Patents

Literature

36 results about "Non-contact force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A non-contact force is a force which acts on an object without coming physically in contact with it. The most familiar example of a non-contact force is gravity, which confers weight. In contrast a contact force is a force applied to a body by another body that is in contact with it.

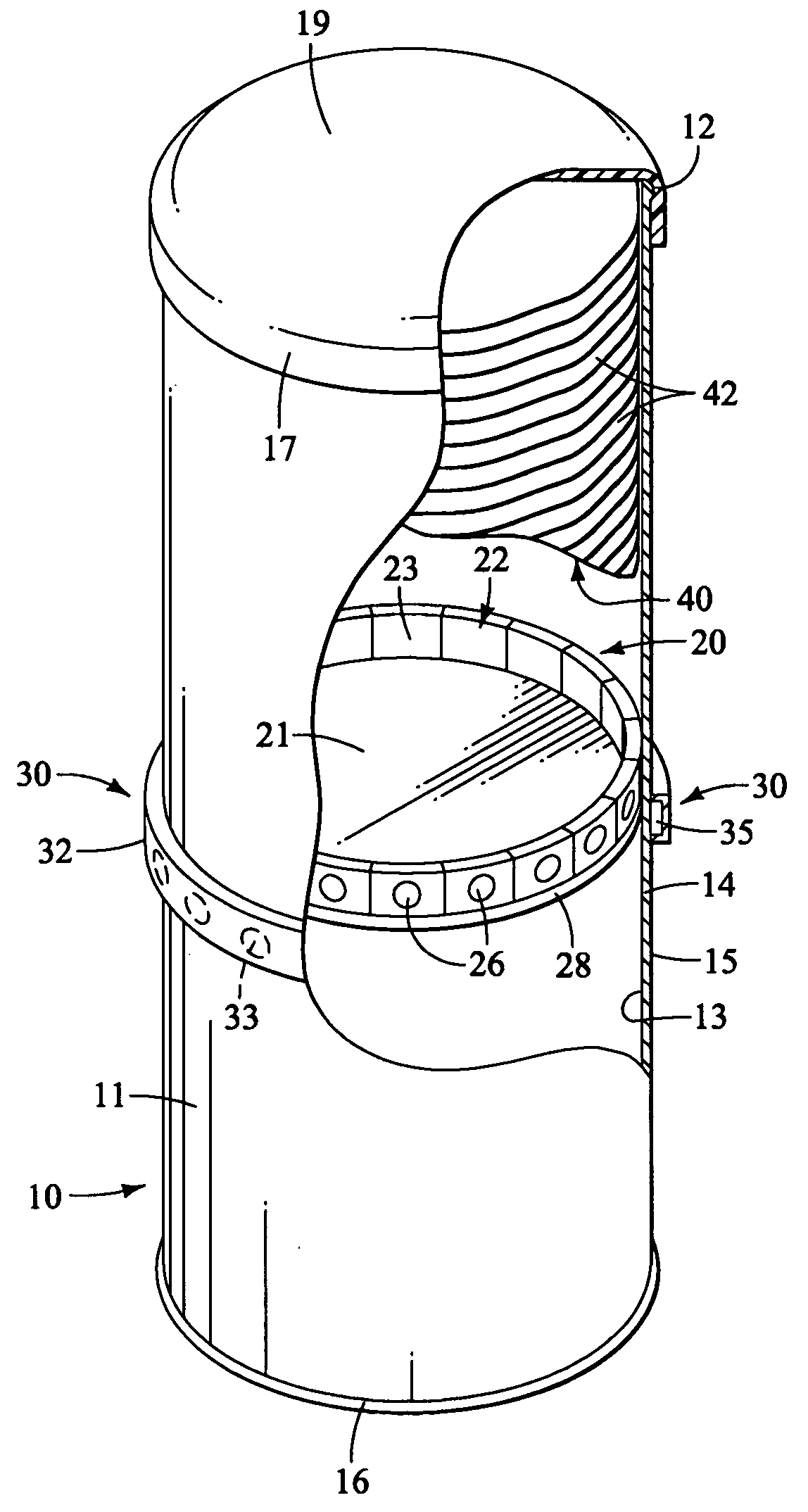

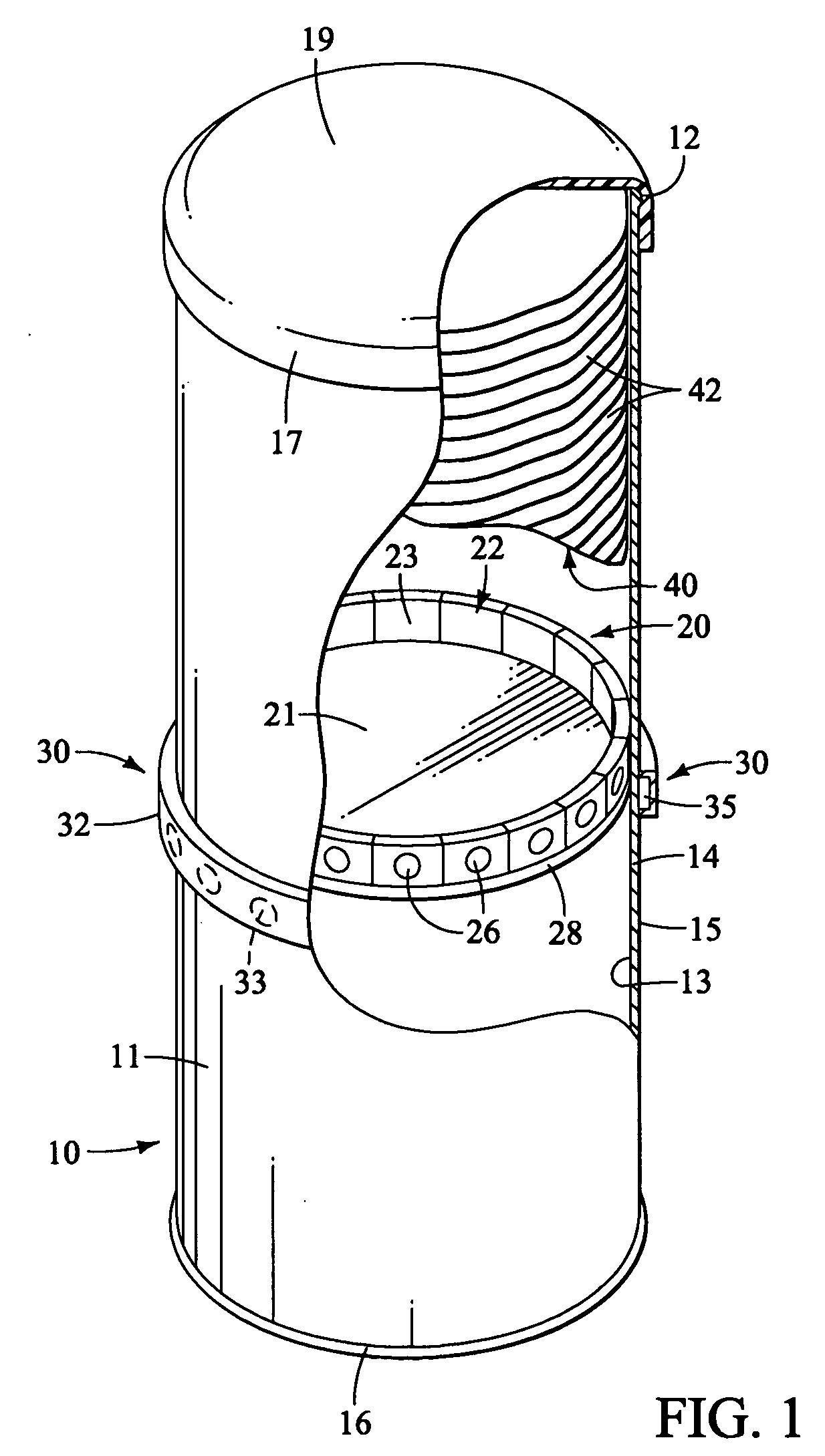

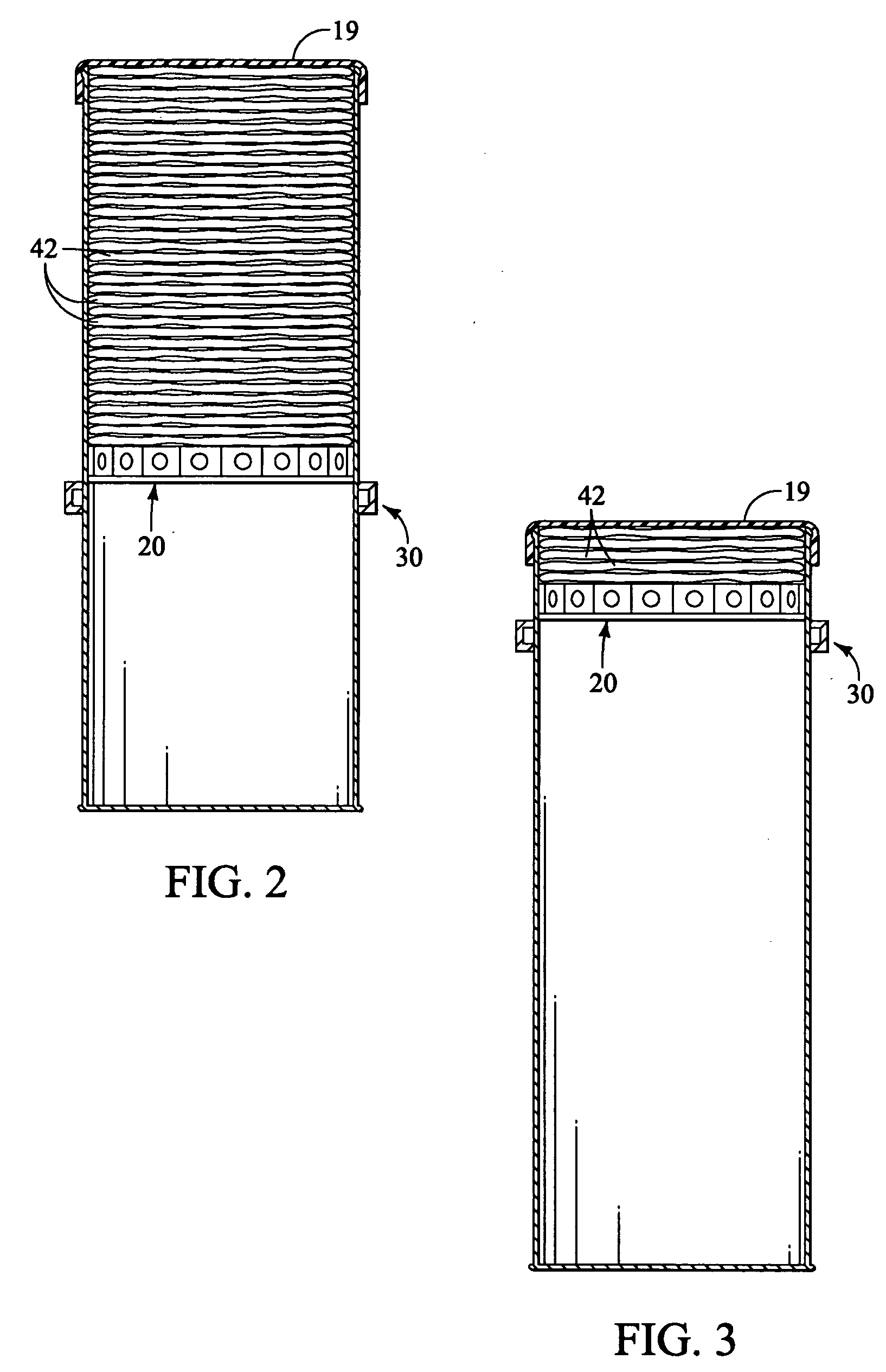

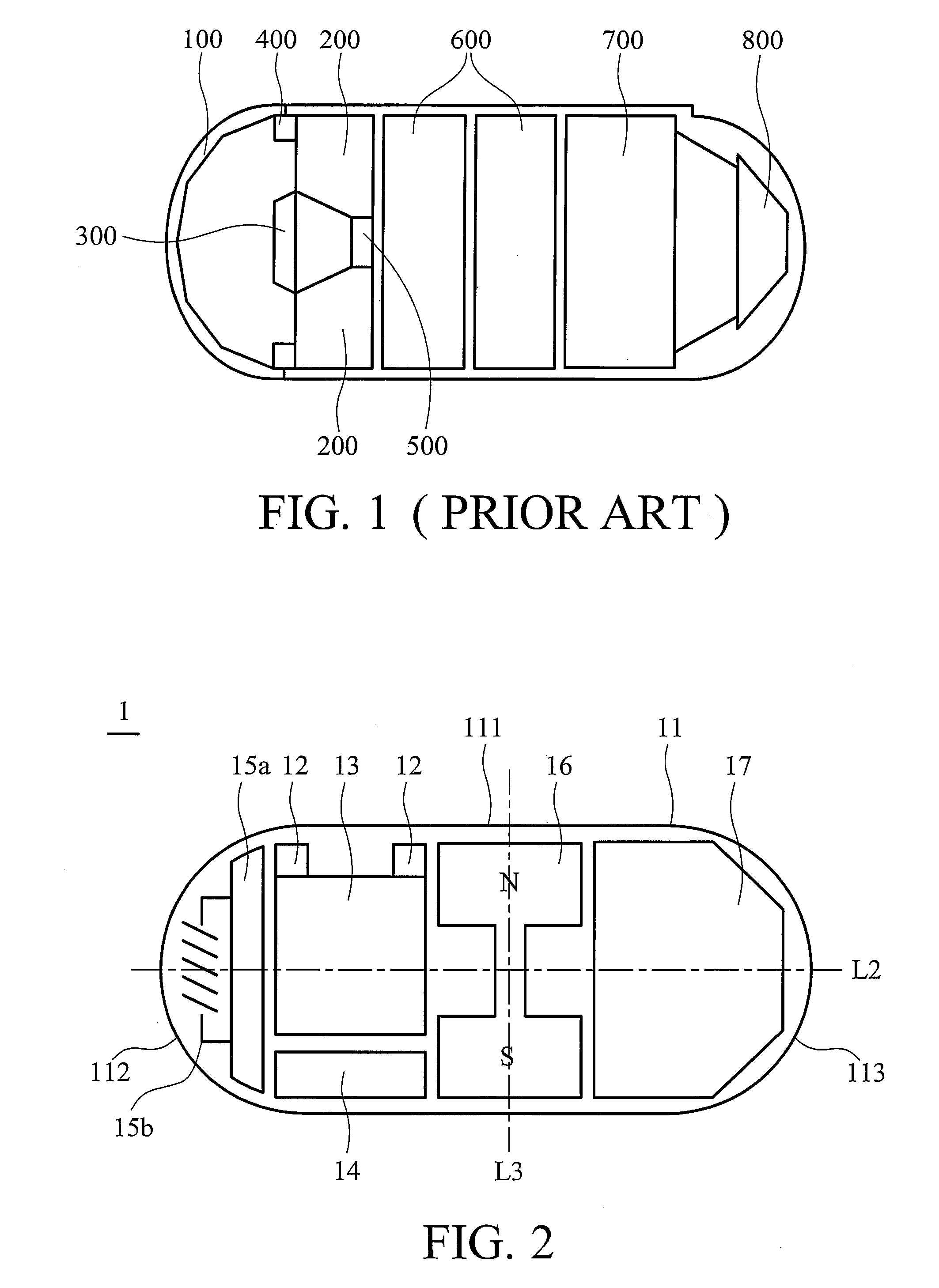

Dispensing container with non-invasive exterior control of interior dispenser lift

InactiveUS20060201963A1High positionDispensing apparatusCoin-freed apparatus detailsElectromagnetic couplingElectrostatic coupling

Containers having at least one container sidewall, such as with a tubular cylinder or tubular polygon shaped cross-section. An external operator applies force through the container wall using a non-contacting