Counterweight control method of tire crane with movable counterweight system

A technology of movable counterweight and control method, which is applied in the field of tire cranes, can solve problems such as potential safety hazards and increased counterweight, and achieve the effects of prolonging service life, ensuring construction safety, and realizing moment balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

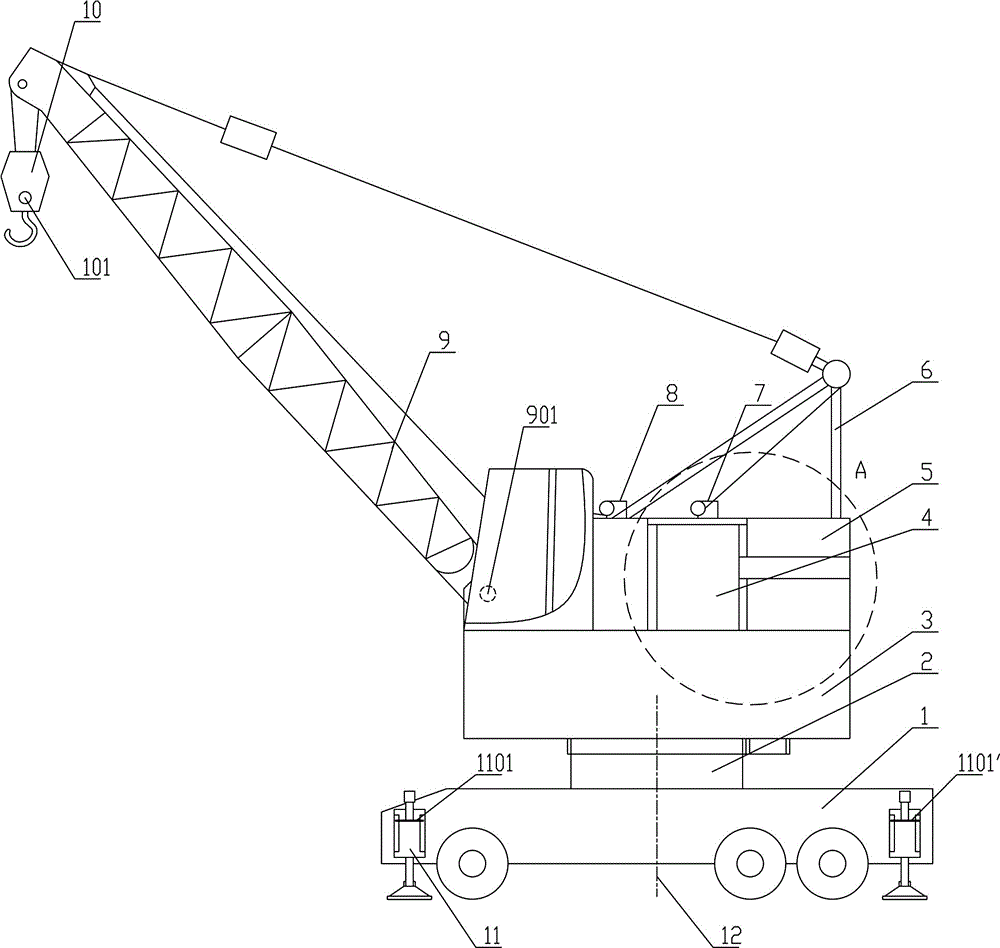

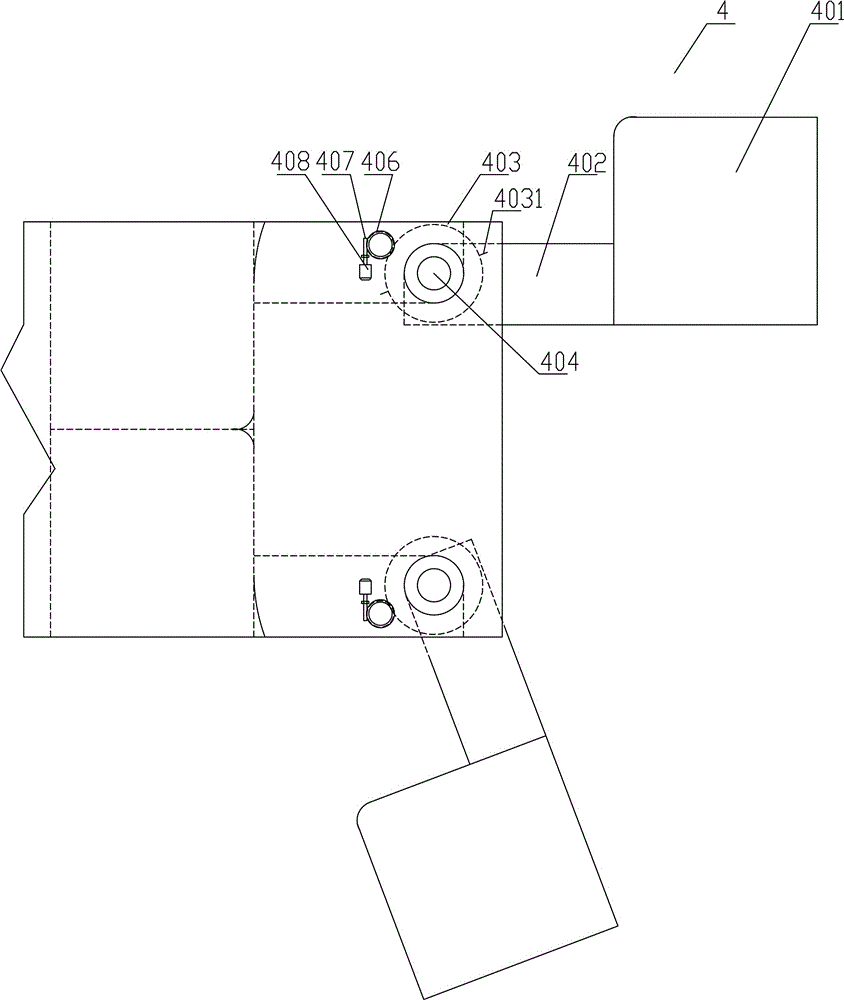

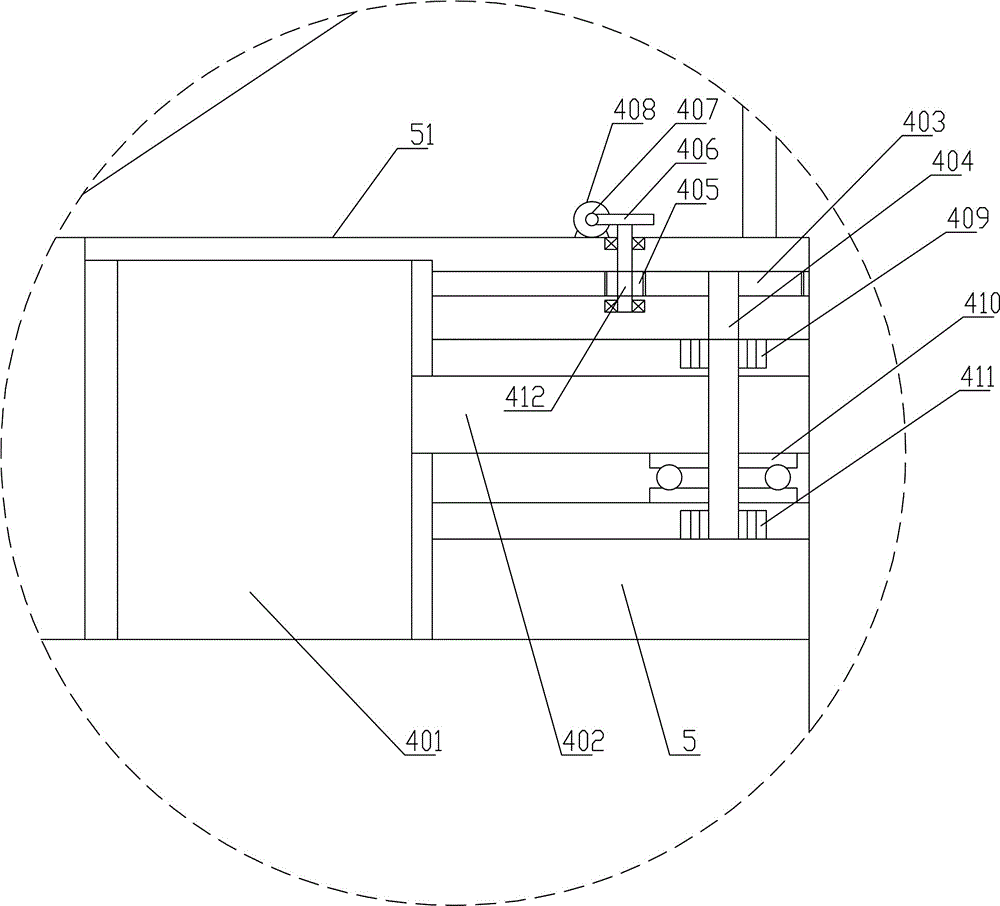

[0037] Such as Figure 1~4 Among them, a tire crane counterweight control method with a movable counterweight system, the turntable 3 is connected with the car body 1 through the column 2, the turntable 3 is provided with a movable counterweight device 4, and the structure of the movable counterweight device 4 is: a movable counterweight The weight 401 is connected with the fixed seat 5 through the connecting rod 402 and the vertical shaft 404, the vertical shaft is located near the tail of the fixed seat 5, and the top of the vertical shaft 404 is provided with a gear plate 403,

[0038] The driving device is connected with the toothed disc 403 , and the driving device drives the vertical shaft 404 and the movable counterweight 401 to rotate through the toothed disc 403 .

[0039] The boom 9 is hinged with the car body 1, and the upper end of the boom 9 is provided with a gravity sensor for detecting the suspension hook 10, and the gravity sensor can also be arranged on the s...

Embodiment 2

[0057] A tire crane counterweight control method with a movable counterweight system, the turntable 3 is connected to the car body 1 through the column 2, the turntable 3 is provided with a movable counterweight device 4, and the structure of the movable counterweight device 4 is: a movable counterweight 401 The connecting rod 402 and the vertical shaft 404 are connected to the fixed seat 5, and the driving device drives the vertical shaft 404 and the movable counterweight 401 to rotate;

[0058] The four corners of the car body 1 are provided with spiral legs 11 , on which are pressure sensors for detecting the pressure received, and a rotation angle sensor is also provided near the column 2 for detecting the rotation angle of the turntable 3 . Include the following steps:

[0059] 1. Detect each pressure sensor and calculate whether the difference between each pressure sensor exceeds the upper limit. If it is, stop the protection, otherwise the next step; the upper limit her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com