Gear pump floating side plate design method

A technology of floating side plate and design method, applied in design optimization/simulation, pump, mechanical equipment, etc., can solve the problems of many tests, long R&D cycle, high R&D cost, reduce the test range, facilitate calculation, and improve design The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this embodiment, the adjustment of the position of the sealing strip on the floating side plate of the gear pump is used for illustration.

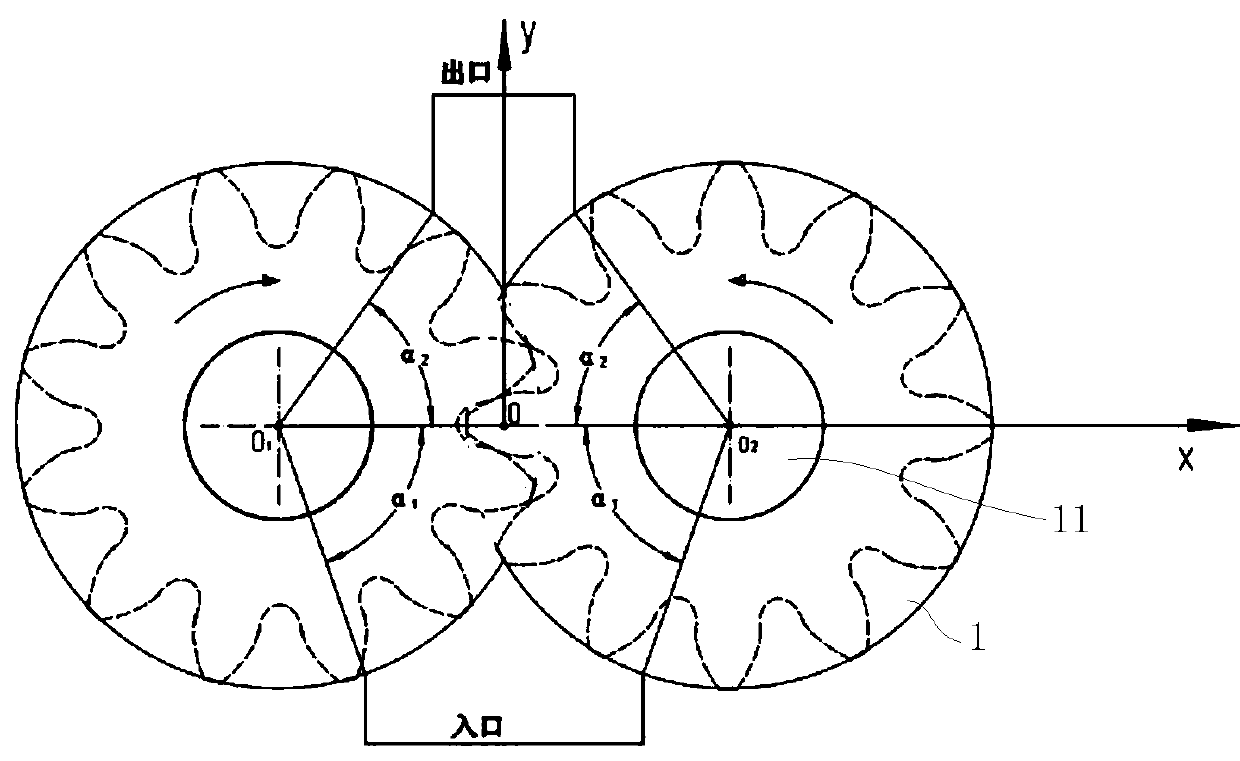

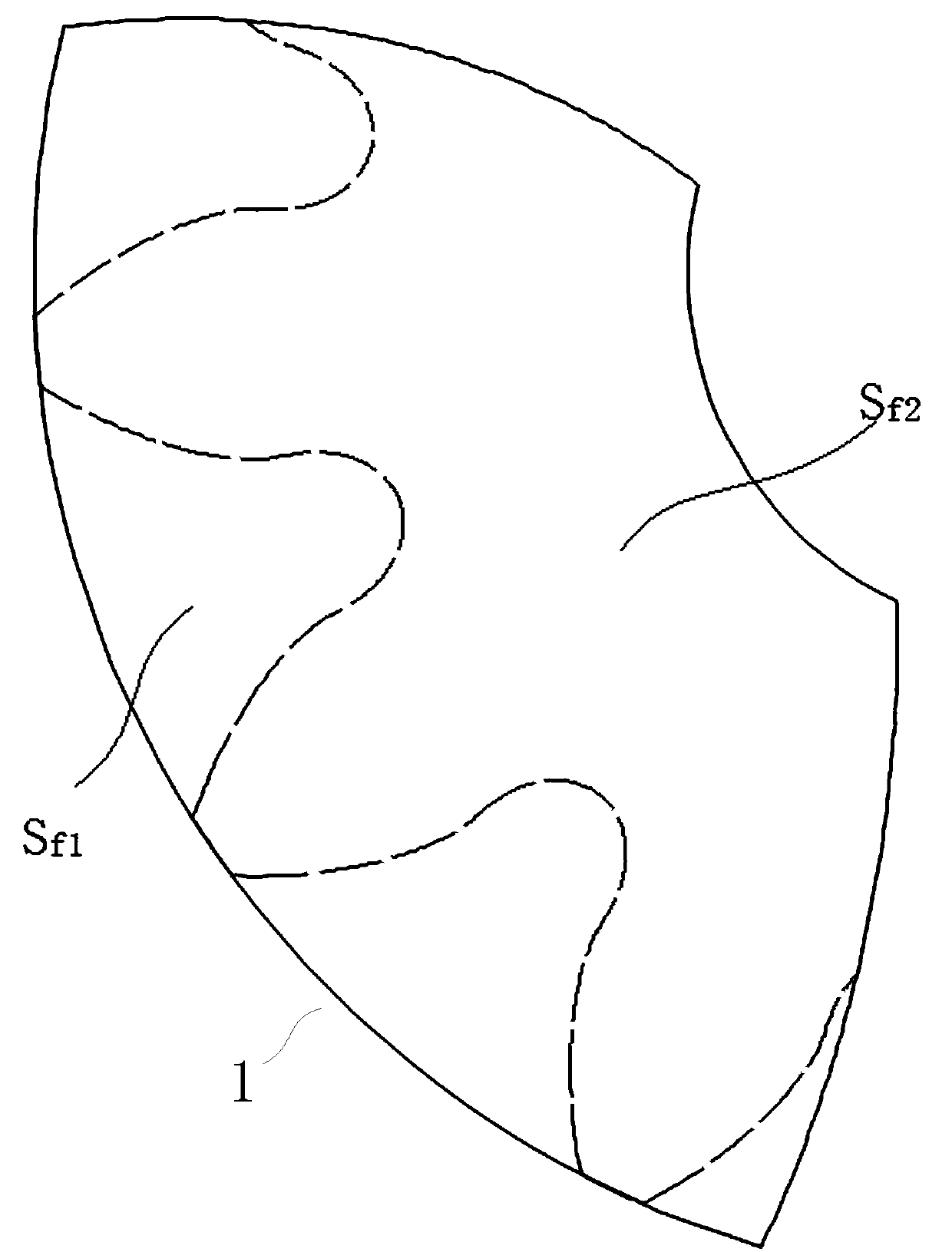

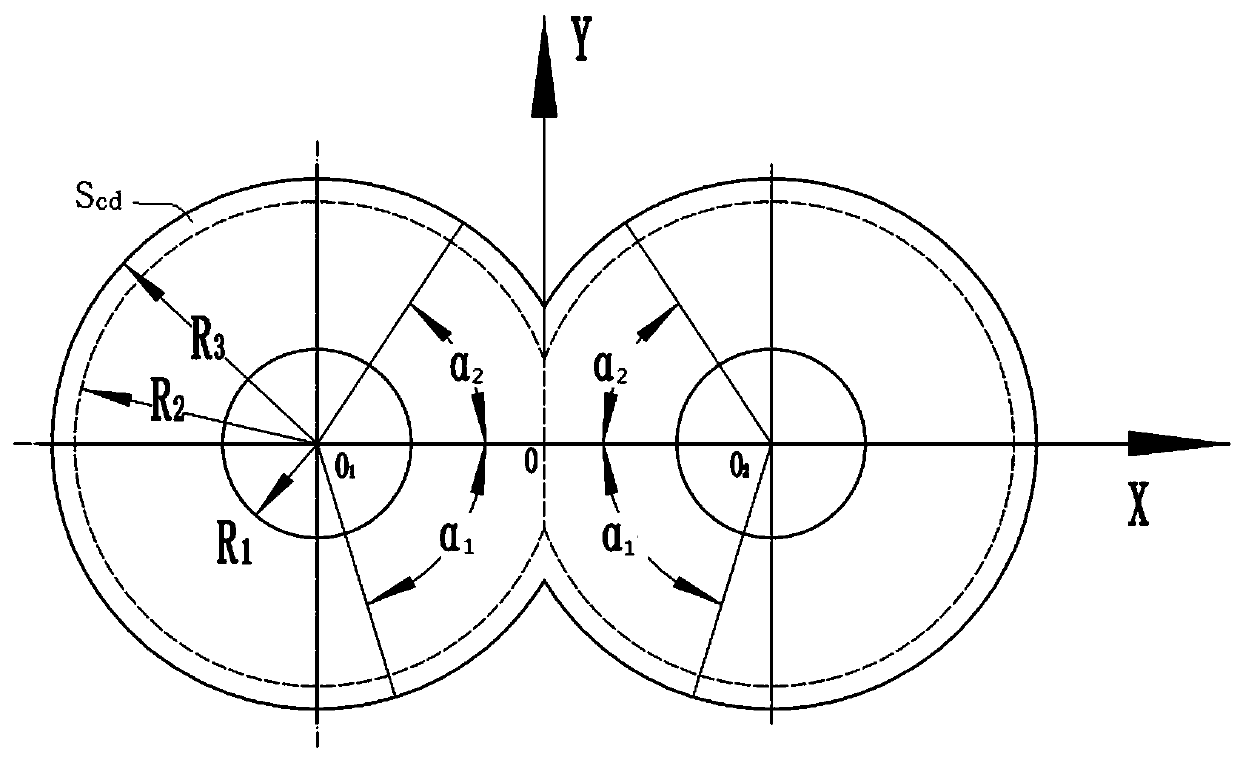

[0067] Such as Figure 1 to Figure 6 As shown, there are two rotating shaft holes 11 on the floating side plate 1, and the two rotating shaft holes 11 are used for the passing of the rotating shaft. A Cartesian