Crimping elastic sheet of single buffer channel

A single buffer and shrapnel technology, which is applied in the field of crimping shrapnel, can solve problems such as poor conductivity and large probe impedance, and achieve the effects of convenient manufacturing, increased area, and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

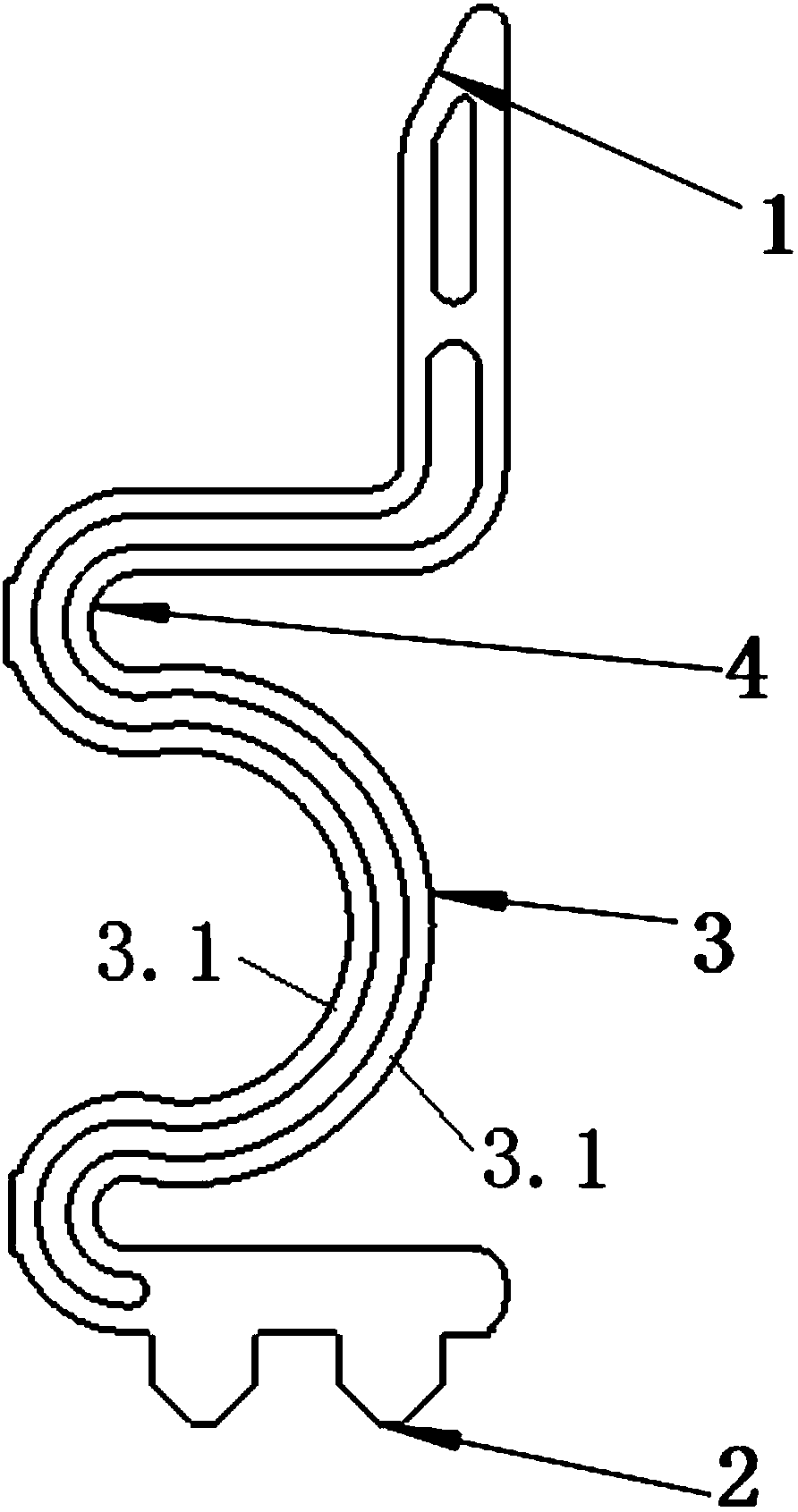

[0032] The crimping spring is a flat plate structure, which includes the first metal transfer part 1 for connecting the product connector, the second metal transfer part 2 for connecting the FPC, and the first metal transfer part 1 and the second metal transfer part 2. The metal bending part 3 between the metal transfer parts 2, the first metal transfer part 1, the second metal transfer part 2 and the metal bending part 3 are integrally formed, the first metal transfer part 1 and the second metal transfer part Probe heads are provided on the connection part 2, and the metal bending part 3 is composed of two metal conduction strips 3.1 arranged in parallel and spaced apart. Each metal conduction strip 3.1 is made of a material that can conduct electricity and can be elastically deformed. The metal conduction strip 3.1 is C-shaped, the width of the probe head / 4≤the width of each metal conduction strip 3.1≤the width / 3 of the probe head, and the two ends of each metal conduction st...

