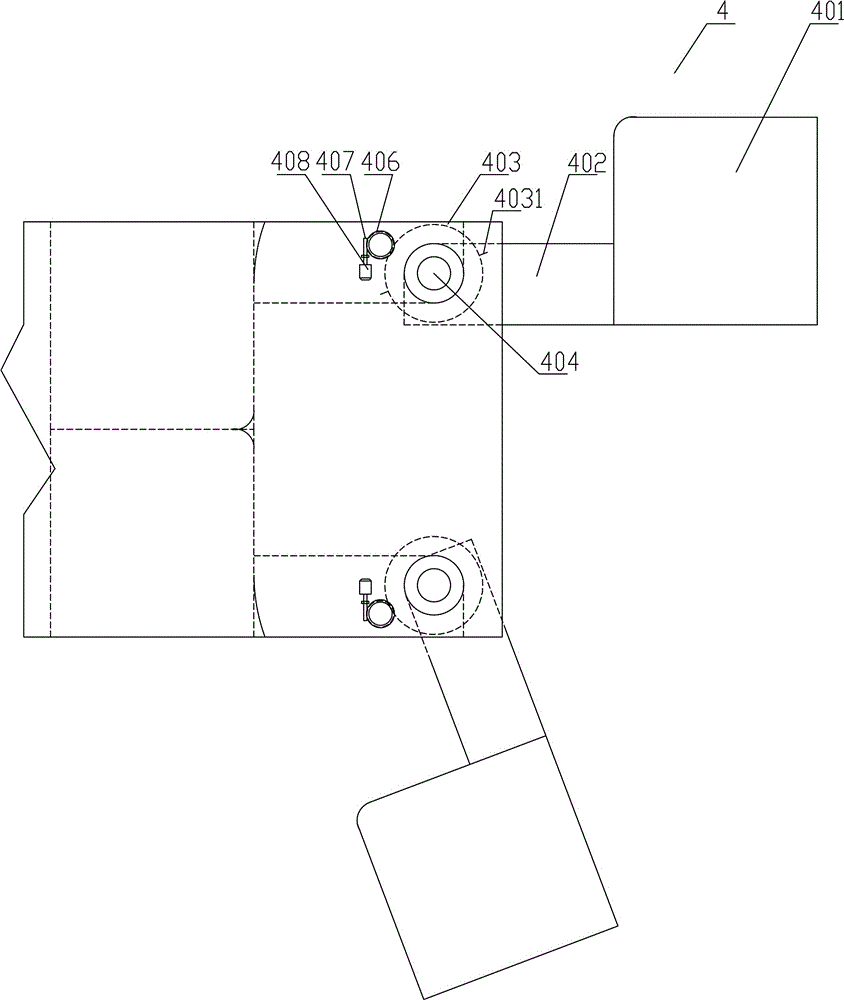

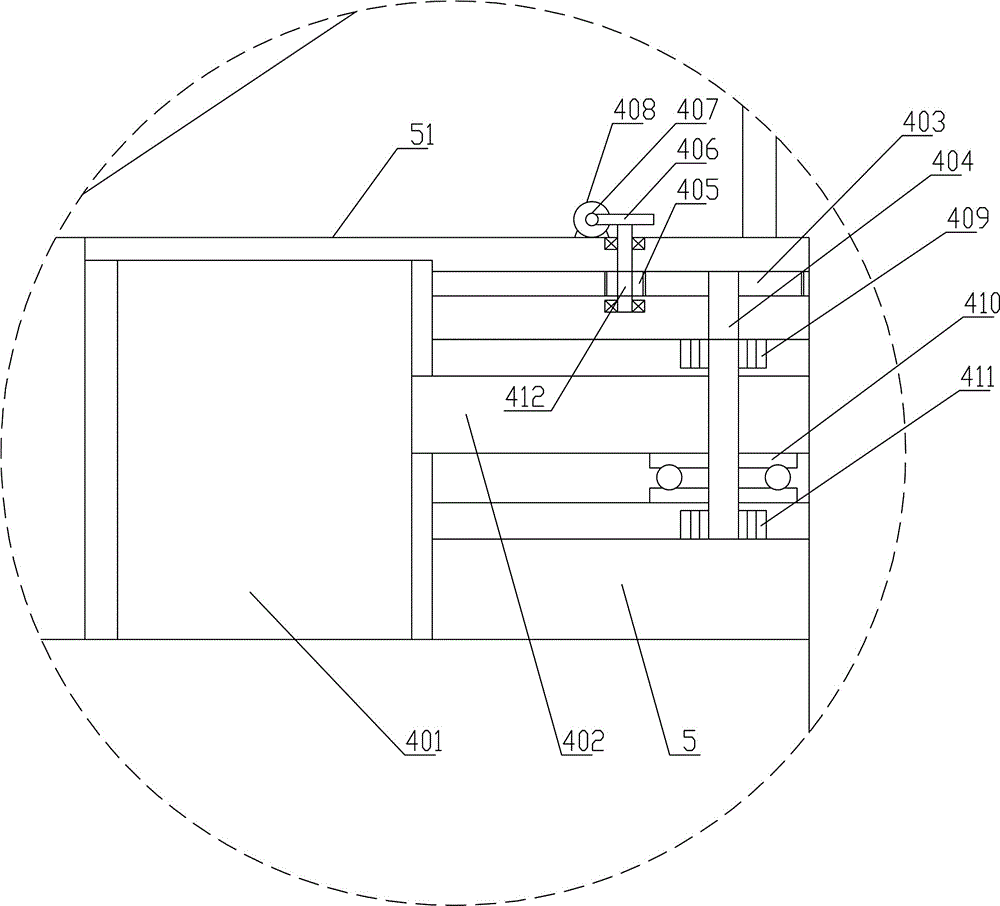

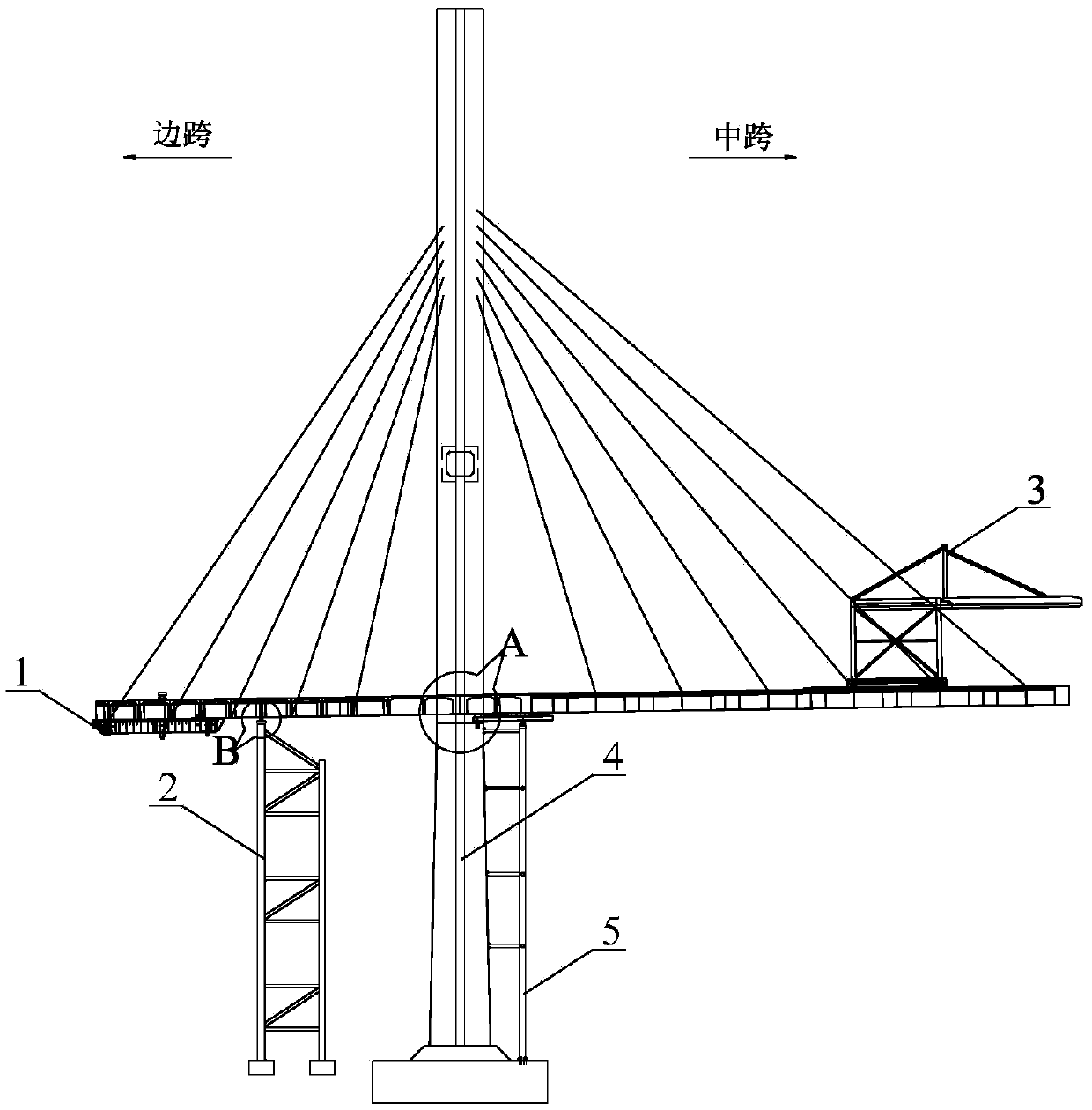

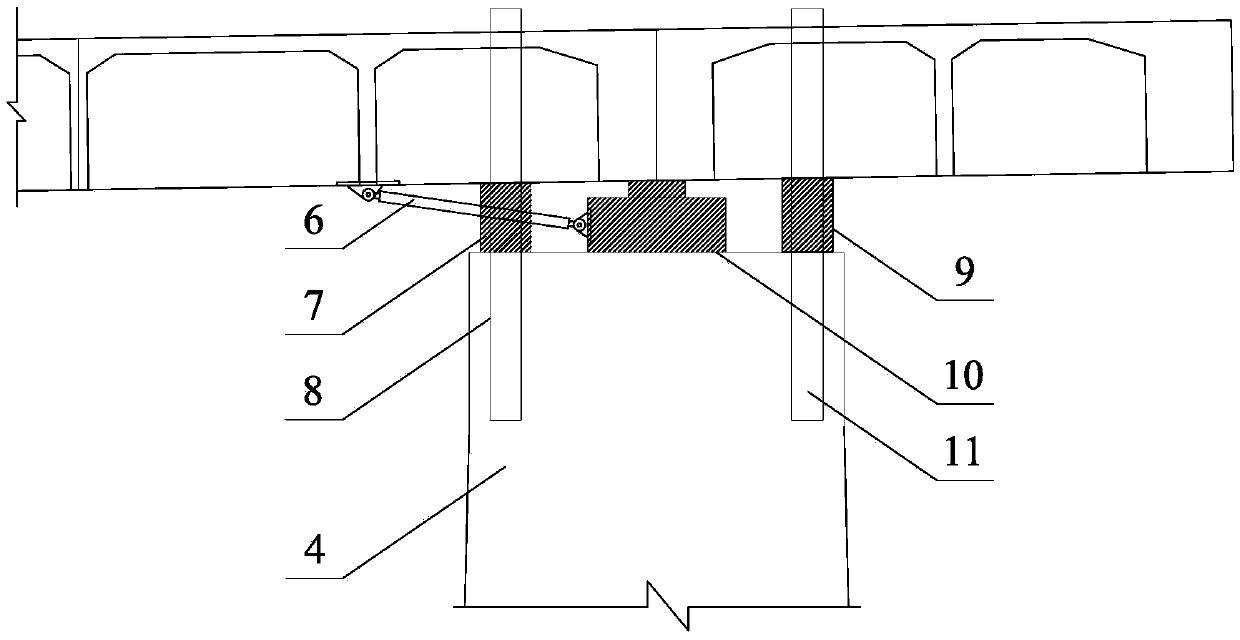

Double suspension arm construction method of ultra-asymmetry combined beam

ActiveCN104314013AAvoid damageReduce construction costsBridge erection/assemblyCable stayedConcrete beams

The invention discloses a double suspension arm construction method of an ultra-asymmetry combined beam and relates to the field of cable-stayed bridge main girder construction. The construction method comprises the following steps of using the existing method to pour a first midspan steel beam, suspending and pulling a first sidespan stay cable and a first midspan stay cable, pouring a second midspan steel beam, manufacturing a template used for manufacturing a second sidespan concrete beam, installing a third midspan steel beam, suspending and pulling a third midspan stay cable, pouring half concrete at the top part of the template, pulling a second sidespan stay cable, pouring the other half concrete at the top part of the template until the line of the template reaches the calculating requirement, obtaining a second sidespan concrete beam, installing a steel beam bridge deck slab at the top part of the third midspan steel beam and pulling the third midspan stay cable. The difference between the constructed bridge line and the preset designed line is small, and the constructed beam is safer.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +2

