Piston dismounting machine of oil cylinder seal head

A technology for dismantling machines and heads, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve problems such as uneven force application, increased maintenance costs, and stuck driving gears, so as to prevent thread jamming and structure Reasonable design and long service life of equipment

Active Publication Date: 2011-01-05

SINOPEC TENTH CONSTR

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the maintenance process of special construction machinery, it is difficult to disassemble and install seals such as cylinder heads and piston seals. The current method used is manual disassembly and installation. In the case of adhesion, etc., you can only use a torsion bar to increase the torque, or use a sledgehammer to smash, but due to uneven force, the effect is not ideal, and it is easy to damage the equipment and increase maintenance costs

In order to solve the above problems, those skilled in the art have designed a disassembly machine driven by a hydraulic device, which is used to disassemble and assemble workpieces that are threaded such as cylinder heads, but the transmission parts of this type of machine cannot provide balanced torque. In the case of high resistance, it is easy to jam the drive gear and damage the equipment, and this type of equipment can only provide rotational torque, and cannot disassemble the piston and other interference-fit workpieces

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

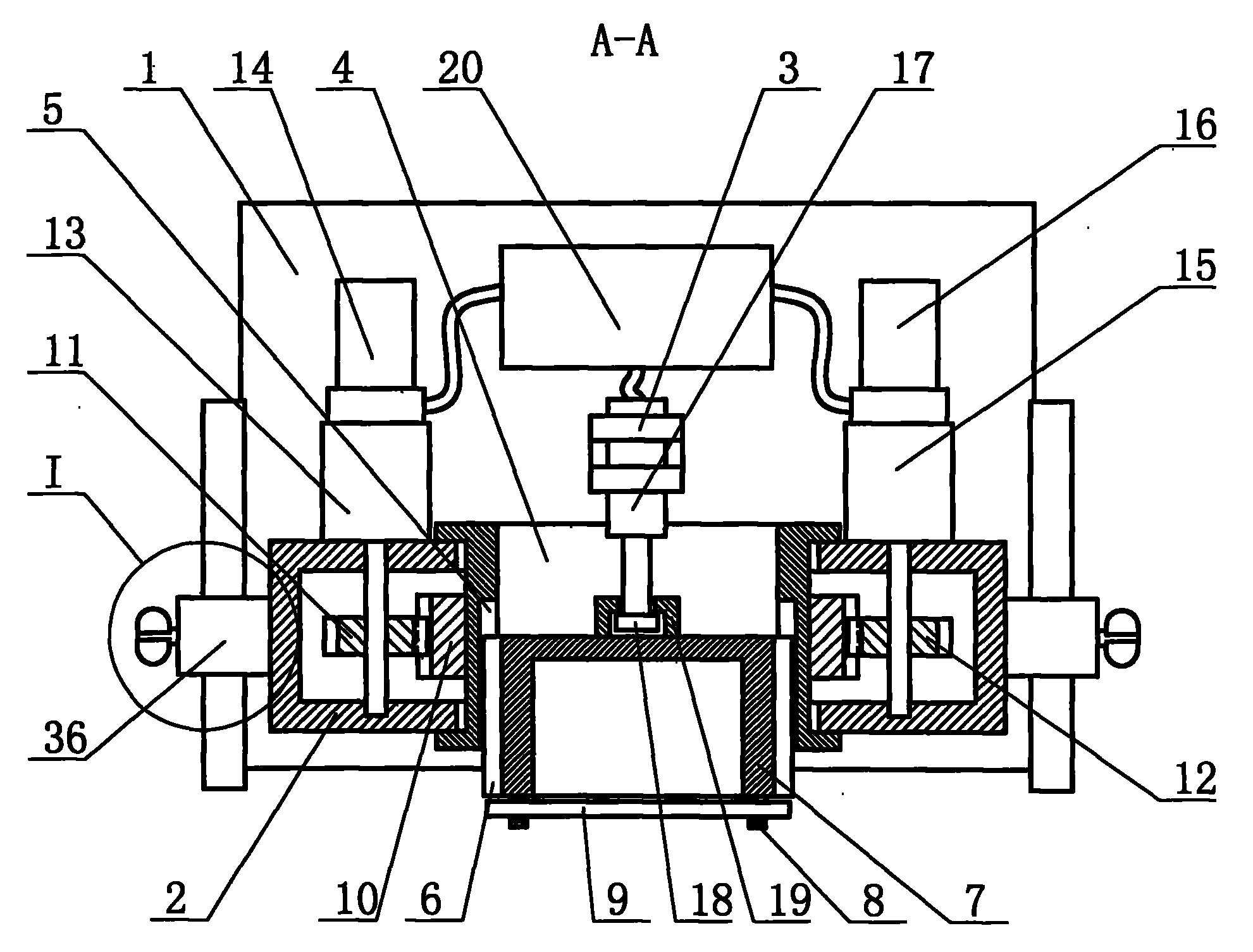

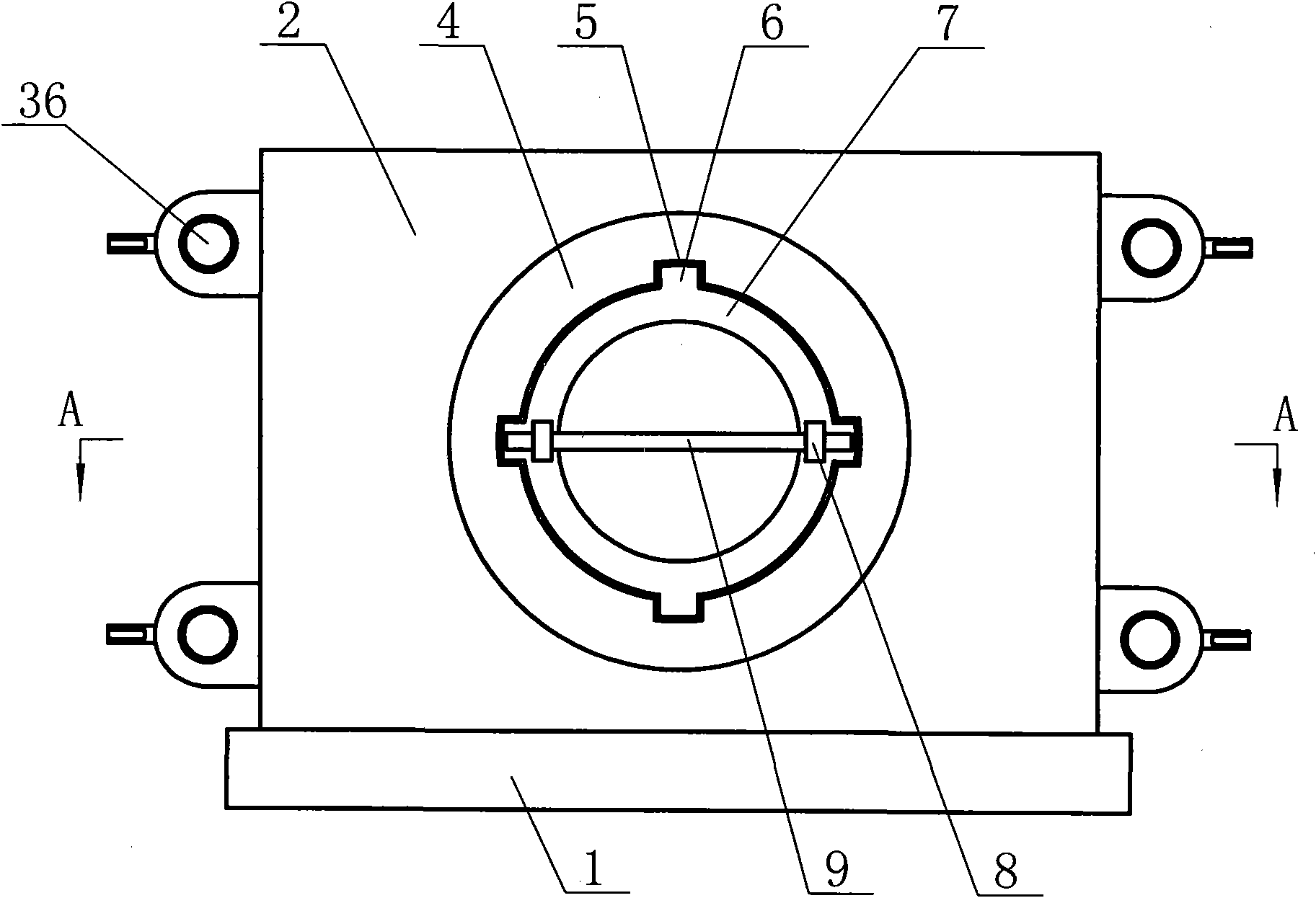

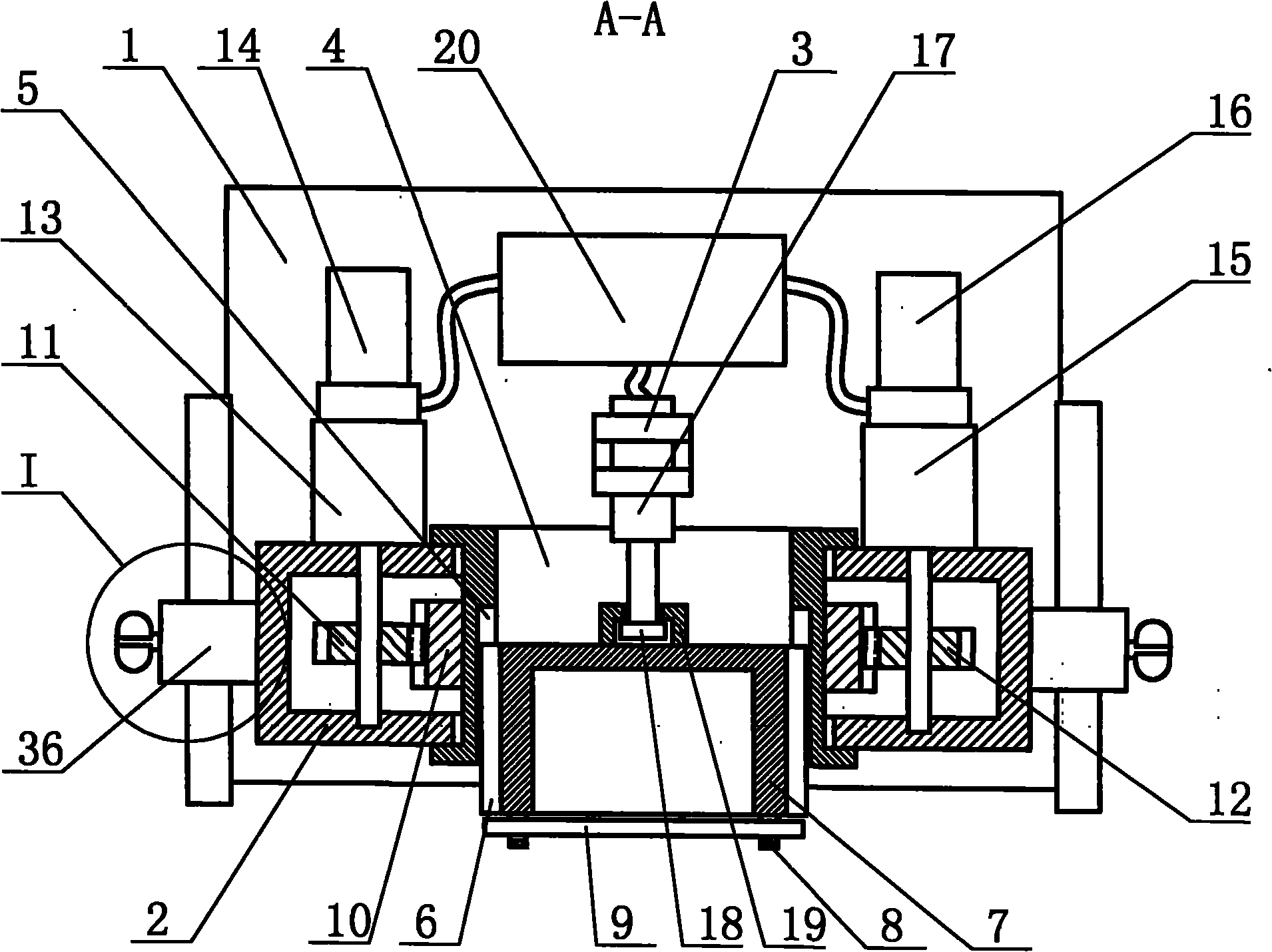

The invention provides a piston dismounting machine of an oil cylinder seal head, comprising a base. The base is provided with a machine shell and a support base; four groups of support devices are mounted on the edge of the machine shell; a rotor drum is mounted in the centre of the machine shell; an inner wall of the rotor drum is provided with a chute which is internally provided with a slide block; the slide block is connected with a rotor which is provided with a suspension ring; the suspension ring is internally provided with a torque lever; the outer wall of the rotor drum is provided with gear rings which are respectively engaged with two groups of transmission gears; the support base is provided with a hydraulic cylinder; an the end part of a push rod of the hydraulic cylinder isprovided with a bulge loop which is mounted in a positioning base; the positioning base is connected with the rotor; and a first hydraulic motor, a second hydraulic motor and the hydraulic cylinder are all connected with a hydraulic device. The transmission member can provide balanced moment without clamping gears, can apply stable torque force to the torque lever to effectively prevent deadlocking of screws and can provide stable pull force or push force without damaging workpieces; the height of the four groups of support devices can be separately regulated, and the devices with irregular surface also can be dismounted.

Description

Oil cylinder head piston disassembly machine technical field The invention relates to an installation and disassembly device, in particular to an oil cylinder head piston disassembly machine. Background technique In the maintenance process of special construction machinery, it is difficult to disassemble and install seals such as cylinder heads and piston seals. The current method used is manual disassembly and installation. In the case of adhesion, you can only use a torsion bar to increase the torque, or use a sledgehammer to smash, but due to uneven force, the effect is not ideal, and it is easy to damage the equipment and increase maintenance costs. In order to solve the above problems, those skilled in the art have designed a disassembly machine driven by a hydraulic device, which is used to disassemble and assemble workpieces that are threaded such as cylinder heads, but the transmission parts of this type of machine cannot provide balanced torque. In the case of hi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P19/04

Inventor 刘玉宝张东梅马寅董雪玮

Owner SINOPEC TENTH CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com