Embodiment approach 2

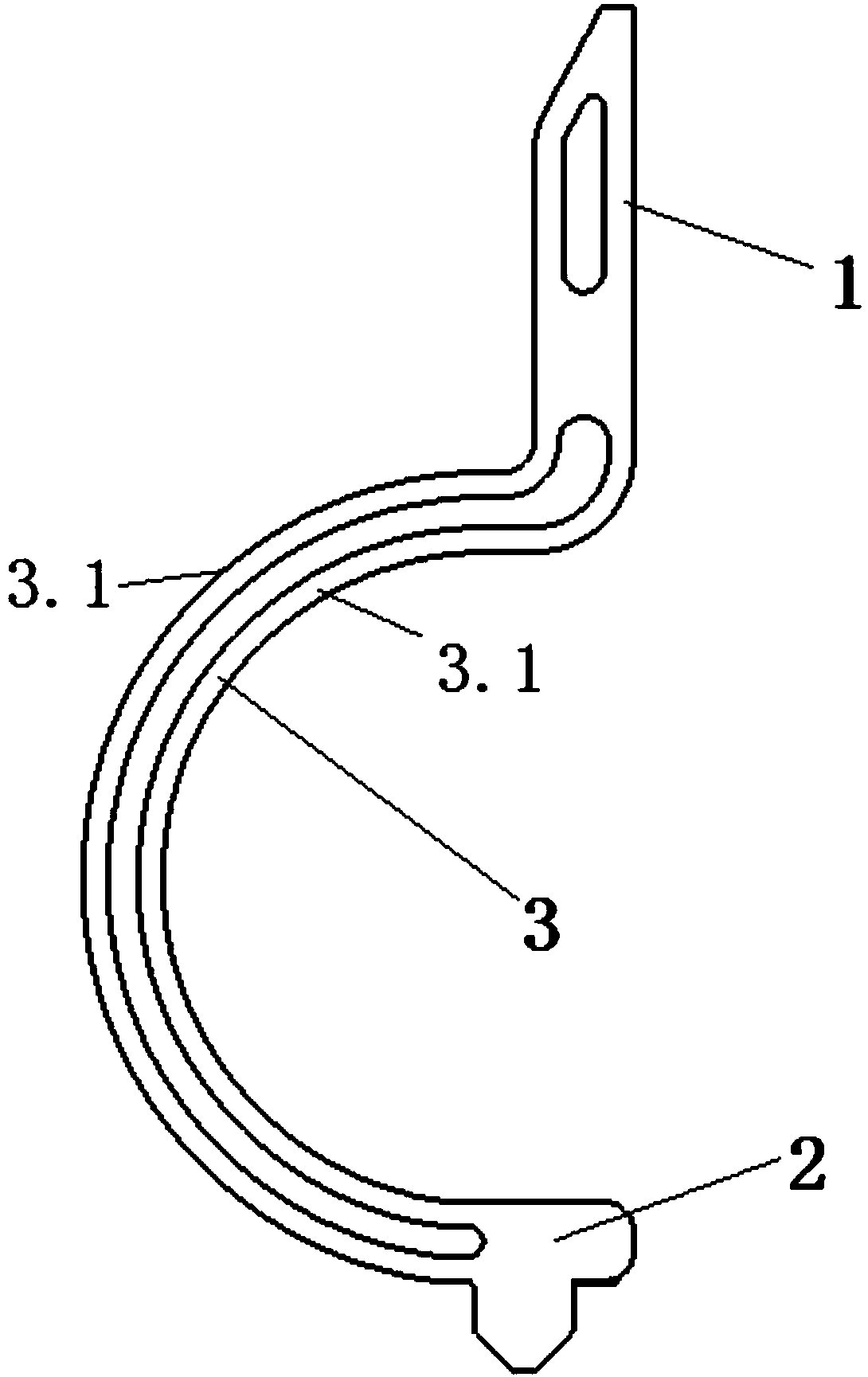

[0034] The crimping spring is a flat plate structure, which includes the first metal transfer part 1 for connecting the product connector, the second metal transfer part 2 for connecting the FPC, and the first metal transfer part 1 and the second metal transfer part 2. The metal bending part 3 between the metal transfer parts 2, the first metal transfer part 1, the second metal transfer part 2 and the metal bending part 3 are integrally formed, the first metal transfer part 1 and the second metal transfer part Probe heads are provided on the connection part 2, and the metal bending part 3 is composed of two metal conduction strips 3.1 arranged in parallel and spaced apart. Each metal conduction strip 3.1 is made of a material that can conduct electricity and can be elastically deformed. The metal conduction strips 3.1 are C-shaped, and the width of the probe head / 4≤the width of each metal conduction strip 3.1≤the width of the probe head / 3. Compared with Embodiment 1, although ...