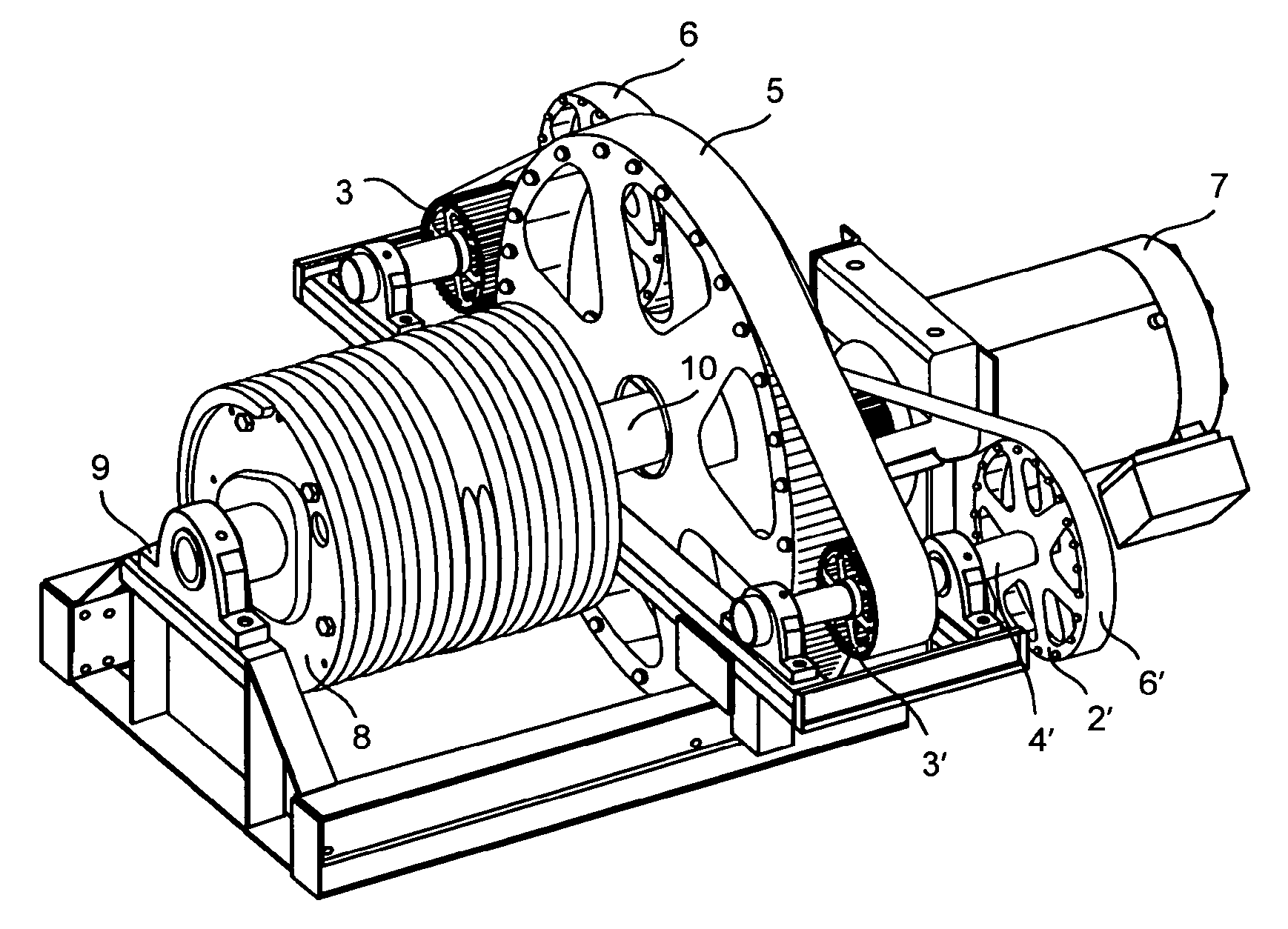

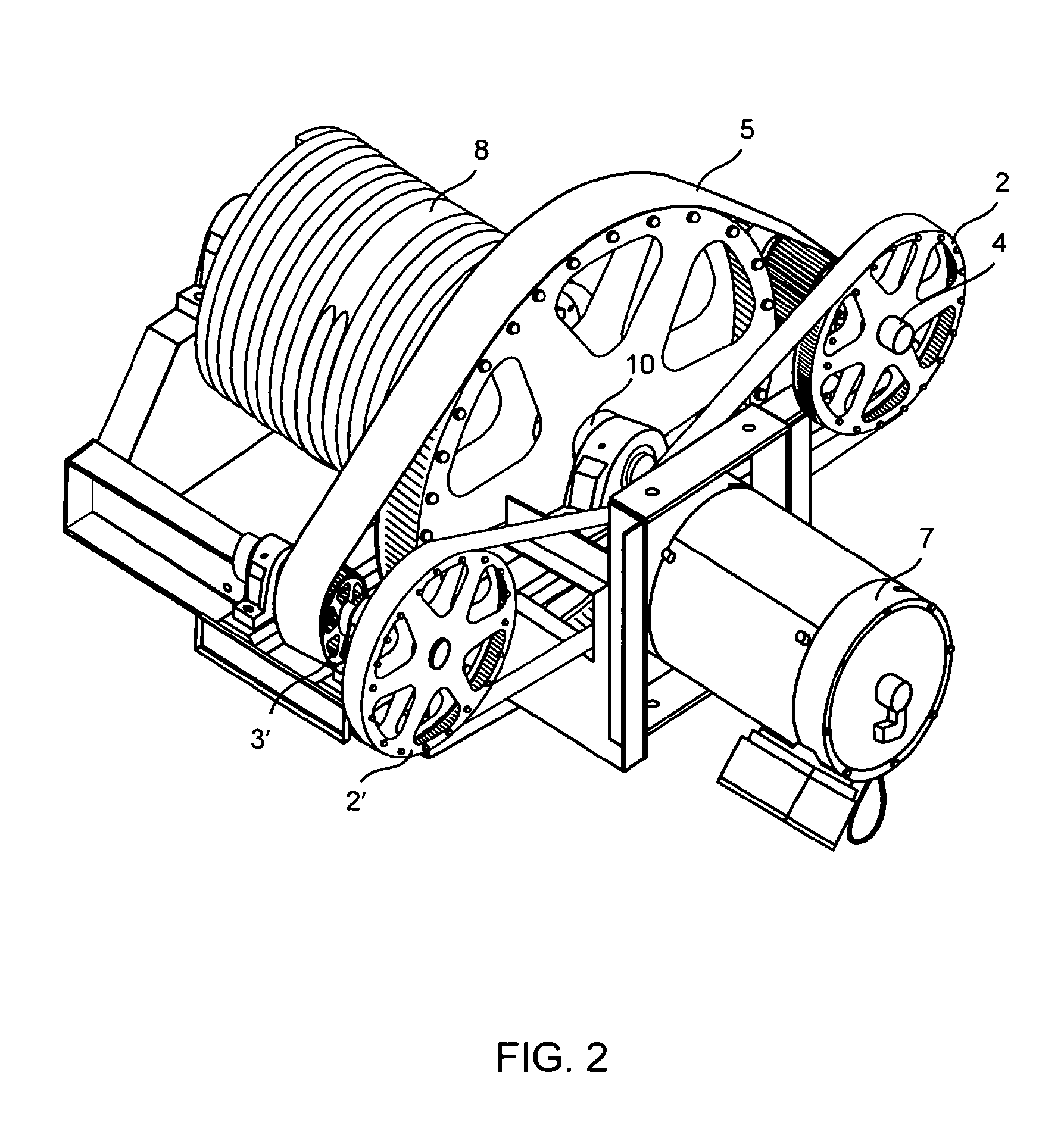

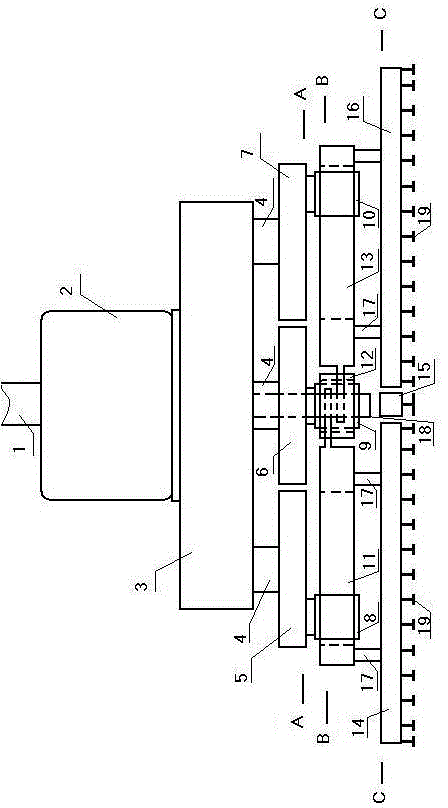

Drive device

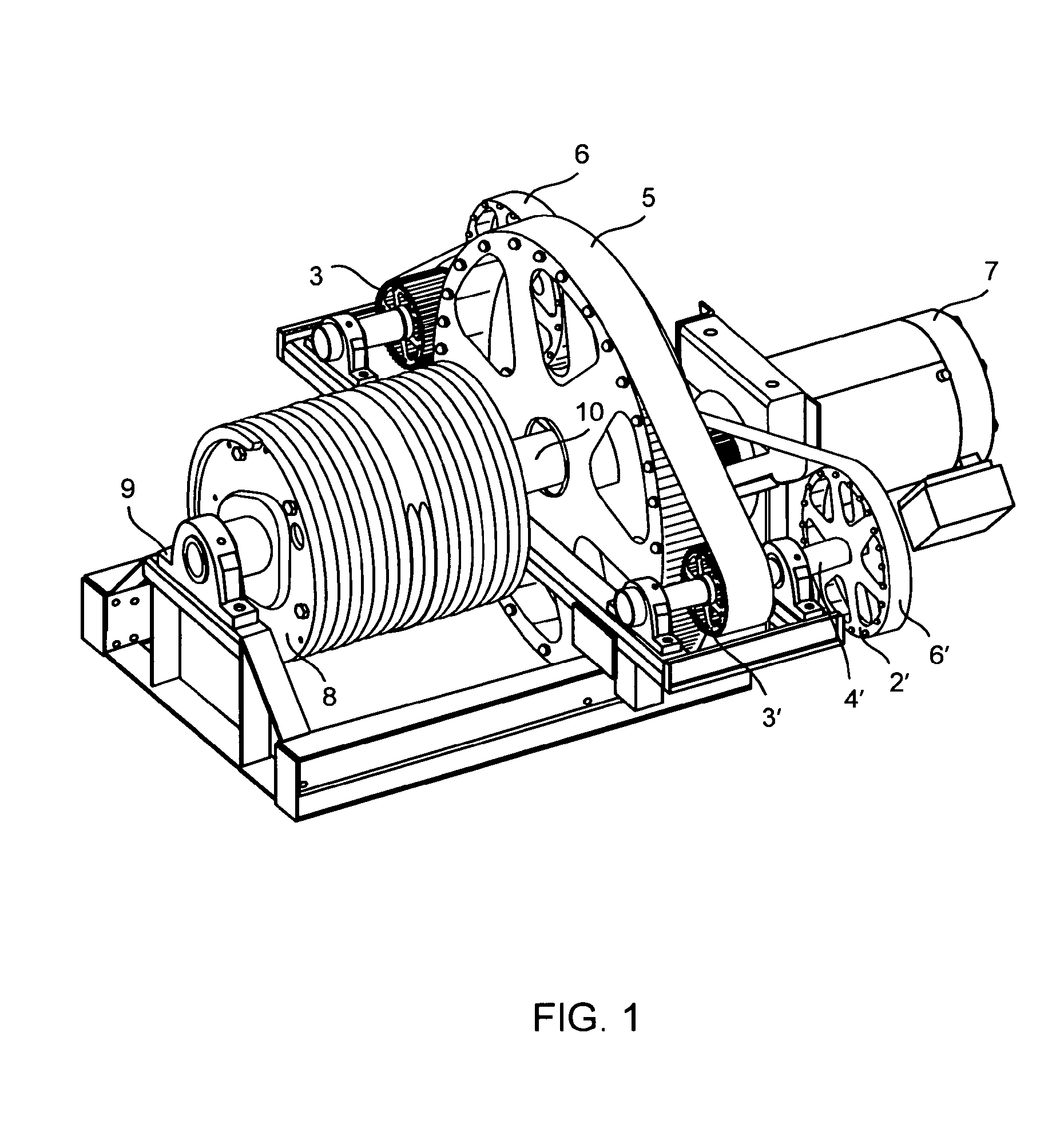

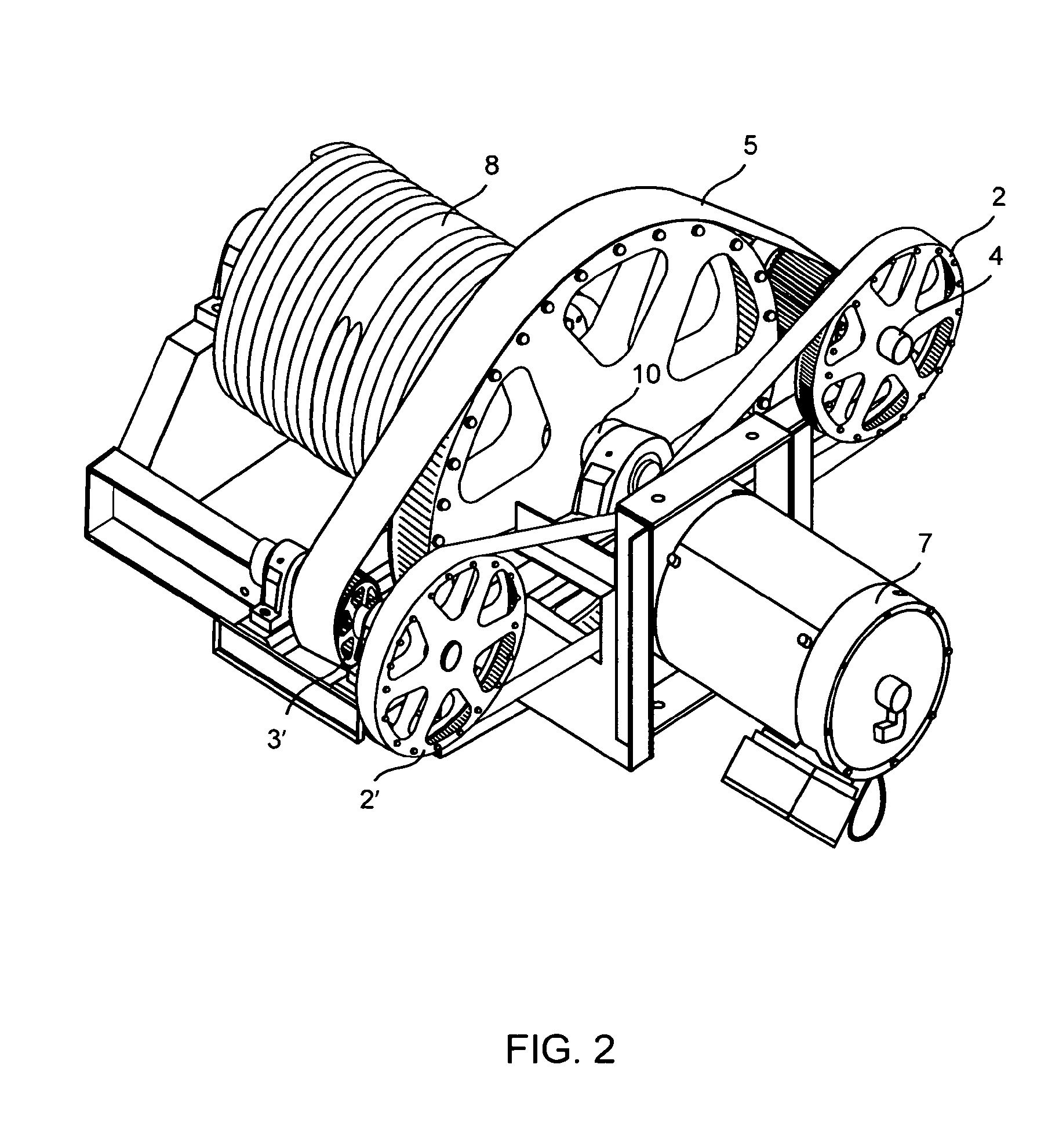

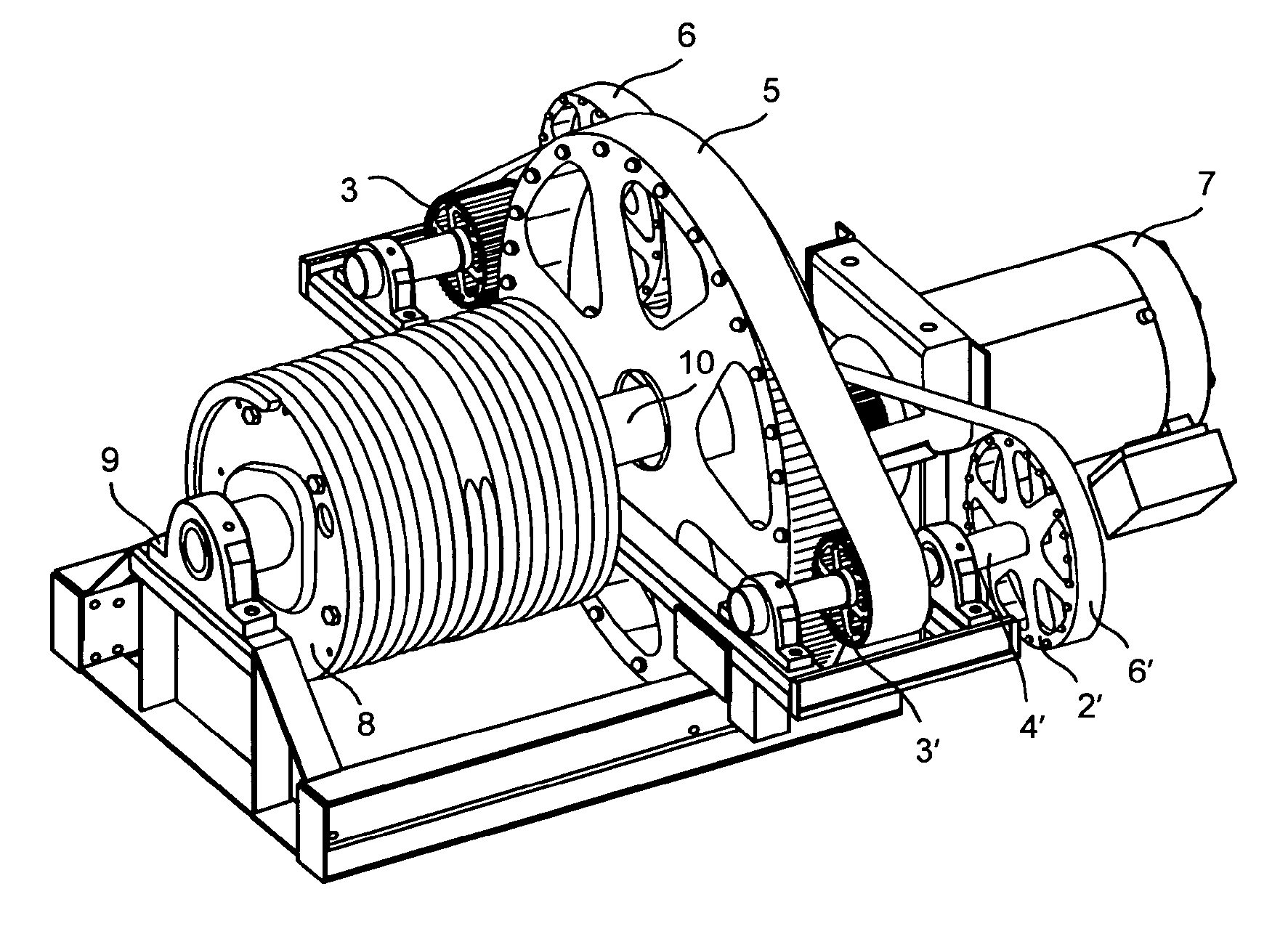

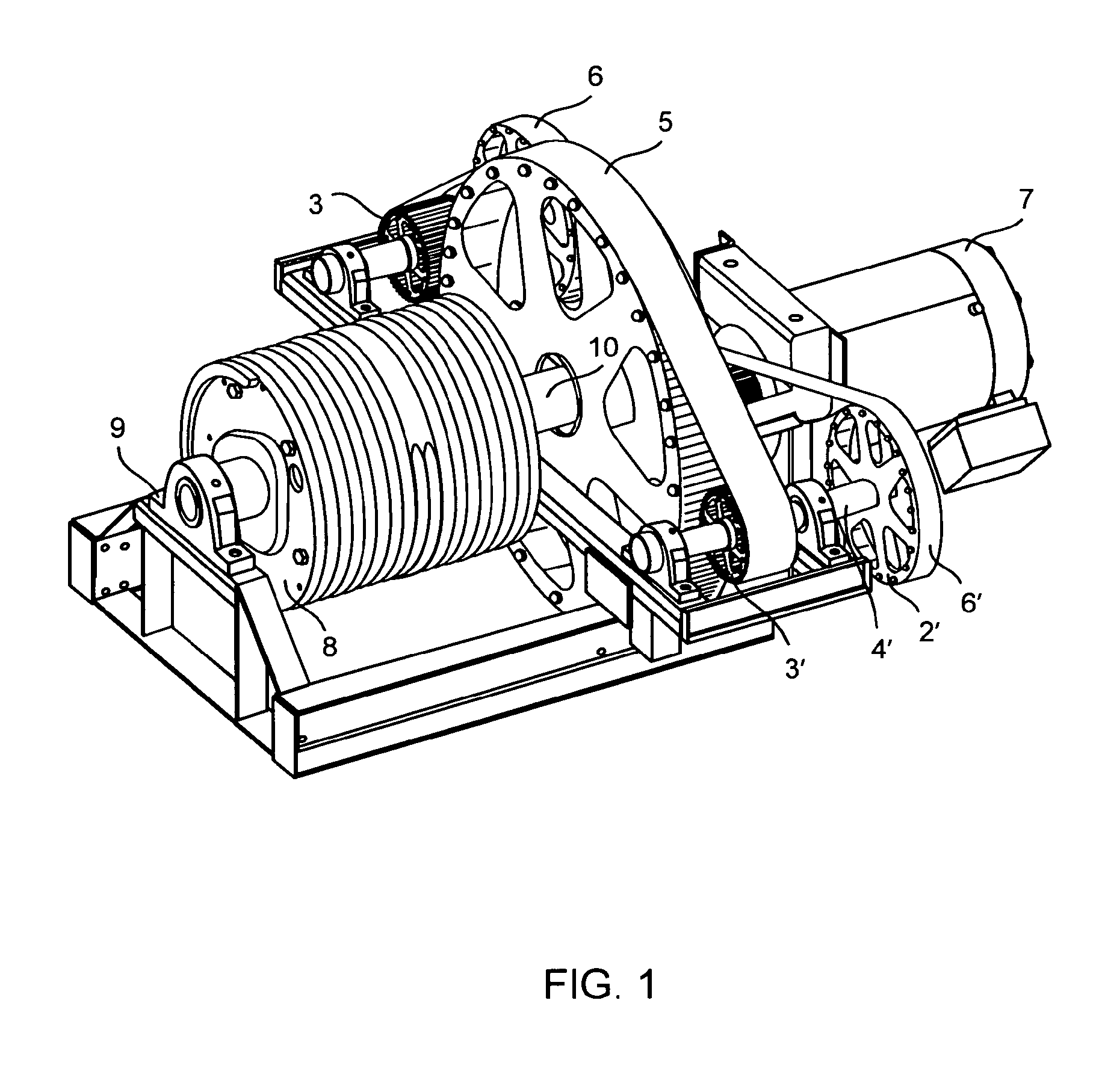

A drive device for a winch (8) comprising a large belt pulley (1) or chain pulley, a winch drum which is connected to the large belt pulley (1). The large belt pulley (1) is rotatably connected to at least one prime mover such as a motor (7). The device has at least two rotatable secondary shafts (4, 4′), each being parallel to the rotational axis of said belt pulley (1). The secondary shafts (4, 4′) are in rotational connection with the large belt pulley (1) via at least one belt / chain. The motor is in rotational connection with one of the secondary shafts. Drive devices according to the same principles for a floating vessel propeller, a hydro turbine and a wave power plant are also described.

Owner:FOBOKS AS

Drive device

A drive device for a winch (8) comprising a large belt pulley (1) or chain pulley, a winch drum which is connected to the large belt pulley (1). The large belt pulley (1) is rotatably connected to at least one prime mover such as a motor (7). The device has at least two rotatable secondary shafts (4, 4′), each being parallel to the rotational axis of said belt pulley (1). The secondary shafts (4, 4′) are in rotational connection with the large belt pulley (1) via at least one belt / chain. The motor is in rotational connection with one of the secondary shafts. Drive devices according to the same principles for a floating vessel propeller, a hydro turbine and a wave power plant are also described.

Owner:FOBOKS AS

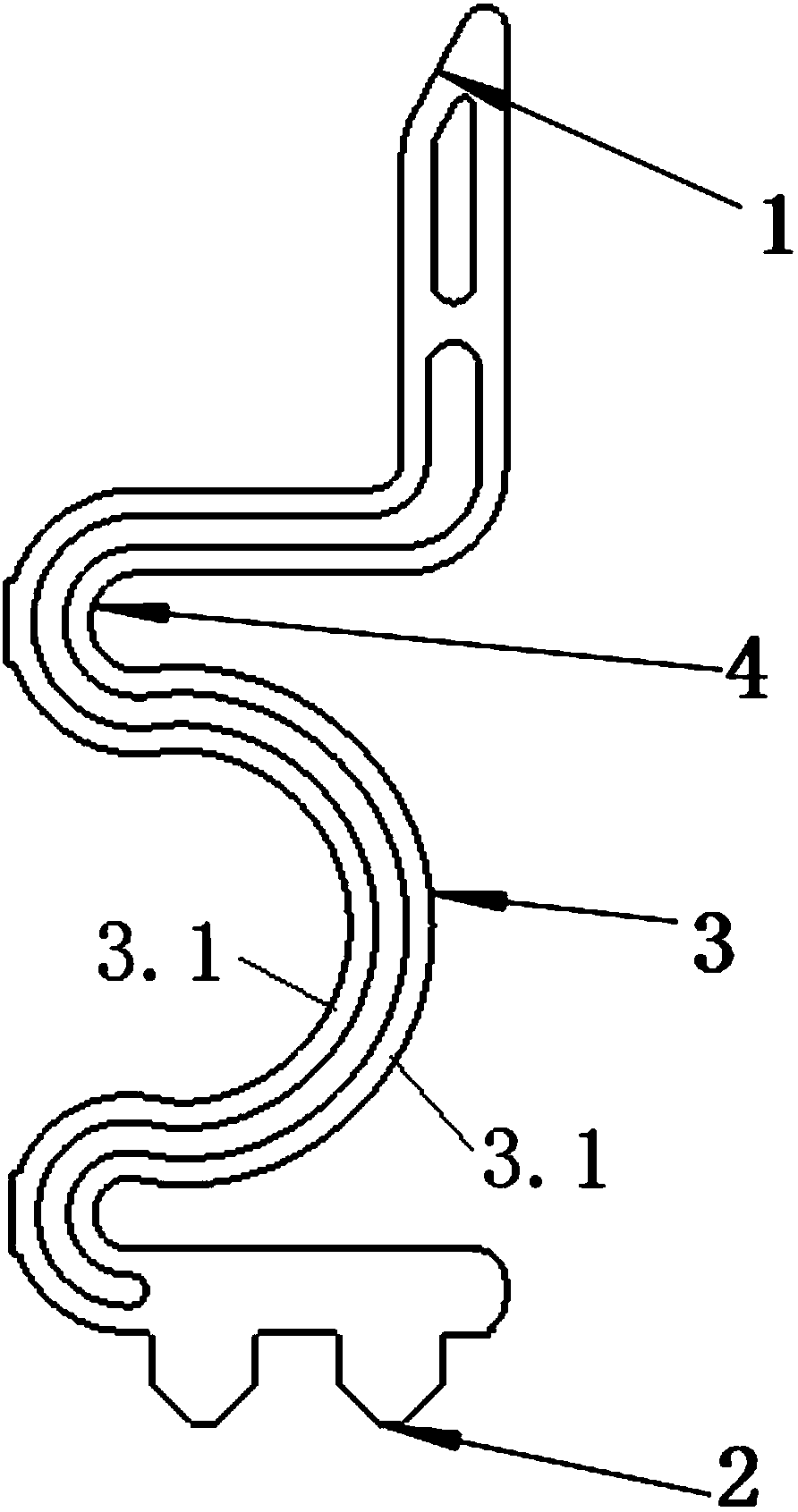

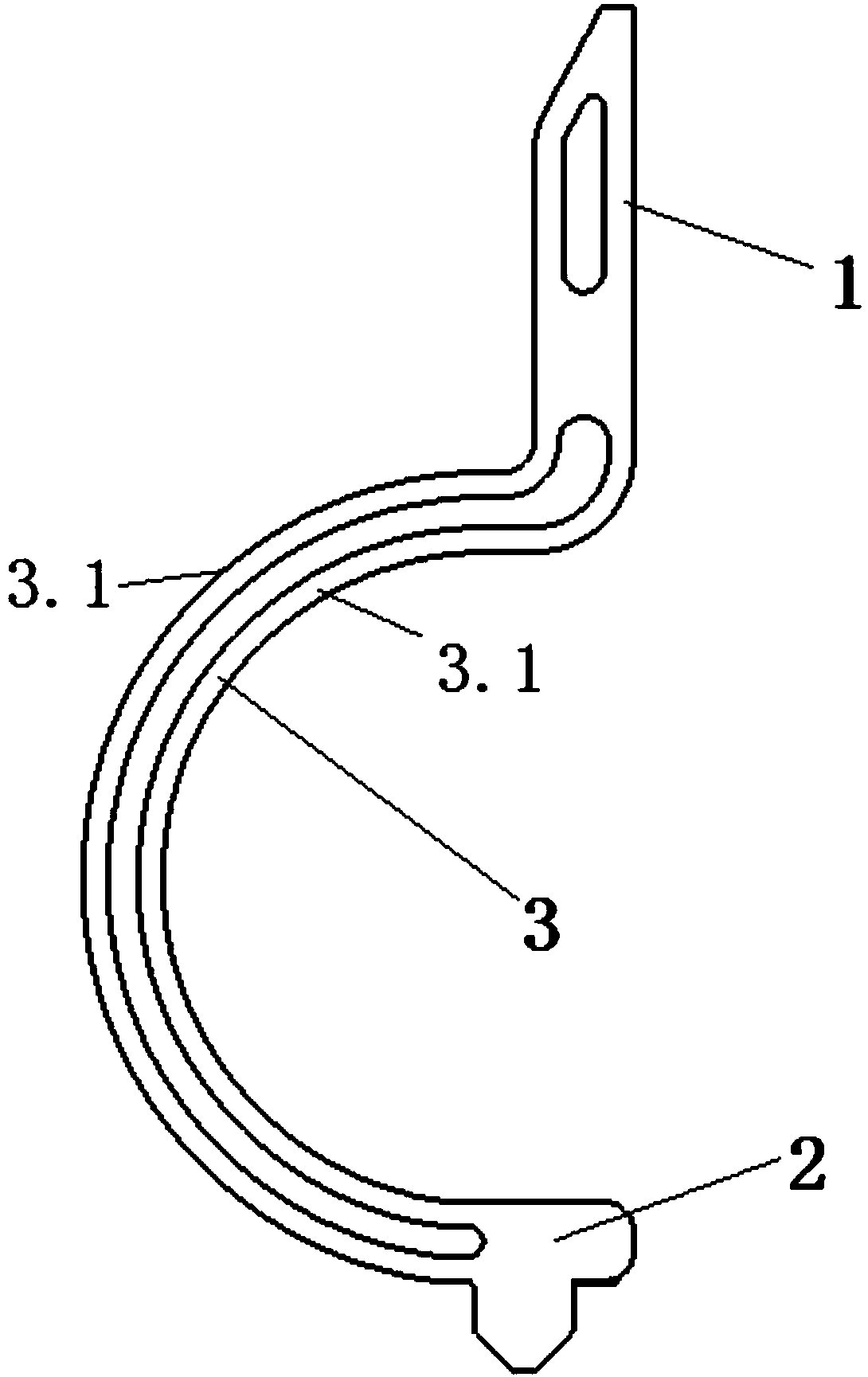

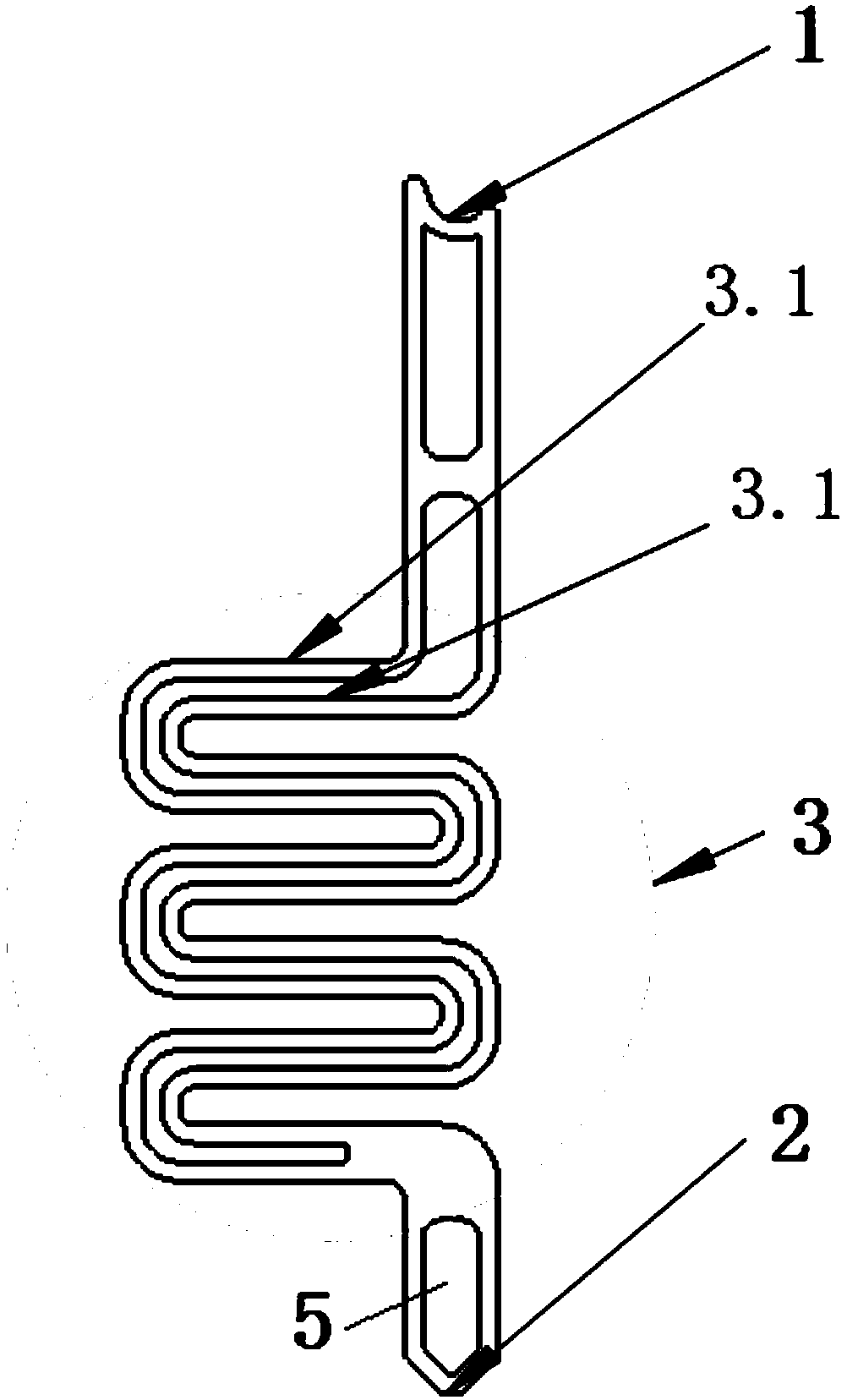

Crimping elastic sheet of single buffer channel

PendingCN108572264ASimple structureEasy to manufactureElectrical testingMeasurement instrument housingElectrically conductiveEngineering

The invention discloses a crimping elastic piece of a single buffer channel. The crimping elastic sheet includes a first metal adapter portion, a second metal adapter portion and a metal bending portion; the first metal adapter portion, the second metal adapter portion and the metal bending portion are integrally formed; the first metal adapter portion and the second metal adapter portion have probe heads; the metal bending portion is composed of two metal conductive strips arranged in parallel and spaced from each other; each metal conductive strip is made of a material that is both electrically conductive and elastically deformable; the width of the probe heads / 4 <= the width of each metal conductive strip <= the width of the probe heads / 3. The invention is simple in structure and is convenient to use; the area of the metal bending portion for conduction is effectively increased by designing the width of the metal bending portion to be 2 to 4 times the width of the probe heads and designing the metal bending portion into the two parallel metal conductive strips spaced from each other; the impedance and continuity of the elastic sheet probe can be improved.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

Power plant

InactiveUS8485290B2Improve efficiencyImprove driving efficiencyToothed gearingsGas pressure propulsion mountingDrive wheelPower station

A power plant which is capable of improving the drive efficiency and the power generation efficiency thereof when the electric power is generated using the power of a driven part thereof. A power plant has an internal combustion engine having a crankshaft, and a rotary motor having a rotor. A planetary gear train includes a sun gear, a ring gear, and a carrier rotatably supporting a planetary gear in mesh with the sun gear and the ring gear. The sun gear and the ring gear are connected to drive wheels. The carrier is connected to the crankshaft. The rotor is connected between one of the sun gear and the ring gear and the drive wheels. A transmission is connected between the other of the gears and the drive wheels, for varying a speed of power of the engine and transmitting the power to the drive wheels.

