Networking type intelligent weighing system and method

A weighing method and intelligent technology, applied in weighing, measuring devices, instruments, etc., can solve the problems of unconscious human error, high cost, difficult to trace the source, etc., and achieve the effect of improving the level of security and confidentiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

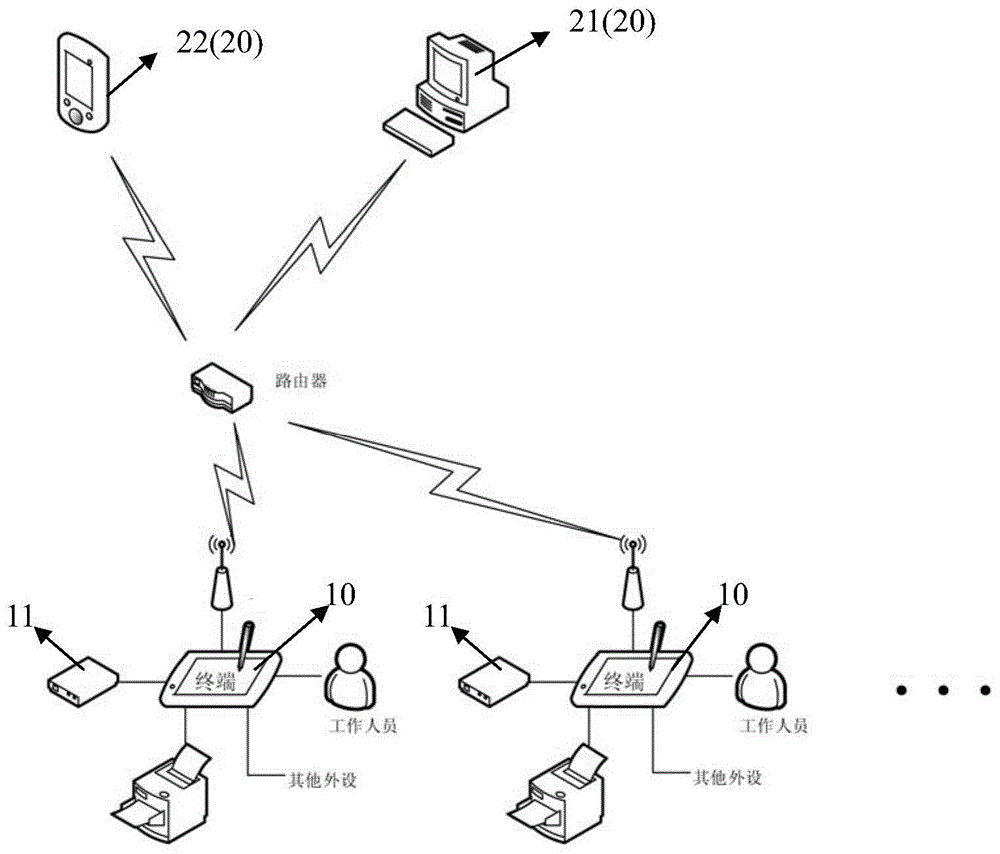

[0029] Please check figure 1 and figure 2 , a networked intelligent weighing system, which includes at least one weighing terminal 10 and a server 20, and the server 20 is connected to the weighing terminal 10 by communication.