Embodiment approach 3

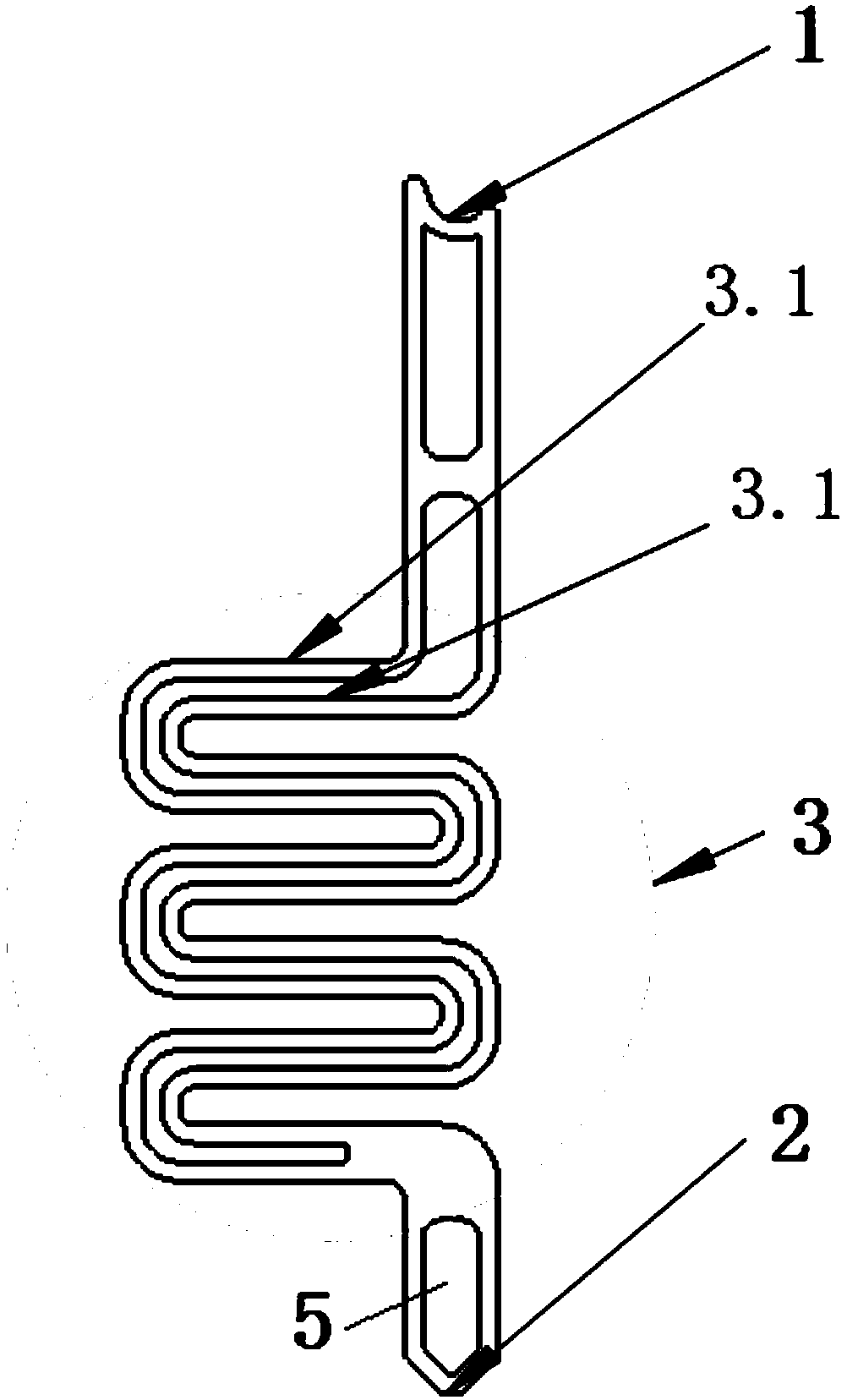

[0036] The crimping spring is a flat plate structure, which includes the first metal transfer part 1 for connecting the product connector, the second metal transfer part 2 for connecting the FPC, and the first metal transfer part 1 and the second metal transfer part 2. The metal bending part 3 between the metal transfer parts 2, the first metal transfer part 1, the second metal transfer part 2 and the metal bending part 3 are integrally formed, the first metal transfer part 1 and the second metal transfer part Probe heads are provided on the connection part 2, and the metal bending part 3 is composed of two metal conduction strips 3.1 arranged in parallel and spaced apart. Each metal conduction strip 3.1 is made of a material that can conduct electricity and can be elastically deformed. The metal conduction strips 3.1 are multi-S-shaped, and the width of the probe head / 4≤the width of each metal conduction strip 3.1≤the width of the probe head / 3. The probe head on the second me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com