Comprehensive determination method for coefficient of roughness of rock mass structure surface

A roughness coefficient and determination method technology, applied to measuring devices, instruments, optical devices, etc., can solve the problem of not being able to quickly give rock mass structural planes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Step 1. On the basis of engineering rock mass structural analysis, select a rock mass structural surface with a diameter of 40mm (this method can be used for rock mass structural surfaces of any size, 40mm here is just an example), and use three-dimensional laser scanning or The rock mass discontinuity surface profile instrument obtains the rock mass discontinuity surface topography data;

[0032] Step 2, using the obtained rock mass discontinuity surface morphology data to generate a rock mass discontinuity surface digital elevation model DEM;

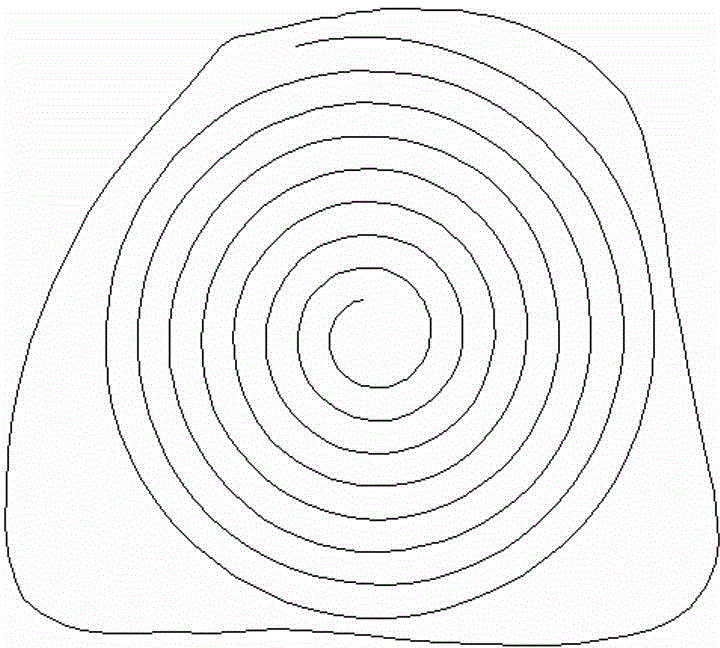

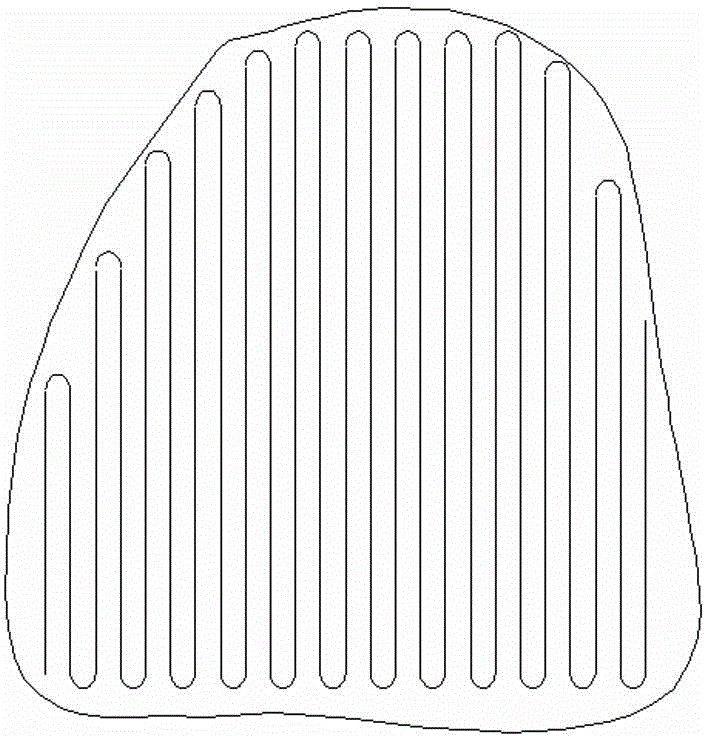

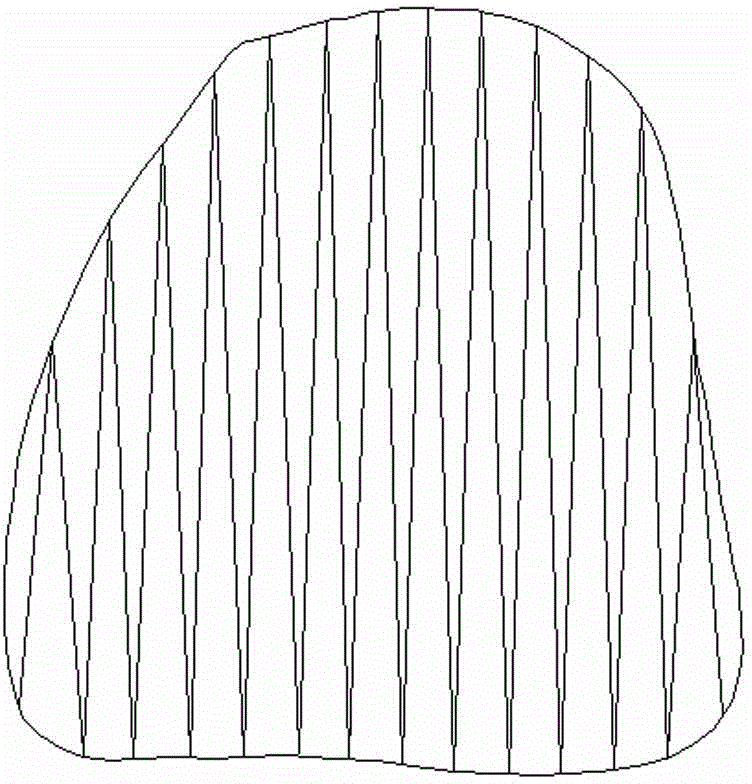

[0033] Step 3, on the digital elevation model of the rock mass structural surface, set the sampling interval as 1.6mm (such as Figure 4 1 in middle), draw a spiral line that can represent the morphology of the rock mass structural plane (such as Figure 4 As shown in 2), for such as figure 1 The approximate circular rock mass structural plane shown in Fig. figure 2 and 3 The rock mass structural plane shown is selected as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com