Integrated dual-axis electromagnetic vibration table

An electromagnetic vibration and biaxial technology, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of increasing calibration time, increasing manufacturing costs, and cumbersome calibration process of vibration measuring sensors, etc., to achieve convenient installation, The effect of reducing manufacturing costs, simplifying the overall design and installation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

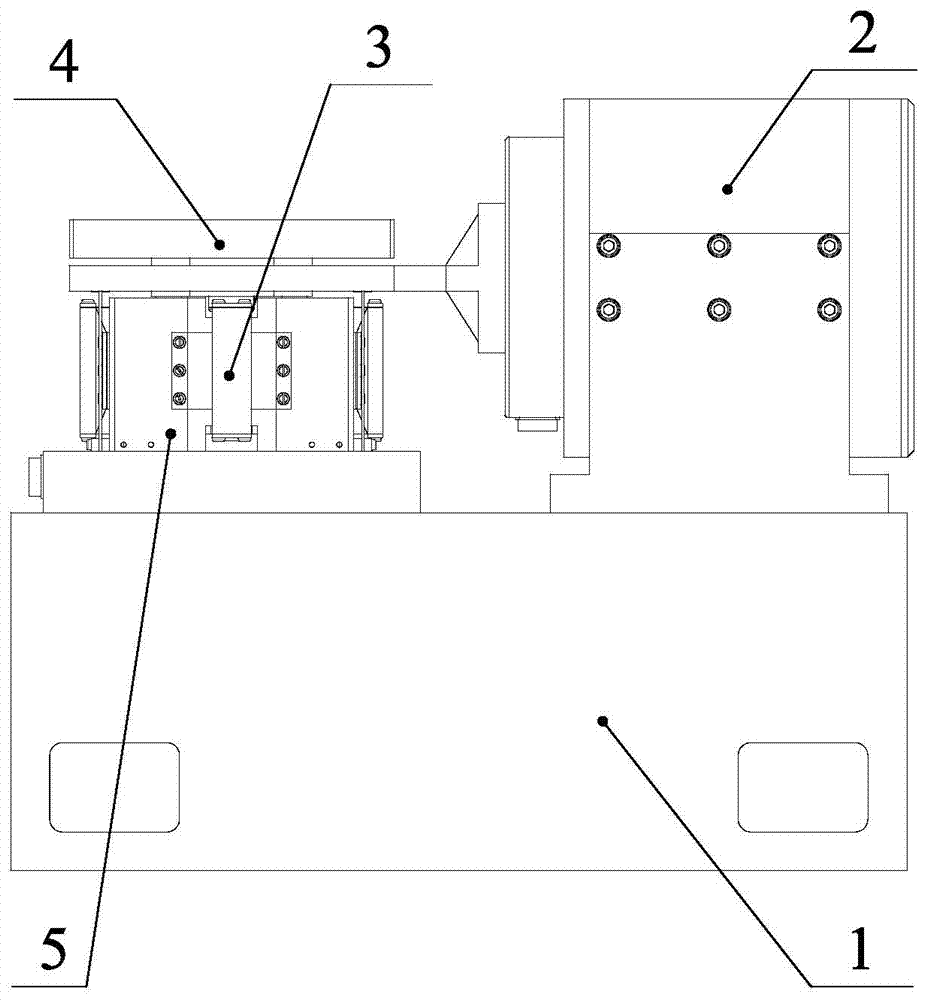

[0031] Integrated biaxial electromagnetic vibration table, such as figure 1 As shown, it includes a base 1, and the base 1 is provided with a horizontal motion device 2, a vertical motion device 3 and a motion platform 4; the horizontal motion device 2 and the vertical motion device 3 respectively include respective vibrating tables and transmission mechanisms;