force coupling which transmits through the sidewalls. The non-contacting forces may be by magnetic coupling, electrostatic coupling, electromagnetic coupling or possibly other non-contacting force couplings. In manually powered units the magnetic coupling is currently preferred. The coupling in such embodiment uses a series of magnets positioned in the exterior operator and another set within an interior lift stage. The exterior operator is moved longitudinally to thus move the interior lift stage and lift product toward the mouth of the dispenser.

Owner:NVENTURE

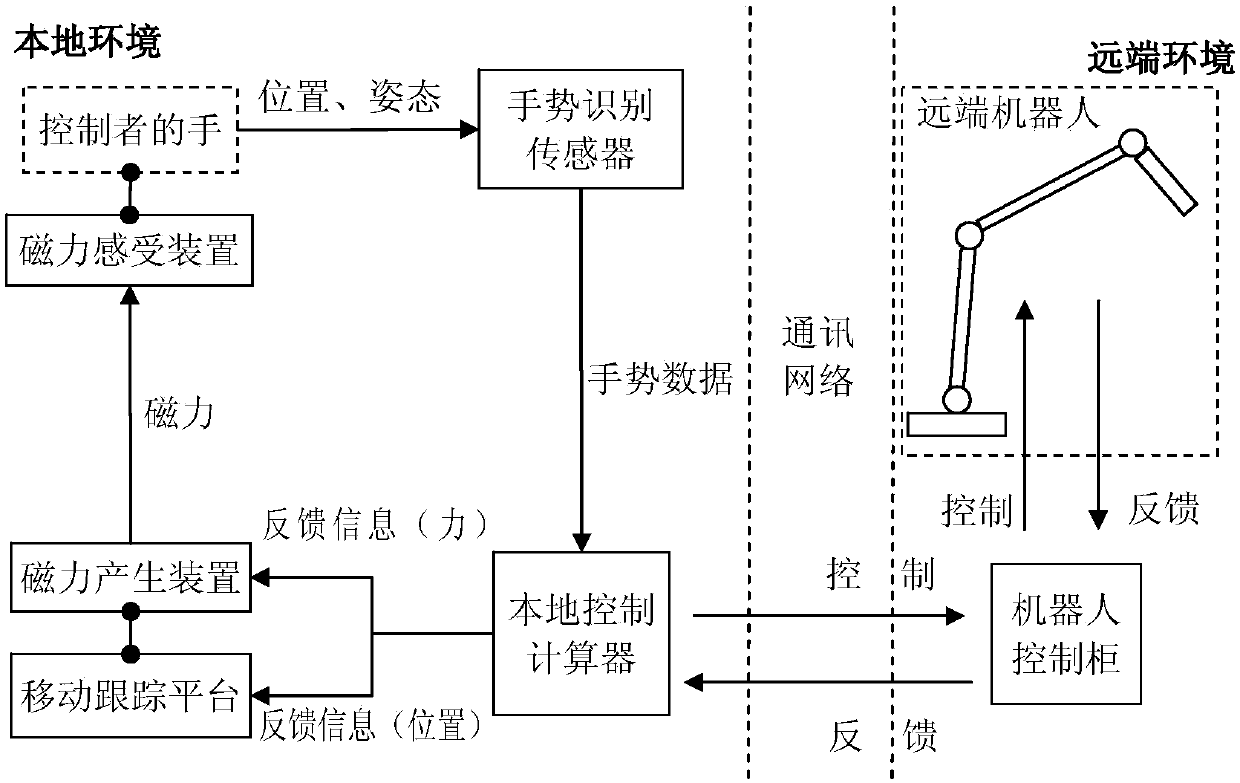

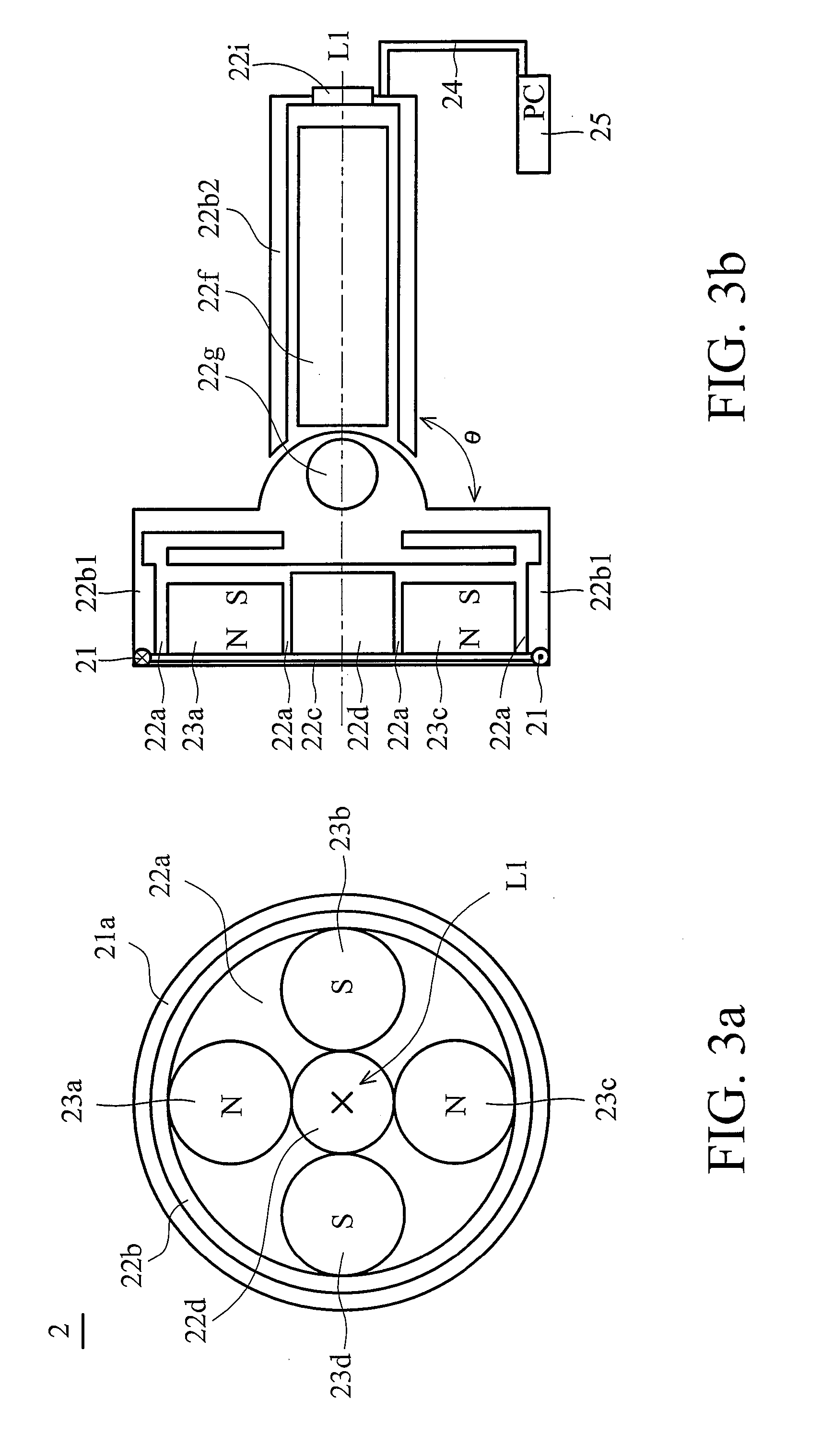

Force feedback man-machine interaction system and method based on electromagnetic theory and mobile tracking

InactiveCN108406725ASolve the problem of magnetic field attenuationKeep the relative position unchangedInput/output for user-computer interactionProgramme-controlled manipulatorInteraction systemsElectromagnetic theory

