Non-contact force measuring device and non-contact force measuring method

A force measuring device and non-contact technology, applied in the field of fluid mechanics, can solve the problems of the influence of the information of the flow field and the influence of the measured dynamic parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

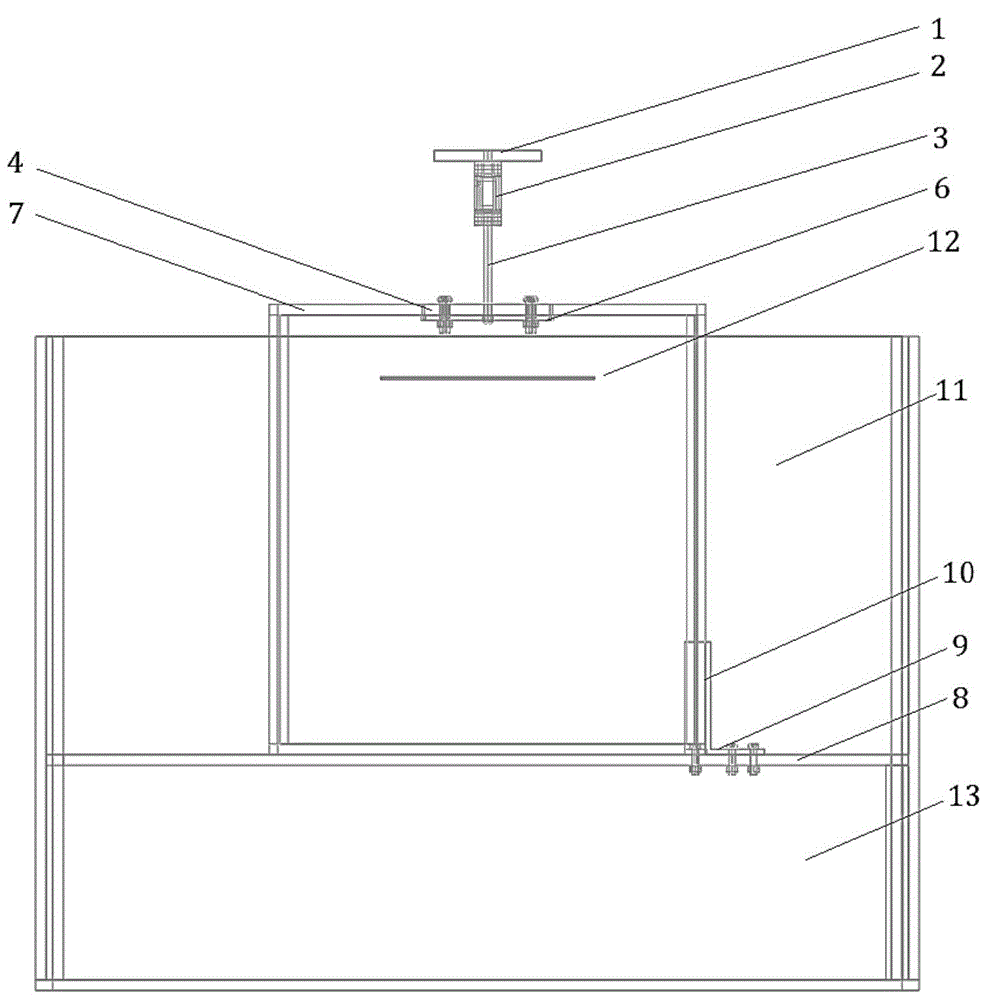

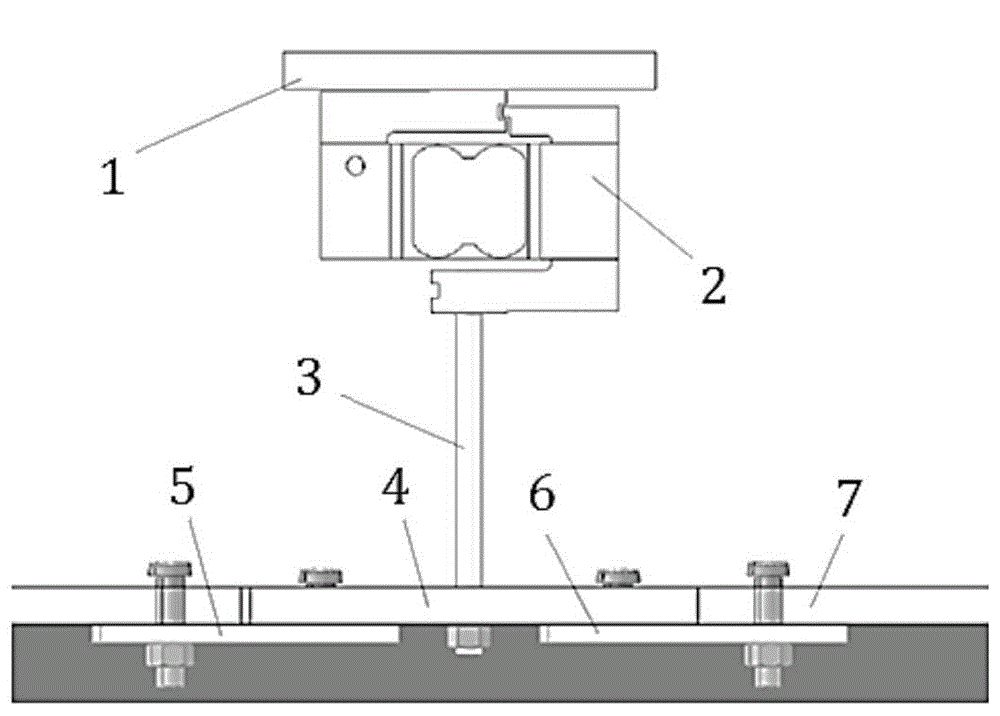

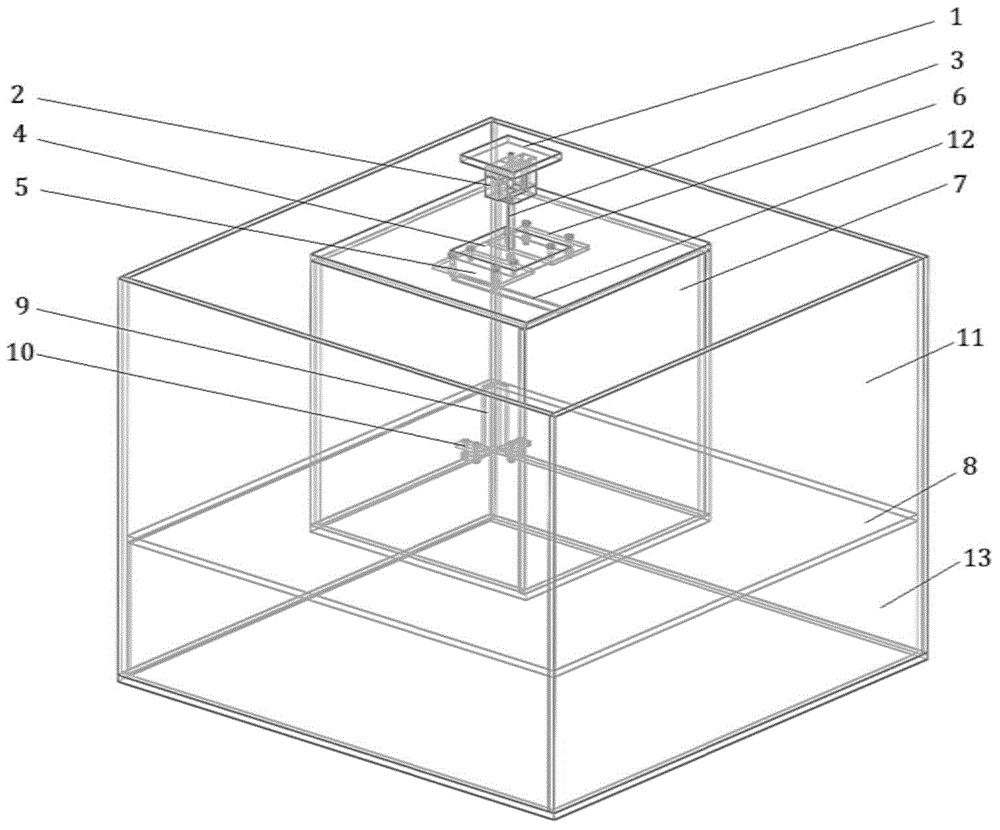

[0024] Such as figure 1 As shown, in this embodiment: the sensor 2 is fixed on the upper fixing plate 1, the lower end of the sensor 2 is connected to the connecting rod 3, and the connecting rod 3 is connected to the detection chamber 7 through the connecting plate 4 and the lower fixing plates 5,6.

[0025] The detection chamber 7 is placed on the support plate 8 by using the first and second positioning plates 9 , 10 , and the support plate 8 floats in the casing 11 . Therefore, the experimental device can be used to measure the fluid force in the detection chamber 7 that the plate 12 is subjected to when it falls freely.

[0026] The first and second positioning plates 9 and 10 are L-shaped structures and are respectively arranged on different sides of the detection chamber 7 .

[0027] The sensor 2 is connected with the connecting rod 3 at the lower end by threads, and the connecting rod 3 is connected with the force-bearing member below.

[0028] The lower fixing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com