An eco-friendly axial flow pump structure that can pass fish

An axial flow pump, friendly technology, applied in axial flow pumps, components of pumping devices for elastic fluids, pumps, etc. Increase the mortality rate and other issues to achieve the effect of reducing fish damage, increasing speed, and reducing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

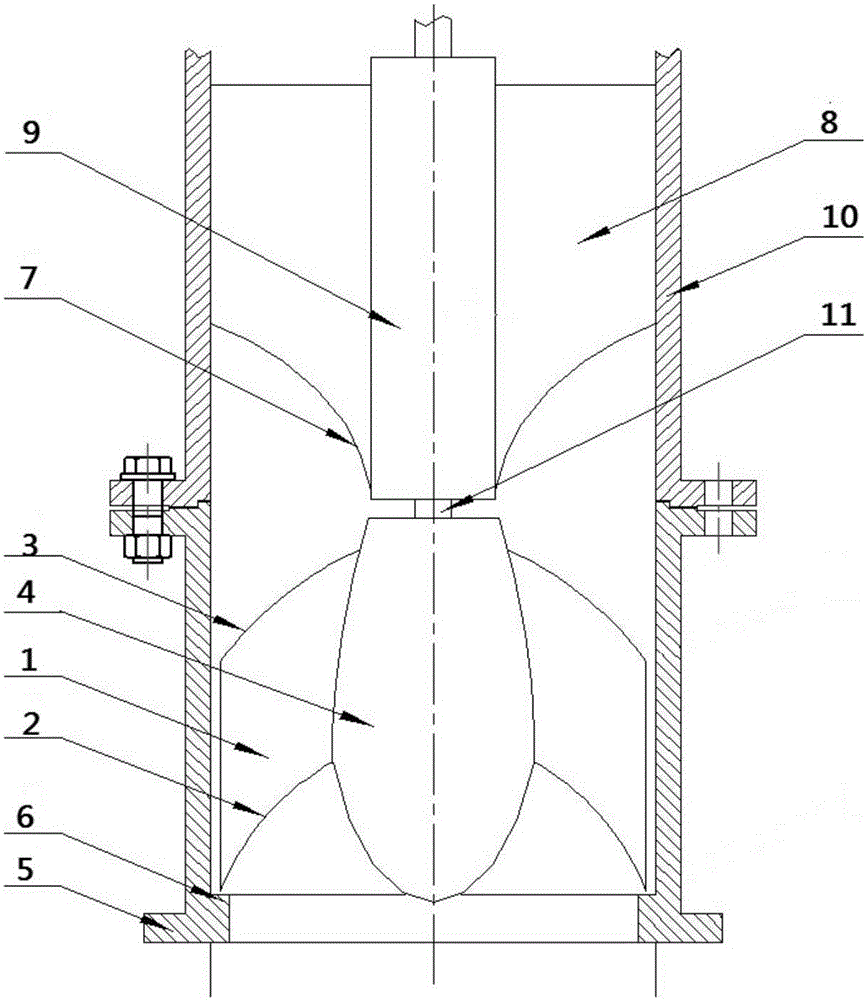

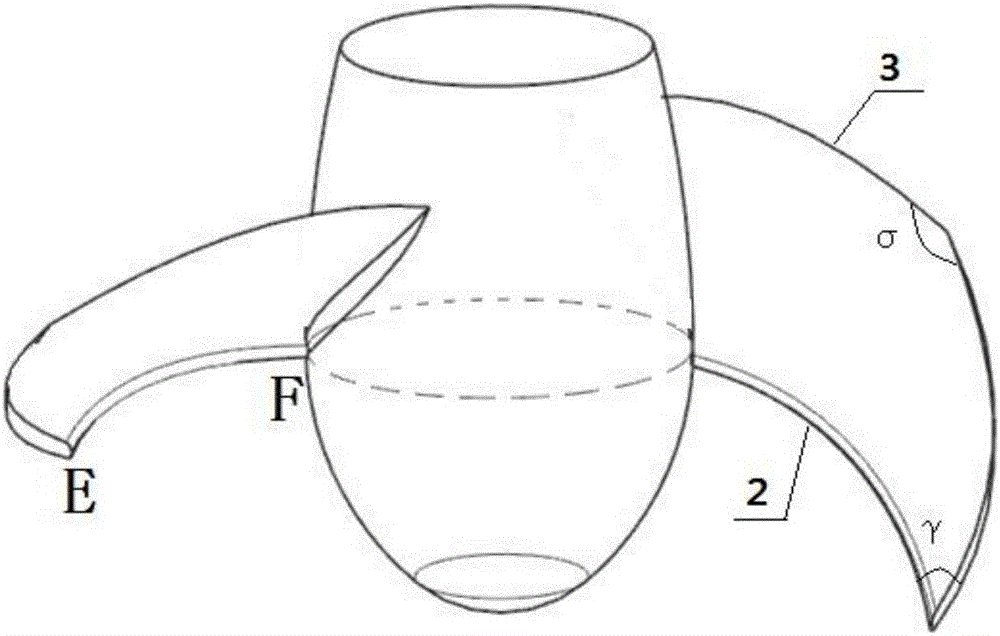

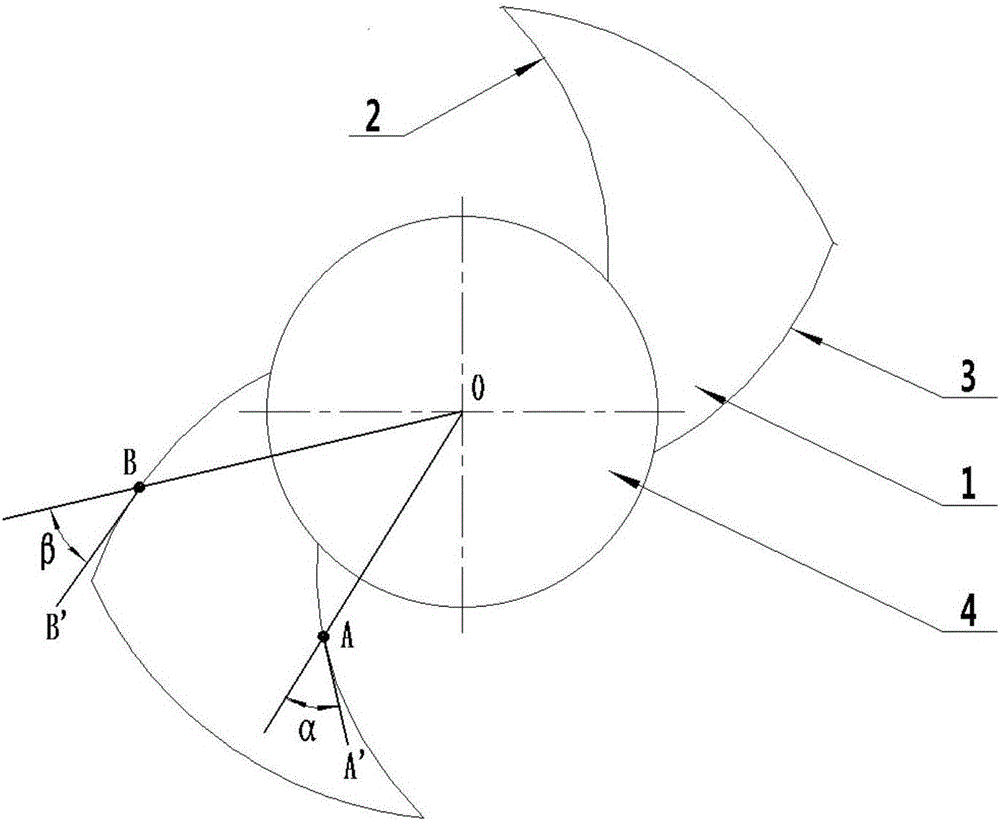

[0031] A kind of eco-friendly axial-flow pump structure that can pass fish according to the present invention is applied in large and medium-sized pumping stations, and the rotational speed of the axial-flow pumps used in this pumping station is usually not greater than 1450r / min, such as figure 1 As shown, it includes an axial flow pump blade 1, an impeller hub 4, a runner chamber 5, a guide vane hub 9 and a guide vane blade 8, and the axial flow pump blade 1 is two and symmetrically fixed on the impeller hub 4, which is different from the traditional Compared with the four-blade or multi-blade axial flow pump impeller, the probability of the axial flow pump blade hitting the fish is greatly reduced. Both the guide vane hub 9 and the impeller hub 4 are connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com