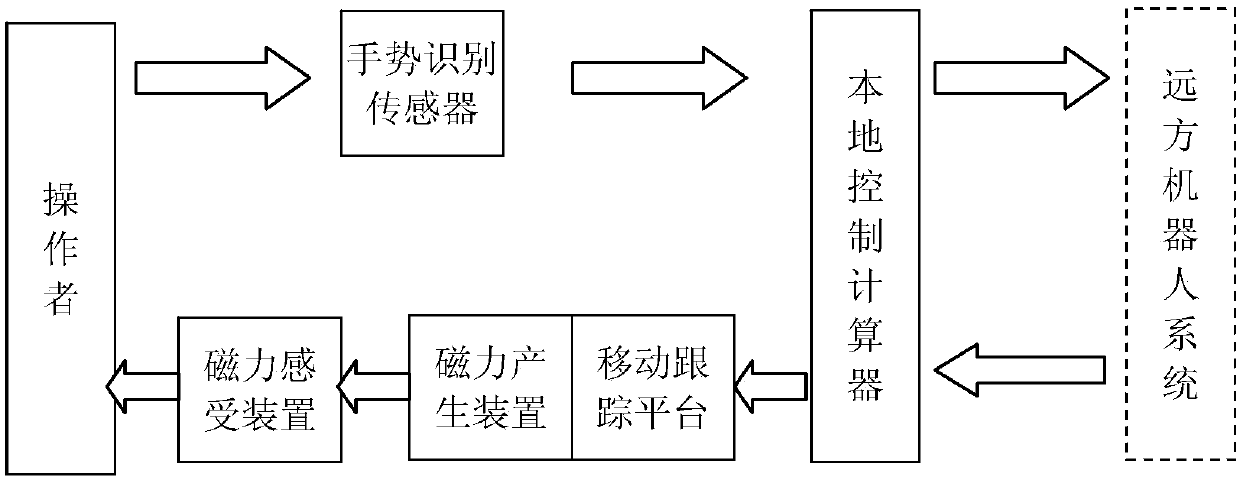

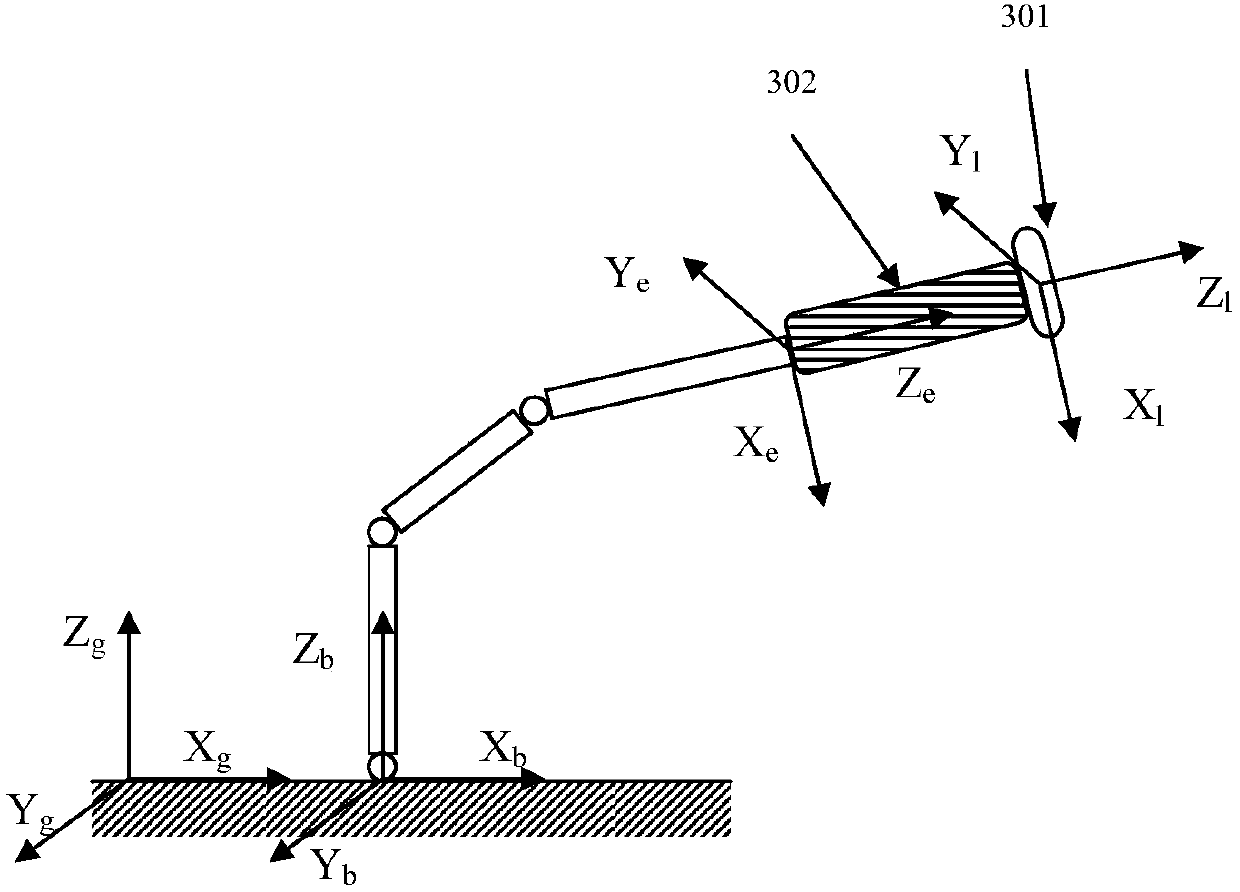

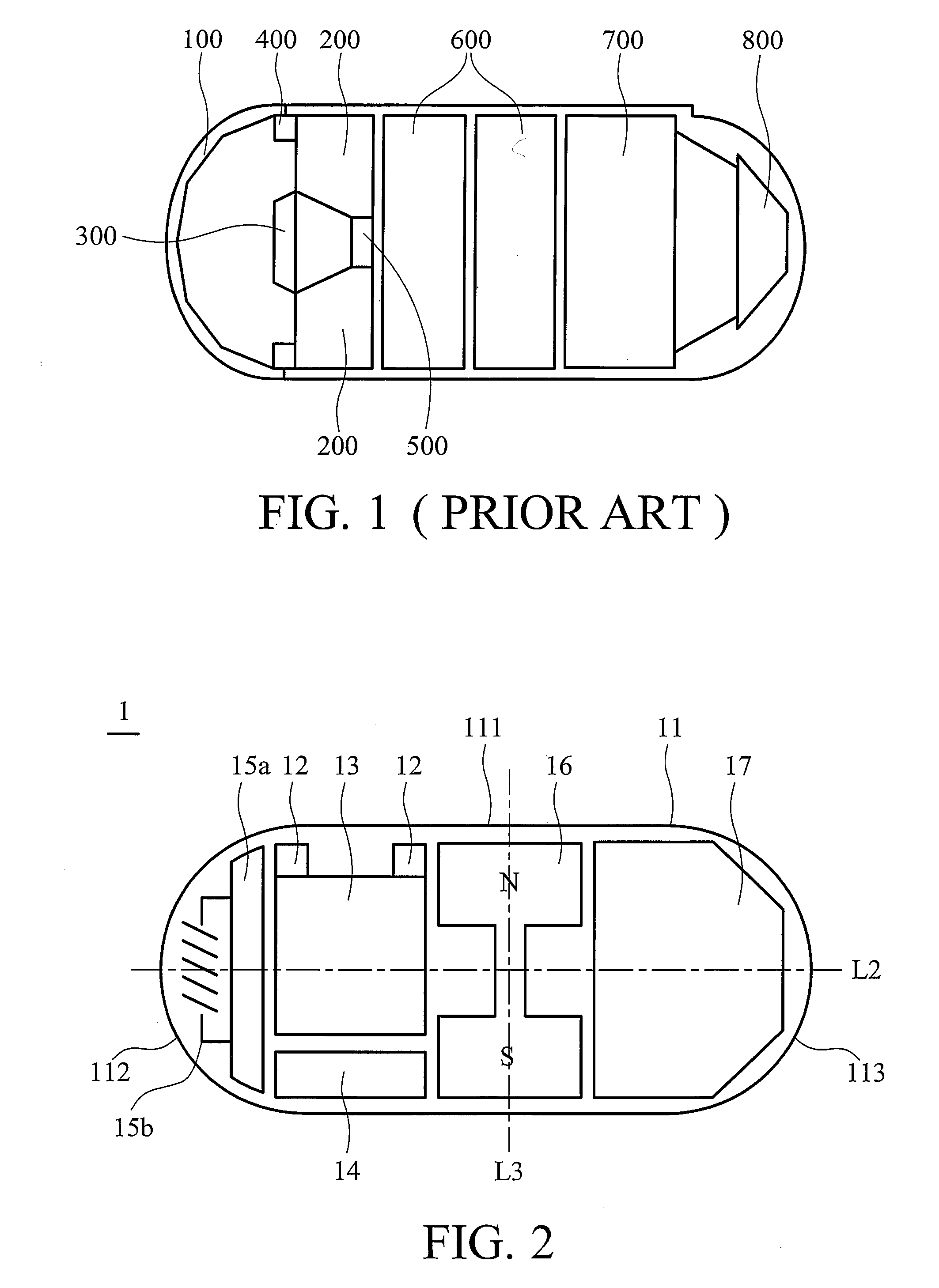

The invention provides a force feedback man-machine interaction system and method based on the electromagnetic theory and mobile tracking. By the adoption of the force feedback man-machine interactionsystem and method, a manipulator is allowed to use gestures to control a robot and meanwhile can feel force feedback in the operation process. The interaction system includes five parts of a local control calculator, a mobile tracking platform, a gesture recognition sensor, a magnetic force generating device and a magnetic force sensing device. The interaction method is divided into two parts ofcontrol and feedback. The control part uses the non-contact gesture based on a visual interface as control information, while the feedback part uses the non-contact force magnetic force as feedback information to reduce the physical limitation when interacting, meanwhile a mobile tracking function is added, and it is ensured that the magnetic force generating device and the magnetic force sensingdevice can keep relative positions and postures of the magnetic force generating device and the magnetic force sensing device unchanged, so that the problem of too little stress caused by the attenuation of a magnetic field is reduced.

