Pipeline connection structure of heat exchanger

A connection structure, heat exchanger technology, applied in heat exchange equipment, adjustable connections, heat exchanger shells, etc., can solve the problems of difficult on-site maintenance, leakage at welding, high working intensity, etc., and avoid the easy vibration of welding joints. damage, eliminating the welding process, reducing the effect of management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

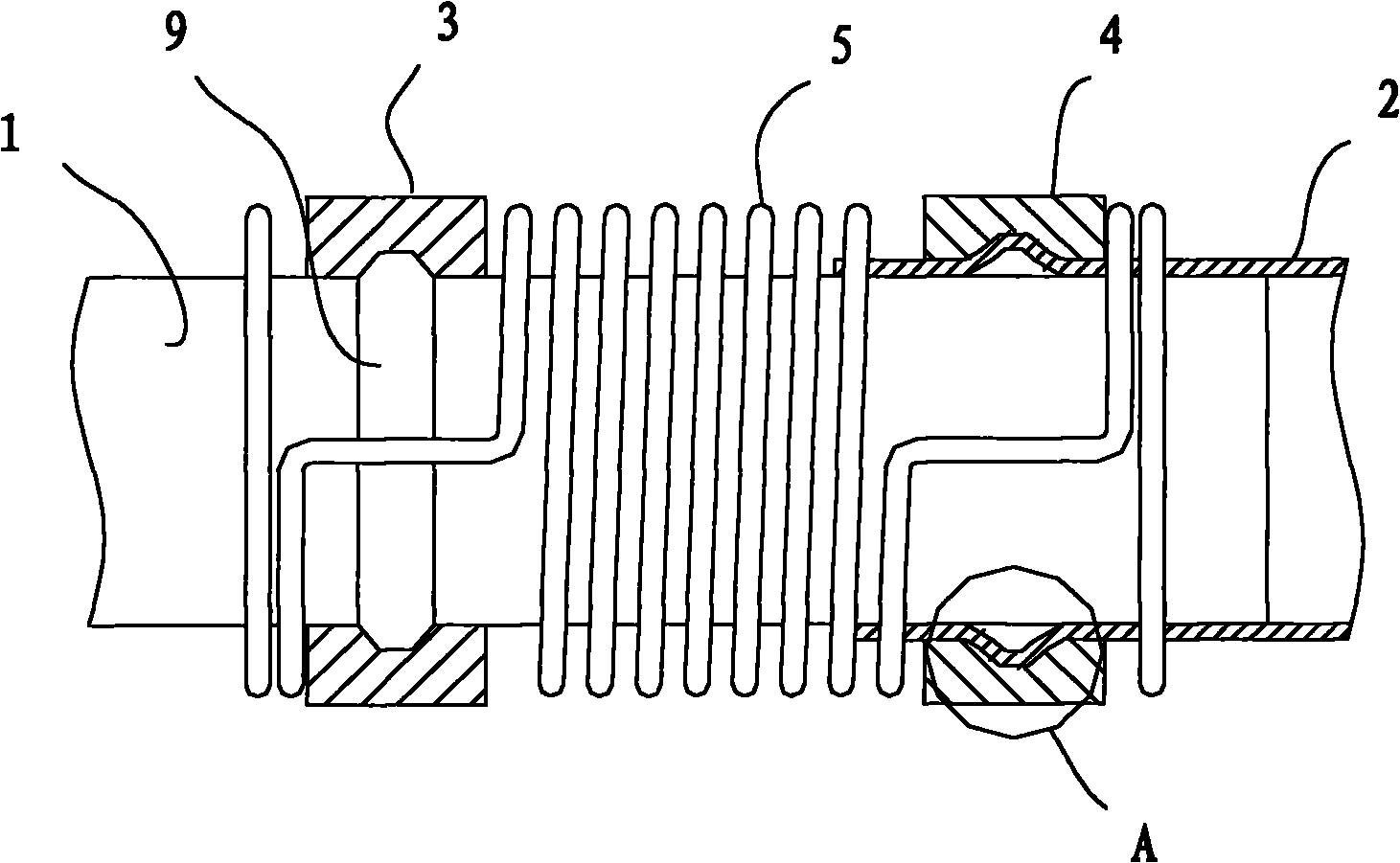

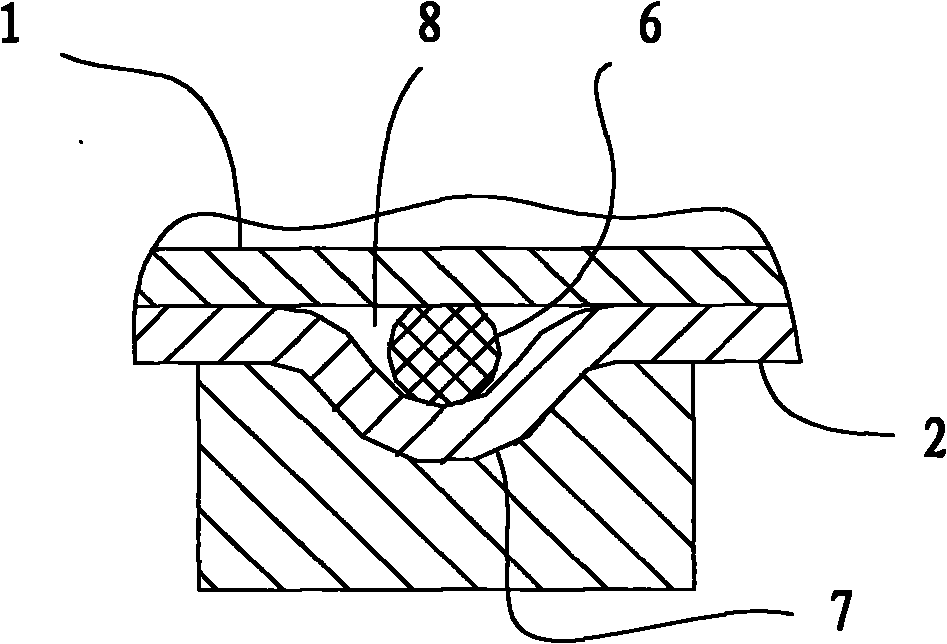

[0027] refer to figure 1 with 2 , a pipe connection structure of a heat exchanger, which includes a connecting pipe 1, a heat dissipation straight pipe 2, a first positioning block 3, a second positioning block 4 and an elastic member 5, wherein the end of the connecting pipe 1 is inserted into the heat dissipation straight pipe In the end of the tube 2, a protrusion 7 with an annular groove 8 is provided on the tube wall of the heat dissipation straight tube 2 at the insertion point, the sealing ring 6 is arranged in the annular groove 8, and the first positioning block 3 is fixed on the connecting tube 1 Above, the second positioning block 4 is fixed on the heat dissipation straight pipe 2, and the two ends of the elastic member 5 are connected to the first positioning block 3 and the second positioning block 4 respectively.

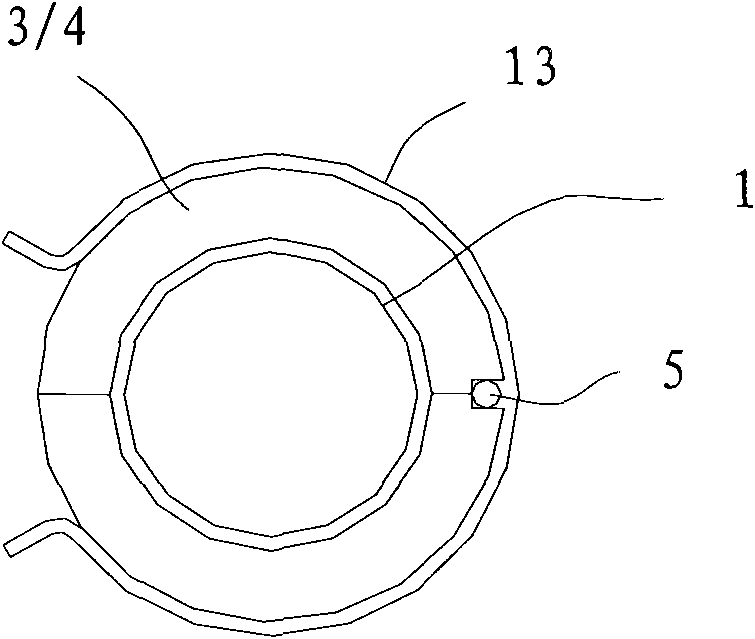

[0028] refer to image 3 , Ring clamps 13 are sheathed outside the first positioning block 3 and the second positioning block 4 respectively.