Owner:HONDA MOTOR CO LTD

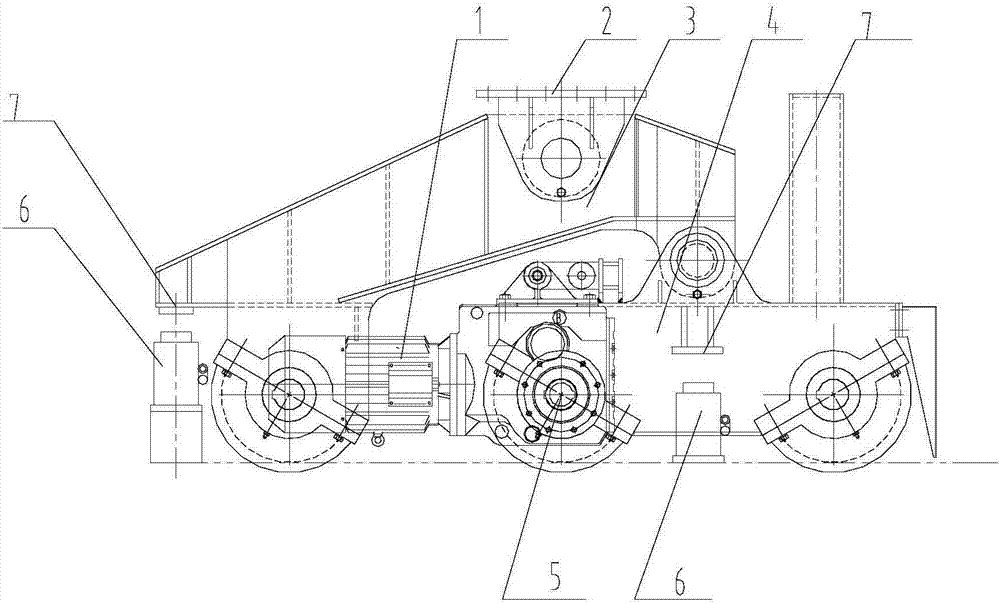

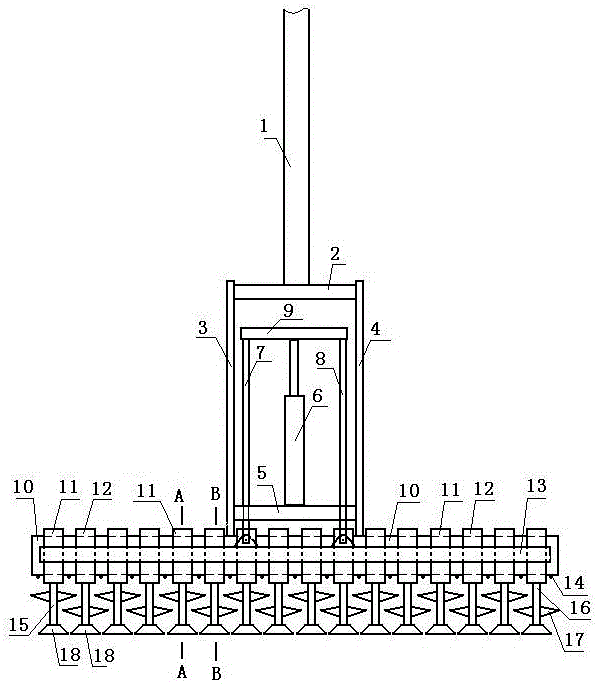

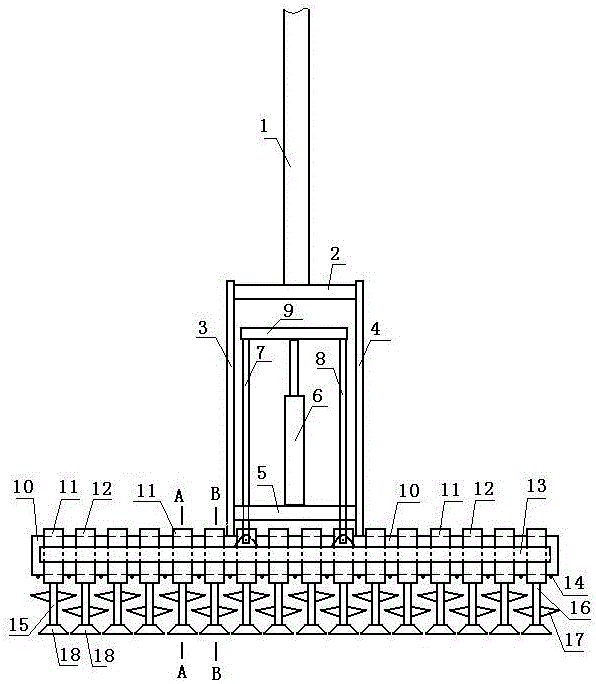

Moment balance drilling machine

Provided is a moment balance drilling machine. A first split shaft is arranged in a rectangular hole of a first rectangular arm. One end, close to a sixth split shaft, of the first rectangular arm is hinged to the sixth split shaft. The upper end of the sixth split shaft is fixed on the middle of the lower portion of a transfer case. The lower portion of the first rectangular arm is fixed on a first drilling arm through two connecting shafts. A second split shaft is arranged in a rectangular hole of a second rectangular arm. One end, close to the sixth split shaft, of the second rectangular arm is hinged to the sixth split shaft. The lower portion of the second rectangular arm is fixed on a second drilling arm through two connecting shafts. A third split shaft is arranged in a rectangular hole of a third rectangular arm. One end, close to the sixth split shaft, of the third rectangular arm is hinged to the sixth split shaft. The lower portion of the third rectangular arm is connected with a third drilling arm through two connecting shafts. A fourth split shaft is arranged on a rectangular hole of a fourth rectangular arm. One end, close to the sixth split shaft, of the fourth rectangular arm is hinged to the sixth split shaft. The lower portion of the fourth rectangular arm is fixed on a fourth drilling arm through two connecting shafts.

Owner:TAIZHOU SANFU SHIP ENG CO LTD

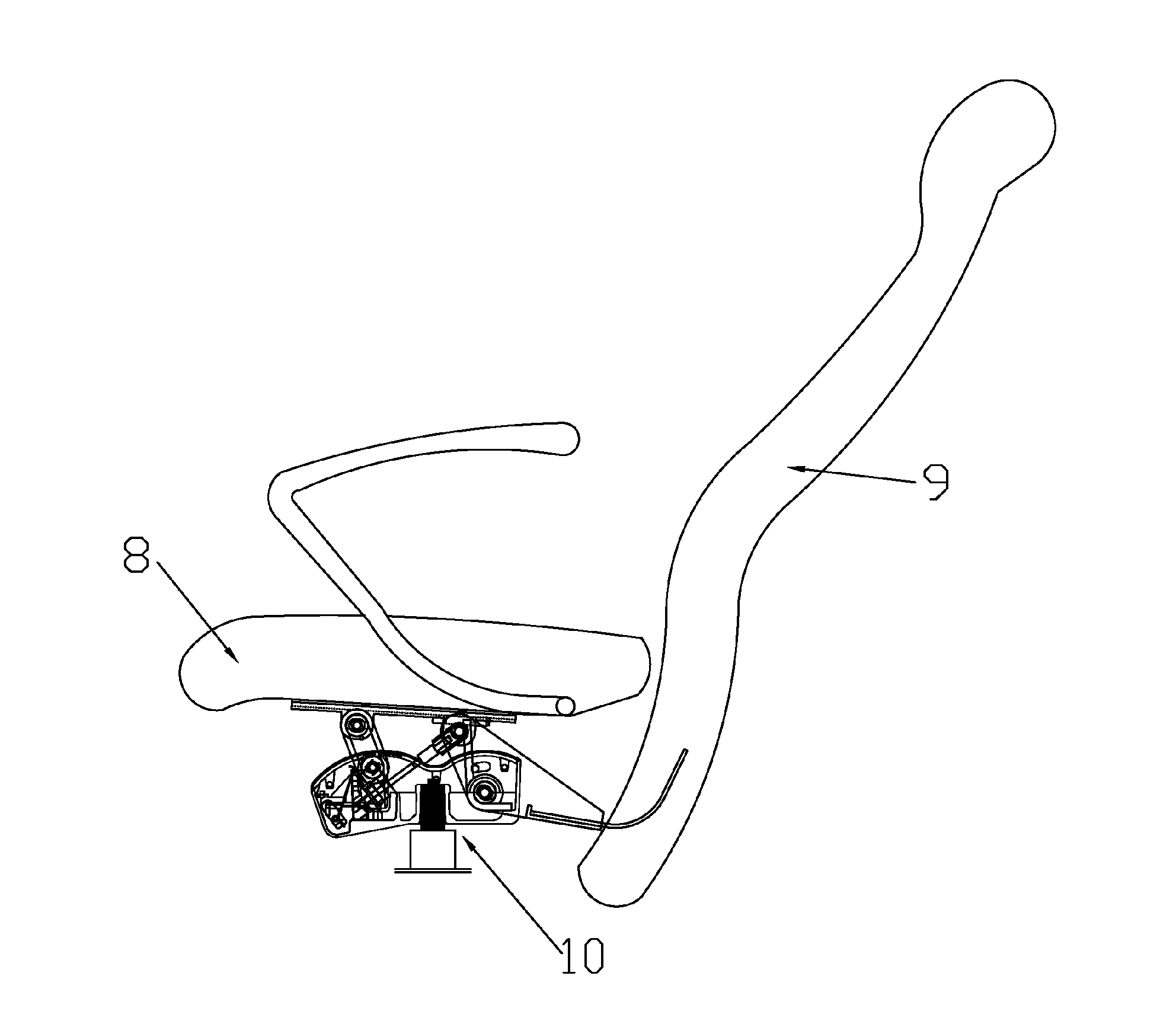

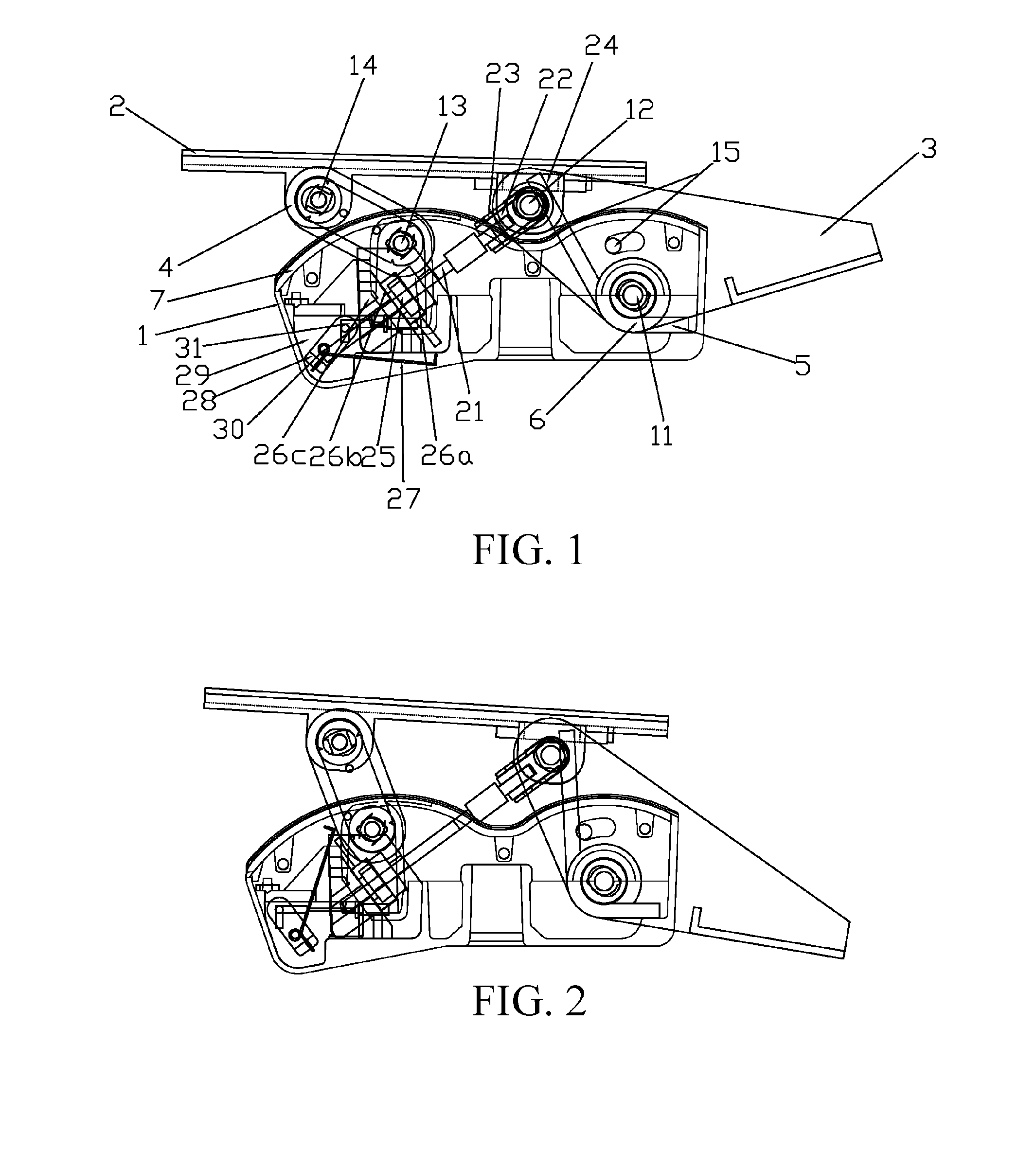

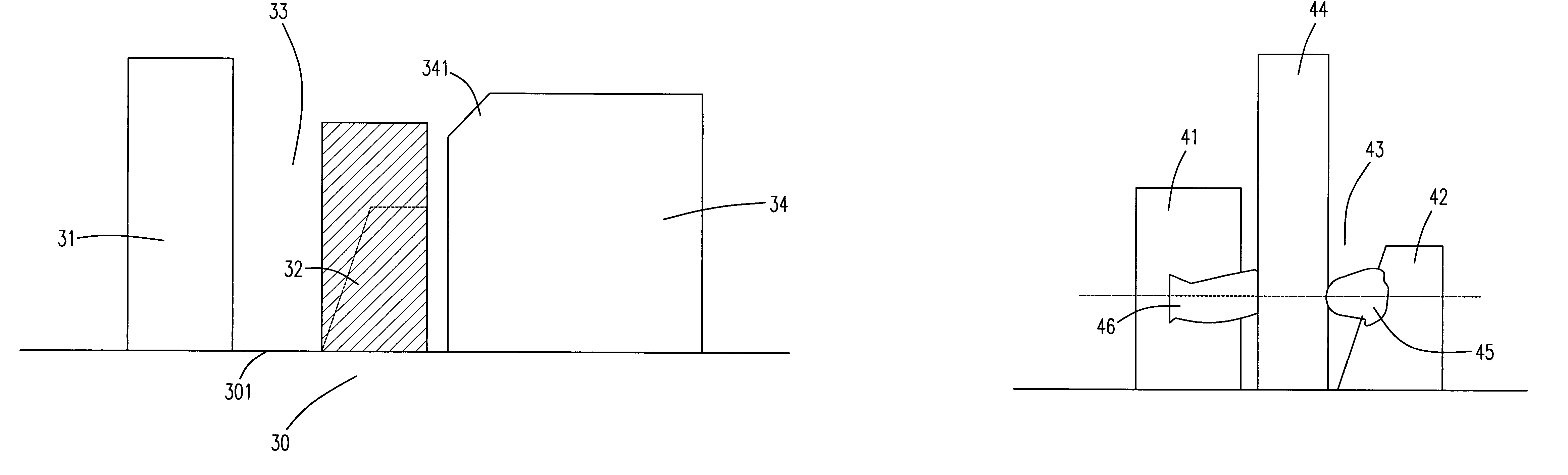

Chair chassis and chair having the same

InactiveUS20150272328A1Rearward pressureMoment balanceOperating chairsDental chairsEngineeringChassis

Disclosed is a chair chassis, wherein a seat bearing plate is disposed above a main tray base, for bearing a seat, a front end of a movable support member is pivotally connected to the seat bearing plate, a lower end thereof is pivotally connected to the main tray base, the movable support member is pivotable, a pair of movable supporting plates are located in front of the movable support member, upper and lower ends of each movable supporting plate are respectively pivotally connected to the seat bearing plate and the main tray base, and a pivot where the movable support member and the main tray base are connected is mounted with an elastic member for resisting the movable support member from rotating rearward. A user is subject to appropriate pressure when leaning back against the backrest, and friction between the backrest and the user's back may be reduced.