Owner:SOUTH CHINA UNIV OF TECH

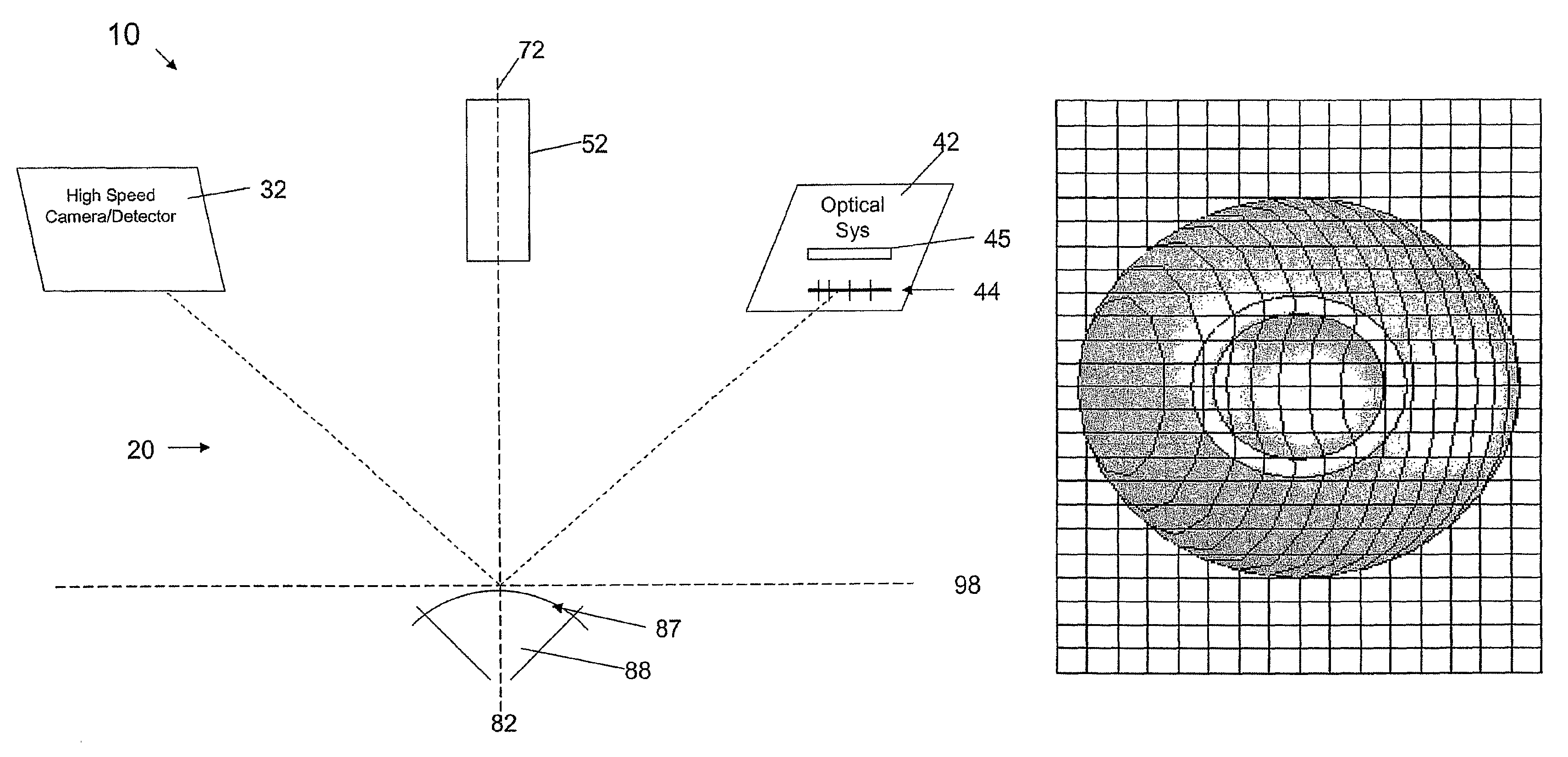

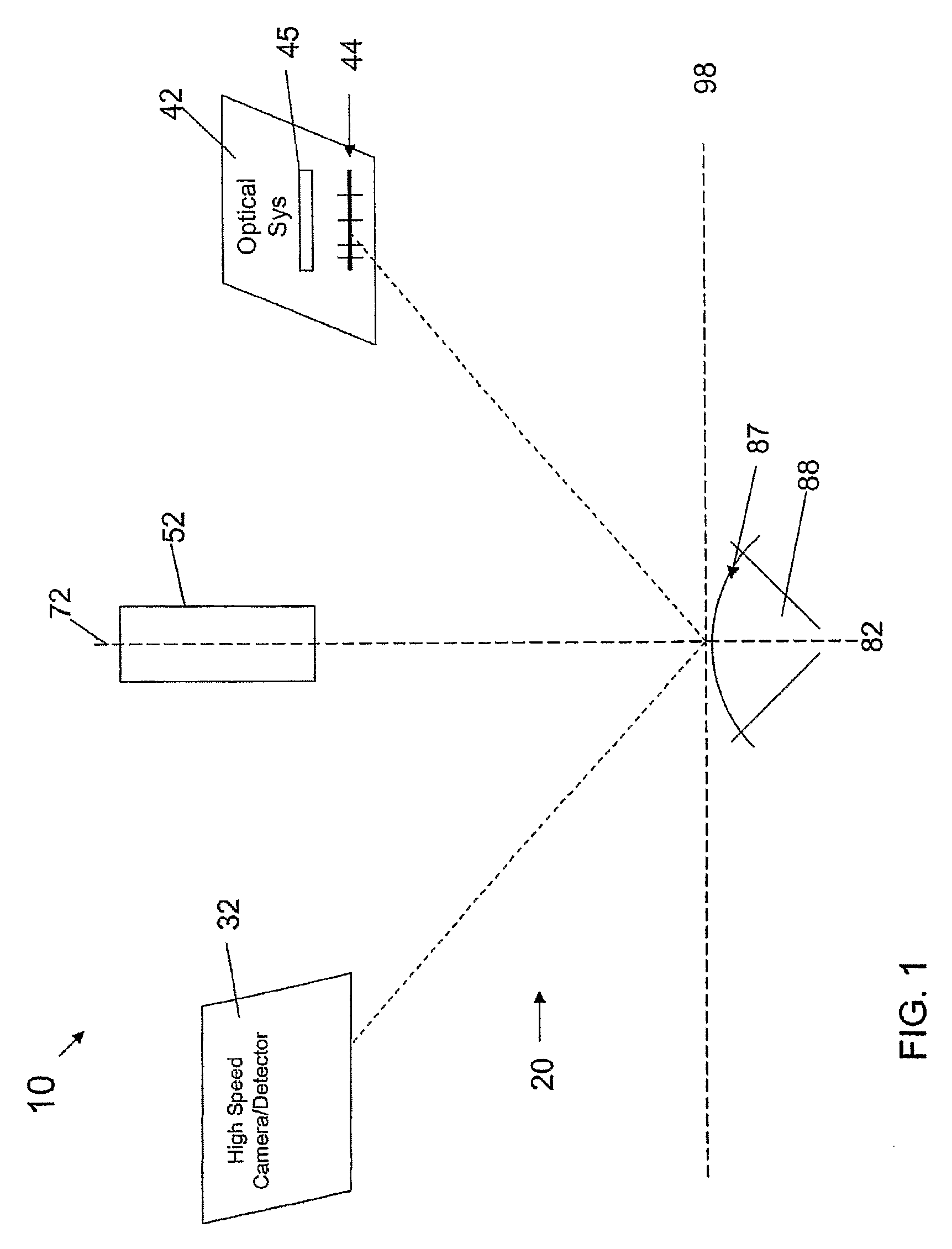

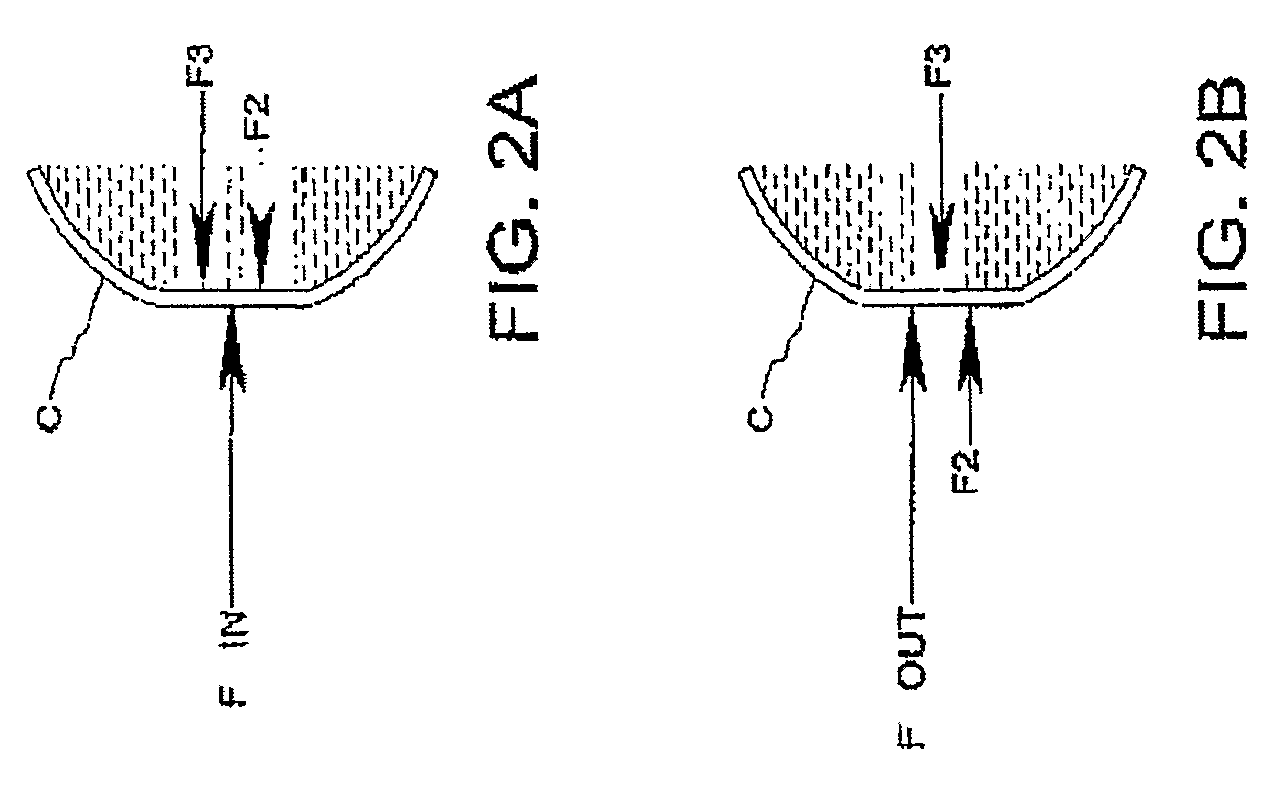

Method and Apparatus For Measuring the Deformation Characteristics of an Object

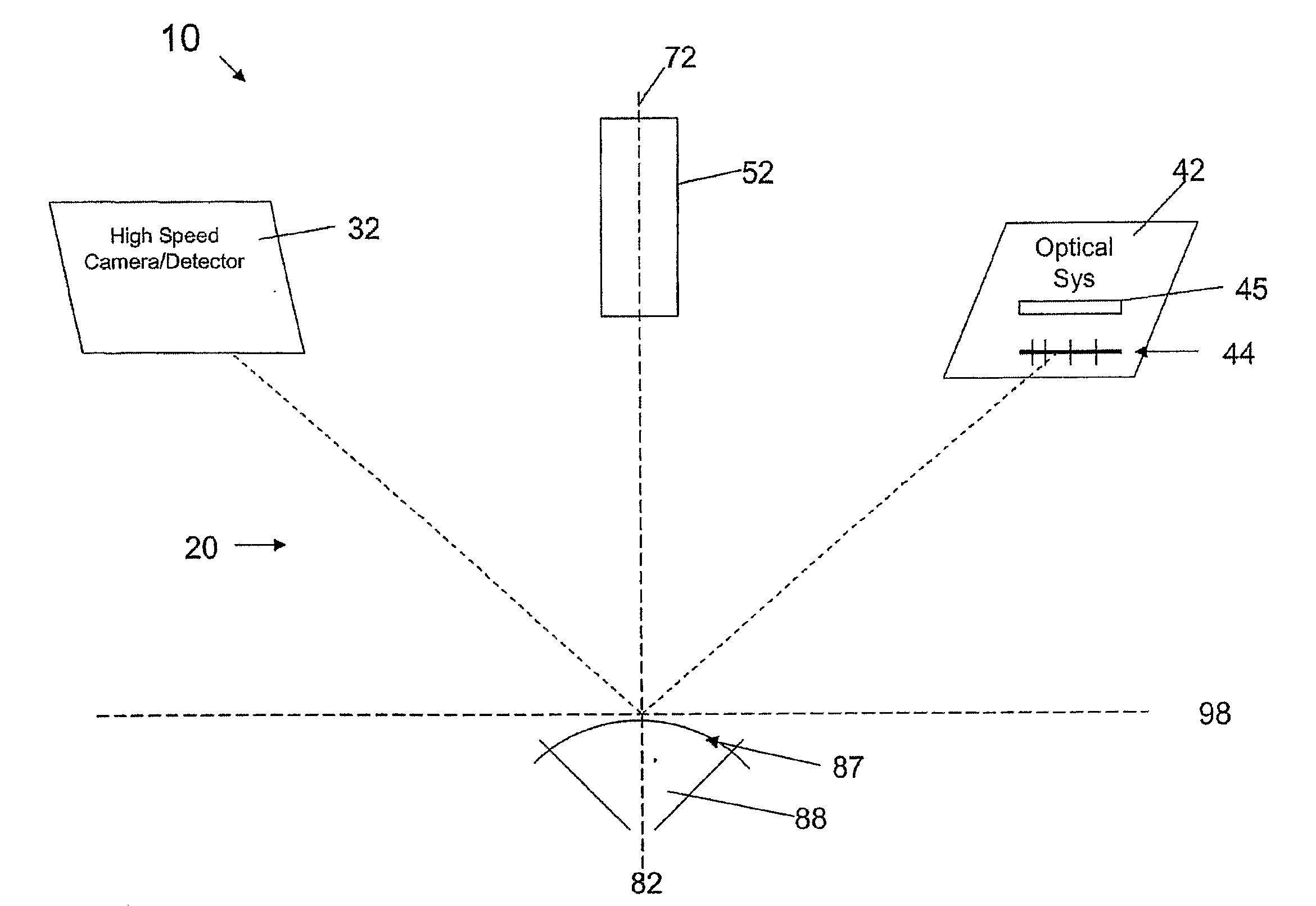

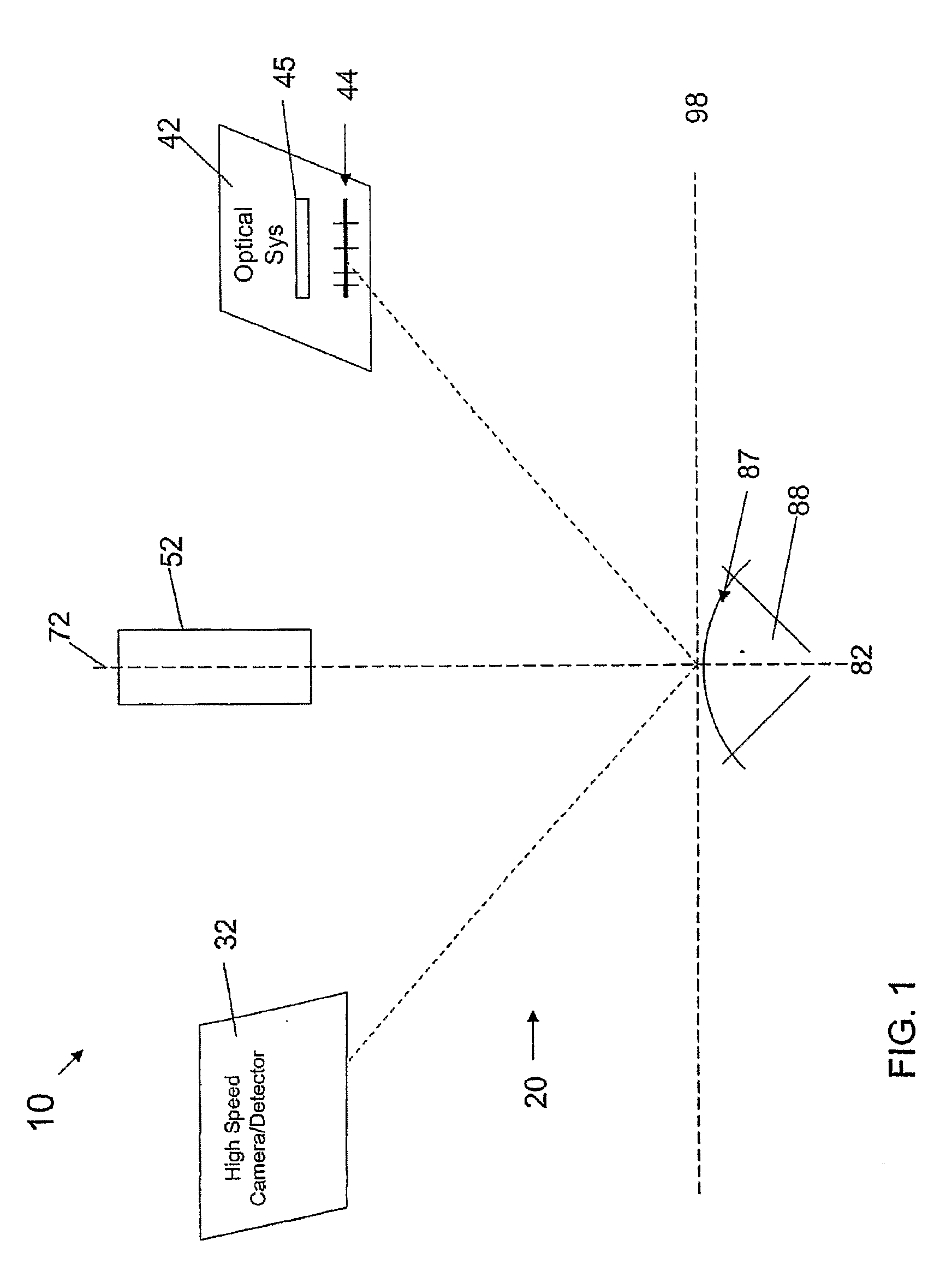

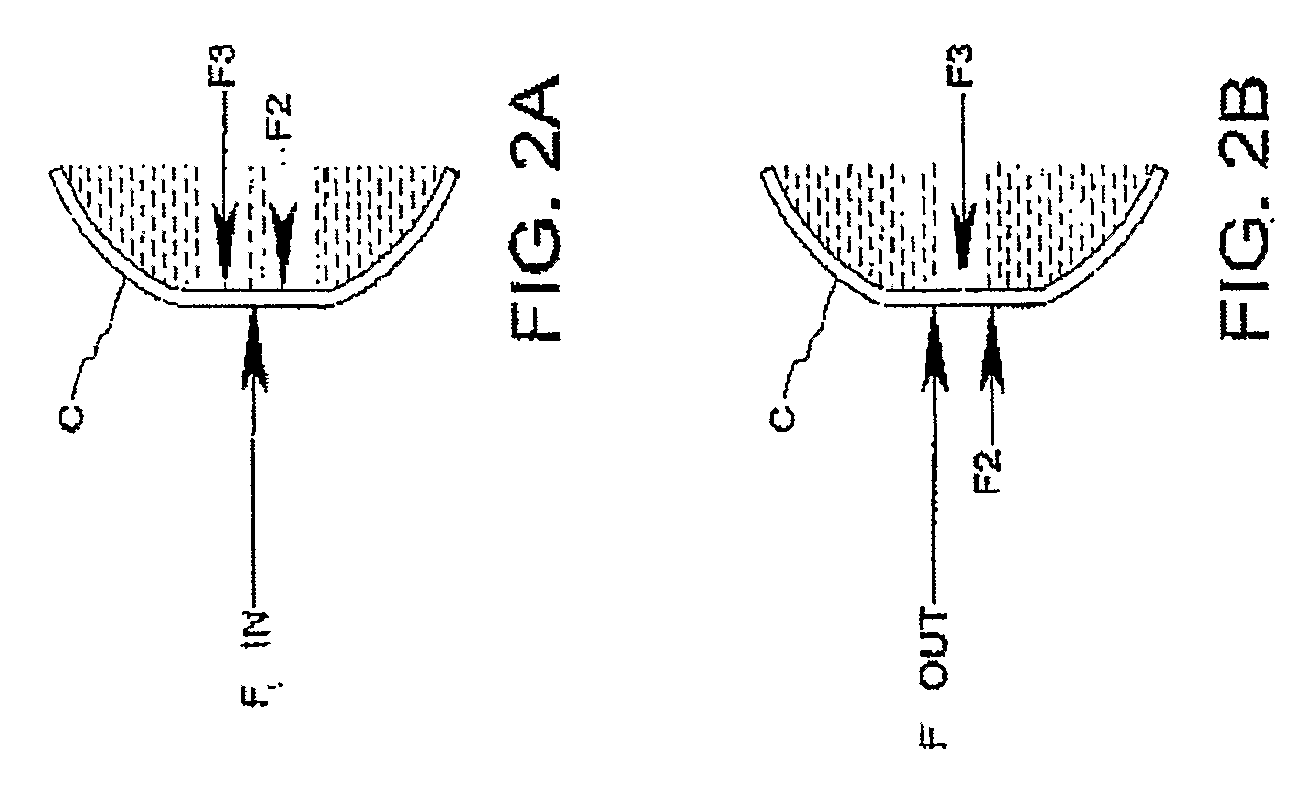

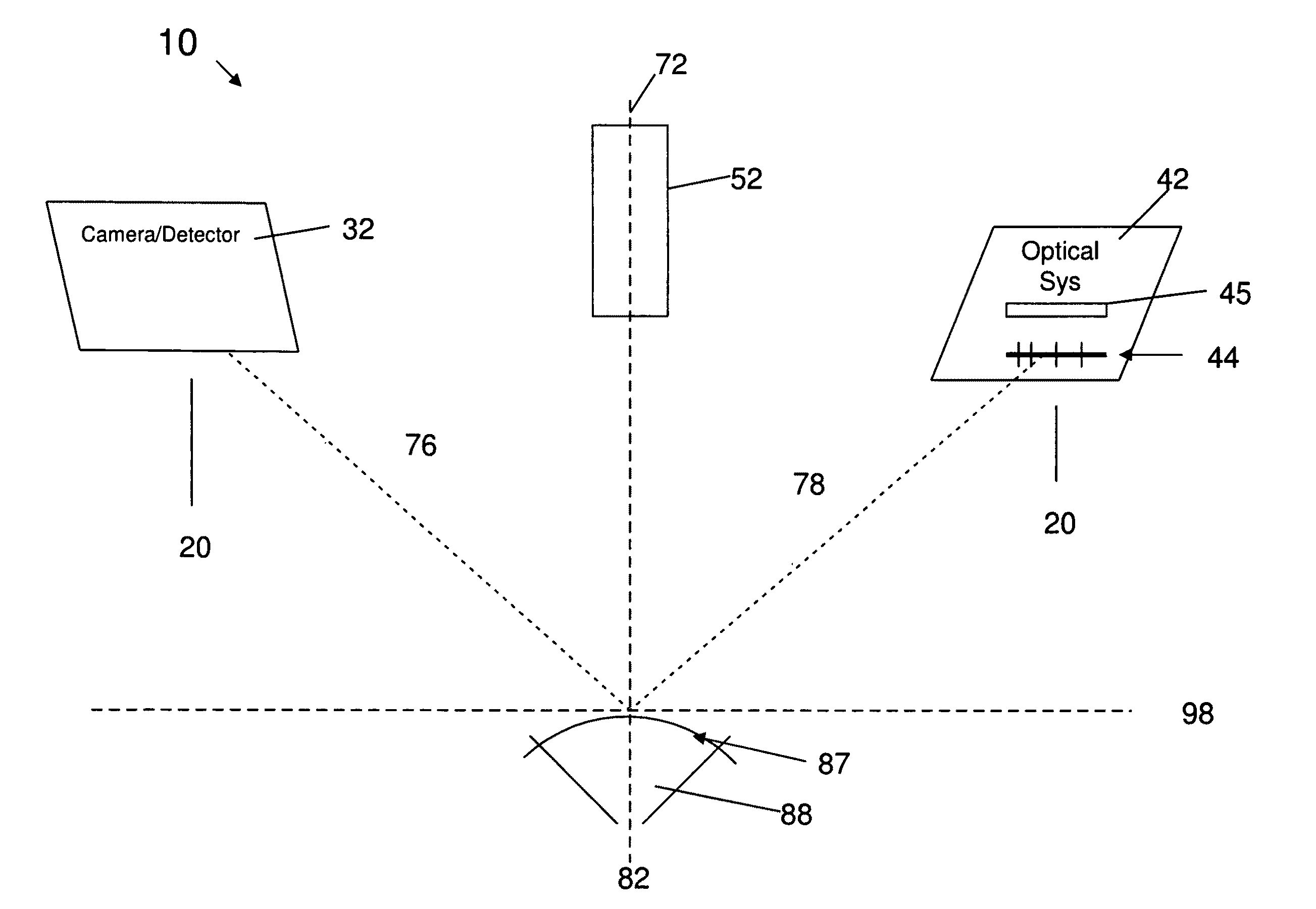

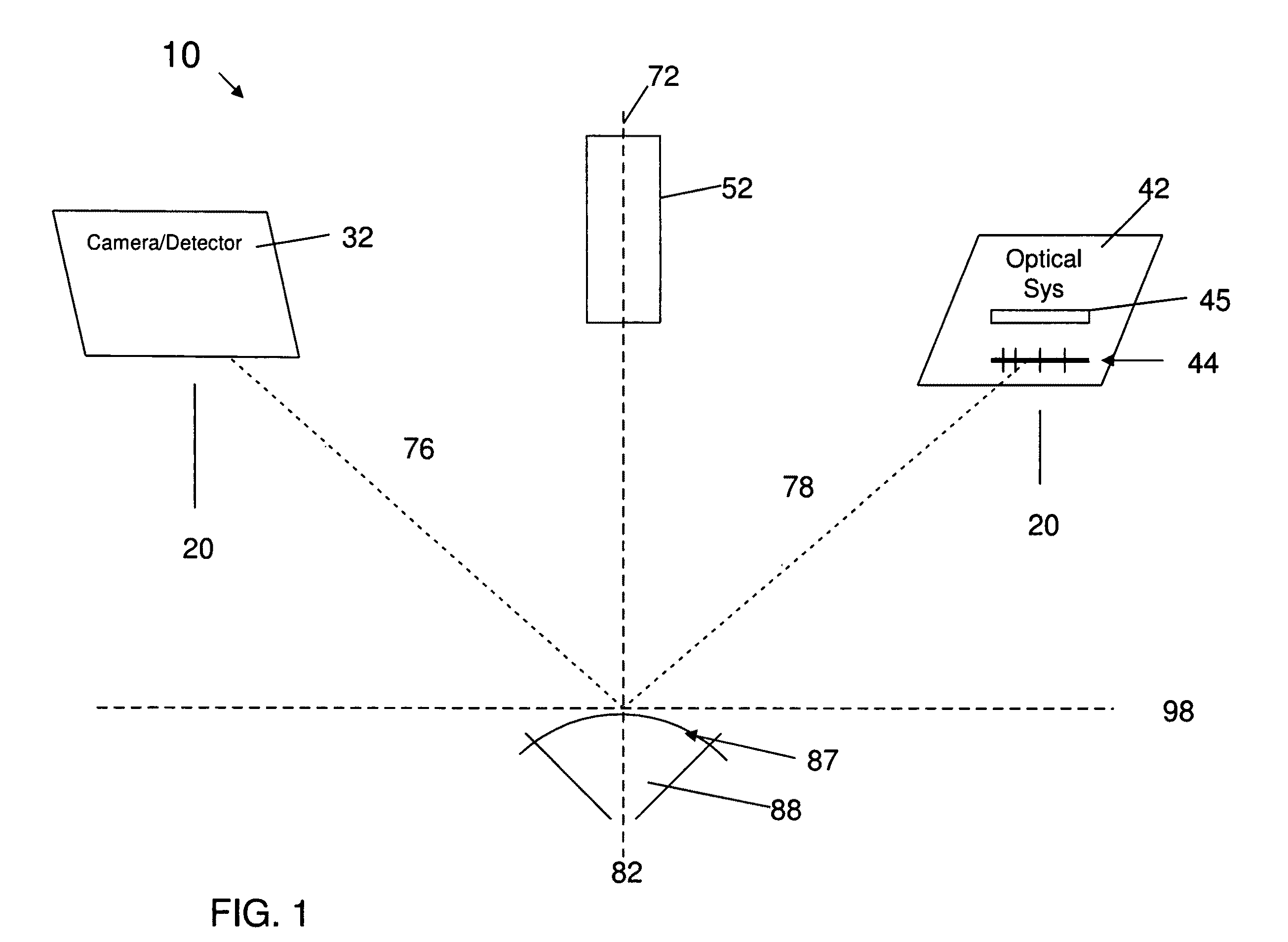

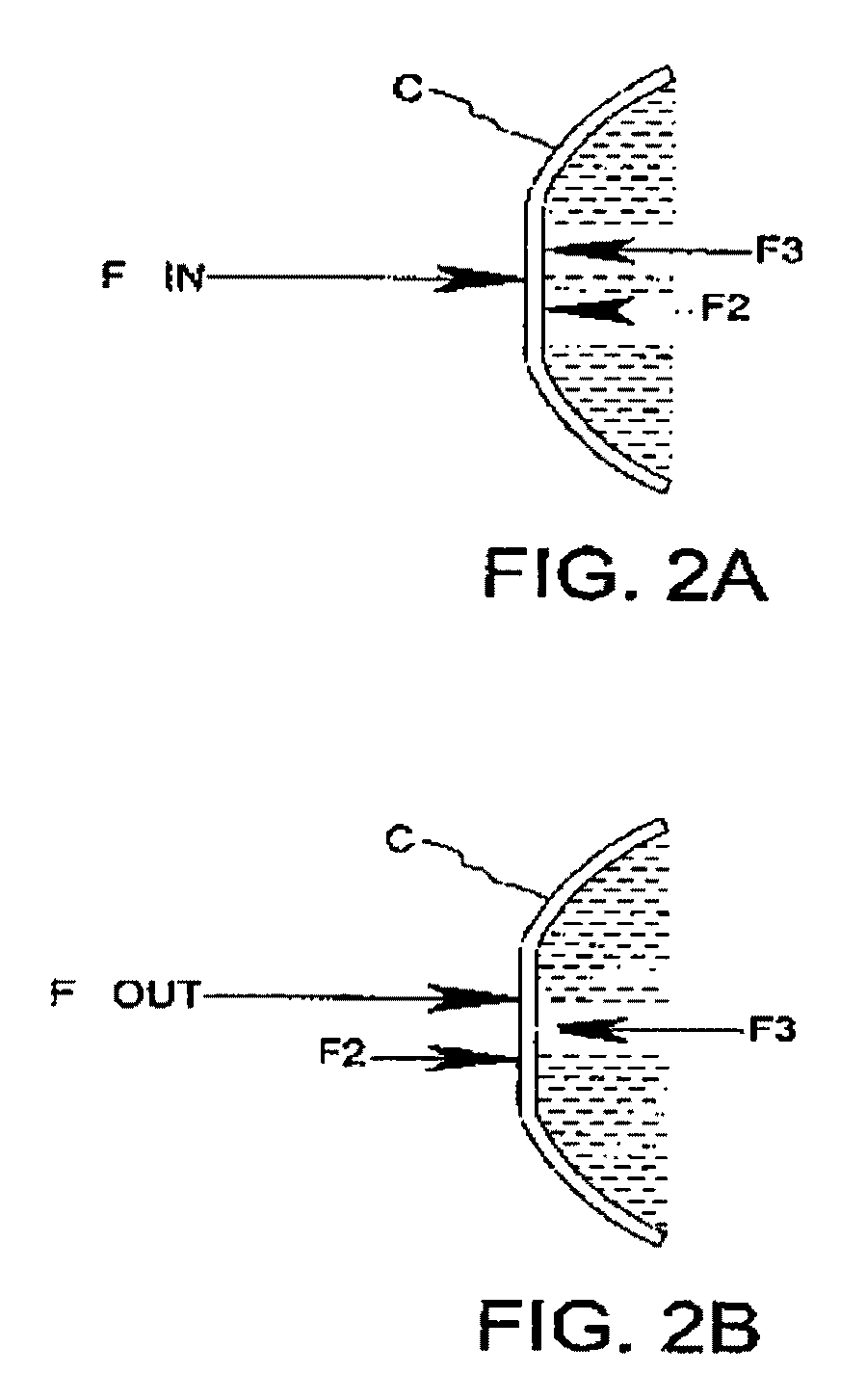

Embodiments of the invention are generally directed to apparatus and methods for measuring a deformation characteristic of a deformable target surface. The measurement principles of the invention may be applied to a large variety of organic (e.g., human, animal or