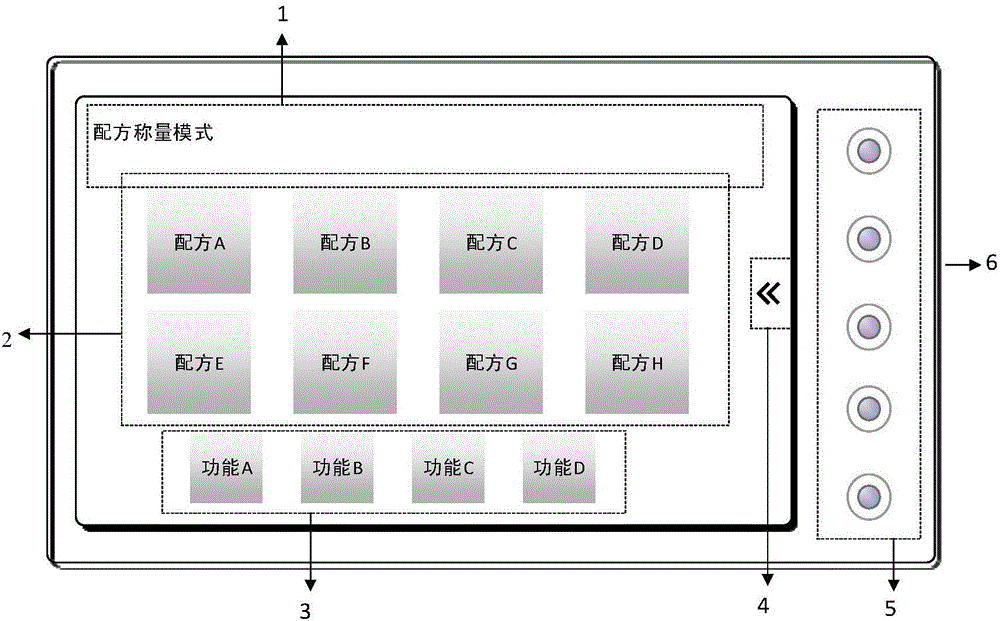

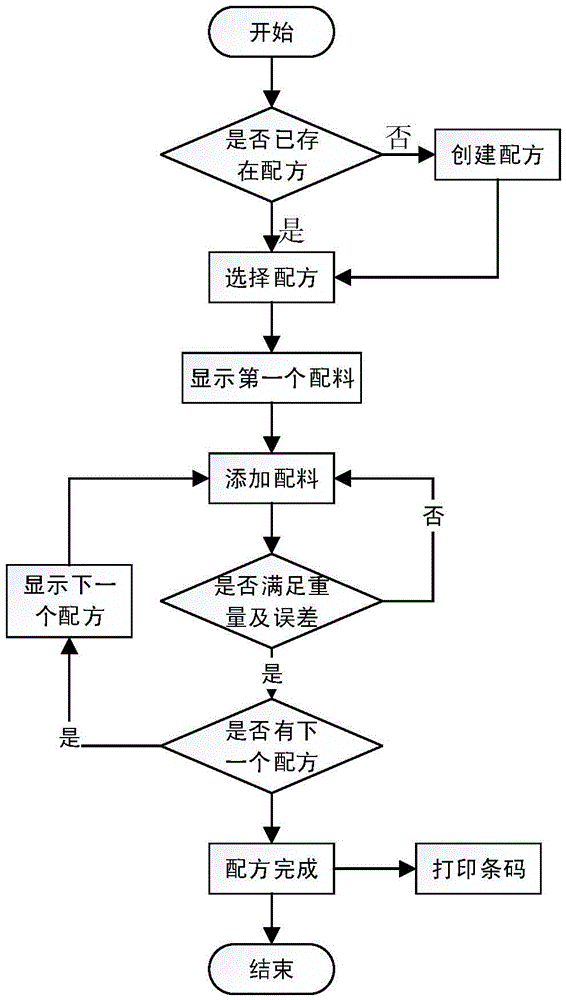

[0030] The weighing terminal 10 is an embedded system device, and the peripheral equipment includes a communication module, an audio module, an operation and display interface, a serial port, a USB port and other embedded system conventional resources, through which the operation and display interface can be displayed, edited, Search or create a weighing formula and store the weighing formula in the weighing terminal 10, the operation and display interface is provided with a touch screen; the communication module includes a wired and / or wireless communication module; and a load cell 11 is also integrated 1. Obtain the weight of the material on the weighing terminal 10 through the load cell 11 . In this embodiment, the weighing terminal 10 runs an A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com