External operation handle

A technology for operating handles and handles, applied in the direction of contact operating parts, electrical components, electric switches, etc., can solve the problems of complex design, high cost, and difficulty in meeting the needs of dustproof and waterproof effects, so as to reduce production costs and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

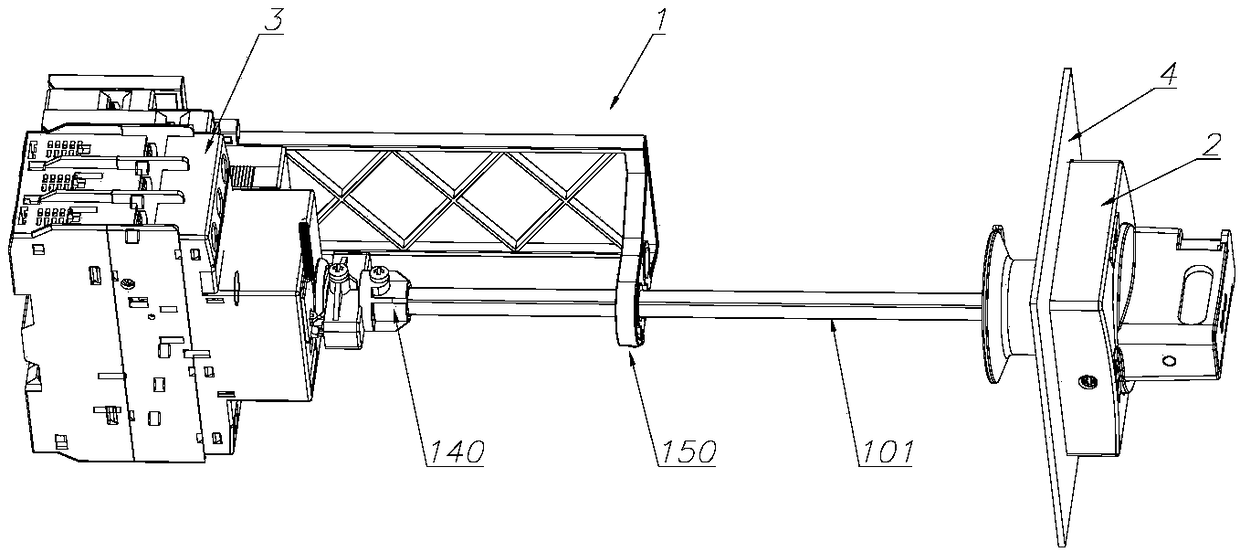

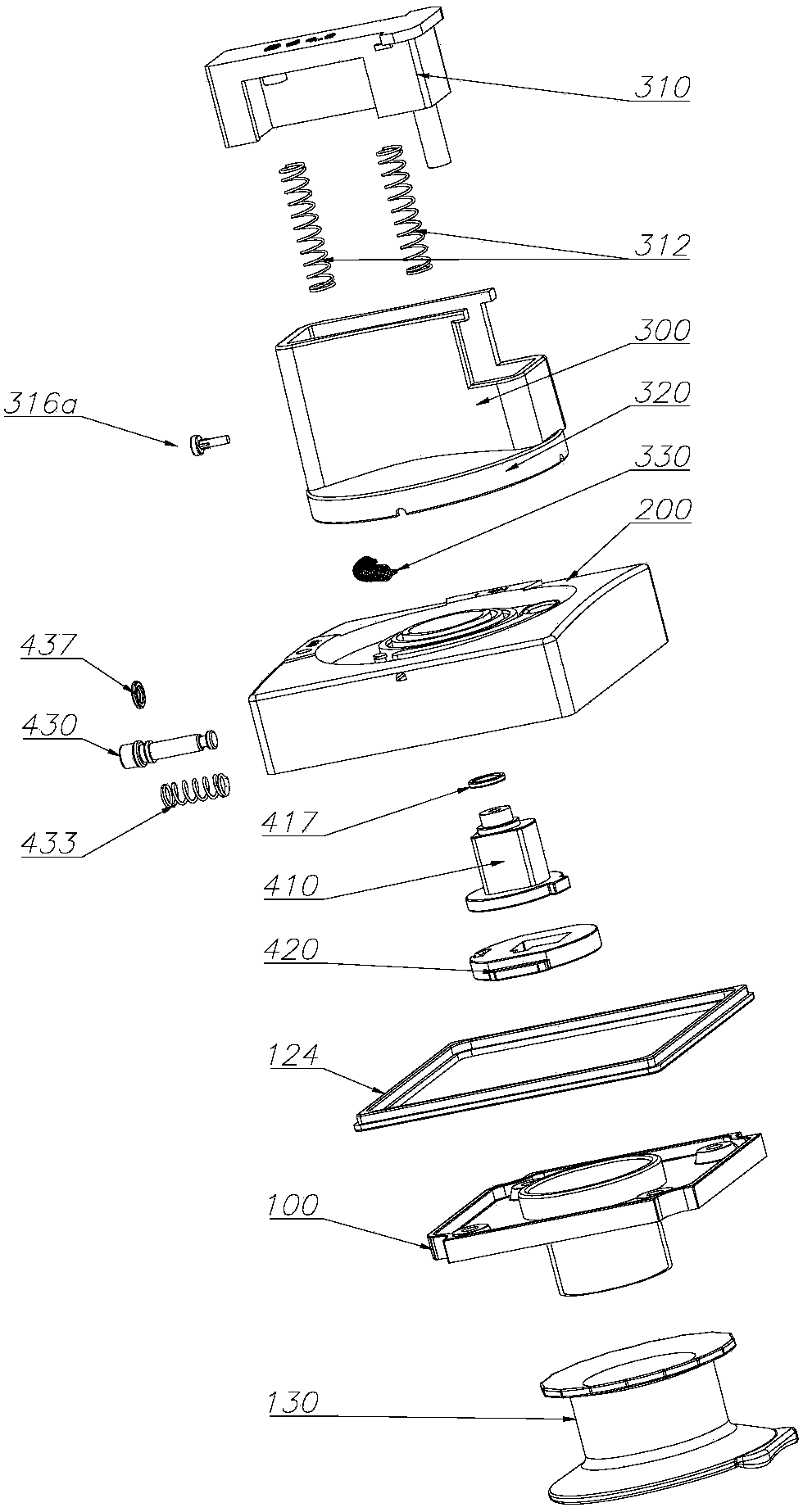

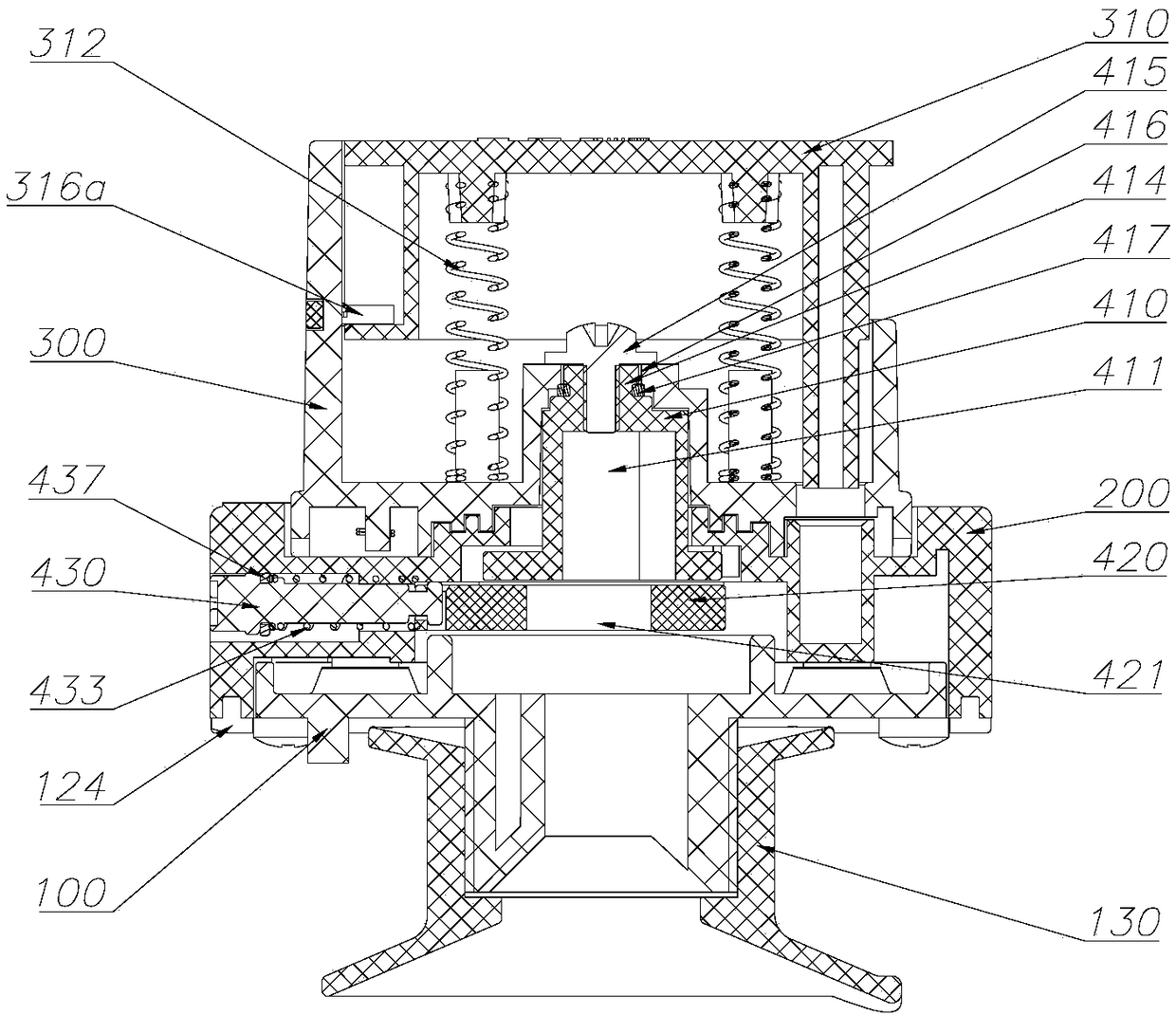

[0113] The external operating handle device of the present invention includes a casing 120, a handle part 300, a limiting part 310, a base 110, a threaded sleeve 130, a linkage part 410, a locking part 420, an unlocking part 430, and a T-shaped casing sealing ring 124. , locking spring 433, limiting spring 312, linkage sealing ring 417, unlocking sealing ring 437, limiting guide shaft 316a, etc., and the external operating handle device can drive the switching device 3 in two positions: closed (ON) and closed (OFF). Switching is performed in order to realize the operation of the switching device 3 . The linkage part 410 passes through the linkage bottom hole 1211 of the casing 120 and is fixedly connected with the handle part 300 through the combination screw 415. By operating the handle part 300, the linkage part 410 can be driven to rotate around the central axis of the casing 120, that is, the handle cover 320 The curved surface on the outside of the cover wall 321 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com