plant tissue) and inorganic materials having a surface that can be deformed by an applied non-contact force. The surface may be light diffusing and non-transparent or non-diffusing and transparent. An illustrative embodiment of the invention is directed to a device for measuring a deformation characteristic of a cornea. The device comprises a corneal topographer and a non-contact tonometer that is operationally integrated with the corneal topographer. In an aspect, the corneal topographer is a rasterstereography-based topographer. Use of the inventive device enables a method for measuring a deformation characteristic of the cornea. In addition to the measurable deformation characteristics listed above, dioptric power, intraocular pressure, corneal hysteresis, corneal elasticity, corneal viscosity and various known corneal topography characteristics can be measured.

Owner:CRS & ASSOCS

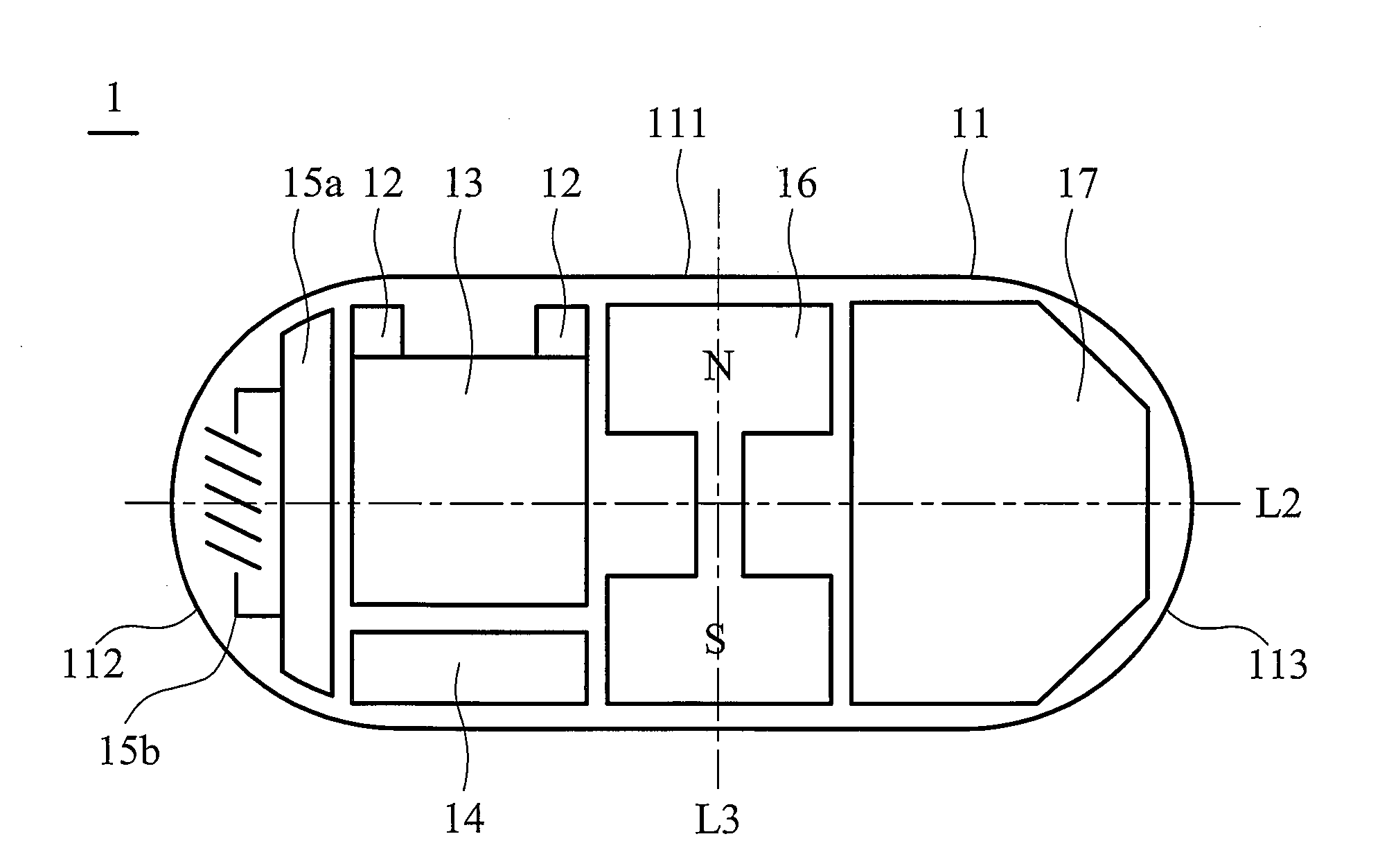

Endoscope and magnetic field control method thereof

An endoscope device is provided. The endoscope device includes a capsule sensor entering a human body for detection and sending a signal, a driving device movably disposed outside of the human body and moving and rotating the capsule sensor in the human body with non-contact force for omni-directional human body detection, a data receiving device disposed outside of the human body and receiving signals from the capsule sensor, and a power supply device providing power to the driving device and the data receiving device.