Owner:SHANTOU LISHI FURNITURE

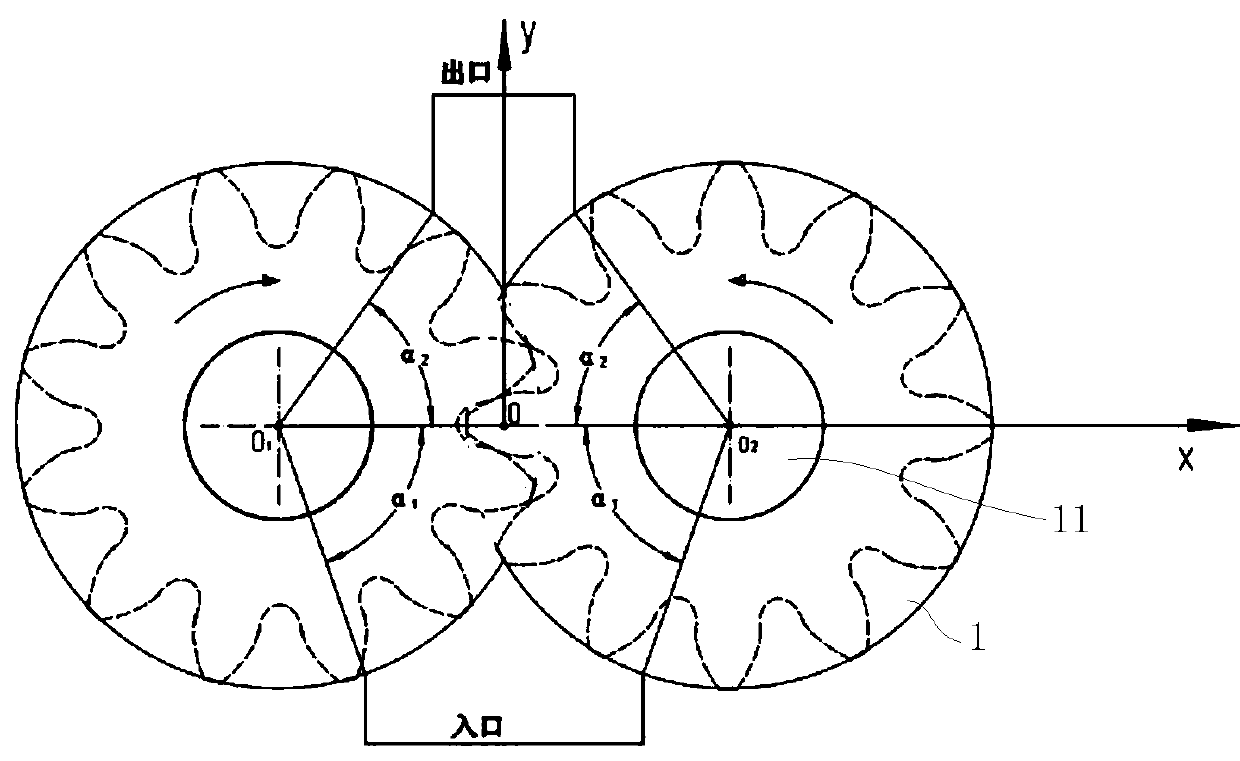

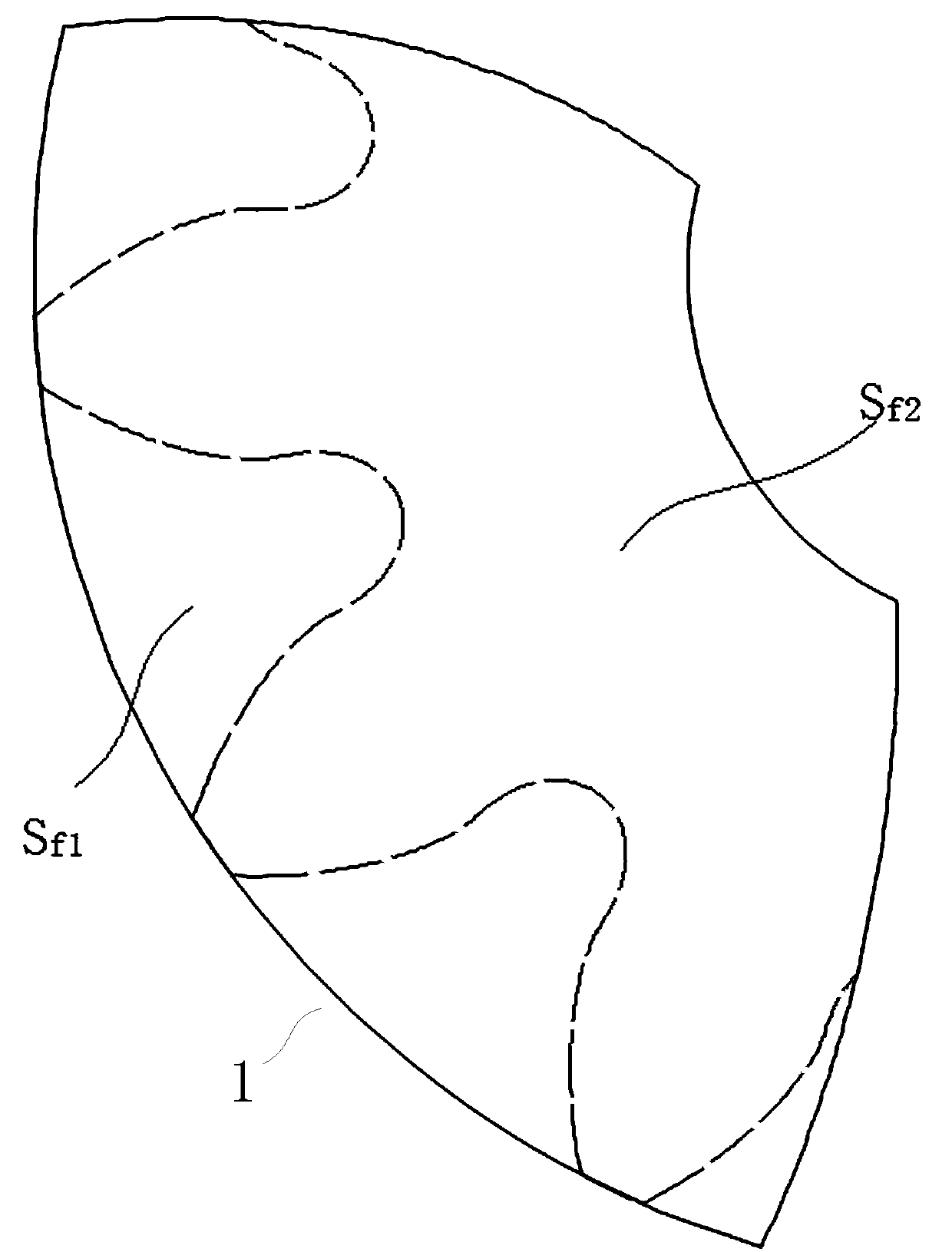

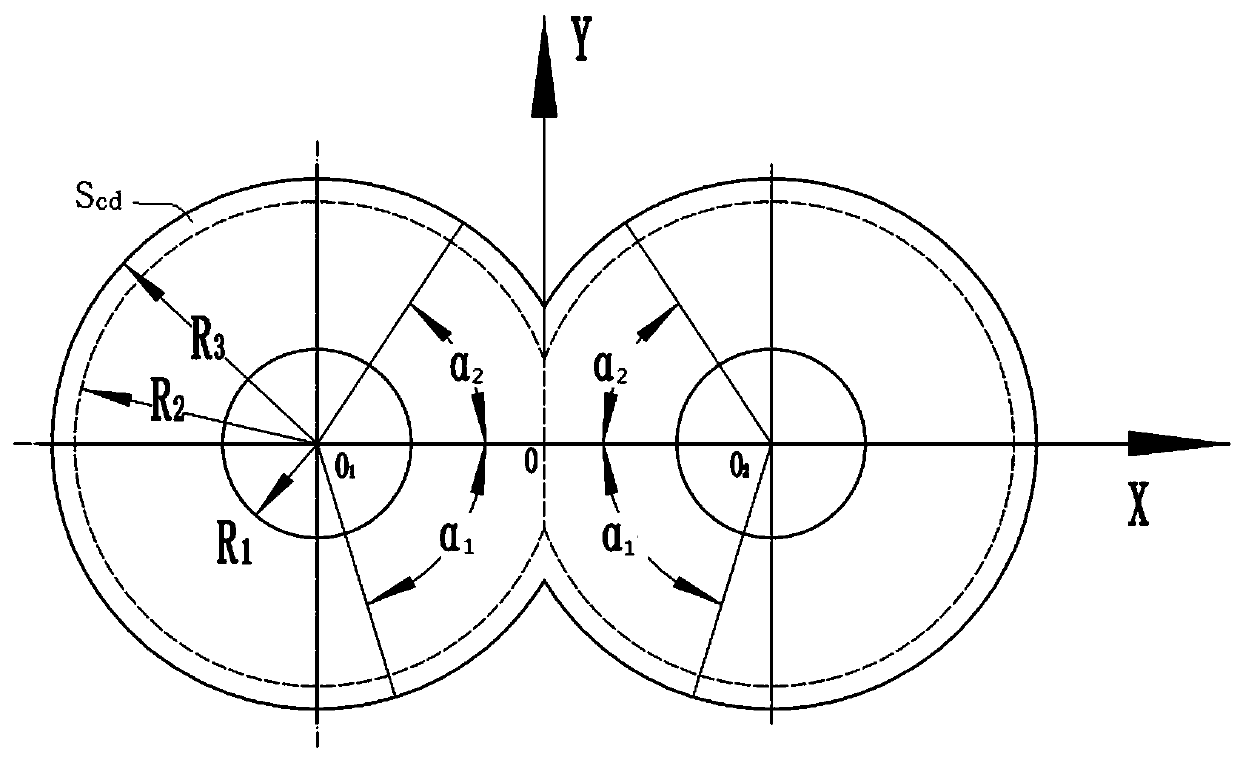

Gear pump floating side plate design method

PendingCN110955944ANarrow the scope of the testReduce the number of simulation trialsGeometric CADRotary piston pumpsGear pumpGear wheel

The invention relates to the field of gear pumps, in particular to a gear pump floating side plate design method. The gear pump floating side plate design method comprises the following steps: calculating the stress of a floating side plate towards one side of a gear end surface, the stress of the floating side plate back to one side of a gear, the torque of the floating side plate towards one side of the gear end surface around an X axis and the torque of the floating side plate back to one side of the gear around the X axis, enabling the resultant force on the two sides of the floating sideplate and the resultant moment around the X axis to be zero, and listing equations: Ff1-Fyj=0, Mf1-x-Myj-x=0, and the parameter adjustment of the floating side plate needs to ensure that the resultantforce on two sides of the floating side plate and the resultant moment around the X axis are zero, so that the test range of floating side plate parameters is reduced, and the simulation test frequency of the floating side plate is reduced, and unnecessary simulation tests on the floating side plate parameters which do not meet the position adjustment equation are avoided, and the technical problems of high test frequency, long research and development period and high research and development cost caused by the fact that the existing gear pump floating side plate parameters are selected onlyby experience are solved.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

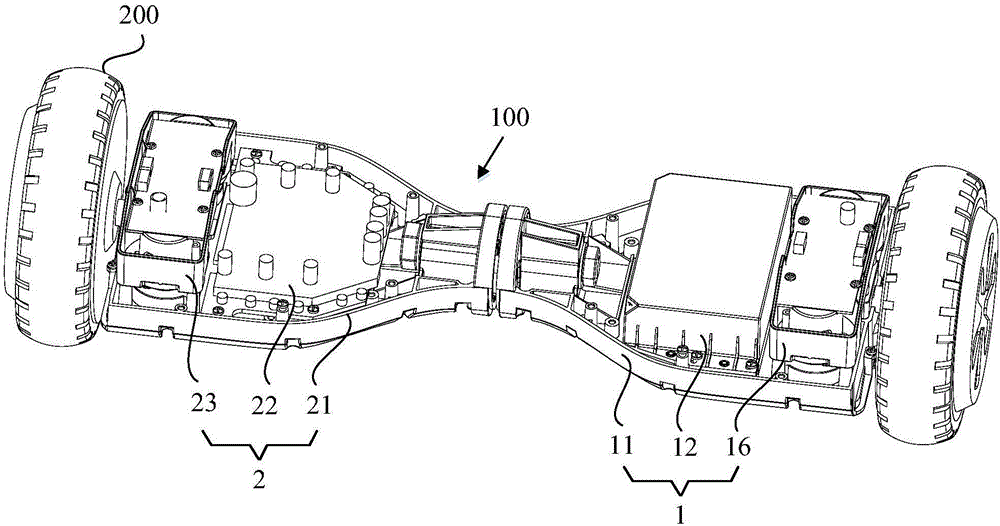

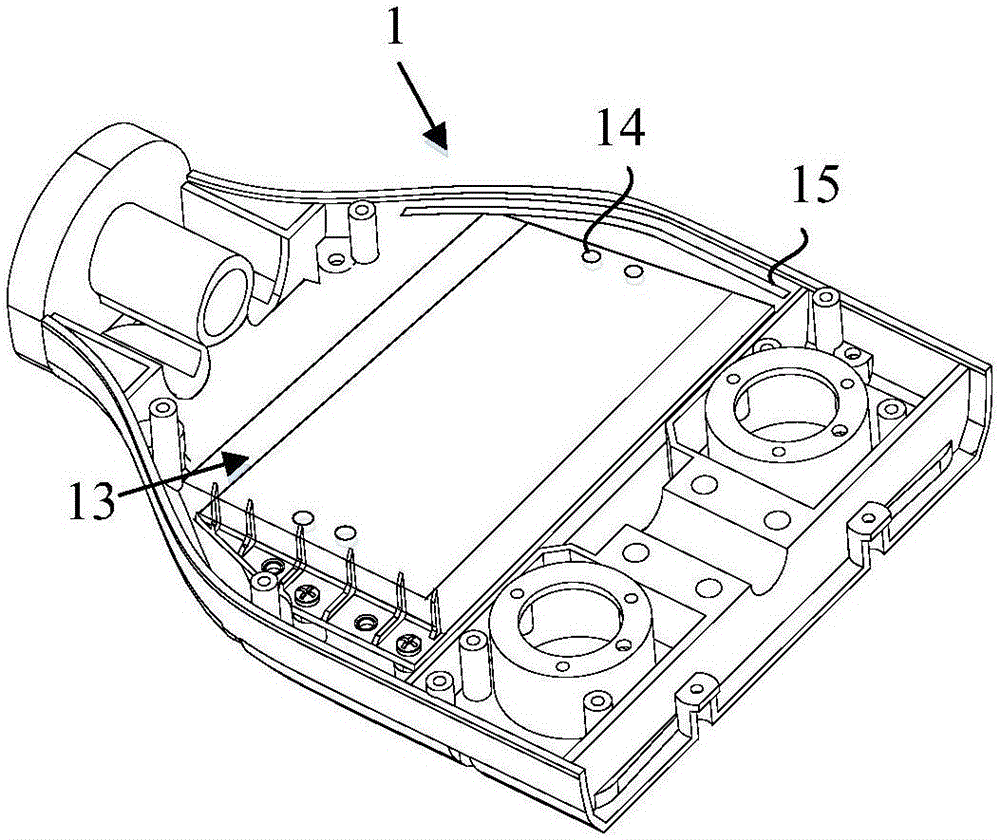

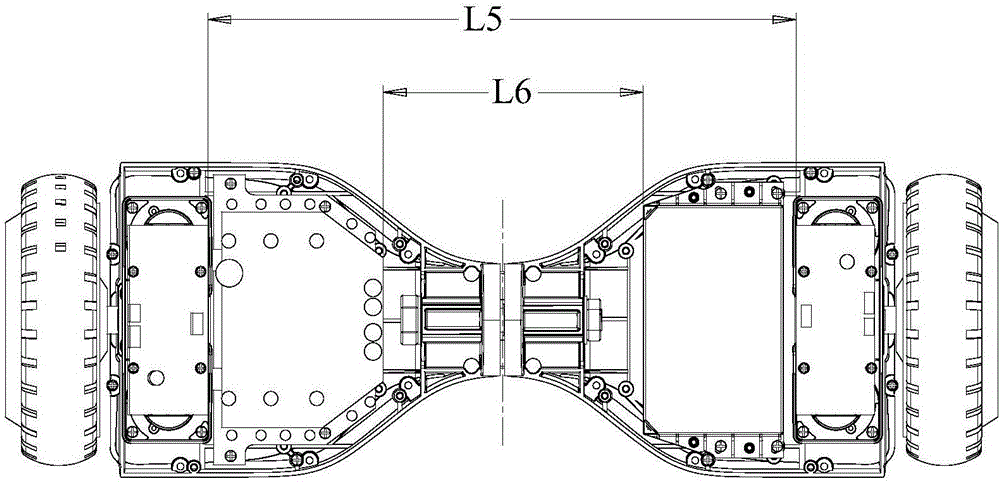

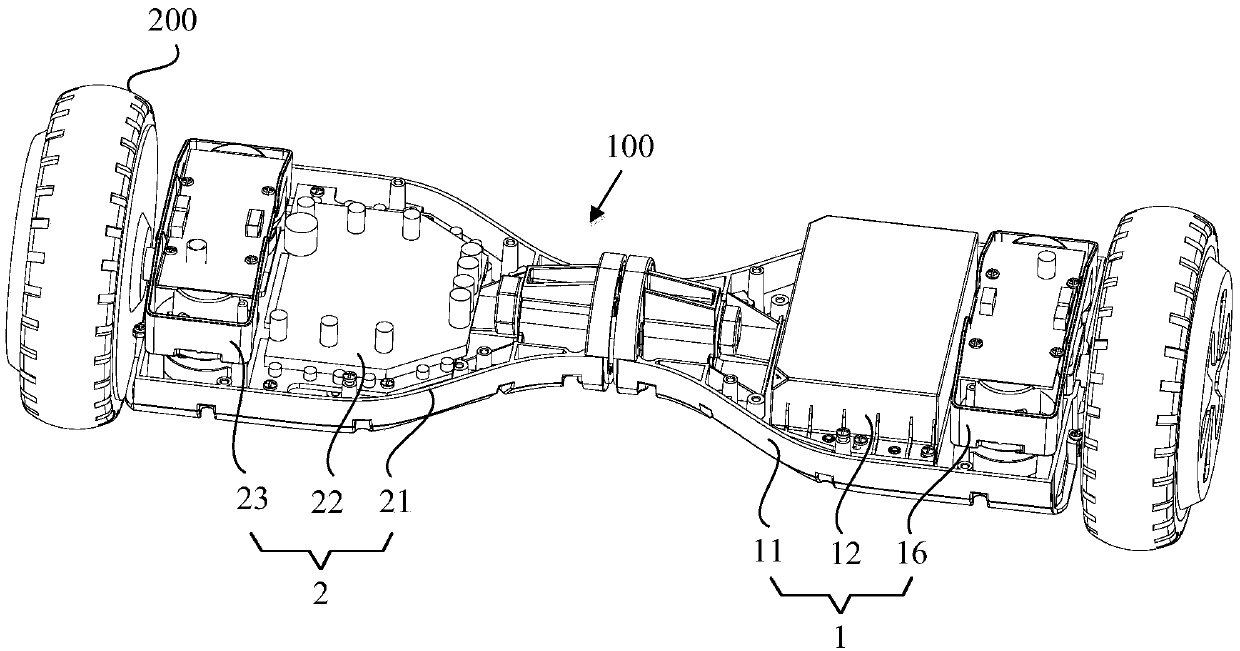

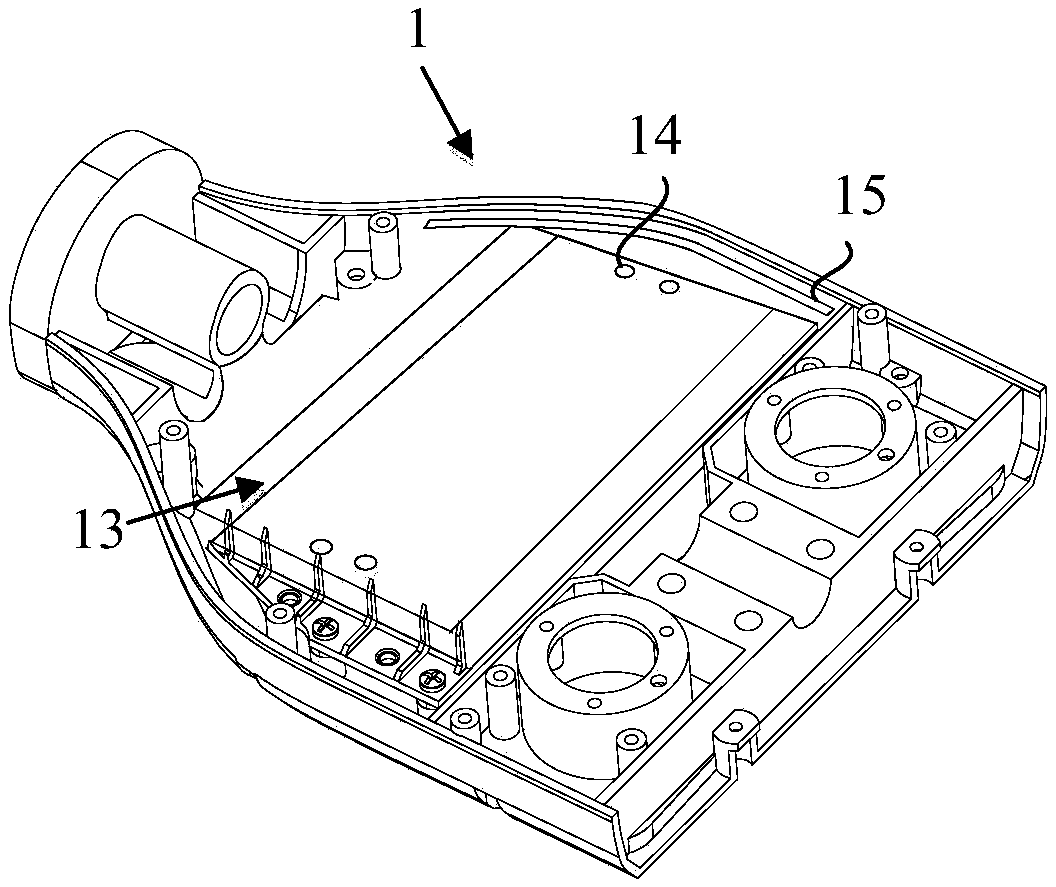

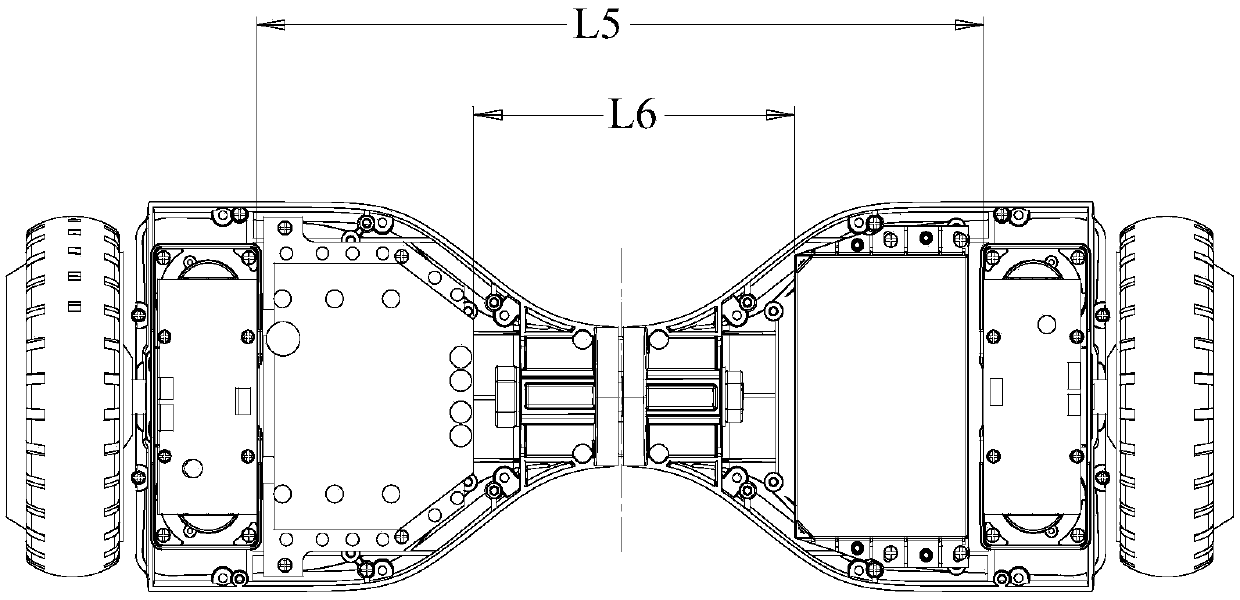

Balance car

The invention discloses a balance car which comprises a first pedal body and a second pedal body, wherein the first pedal body comprises a first frame body and a battery arranged on the first frame body; and the second pedal body is connected with the first pedal body, and comprises a second frame body and a control circuit module arranged on the second frame body. According the structure of the balance car, the distance between the battery and the control circuit module can be adjusted, so that the moments of the first pedal body and the second pedal body can be adjusted by adjusting the distance between the battery and the control circuit module. Accordingly, the moment balance between the first pedal body and the second pedal body can be maintained, and the size of the balance car can be reduced.