[00...

Embodiment 2

[0034] refer to Figure 8 with 9 , a pipe connection structure of a heat exchanger, which differs from Embodiment 1 in that: the connection pipe 1 is a U-shaped pipe, and its two ends are respectively inserted into two heat dissipation straight pipes 2, and the second positioning block 4 The two ends are respectively fixed behind the protrusions 7 of the two heat dissipation straight pipes 2 , and the middle part of the connecting pipe 1 is provided with a circular ring 9 .

[0035] Installation of Embodiment 2 of the present invention: Set sealing rings 6 in the protrusions 7 of the two heat dissipation straight pipes 2 respectively, then insert the two ends of the connecting pipe 1 into the ends of the two heat dissipation straight pipes 2 respectively, and install the second The first positioning block 3 and the second positioning block 4 are provided with an elastic member 5 to realize the connection of the pipelines.

[0036] When the pressure of the heat exchange mediu...

Embodiment 3

[0038] refer to Figure 10 with 11 , a pipe connection structure of a heat exchanger, which is different from Embodiment 2 in that: the connection pipe 1 is a U-shaped pipe, and its two ends are respectively inserted outside the ends of two heat dissipation straight pipes 2. A ring protrusion 15 with a ring groove 16 is provided on the pipe wall of the connecting pipe 1 at the location, and the sealing ring 6 is arranged in the ring groove 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com