Owner:NAT TAIWAN UNIV

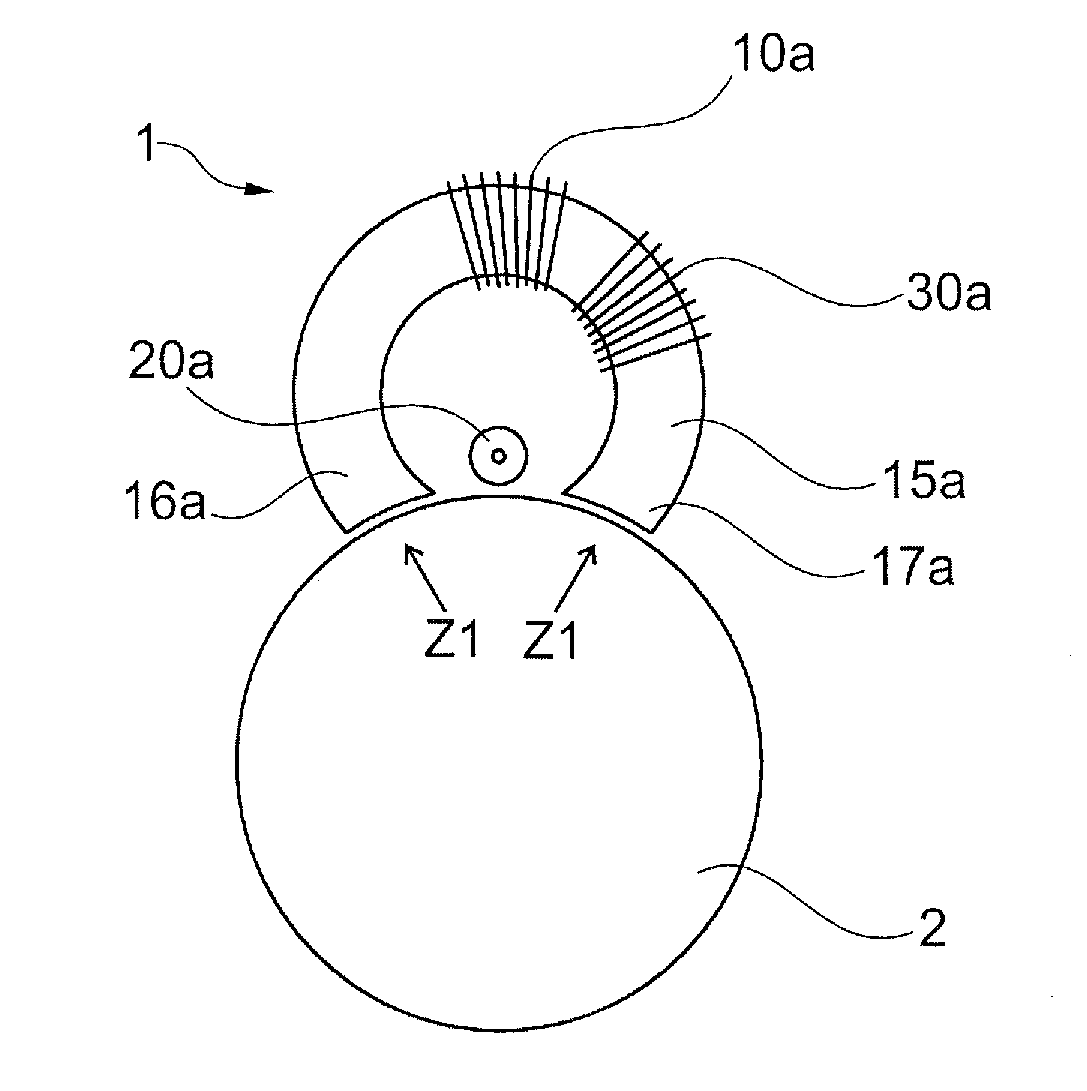

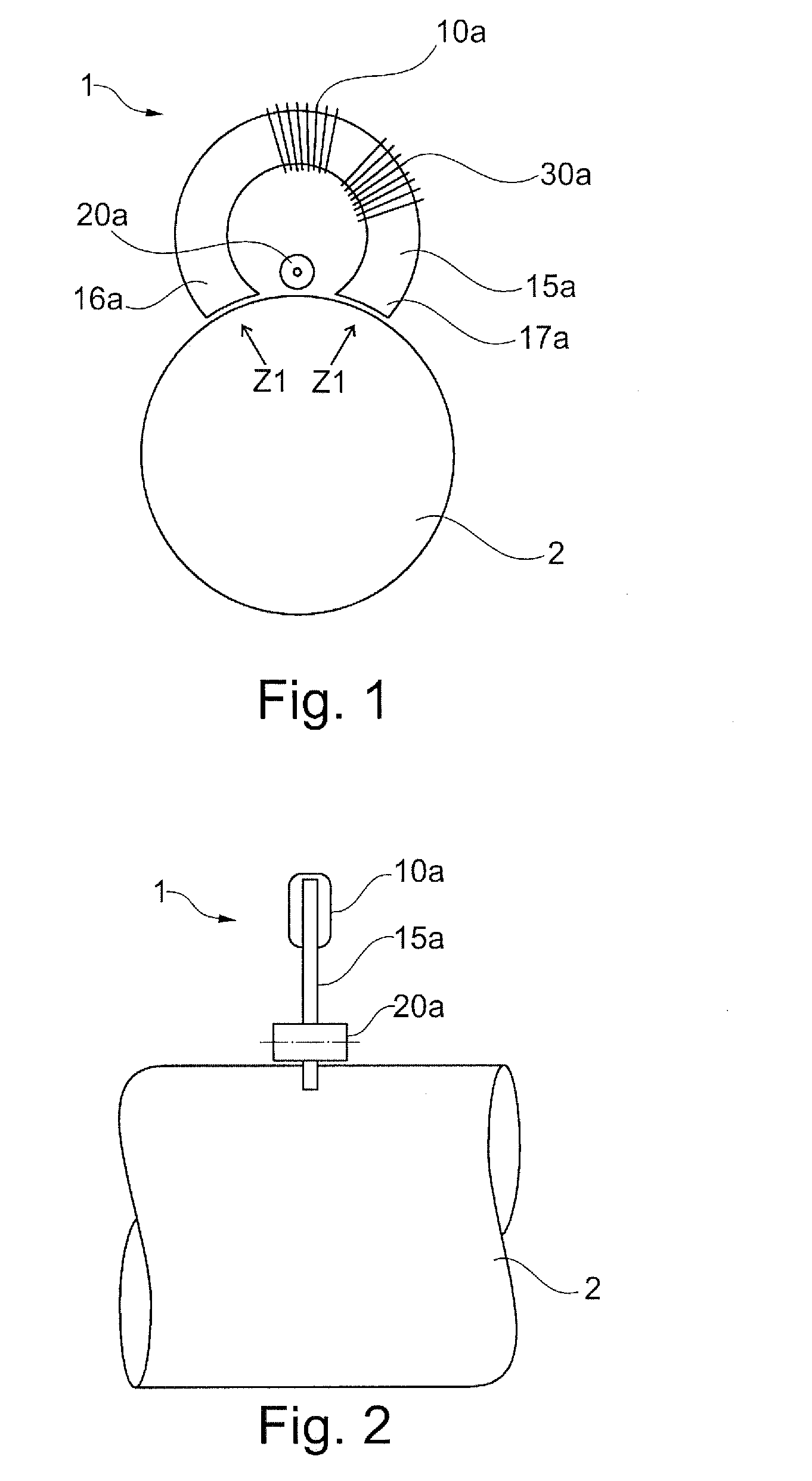

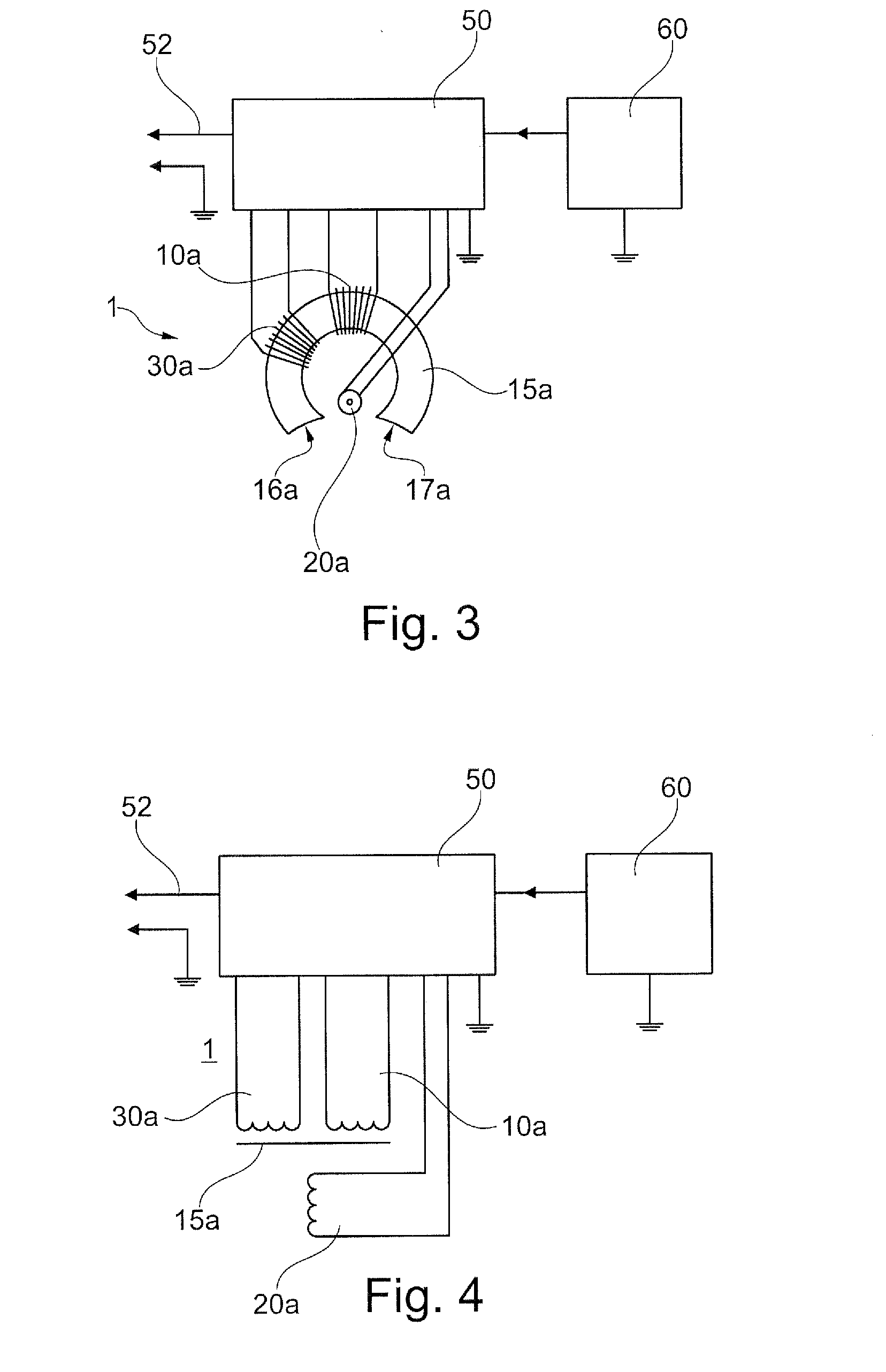

Controlled contact or contactless force transmission in a timepiece

InactiveUS20130170330A1Limit and eliminate any contactFrictionGearworksRepair toolsContact forceNon-contact force

The invention concerns a method of making a controlled or reduced contact or contactless transmission in a timepiece movement.At least one pair of opposing cooperating surfaces of said timepiece movement, one of which drives the other or is supported thereby, is made or transformed by applying a surface or through treatment conferring an electrostatic and / or magnetic charge of the same polarisation and / or magnetisation on said opposing cooperating surfaces, such that said opposing components tend to repel each other when they are moved closer to each other.Said treatment consists in creating or depositing at least one thin layer on said cooperating surface and / or on said opposing cooperating surface.The invention also concerns a timepiece mechanism incorporating at least one pair of opposing components, one of which drives the other or is supported thereby, said pair being made or transformed by implementing this method.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