Owner:常熟东南高新技术创业服务有限公司

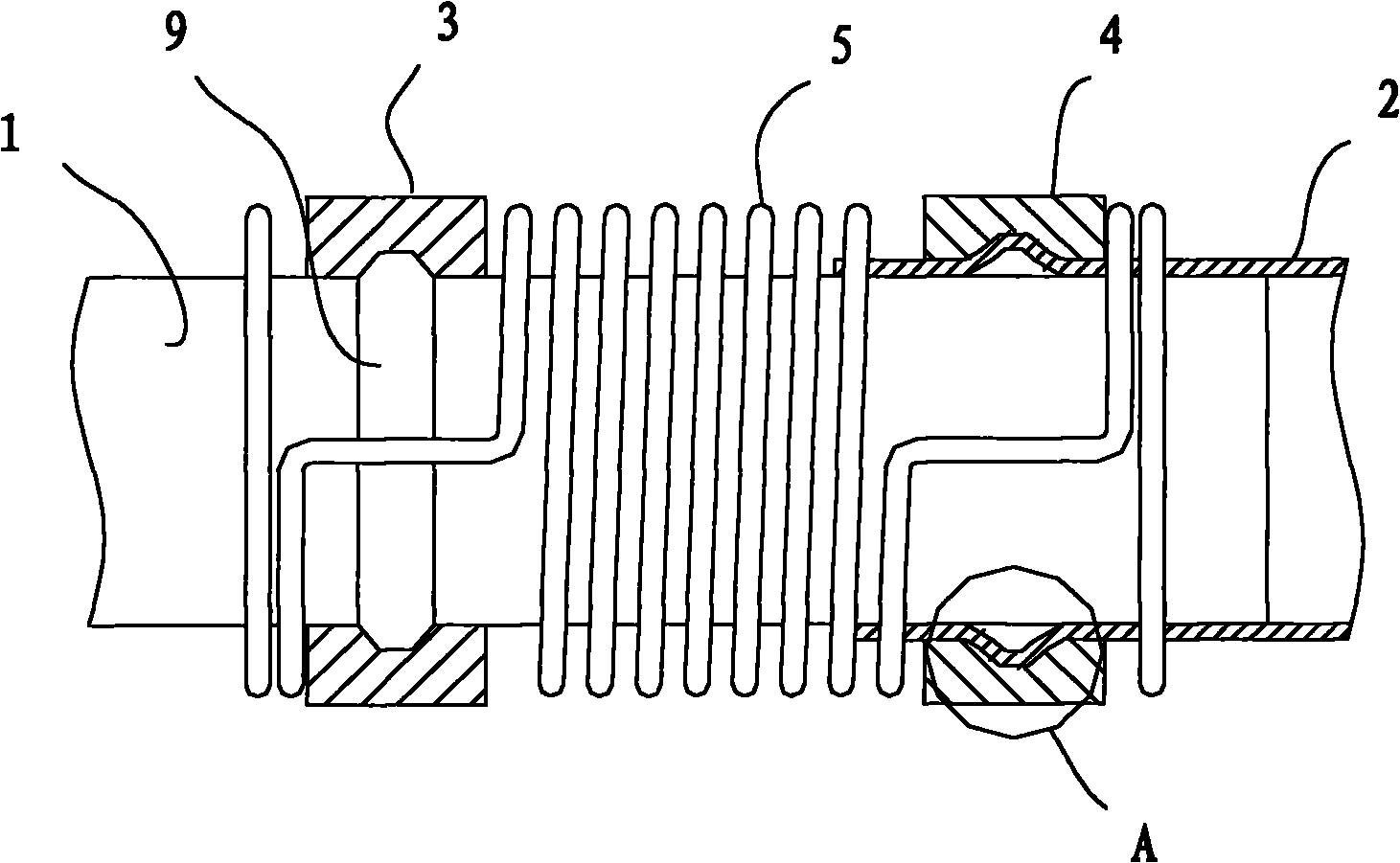

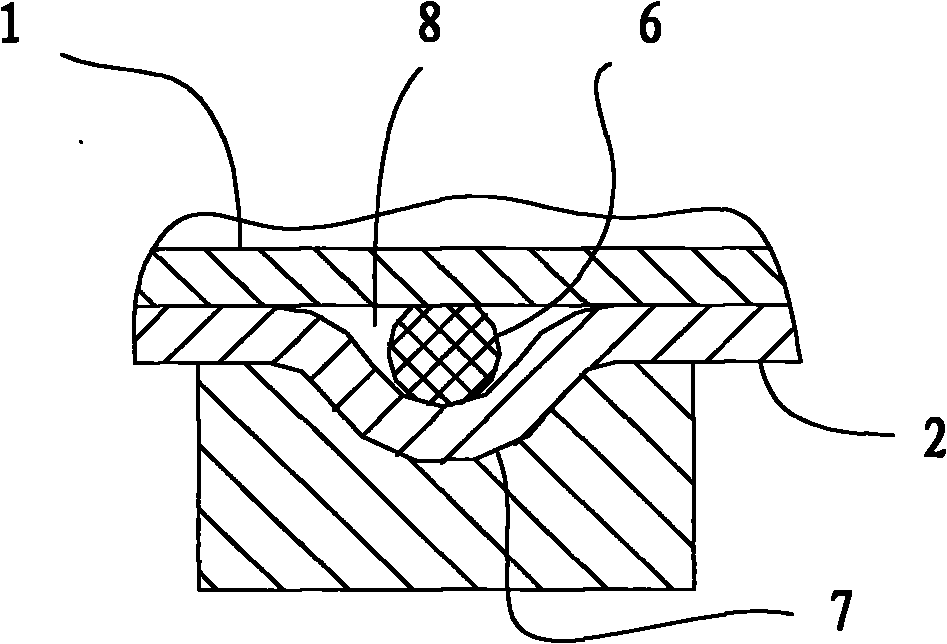

Pipeline connection structure of heat exchanger

InactiveCN101852570AEasy to installAutomatically adjust displacementPipeline expansion-compensationAdjustable jointsPlate heat exchangerStraight tube

The invention discloses a pipeline connection structure of a heat exchanger, comprising a connecting tube, a heat-radiating straight tube, a first locating block, a second locating block and an elastic piece, wherein the connecting tube and the heat-radiating straight tube are sheathed, spliced and connected by an end part; a seal ring is arranged between the walls of the heat-radiating straight tube and the connecting tube at the splicing position; the first locating block is fixed on the outer wall of the connecting tube, the second locating block is fixed on the outer wall of the heat-radiating straight tube, and two ends of the elastic piece are respectively connected with the first locating block and the second locating block. The invention has the advantage that installation and arrangement are convenient, the working procedure of welding omitted, parts and components transportation of large rack tubes can be realized and installation on the spot is simple so that the phenomenon that welded junctions are easy to be damaged due to the transportation, and at the same time, the structure of the sealed rack tube is changed along with the variation of the volume of medium in the tube under the sealing without breaking and the management cost of the heat exchanger in the operation is lowered.

Owner:谭仲禧

External operation handle

PendingCN108269703AGuaranteed reliabilityEnhance resilienceContact operating partsLocking mechanismCoupling

An external operation handle comprises a coupling shaft connected with a switch electric appliance and a linkage member connected to the connecting shaft. The linkage member is arranged in a casing, the top side of the casing is provided with a handle member connected to the linkage member, the bottom side of the linkage member is provided with a linkage shaft groove in sliding fit to the couplingshaft, a linkage keyway in sliding fit to a connecting key on the coupling shaft is arranged in the linkage shaft groove, a movable locking piece and an unlocking piece connected with the locking piece are arranged under the linkage member, the locking piece is provided with a locking shaft hole corresponding to the linkage shaft groove, a locking key hole corresponding to the linkage keyway is arranged in the locking shaft hole, and the unlocking piece can drive the locking piece to move so that the locking key hole is offset from or overlapped with the linkage keyway. The bottom side of thelinkage member is provided with the locking piece in cooperation with the connecting key, so that a locking mechanism can lock or release, in emergency, the coupling shaft via a simple structure, itis not required to prepare other structures on the coupling shaft, the manufacturing cost is reduced, the reliability of the coupling shaft is ensured.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD +1

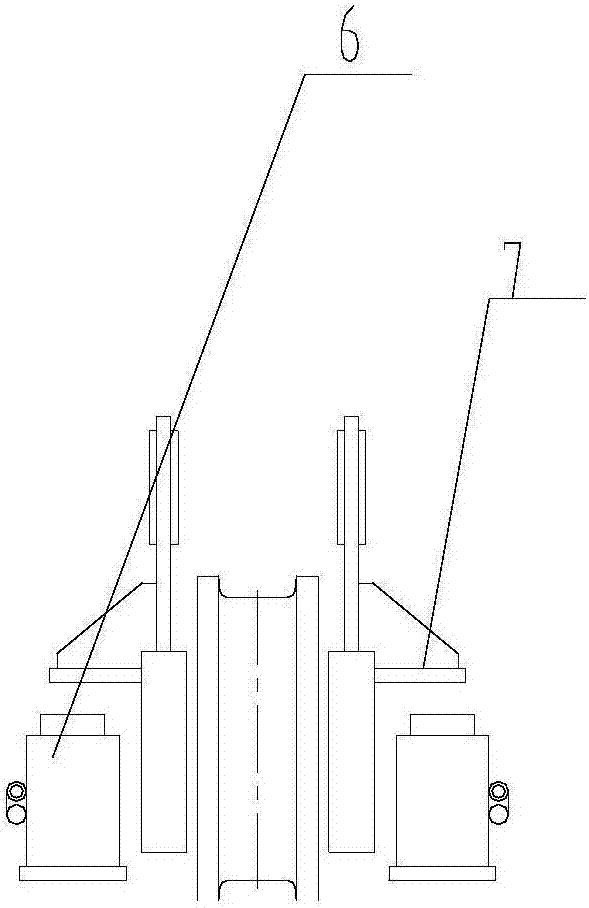

A traveling trolley and wheel quick replacement method of a container gantry crane

InactiveCN105883635BRealize the lightweight of its own structureReduce load weightBase supporting structuresBraking devices for hoisting equipmentsContainerizationEngineering

The invention discloses a travel trolley of a container gantry crane and a method for quickly changing wheels. The travel trolley comprises a balance beam. The upper end of the balance beam is used for being connected with a lower transverse beam of a crane gantry assembly, the lower end of the balance beam is connected with a trolley frame, and a travel wheel set and a gear motor with a brake are arranged on the trolley frame. The travel trolley is characterized in that a jack seat which is fittingly connected with a jack is arranged at the front end of the balance beam, jack seats which are fittingly connected with two other jacks are arranged on two sides of the trolley frame, and a triangle is formed by the three jack seats. The jacks can start to be lifted after being arranged in place if the travel wheel set is required to be changed, so that travel wheels can be separated from rail surfaces, bearings can be separated from the trolley frame by the aid of tools, and then the travel wheel set can be changed. The travel trolley and the method have the advantages that designed special jack supports are used as action points of the jacks, the damaged wheels can be directly changed, the time and labor can be saved, and the travel trolley and the method are convenient and speedy.

Owner:CHINA RAILWAYS CORPORATION +3

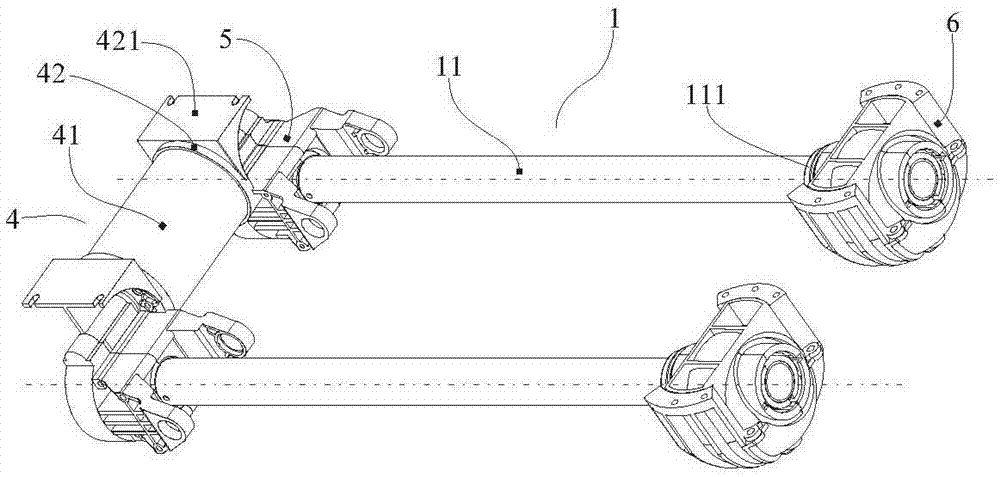

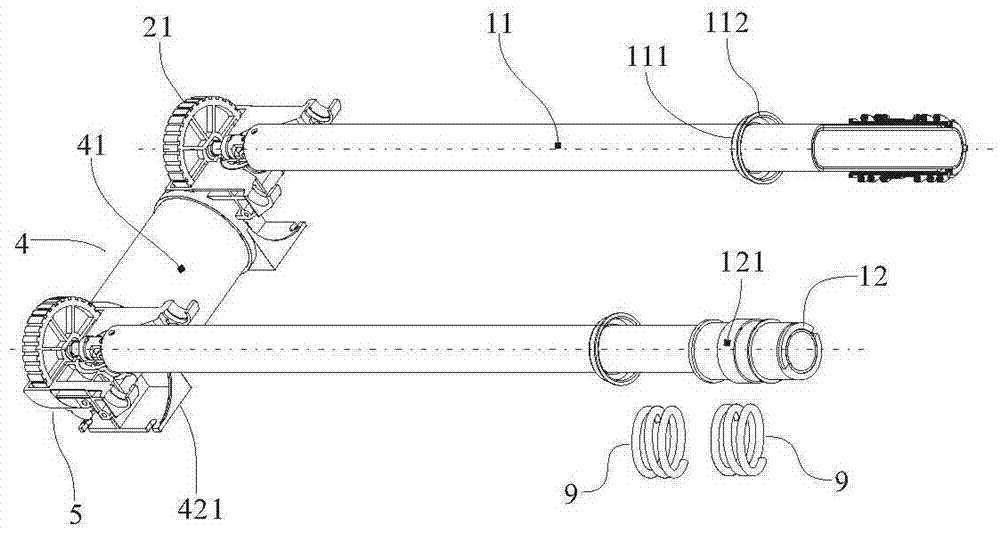

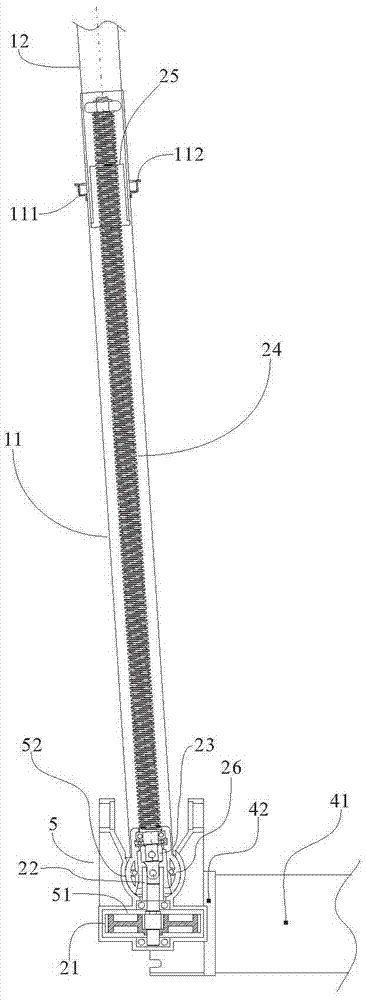

Single-machine-driven double-pendulum synchronous push-and-pull device and method for avoiding unfavorable push and pull

PendingCN106901914AMoment balanceSimple designToothed gearingsWheelchairs/patient conveyancePush and pullUniversal joint

The invention relates to a single-machine-driven double-pendulum synchronous push-and-pull device and a method for avoiding unfavorable push and pull. The single-machine-driven double-pendulum synchronous push-and-pull device comprises a first universal joint rod, a second universal joint rod and a universal bearing ball, wherein the first universal joint rod and the second universal joint rod are connected in a rotating mode and installed in a through hole of the universal joint rod of the universal bearing ball in a clamping mode so that a cross point of a first shaft and a second shaft coincides with a center of a sliding outer wall of the universal bearing ball. The single-machine-driven double-pendulum synchronous push-and-pull device has the advantages that axes of a push-and-pull sleeve assembly is adapted to sway and change with the torque changing and the center of gravity displacing during the change process of a variable device; the overall torque balance of the variable device and the smooth movement of the center of gravity are maintained; and further the situation of unfavorable push and pull in the prior art is prevented from occurring with a feedback sleeve, a pressure switch and a feedback boss structure.

Owner:SHENZHEN TUOAN MEDICAL DEVICES CO LTD

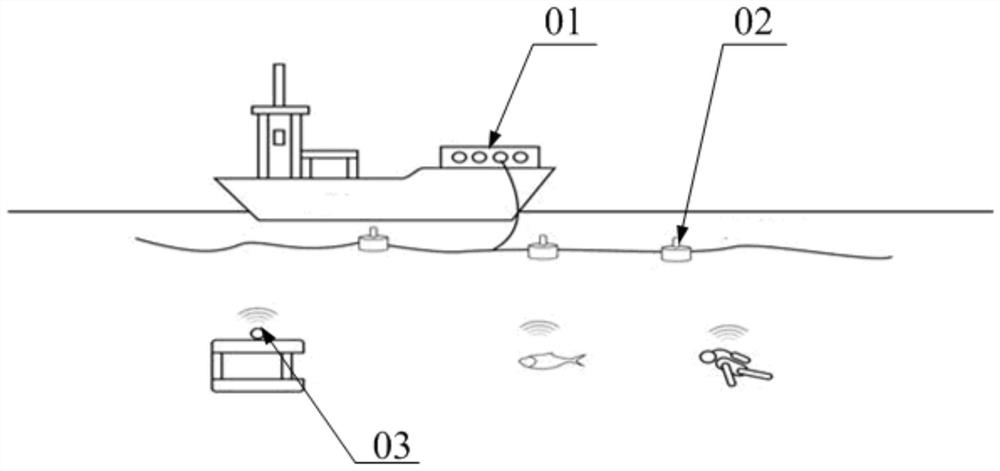

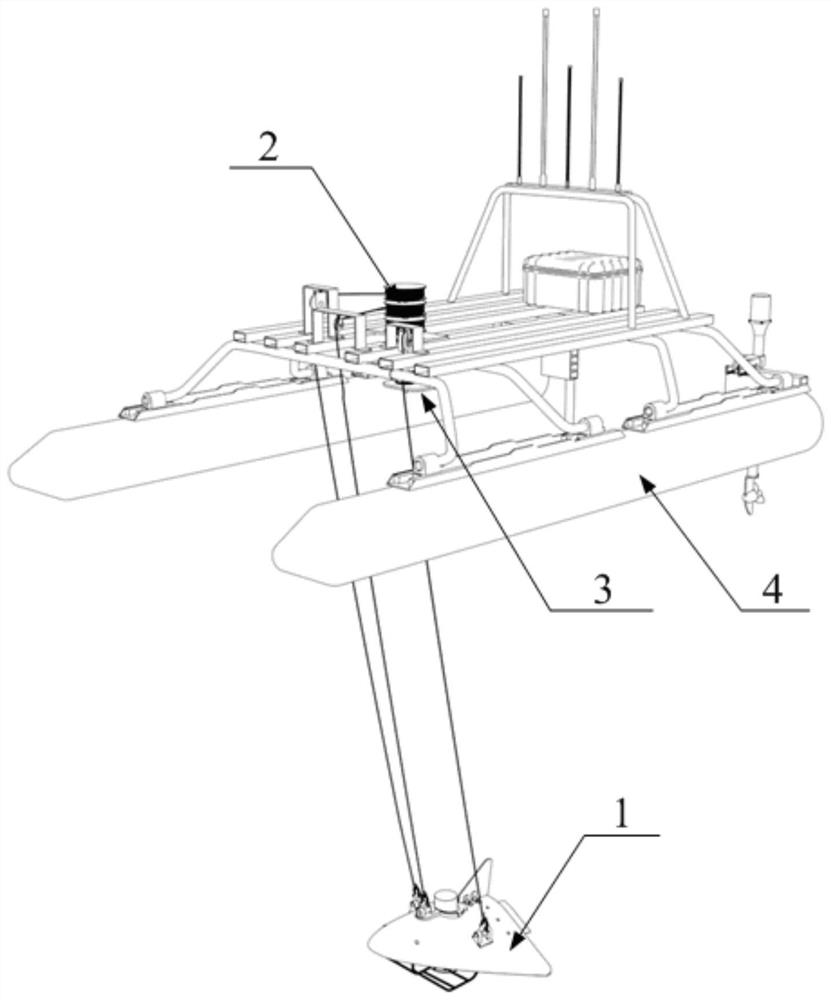

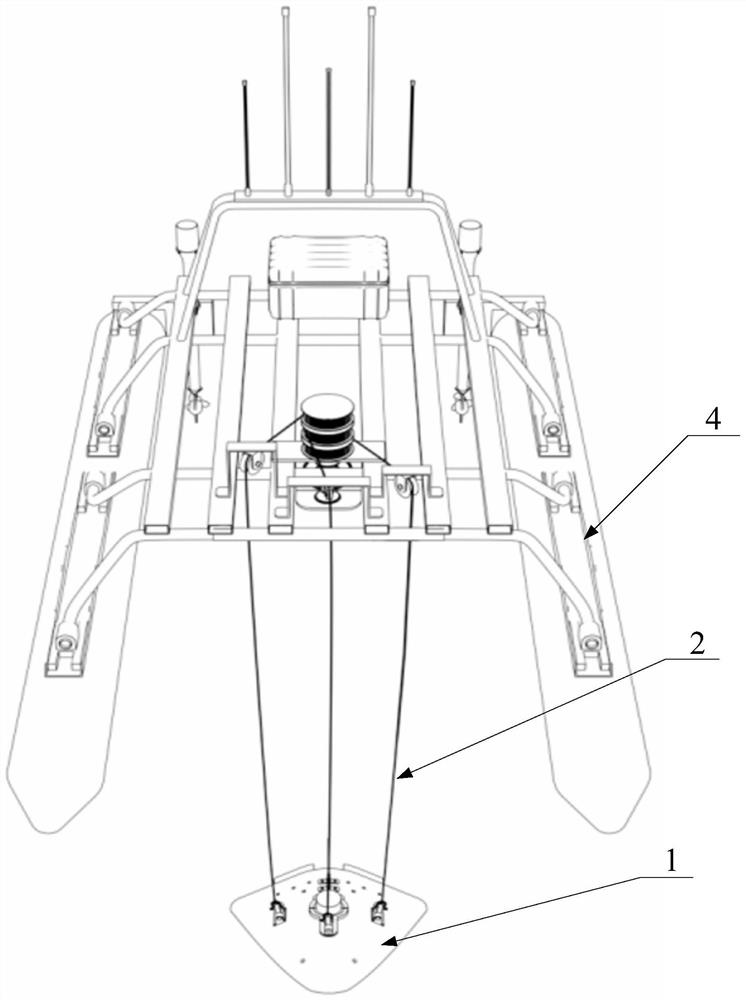

Underwater stabilizing system

ActiveCN111717349ARetractable and stableBalance buffering force of ocean currentsTowing/pushing equipmentUnderwater equipmentVertical planeUnderwater

The invention discloses an underwater stabilizing system. The underwater stabilizing system comprises a hydrofoil device; the hydrofoil device comprises a hydrofoil body; in the working process of thehydrofoil device, the pressure intensity of the lower wing surface of the hydrofoil body is smaller than that of the upper wing surface of the hydrofoil body; the hydrofoil body is of a symmetrical structure; when the underwater stabilizing system is in a working state, the vertical plane which passes through the gravity center of the hydrofoil body and divides the hydrofoil body into two symmetrical parts is a first vertical plane; the system further comprises a traction device; the traction device comprises a plurality of groups of side traction assemblies; each side traction assembly comprises a side traction rope, a guide wheel and a winch; the first end of each side traction rope is wound on the corresponding winch, the second end of each side traction rope bypasses the correspondingguide wheel and then is connected with the upper wing surface of the hydrofoil body, and the mounting positions of the side traction ropes of the multiple groups of side traction assemblies on the hydrofoil upper body are symmetrically arranged; the system further comprises a power device which can drive the winch to rotate. Due to the structural design of the underwater stabilizing system, underwater equipment can keep a stable relative pose with a ship / overwater operation platform according to the use requirements of the underwater equipment.