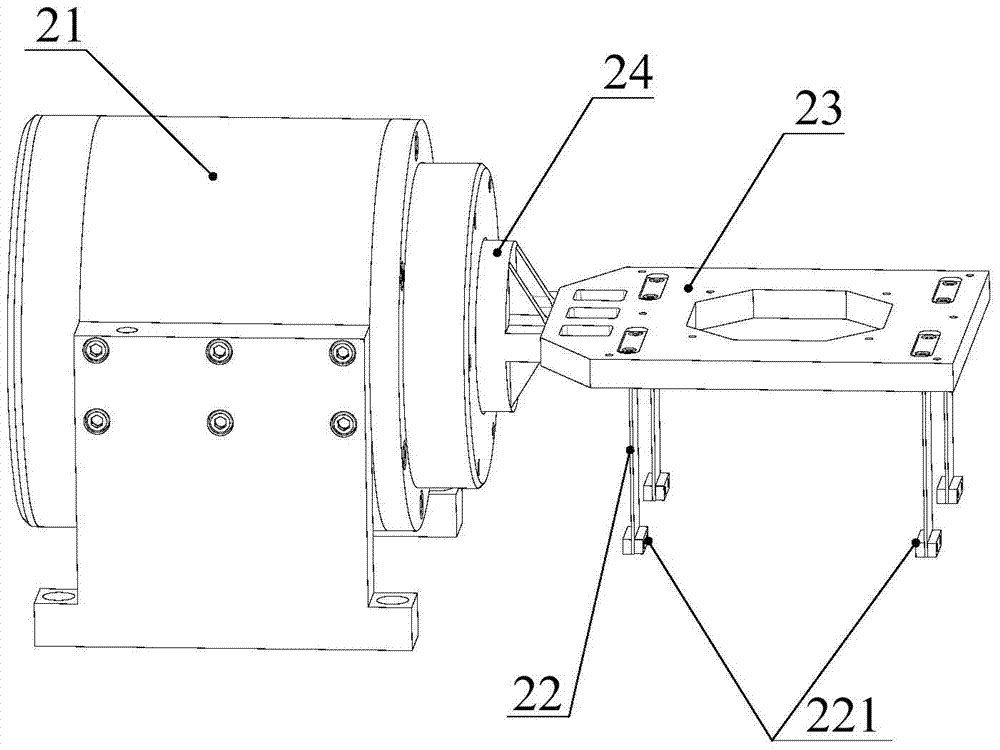

[0032] Such as figure 2As shown, the horizontal transmission mechanism is mainly composed of a horizontal connecting piece 23 capable of connecting the motion platform 4 and a plurality of horizontal supporting reeds 22, and the horizontal connecting piece 23 is fixed to the horizontal moving part 24 of the horizontal vibrating table 21; The horizontal supporting reeds 22 evenly support the horizontal connecting piece 23, one end of each horizontal supporting reed 22 is fixed to the horizontal connecting piece 23, and the other end is fixed relative to the base 1;

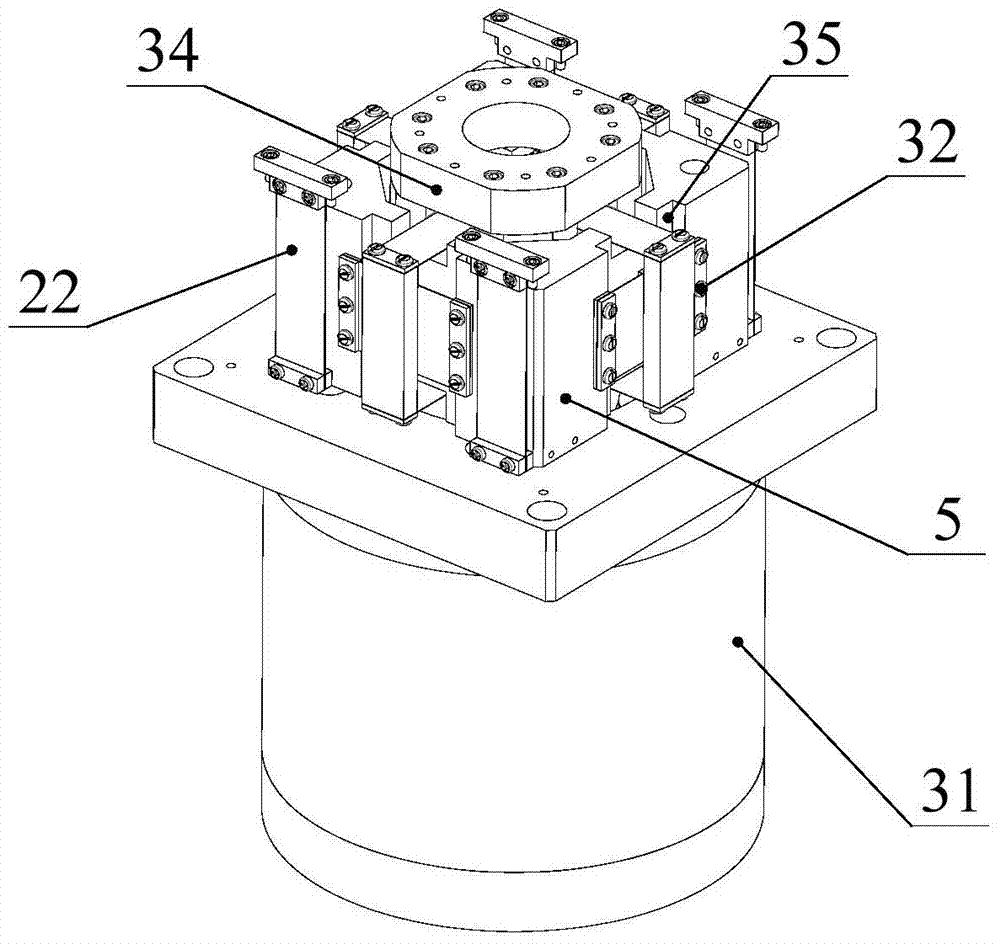

[0033] Such as image 3 , Figure 4 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com