Continuous stirring drilling machine

A technology of mixing drilling rig and mixing knife, which is applied in the direction of construction, sheet pile wall, foundation structure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

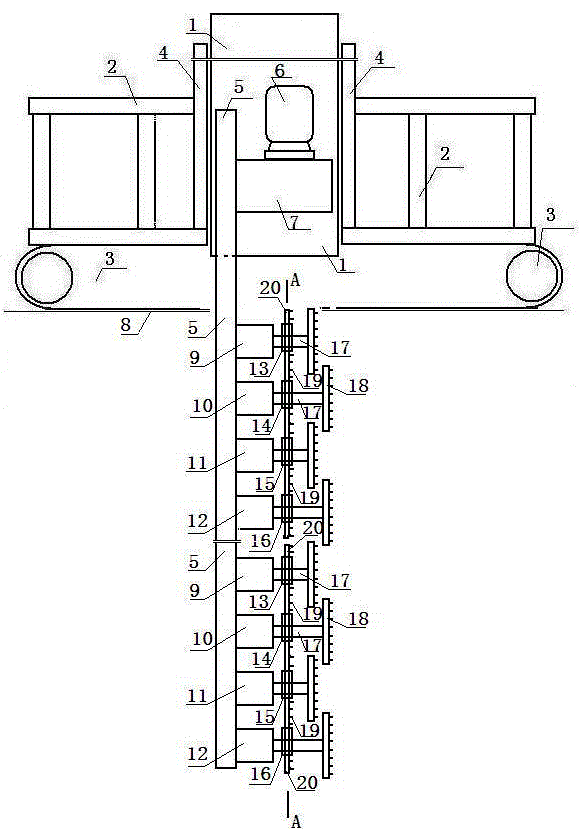

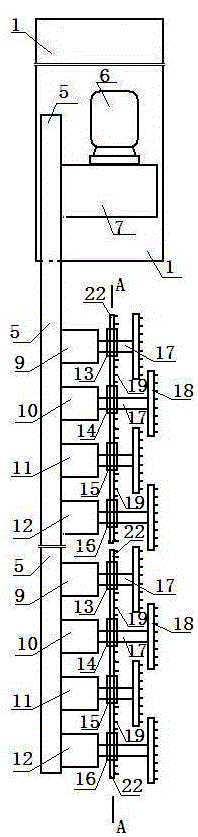

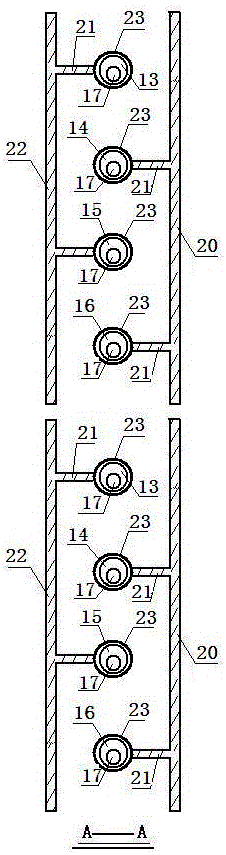

[0013] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment comprises the gantry main frame 2 that supports, the guide column 1 that lifts and lowers guiding use and the crawler belt walking part 3 that moves; Column, the active box 7 is fixed on the right end of the upper part of the power transmission tube, the upper part of the active box is installed with a motor 6, and the left part of the power transmission tube 5 is arranged in sequence from top to bottom. Force tube, the right end of each transfer case is respectively provided with a transfer shaft 17, and the right end of each transfer shaft is respectively provided with a cutting head 18; multiple transfer cases form a group of four from top to bottom, The first one is transfer case one 9, and transfer disc one 13 is installed eccentrically on the transfer shaft at the right end of transfer case one; the second one is transfer case two 10, and the transfer shaft at the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com