coordinate system is established with the midpoint of the line connecting the centers of the two shaft holes 11 as the origin, the line connecting the centers of the two shaft holes 11 is on the X axis, and the floating side plate 1 is symmetrical about the Y axis. By calculating the force F on the side of the gear end face of the floating side plate 1 f1 , The force F on the side of the floating side plate 1 facing away from the gear yj , The floating side plate 1 is facing the gear end face and the moment M around the X axis is stressed f1-x , Moment M of floating side plate 1 around the X axis under force on the sid...

specific Embodiment 2

[0128] The only difference with the specific embodiment 1 is that in this embodiment, the wrap angle of the high pressure zone is selected as α according to experience 2 After other parameters are determined, the value of the wrap angle in the high pressure area is determined according to the parameter adjustment equation group, and then the simulation test is carried out on the floating side plate. In other embodiments, other values of the parameters of the floating side plate, such as the wrap angle of the low-pressure area, can also be determined according to the parameter adjustment equations.

[0129] In other embodiments, in the gear pump floating side plate design method, F f1 , F yj , M f1-x , M yj-x Other calculation methods can be used for the calculation, such as the force F of the floating side plate towards the gear end face f1 , the part opposite to the end opening of the alveolar is not equivalent to a ring, and is calculated according to the actual area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com