Transmission shaft of heavy-duty speed reducer

A transmission shaft and reducer technology, applied in the field of transmission shafts, can solve problems such as unbalanced transmission torque, low transmission efficiency, and reduced reliability, and achieve the effect of torque balance and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

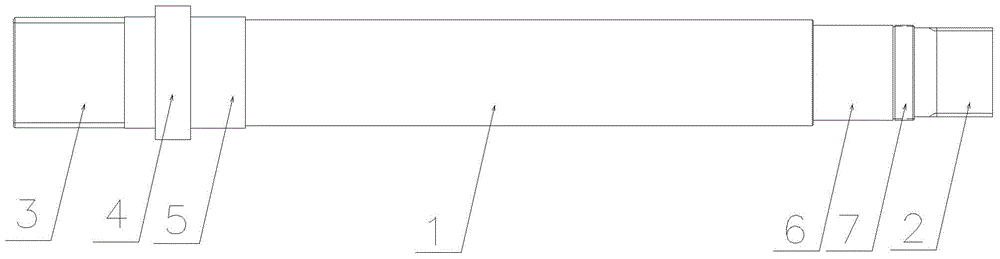

[0012] Such as figure 1 As shown, a transmission shaft of a heavy-duty reducer includes a transmission shaft body 1, one end of the transmission shaft body 1 is provided with a gear I2, and the other end is provided with a gear II3, and the gear I2 and gear II3 are connected to the transmission shaft body 1 interconnected to form an overall structure.

[0013] In this embodiment, the inner side of the gear I is set as the journal 7, and the inner side of the journal 7 is set as the bearing installation position I6; It is the bearing installation position Ⅱ5. The normal modulus of the gear I2 and the gear II3 is 5, the number of teeth is 22, 24 or 26, and the profile angle is 30 degrees. In this embodiment, the preferred number of teeth is 24, the coefficient of addendum height is 0.5, and the coefficient of addendum clearance is 0.25. The material of the transmission shaft body 1 is 42CrMo, which has been quenched and tempered to HB260-280, and the gear part has been subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com