Owner:PENG CHENG LAB

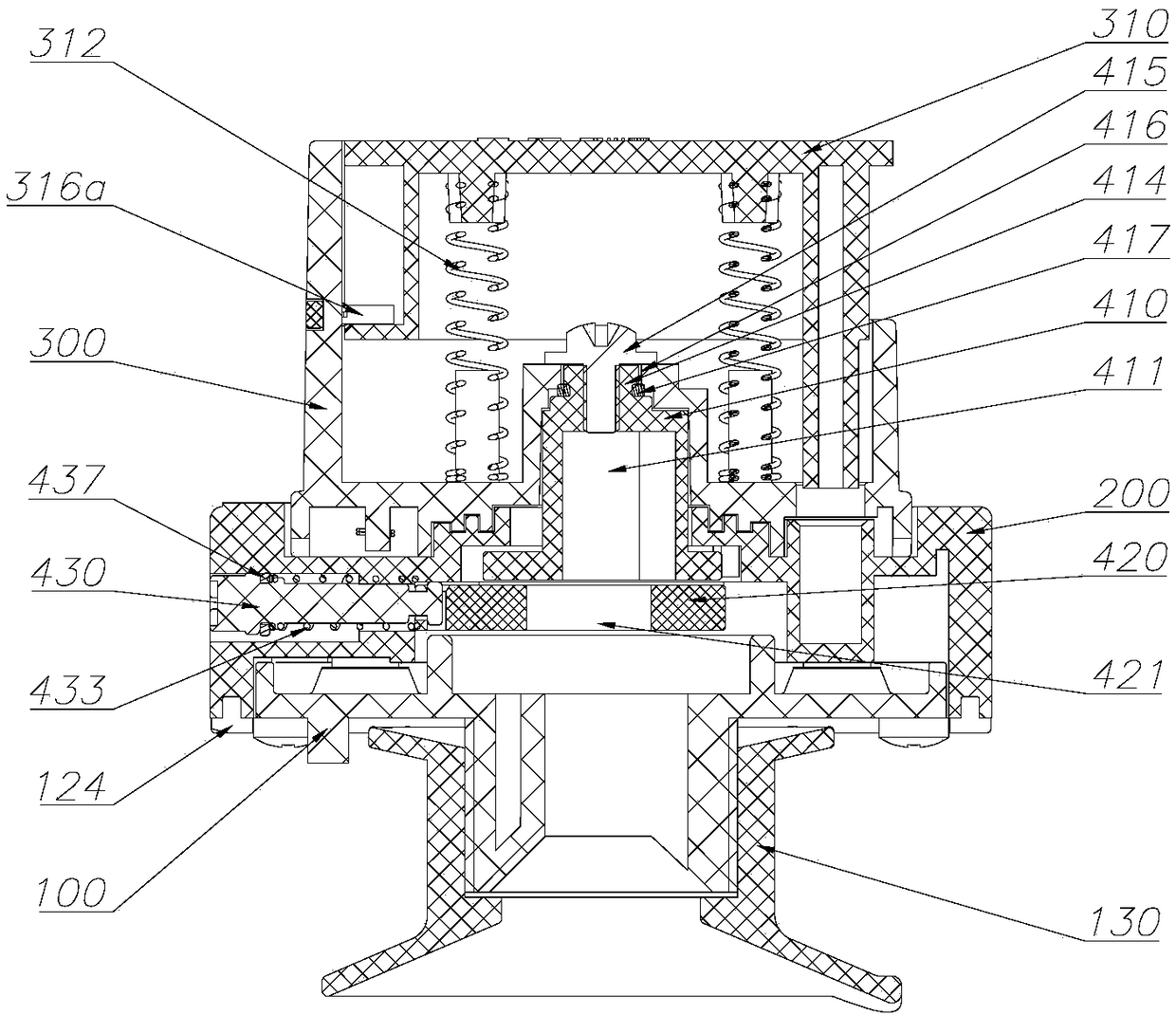

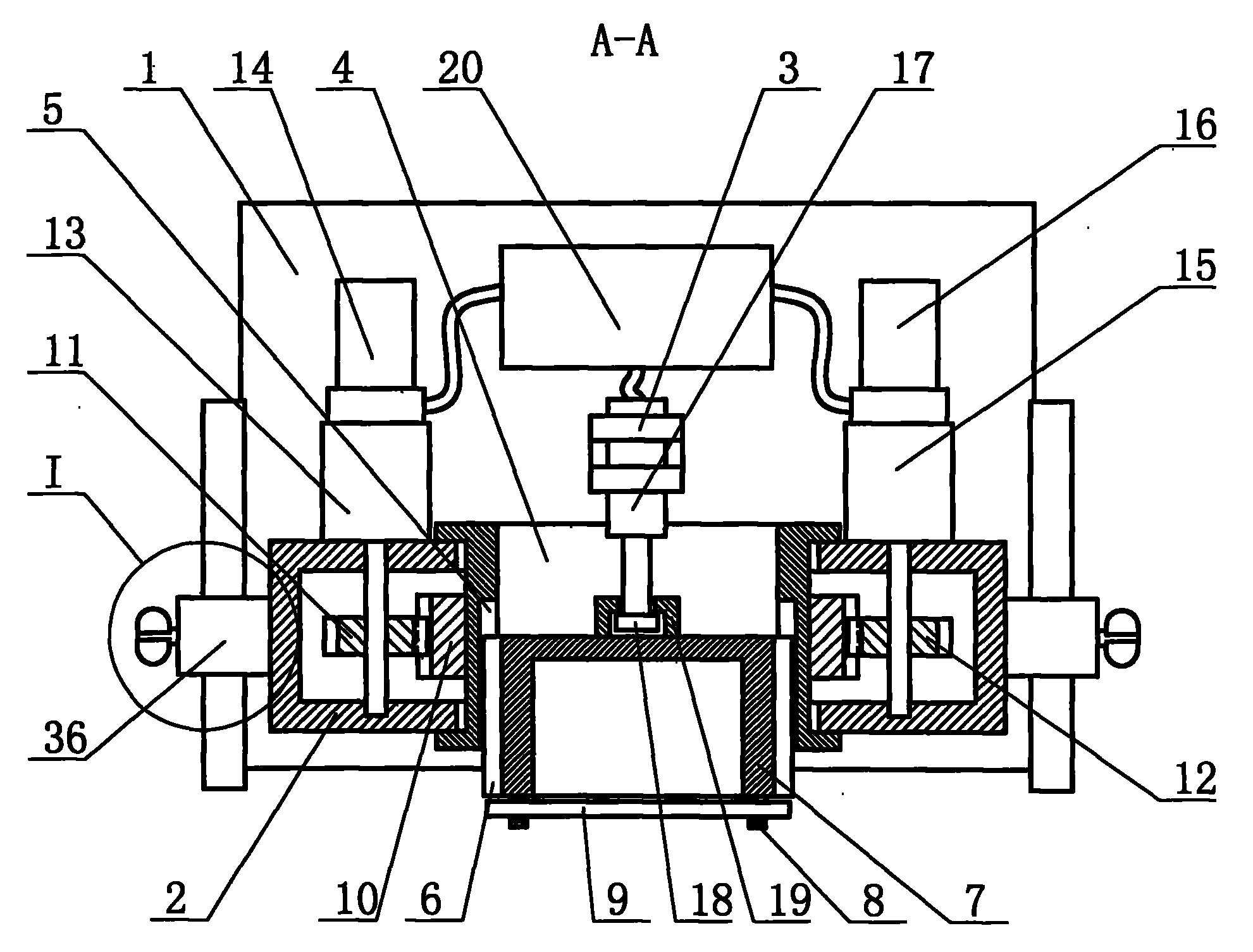

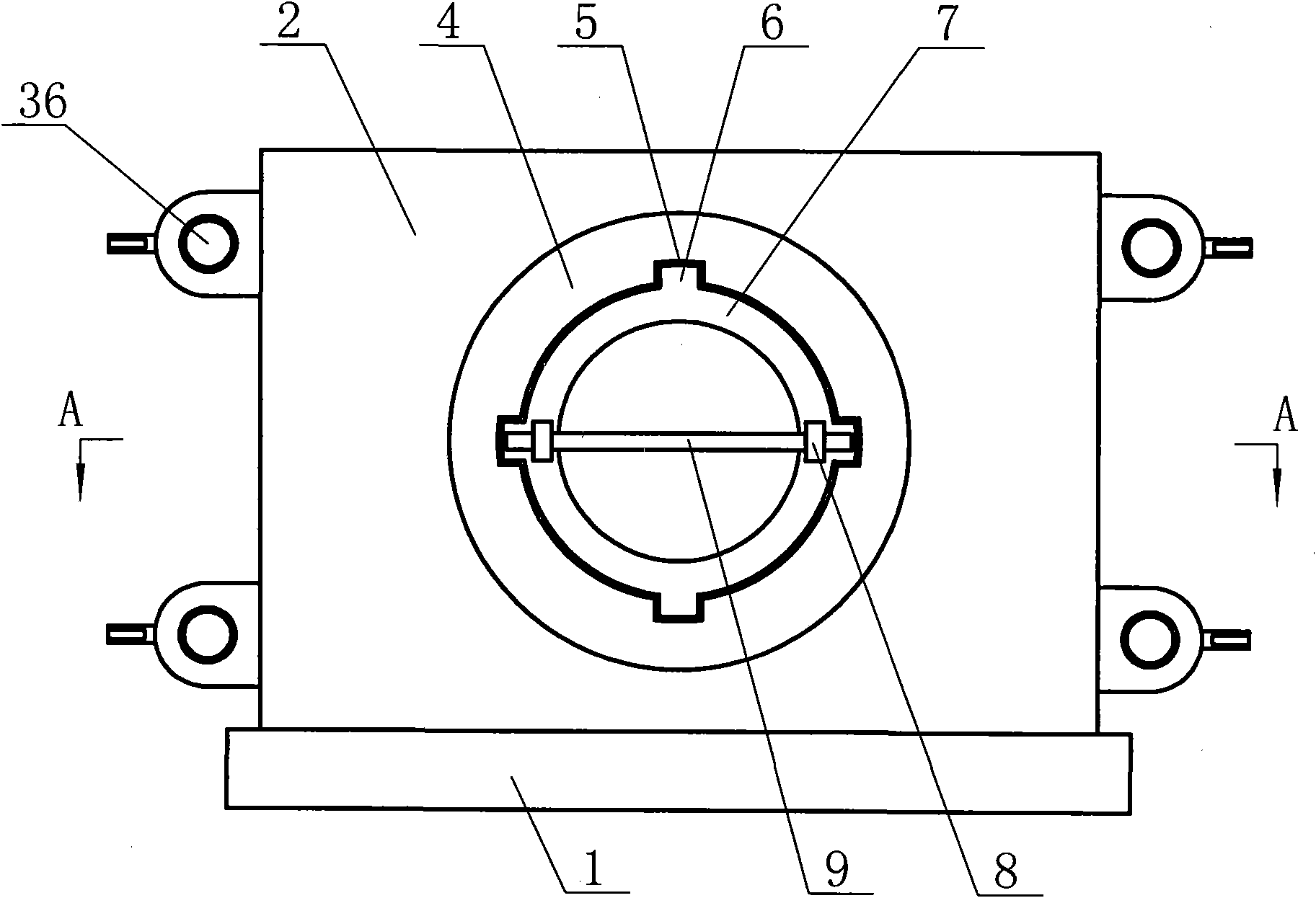

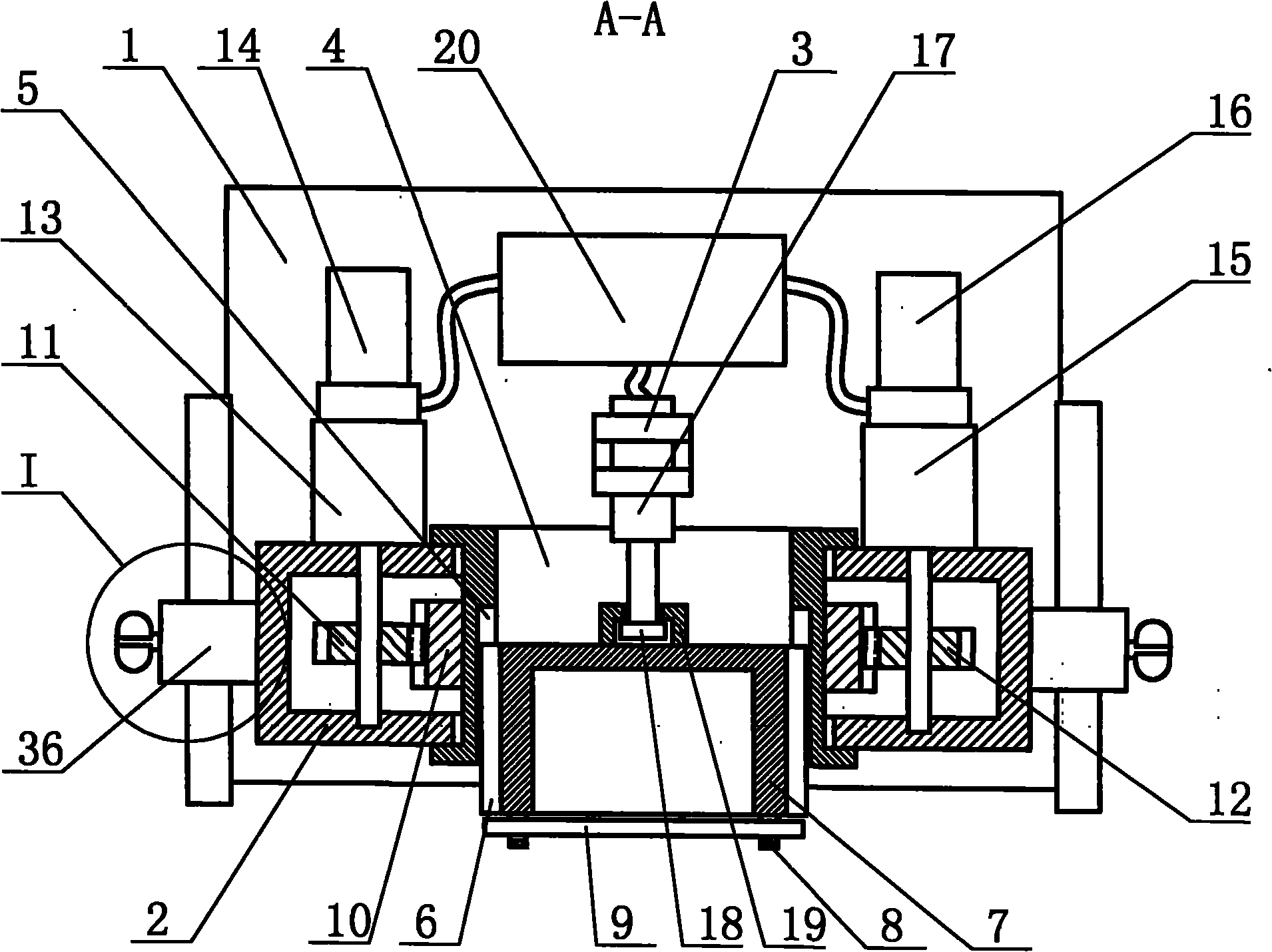

Piston dismounting machine of oil cylinder seal head

ActiveCN101659006BSo as not to damageWon't hurtMetal working apparatusHydraulic motorHydraulic cylinder

The invention provides a piston dismounting machine of an oil cylinder seal head, comprising a base. The base is provided with a machine shell and a support base; four groups of support devices are mounted on the edge of the machine shell; a rotor drum is mounted in the centre of the machine shell; an inner wall of the rotor drum is provided with a chute which is internally provided with a slide block; the slide block is connected with a rotor which is provided with a suspension ring; the suspension ring is internally provided with a torque lever; the outer wall of the rotor drum is provided with gear rings which are respectively engaged with two groups of transmission gears; the support base is provided with a hydraulic cylinder; an the end part of a push rod of the hydraulic cylinder isprovided with a bulge loop which is mounted in a positioning base; the positioning base is connected with the rotor; and a first hydraulic motor, a second hydraulic motor and the hydraulic cylinder are all connected with a hydraulic device. The transmission member can provide balanced moment without clamping gears, can apply stable torque force to the torque lever to effectively prevent deadlocking of screws and can provide stable pull force or push force without damaging workpieces; the height of the four groups of support devices can be separately regulated, and the devices with irregular surface also can be dismounted.

Owner:SINOPEC TENTH CONSTR

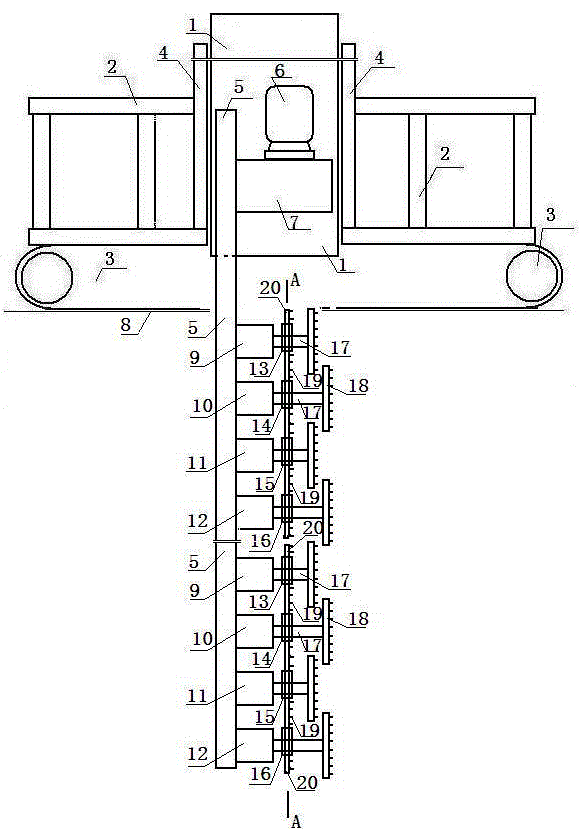

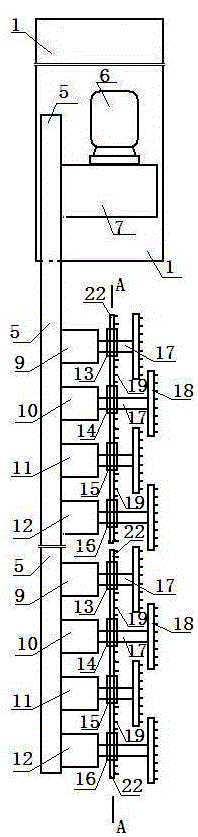

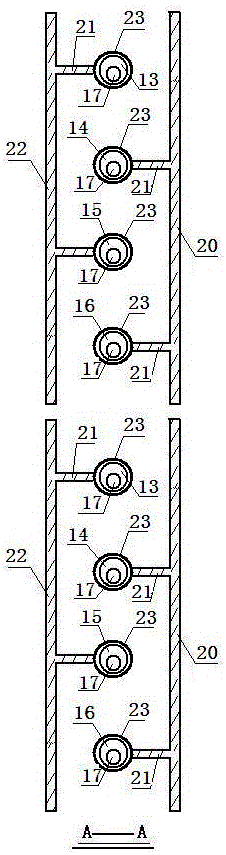

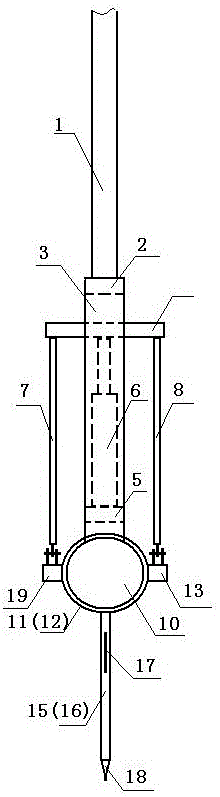

Continuous stirring drilling machine

Disclosed is a continuous stirring drilling machine. A cement paste pouring and spraying device injects cement paste to the right end of each cutting head. The cutting heads cut and stir the soil mass and cement paste in the rotating process. In the swinging process, a plurality of first stirring blades, a plurality of second stirring blades, cutting teeth on the first stirring blades and cutting teeth on the second stirring blades cut and stir the soil mass, which is located inside a front wall and rear wall and not stirred by the cutting heads, with the cement paste. In the rightward moving process of the stirring drilling machine, continuous cement-soil walls are formed on the left side underground.

Owner:刘玉秋

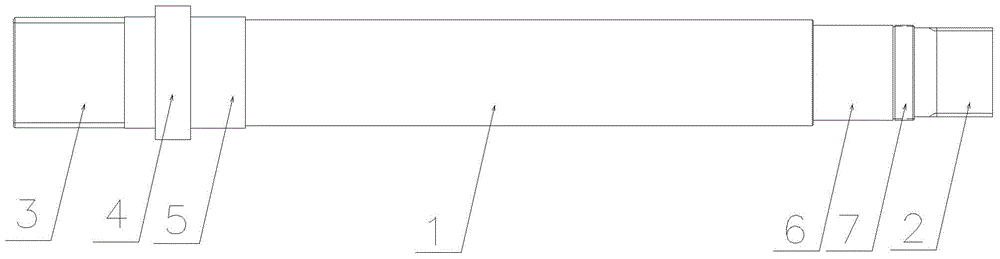

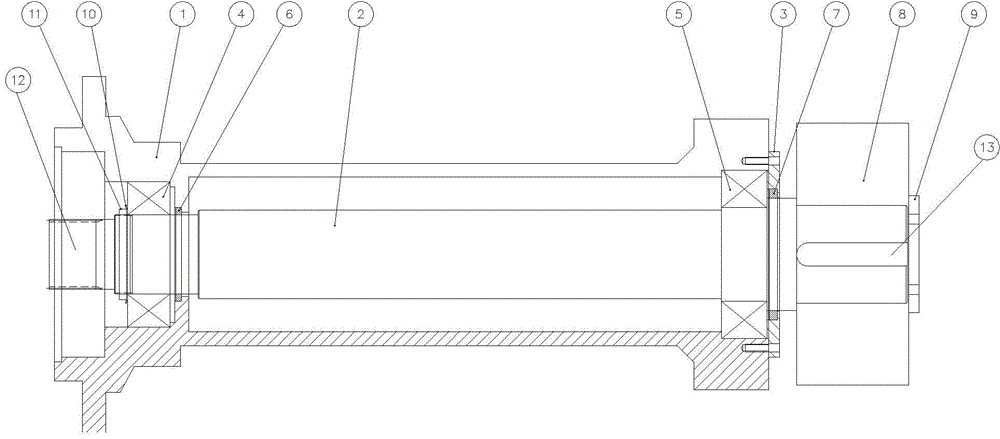

Transmission shaft of heavy-duty speed reducer

InactiveCN105650100AHigh transmission efficiencyMoment balanceShaftsPortable liftingEngineeringHeavy duty

The invention relates to a transmission shaft of a heavy-duty speed reducer. The transmission shaft comprises a transmission shaft body. One end of the transmission shaft body is provided with a gear I, and the other end of the transmission shaft body is provided with a gear II. The gear I and the gear II are both connected with the transmission shaft body to form an integral structure. The inner side of the gear I is arranged to be a shaft neck, and the inner side of the shaft neck is arranged to be a bearing mounting position; the inner side of the gear II is arranged to be a limiting convex ring structure, and the inner side of the convex ring structure is arranged to be a bearing mounting position. The normal module of the gear I and the normal module of the gear II are both 5. The number of teeth of the gear I is 22, 24 or 26, and the number of teeth of the gear II is 22, 24 or 26. The tooth profile angle of the gear I and the tooth profile angle of the gear II are both 30 degrees. The transmission shaft body is made of a material comprising 42CrMo. The two ends of the transmission shaft body are provided with shaft end covers correspondingly. Compared with the prior art, the shaft ends of the transmission shaft are provided with the gears to form the integral structure, so that the transmission efficiency is high, and transmitted torque is balanced and stable. The transmission shaft is applicable to the large or heavy-duty speed reducer.

Owner:彭芹

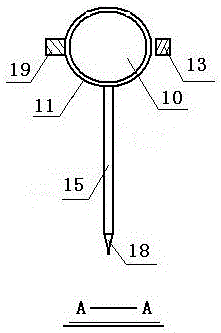

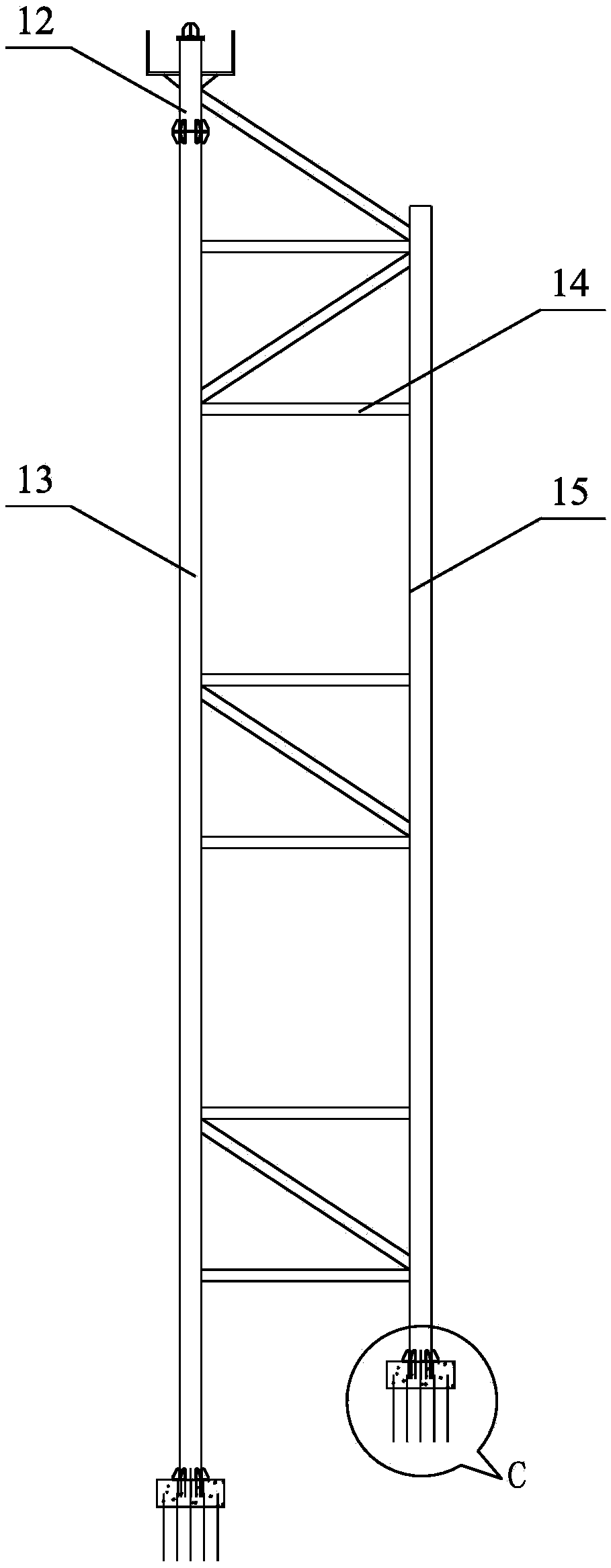

Cement soil mixing and stirring drilling machine

A cement-soil mixing drilling rig, the left end of the second cross arm is fixed on the lower part of the first vertical arm, the right end of the second cross arm is fixed on the lower part of the second vertical arm, a jack is fixed on the second cross arm, and the upper end of the jack Fixed in the middle of the third cross arm, the left end of the third cross arm is fixed on the upper end of the third vertical arm, the lower end of the third vertical arm is hinged to the fifth cross arm, and the right end of the third cross arm is fixed on the upper end of the fourth vertical arm , the lower end of the fourth vertical arm is hinged to the fourth cross arm; a second knife arm is fixed at the lower end of each second coat, and a triangular knife is respectively fixed on the left and right sides of the lower part of each second knife arm, and the lower end of each second knife arm A trapezoidal knife is fixed, a first knife arm is fixed at the lower end of each first coat, a triangular knife is respectively fixed on the left and right sides of the upper part of each first knife arm, and a trapezoidal knife is fixed at the lower end of each first knife arm.

Owner:刘玉秋

Implementation method of cement soil mixing stirring drilling machine

The invention provides an implementation method of a cement soil mixing stirring drilling machine. When the cement soil mixing stirring drilling machine works, a jack stretches out and draws back in a reciprocating mode to push and pull a fifth transverse arm through a third vertical arm in a reciprocating mode and push and pull a fourth transverse arm through a fourth vertical arm in a reciprocating mode, and thus a plurality of first knife arms as well as triangular knives on the first knife arms and trapezoid knives at the lower ends of the first knife arms are driven to swing front and back in a reciprocating mode with a transverse pipe being the axis; at the same time, a plurality of second knife arms as well as triangular knives on the second knife arms and trapezoid knives at the lower ends of the second knife arms are driven to swing back and front in a reciprocating mode with the transverse pipe being the axis; and meanwhile, high-pressure water enters a vertical pipe, enters the transverse pipe through a water pipe and is sprayed out through a plurality of nozzles on the lower part of the transverse pipe, the trapezoid knives at the lower ends of the first knife arms and the trapezoid knives at the lower ends of the second knife arms cut soil during relative swing, the triangular knives on the first knife arms and the triangular knives on the second knife arms stir the soil with water to form slurry during relative swing, the slurry flows out of rectangular holes, the downward drilling power is provided by the vertical pipe, and the rectangular holes are formed in the downward drilling process of the drilling machine.

Owner:刘玉秋

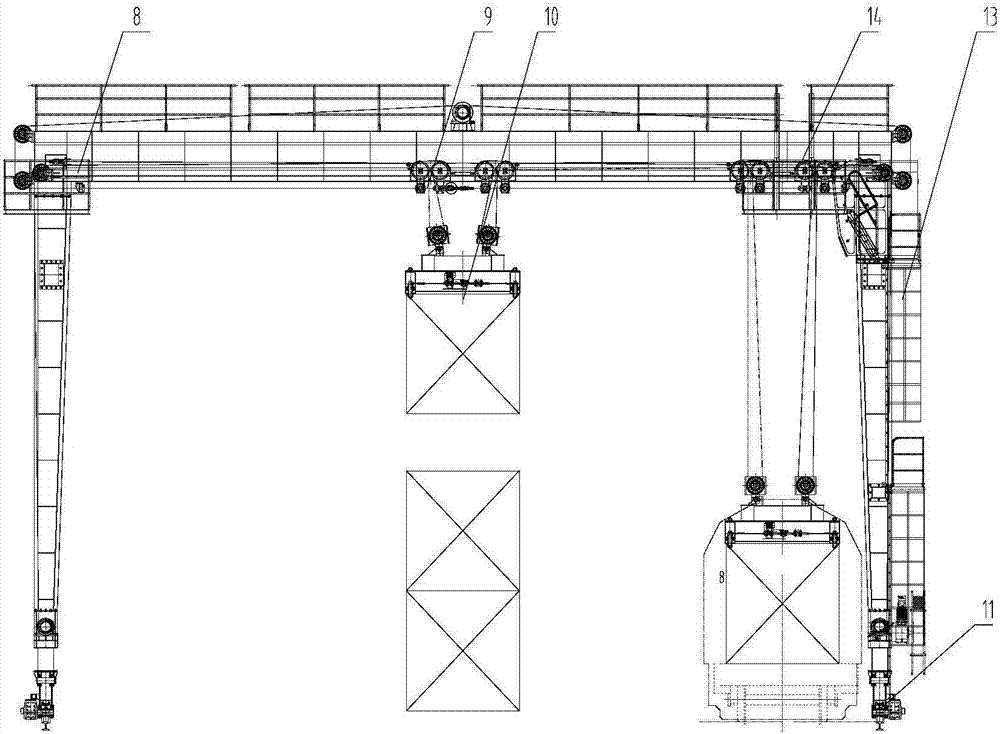

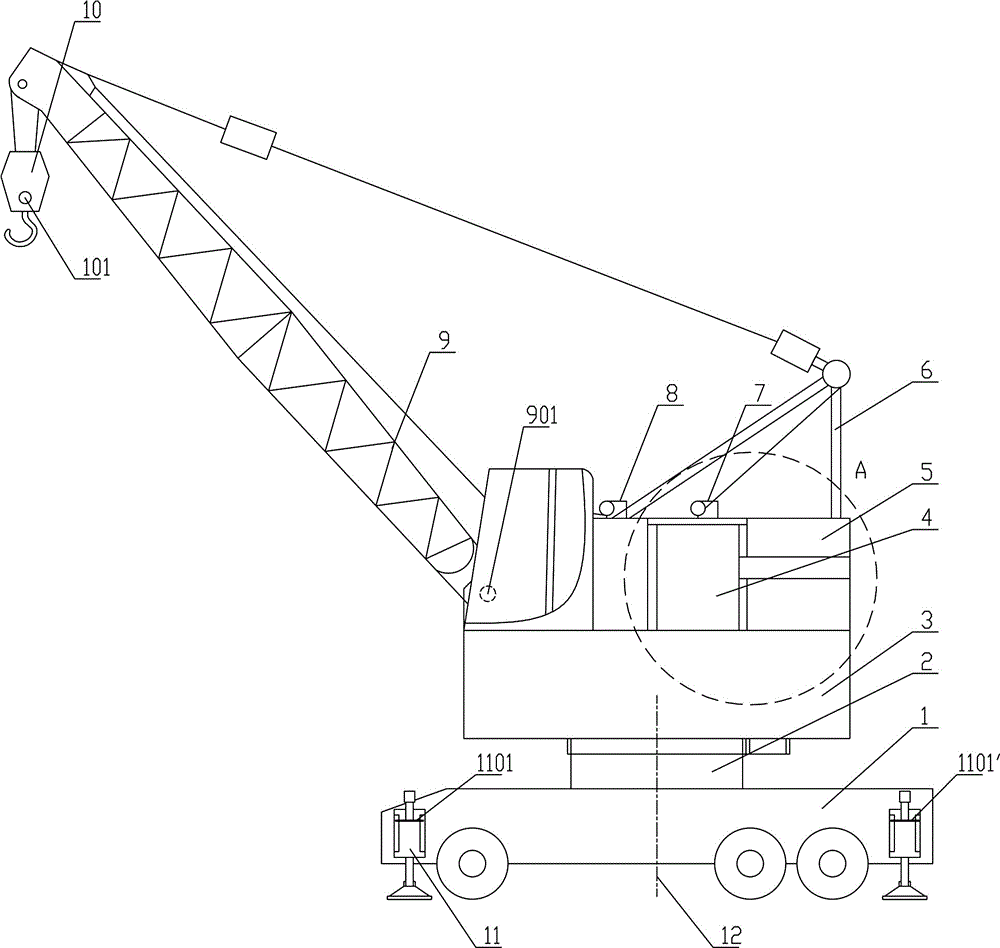

Counterweight control method of tire crane with movable counterweight system

ActiveCN105110190BRealize automatic controlMoment balanceLoad-engaging elementsAutomatic controlEngineering

Provided is a control method for a balance weight of a tire crane with a movable balance weight system. According to the method, a gravity sensor and a tilt angle sensor are detected, a tilt angle and a sling load are converted to moment, a movable balance weight device is started, and the rotation angle of the movable balance weight device is detected for feedback. By means of the steps, balance control over a movable balance weight of the tire crane is achieved. Alternatively, spiral landing legs are arranged at the four corners of a crane body, pressure sensors used for detecting pressure exerted on the spiral landing legs are arranged on the spiral landing legs, the difference values between the pressure sensors are compared, the movable balance weight device is started, and the rotation angle of the movable balance weight device is detected for feedback, and by means of the steps, balance control over the movable balance weight of the tire crane is achieved. According to the control method for the balance weight of the tire crane with the movable balance weight system, by the adoption of the steps, automatic control over the movable balance weight can be achieved, the movable balance weight can be matched with the moment of the sling load, moment balance is achieved, construction safety is ensured, and the service life of equipment is prolonged.

Owner:宜昌常丰港机制造有限公司

A Double Cantilever Construction Method for Extremely Asymmetric Composite Beams

ActiveCN104314013BAvoid damageReduce construction costsBridge erection/assemblyConcrete beamsCable stayed

The invention discloses a double suspension arm construction method of an ultra-asymmetry combined beam and relates to the field of cable-stayed bridge main girder construction. The construction method comprises the following steps of using the existing method to pour a first midspan steel beam, suspending and pulling a first sidespan stay cable and a first midspan stay cable, pouring a second midspan steel beam, manufacturing a template used for manufacturing a second sidespan concrete beam, installing a third midspan steel beam, suspending and pulling a third midspan stay cable, pouring half concrete at the top part of the template, pulling a second sidespan stay cable, pouring the other half concrete at the top part of the template until the line of the template reaches the calculating requirement, obtaining a second sidespan concrete beam, installing a steel beam bridge deck slab at the top part of the third midspan steel beam and pulling the third midspan stay cable. The difference between the constructed bridge line and the preset designed line is small, and the constructed beam is safer.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +2

balance car

The invention discloses a balance car which comprises a first pedal body and a second pedal body, wherein the first pedal body comprises a first frame body and a battery arranged on the first frame body; and the second pedal body is connected with the first pedal body, and comprises a second frame body and a control circuit module arranged on the second frame body. According the structure of the balance car, the distance between the battery and the control circuit module can be adjusted, so that the moments of the first pedal body and the second pedal body can be adjusted by adjusting the distance between the battery and the control circuit module. Accordingly, the moment balance between the first pedal body and the second pedal body can be maintained, and the size of the balance car can be reduced.

Owner:常熟东南高新技术创业服务有限公司

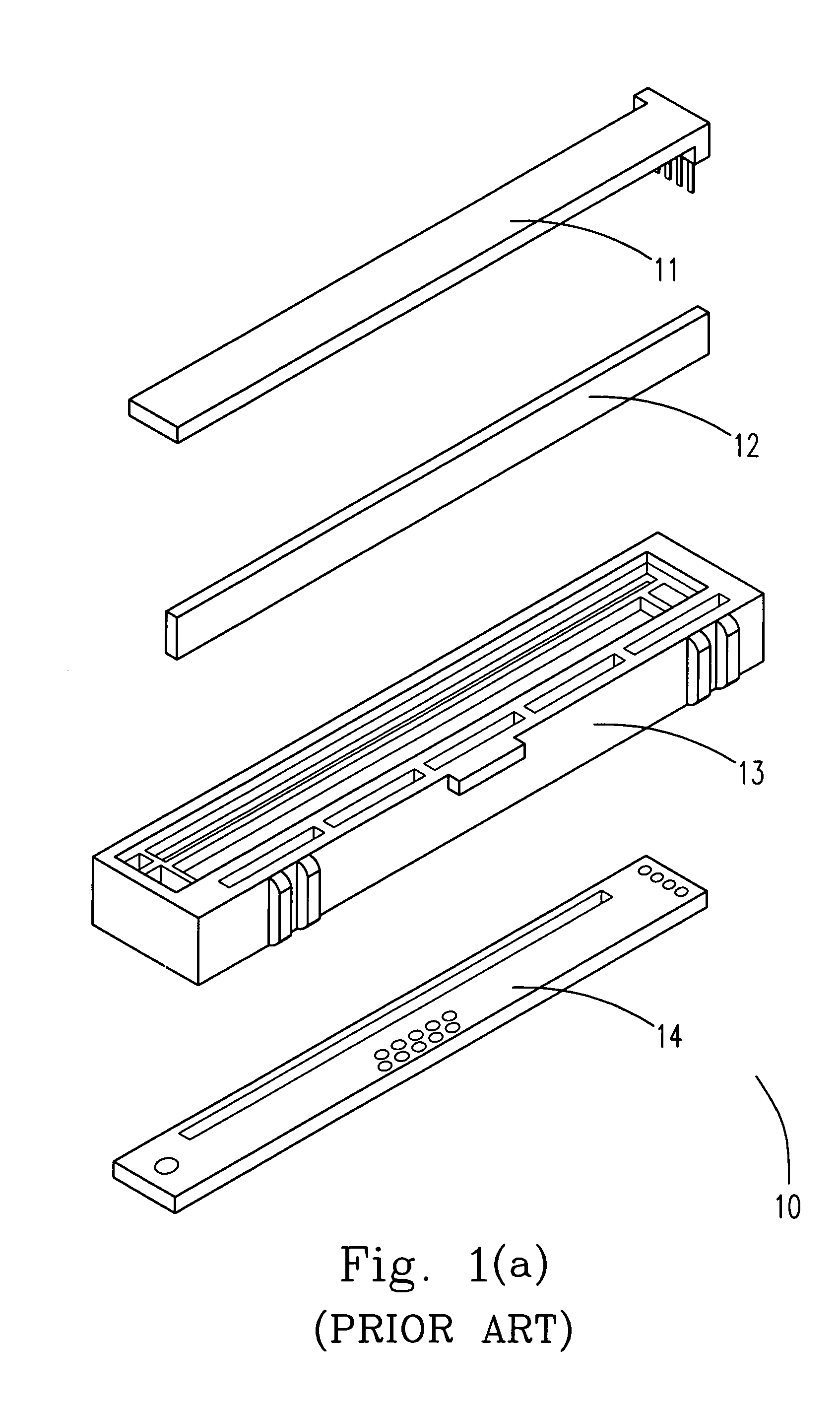

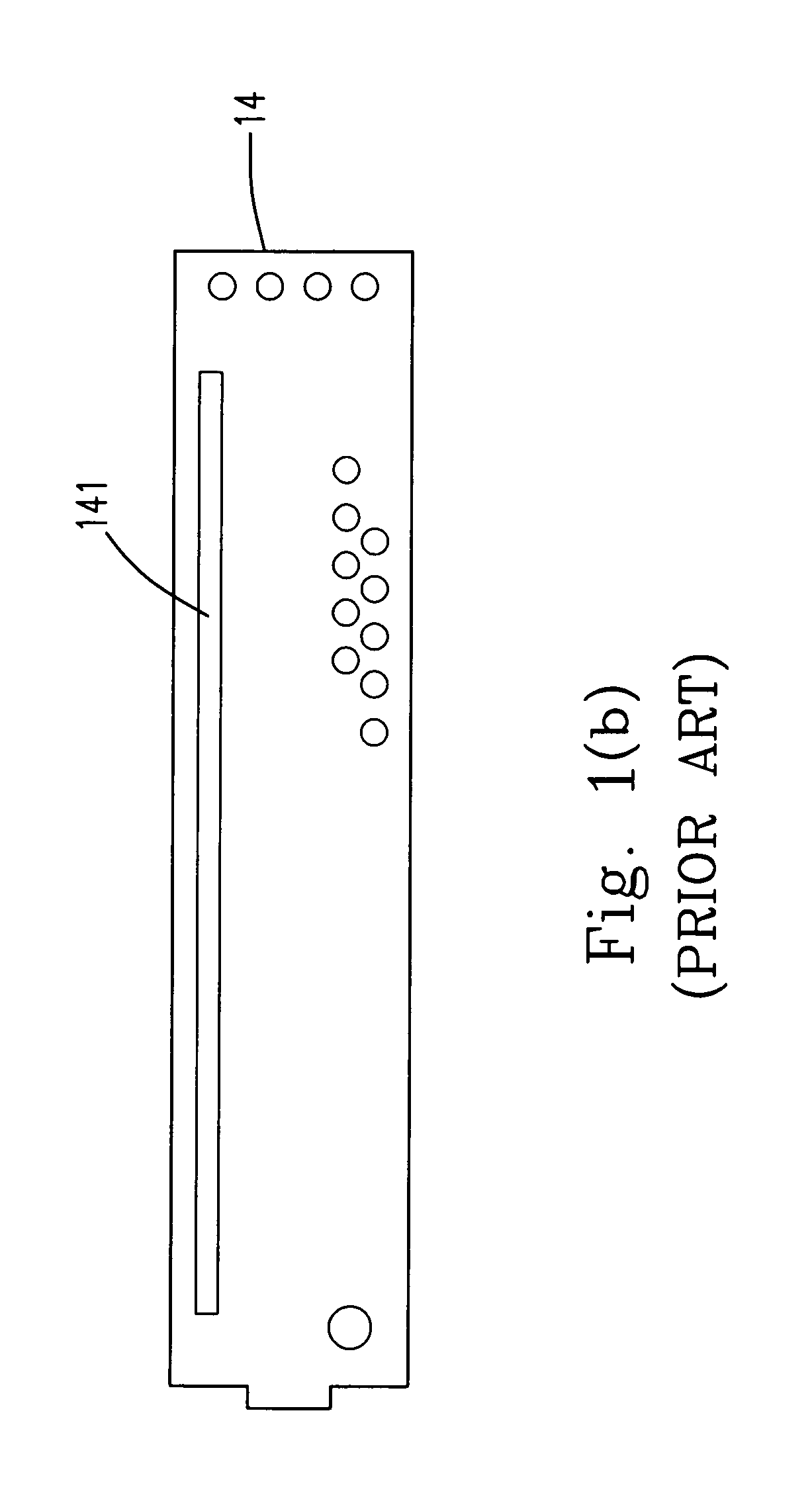

Structure and method for fixing lens of optical module

InactiveUS6965485B2Torque on lens is balancedImprove image qualityCoupling light guidesMountingsCamera lensOptical Module

A lens fixing structure for an optical module of a scanner, a multi-function printer, a fax machine or a copy machine is disclosed. The lens fixing structure for an optical module of a scanner, a multi-function printer, a fax machine or a copy machine, wherein the optical module has a housing, and the lens fixing structure is installed on the housing, includes a slot structure for placing and fixing a lens therein, wherein the slot structure includes a first slot wall positioned on the housing; and a second slot wall positioned on the housing and being parallel to the first slot wall, wherein the second slot wall is perpendicular to a surface of the housing.

Owner:CREATIVE SENSOR INC

Heavy reducer supporting body

InactiveCN105673819AImprove transmission efficiencyMoment balanceShaftsGearing detailsDrive shaftEngineering

The invention relates to a heavy reducer supporting body which comprises a shell and a drive shaft. A gear I is arranged at one end of the drive shaft, a gear II is arranged at the other end of the drive shaft, and the gear I and the drive shaft are connected into an integral structure; the gear II and the drive shaft are connected and fixed through key pins. A bearing I is arranged on the inner side of the gear I, and a bearing II is arranged on the inner side of the gear II. An oil seal I is arranged on the inner side of the bearing I, and a lock washer and a cap are sequentially arranged on the outer side of the bearing I. A bearing cap is arranged on the outer side of the bearing II, an oil seal II is arranged between the bearing cap and the bearing II, and the gear II and the drive shaft are connected and fixed through three key pins which are evenly distributed on the outer circumference of the drive shaft. Compared with the prior art, the shaft end of the drive shaft is directly provided with the corresponding gear to form the integral structure, and the other end of the drive shaft and the corresponding gear are connected and fixed through the three evenly distributed key pins, so that the drive efficiency of the whole supporting body is improved, and transmitted torque is more balanced and stable; the heavy reducer supporting body is suitable for a large or heavy reducer.

Owner:彭芹

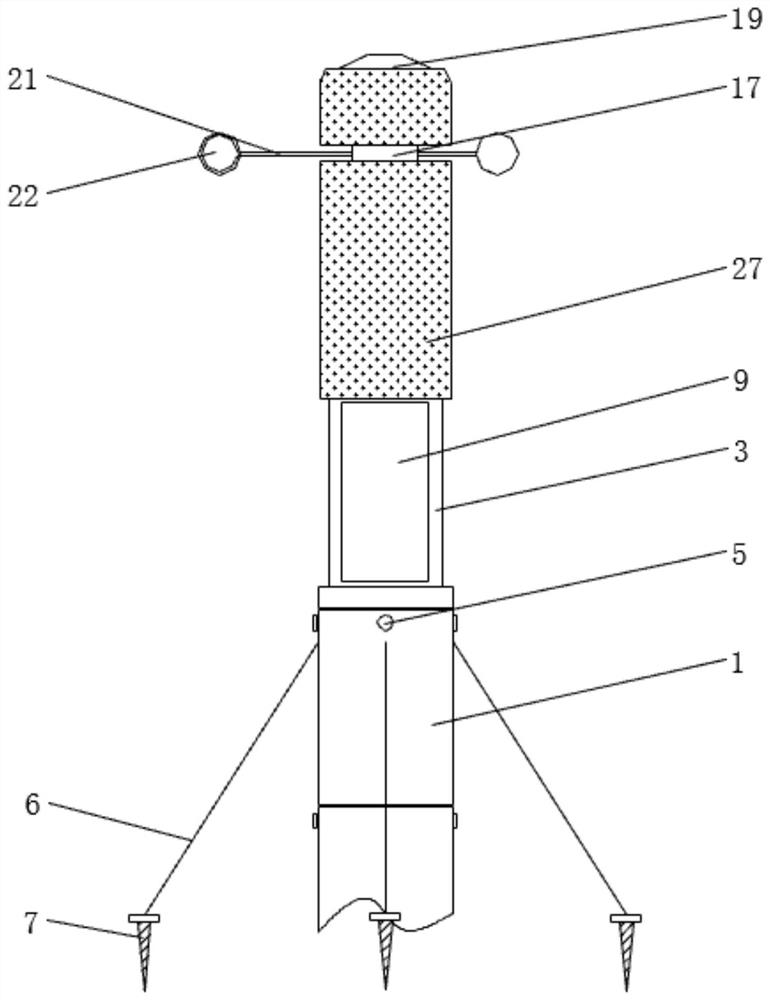

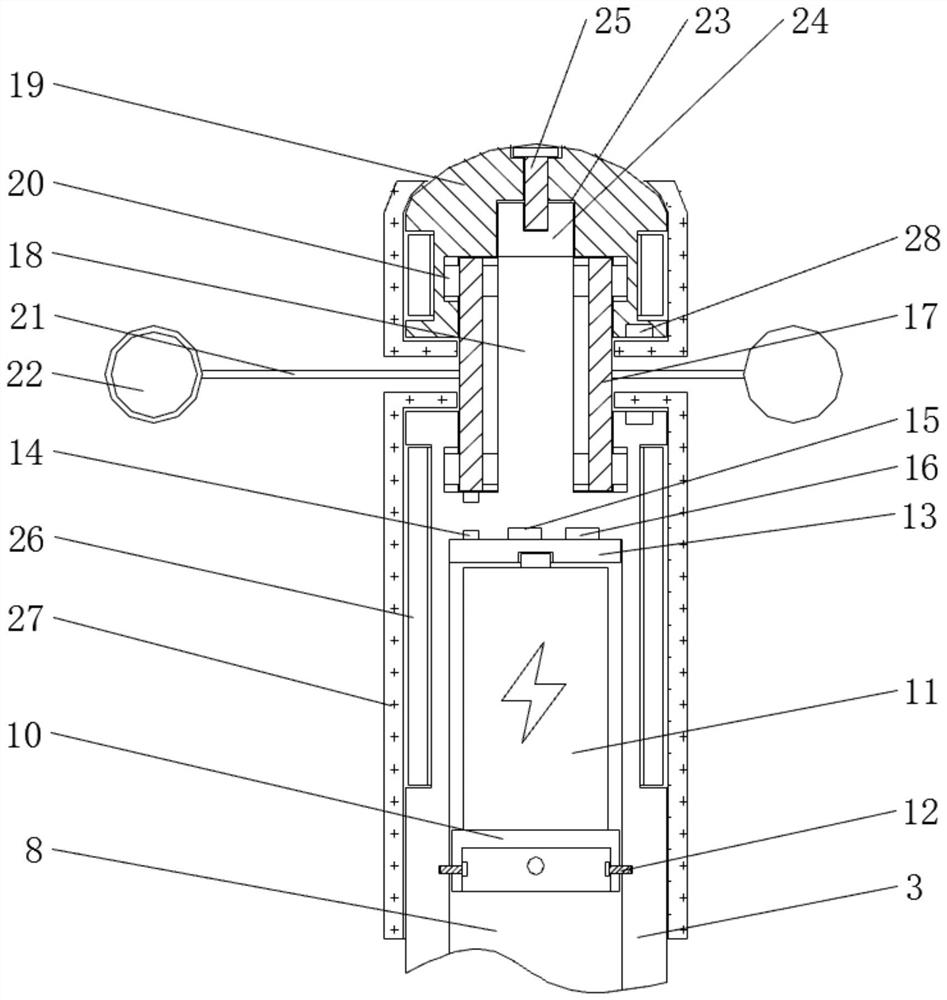

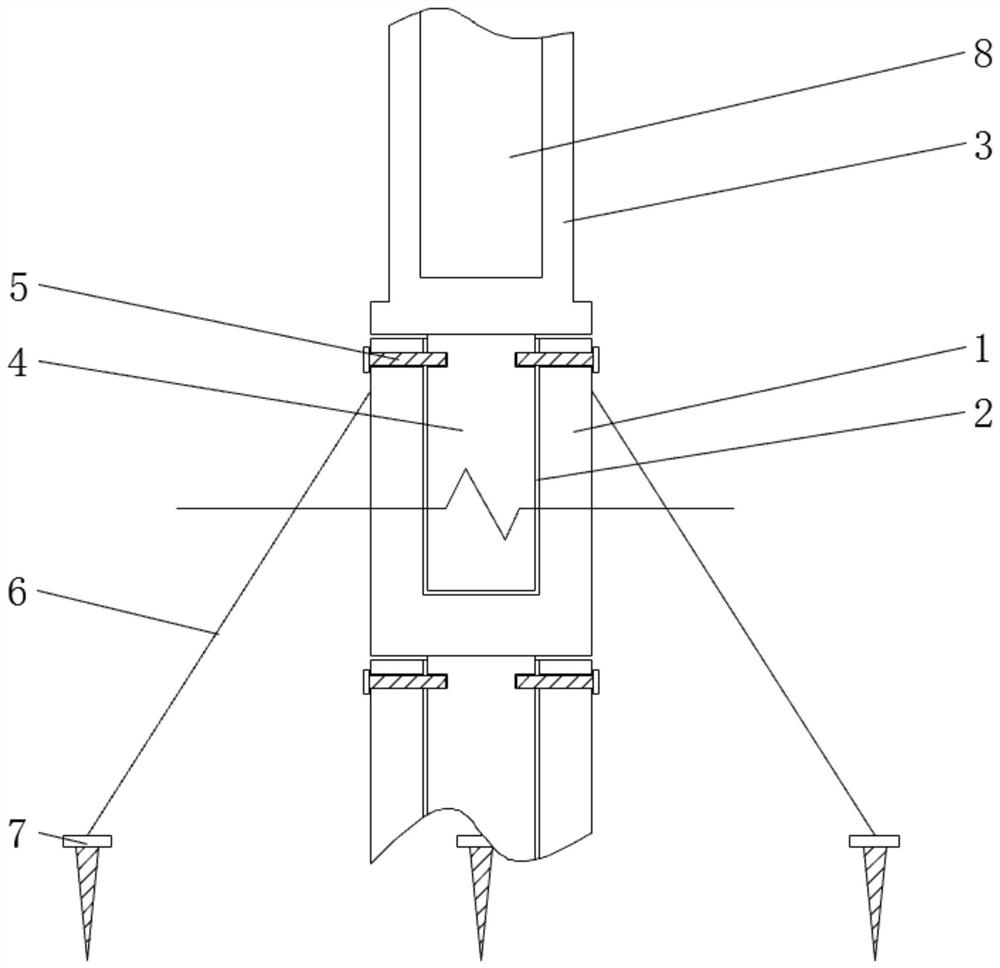

Multifunctional anemograph

The invention discloses a multifunctional anemograph which comprises connecting sleeves, first bolts, a battery jar, a second bolt, a rotating piece, a limiting hole and a third bolt, a connecting hole is formed in the top of each connecting sleeve; and a fixed case is arranged above the connecting sleeve on the uppermost side, connecting columns are fixed to the bottom of the fixed case and the bottoms of the connecting sleeves, the fixed case and the connecting sleeve on the uppermost side are connected through the connecting columns, every two adjacent connecting sleeves are connected through the connecting columns, and the first bolts penetrate through the connecting sleeves to be in threaded connection with the connecting columns. The multifunctional anemograph is provided with a movable case and a center shaft; a rotating piece is rotationally connected with the outer side of the center shaft through a ball bearing; meanwhile, the rotating piece is rotationally connected with thefixed case and the movable case through other ball bearings, so that the upper side and the lower side of the rotating piece are supported at the same time, the moment of force of the rotating pieceis kept balanced, vibration of the rotating piece during high-speed rotation is reduced, and the measurement accuracy of the anemograph is improved.

Owner:江苏鸿渐投资咨询管理有限公司

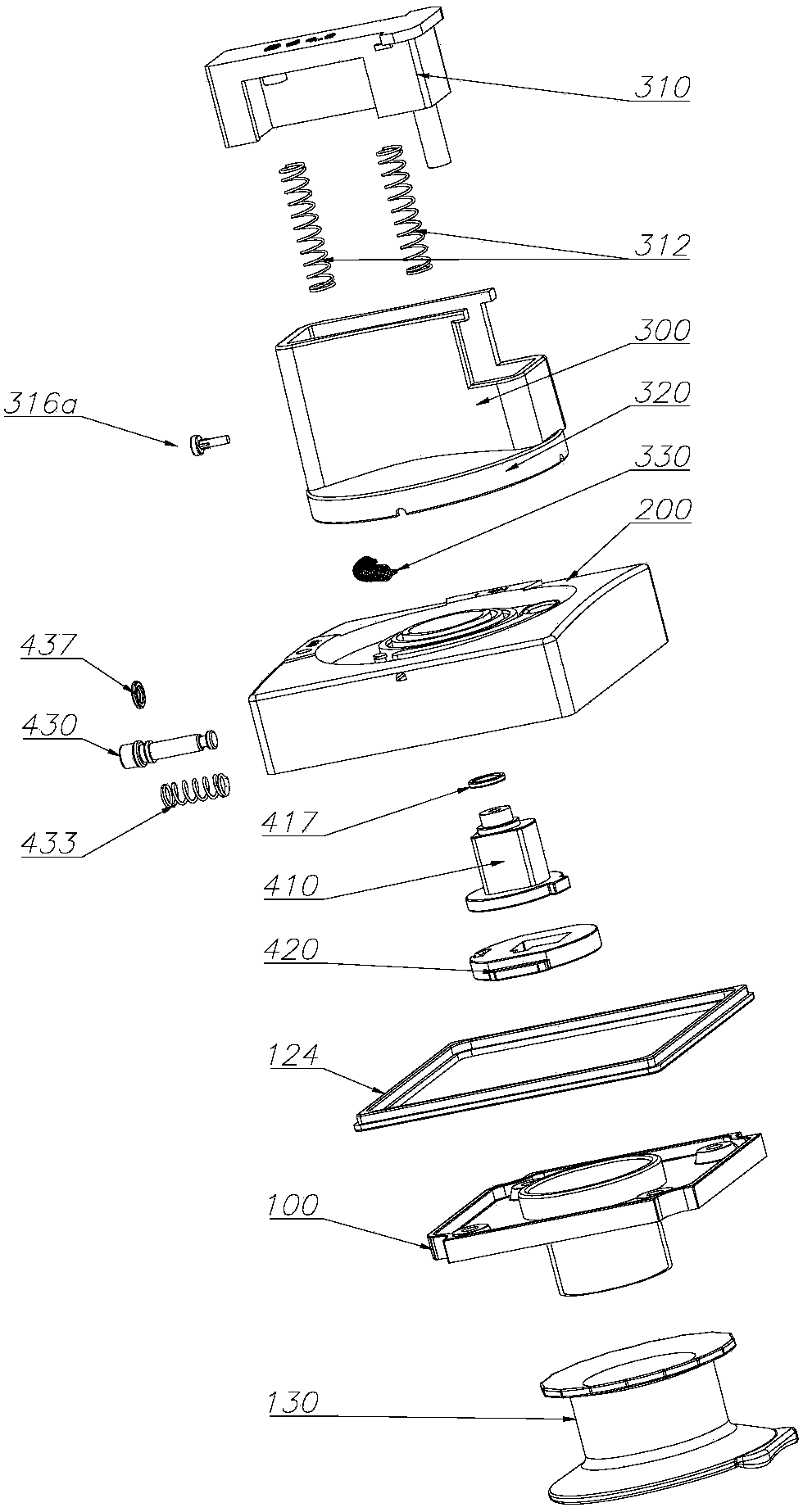

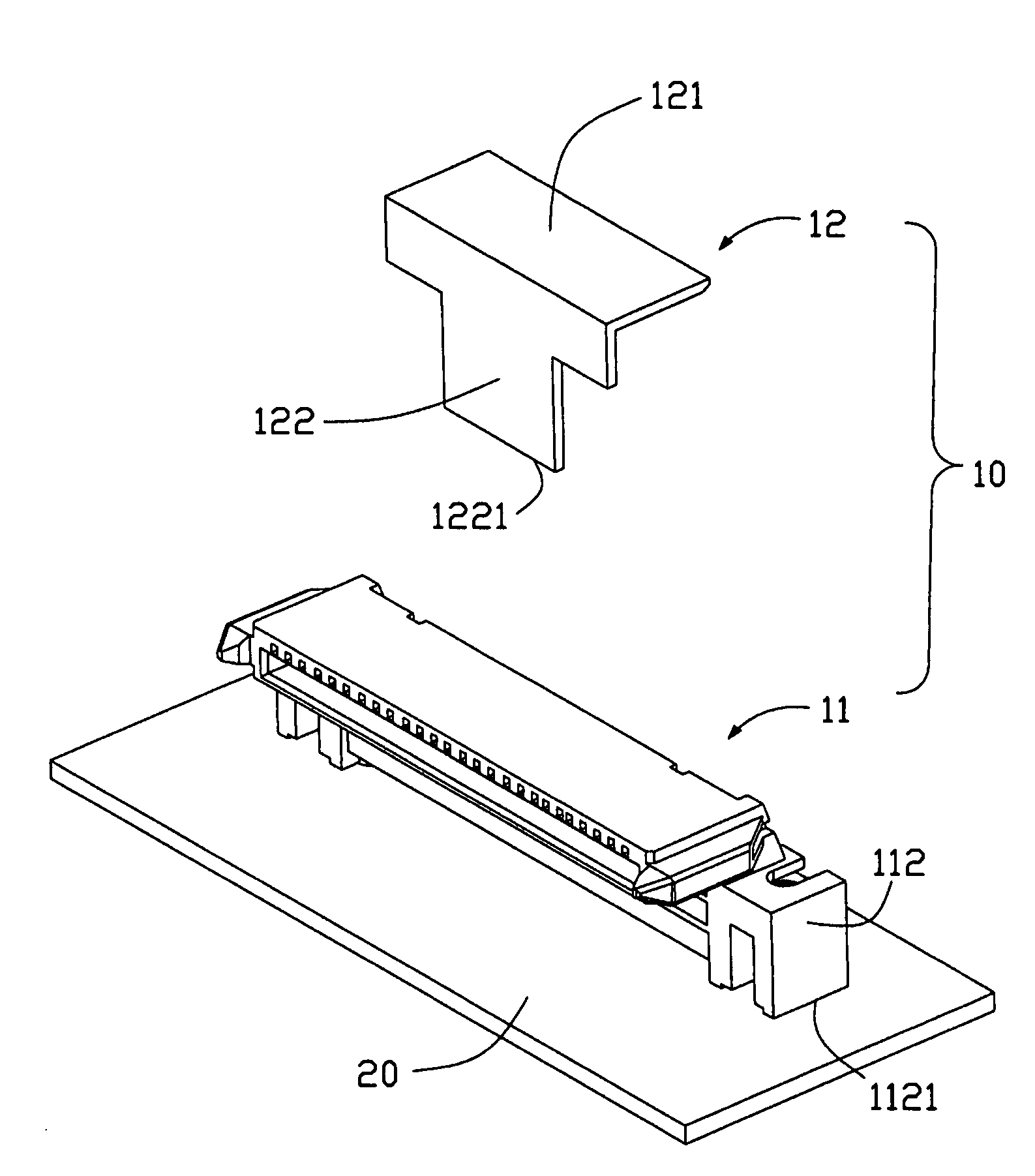

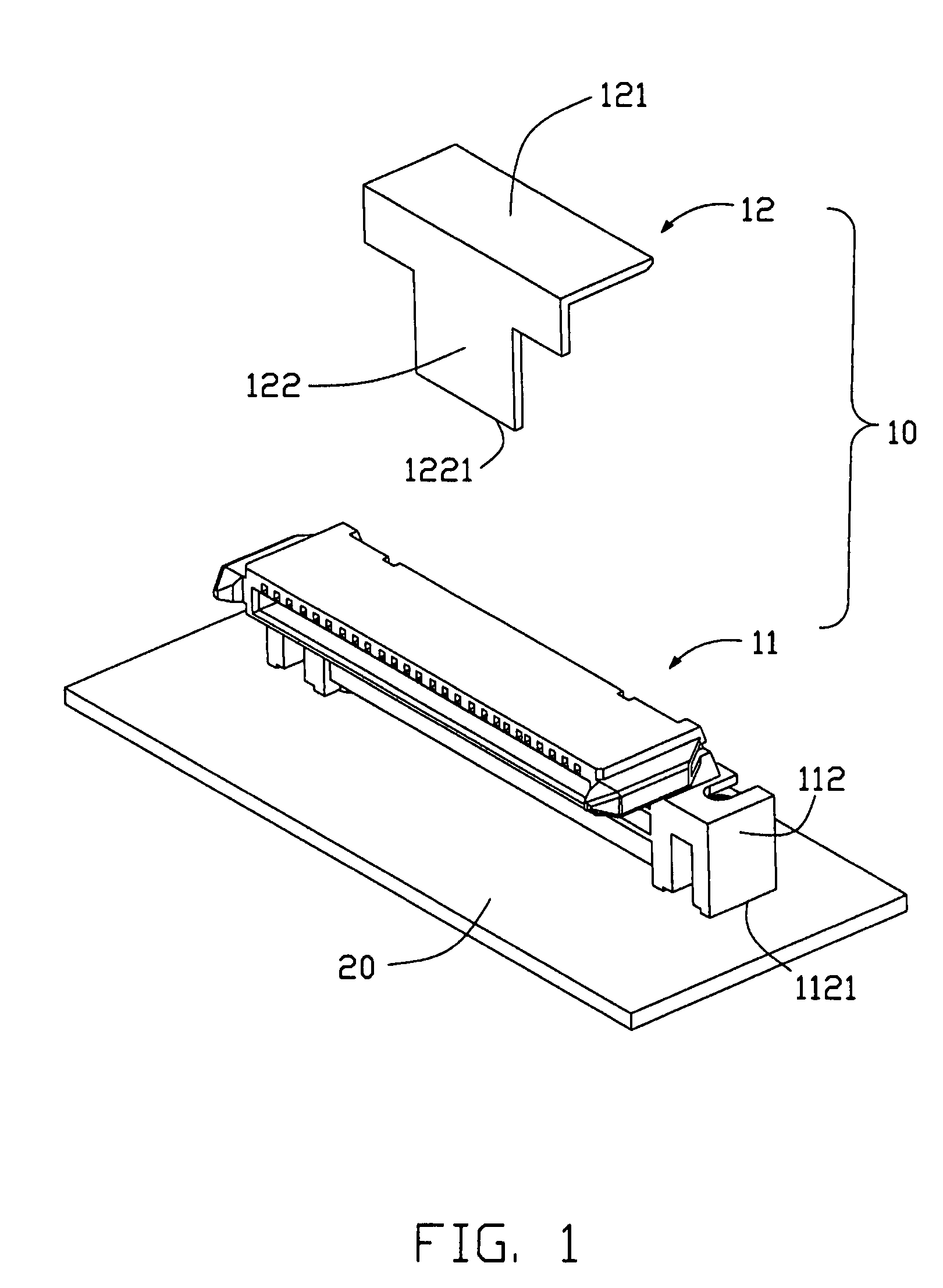

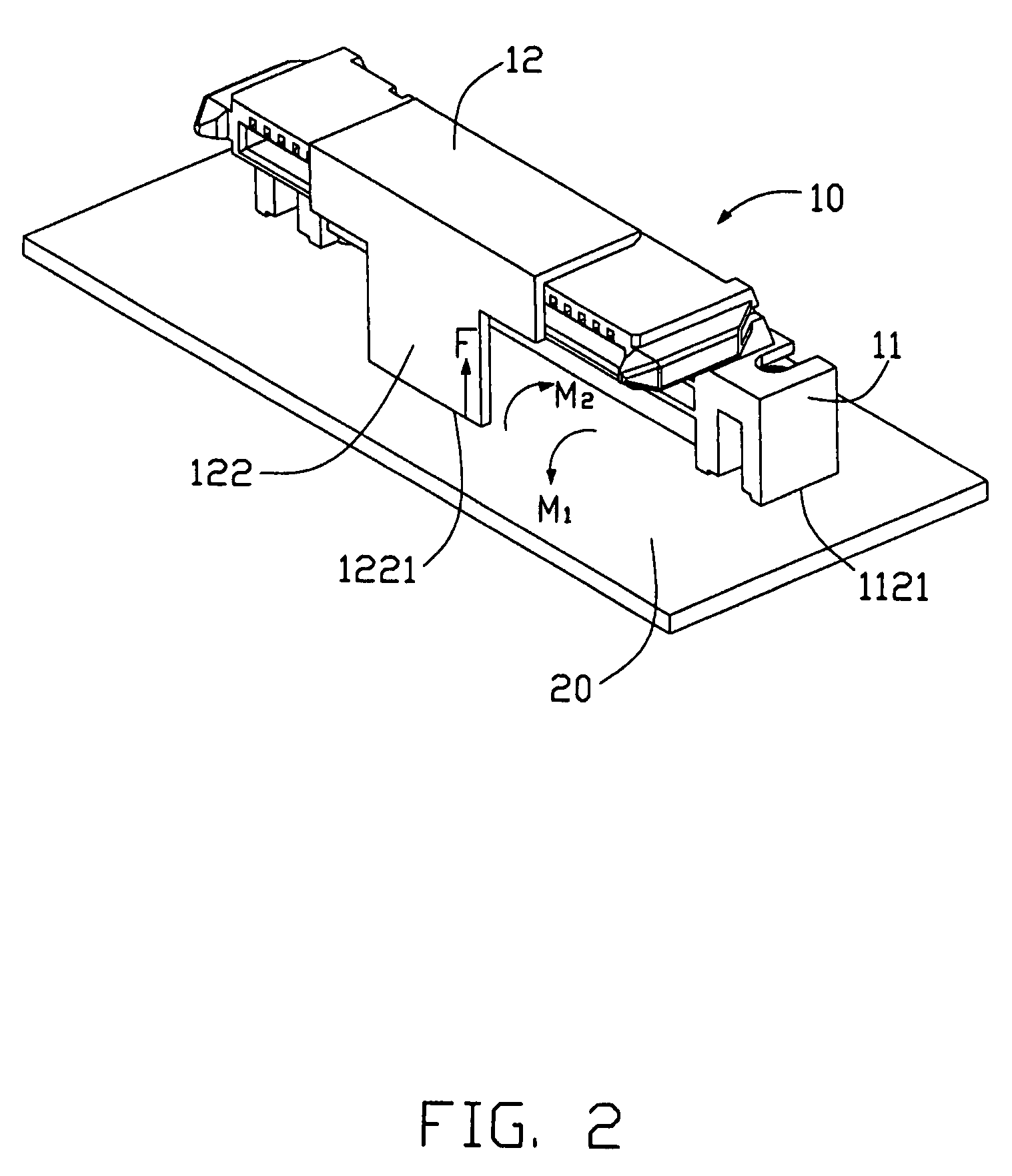

Electrical connector assembly with pick up device

InactiveUS7467957B2Moment balanceLine/current collector detailsLive contact access preventionEngineeringElectrical connector

An electrical connector assembly includes an electrical connector unit (11) to be mounted onto a printed circuit board (11), a supporting member for supporting the electrical connector unit, and a pick up device (12) attachable onto the electrical connector unit. The supporting member includes a supporting portion (112) extending from one side of the electrical connector unit, with the supporting portion defining a supporting surface (1121) resting on the printed circuit board. The pick up device includes a balance section (122) defining a balance surface (1221) extending parallel to the supporting surface such that when the pick up device is attached onto the printed circuit board, the balance surface of the pick up device is operable to be rested on the printed circuit board so as to counterbalance force torque caused by introduce of the supporting portion.

Owner:HON HAI PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com