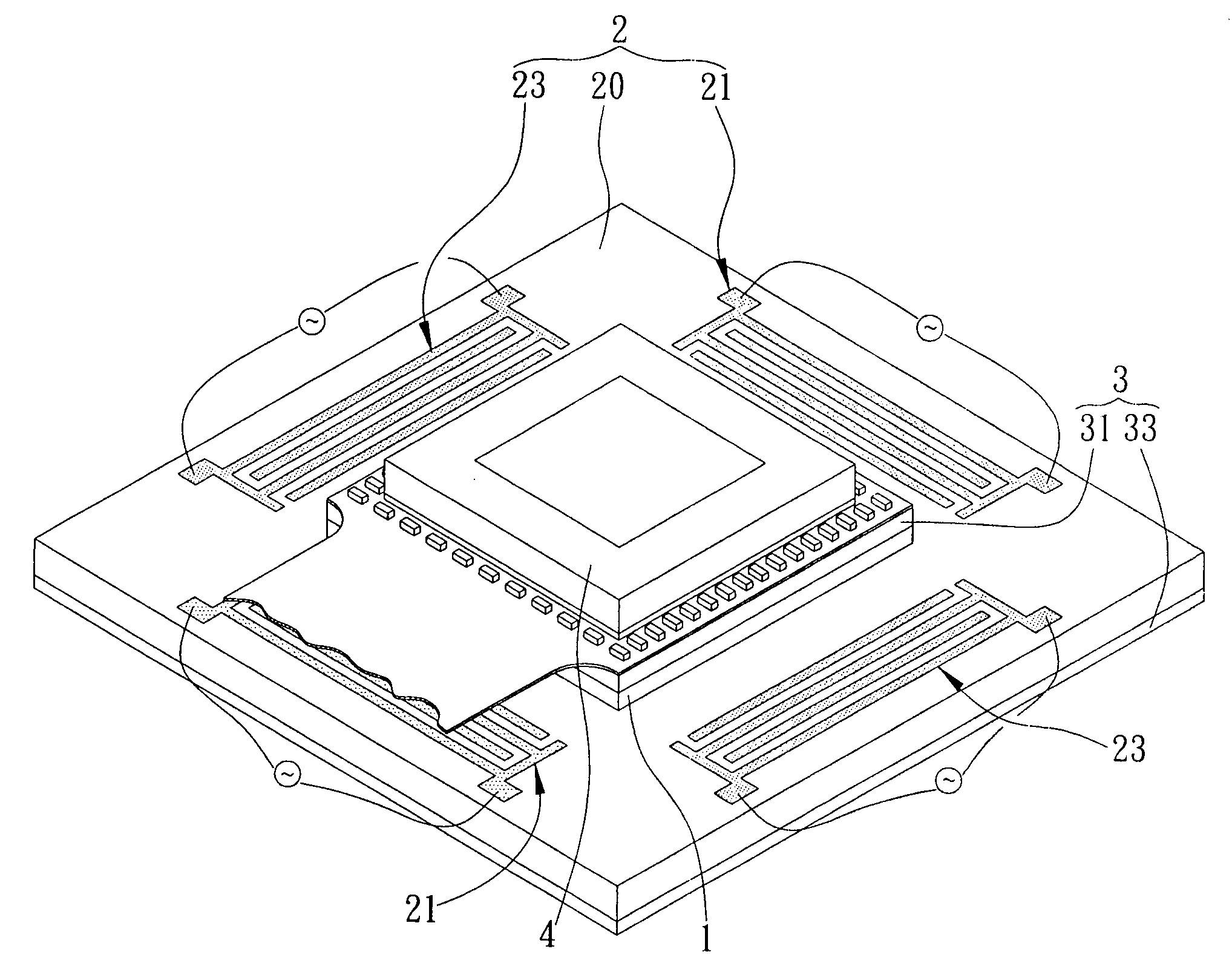

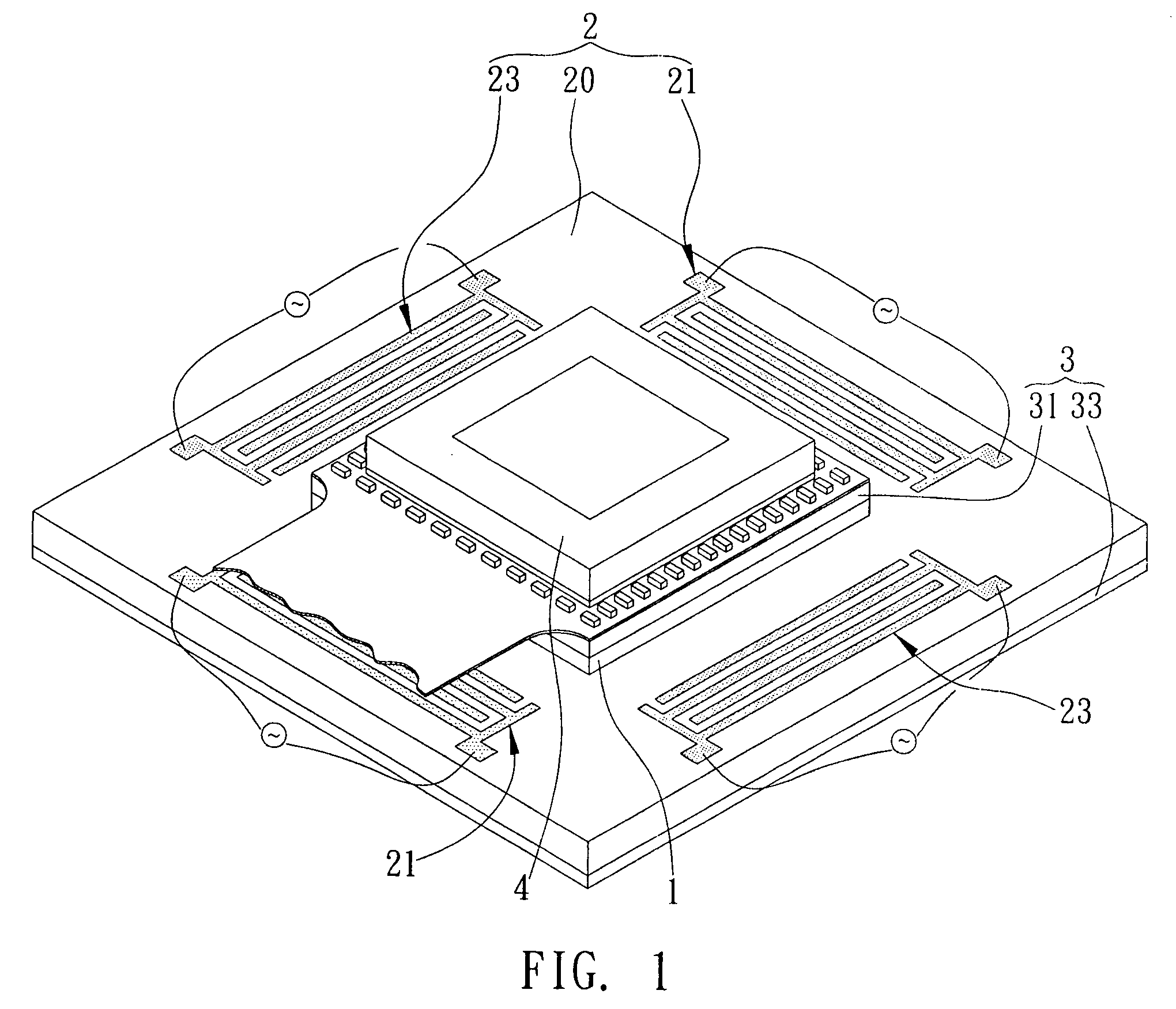

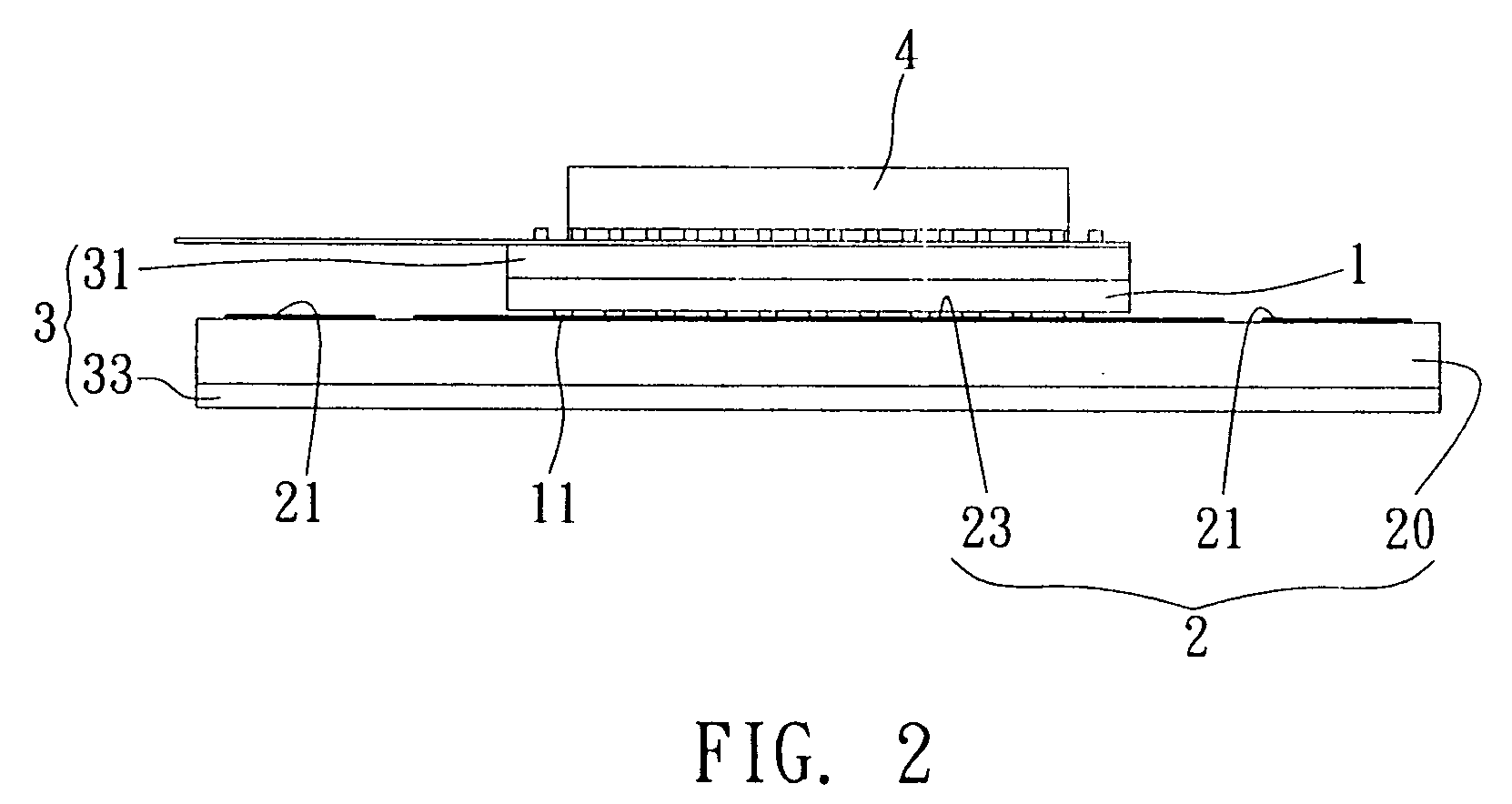

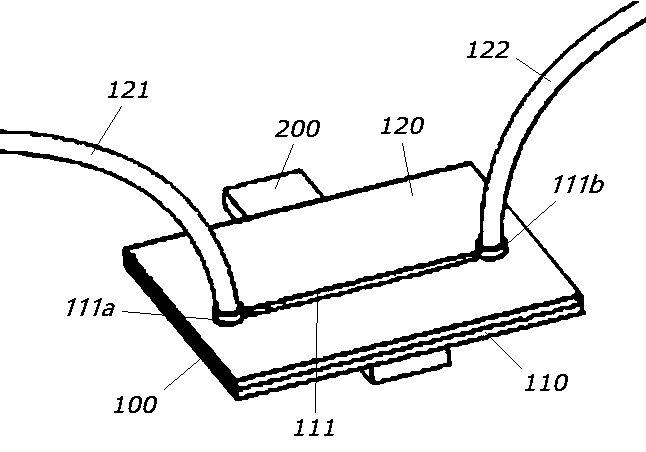

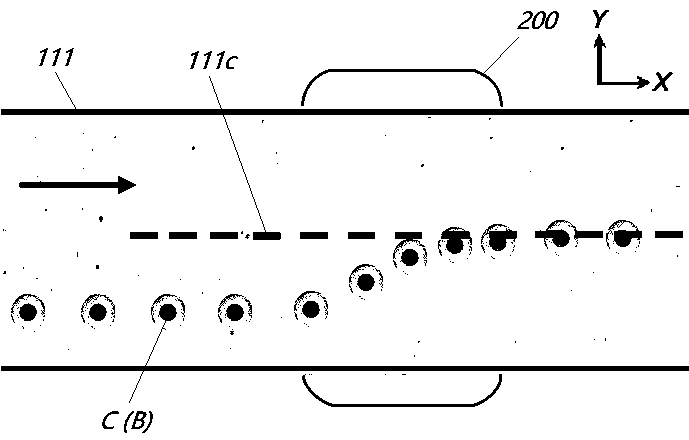

Image stabilization driving device

InactiveUS20080284860A1Broaden applicationEasy to assembleTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesImage stabilizationAcoustic wave

An image-stabilizing driving device is proposed, including a slidable block coupled to an image sensor, a flat surface acoustic wave actuator for contacting with and driving the slidable block to move on a surface contacted therewith, and a contactless force action unit having a first and a second contactless force action layers. The first contactless force action layer is formed between the slidable block and the image sensor and the second contactless force action layer is formed on a bottom surface of the flat surface acoustic wave actuator, thereby providing preload force for the slidable block to contact with flat surface ascoustic wave actuator so as to form a thin image-stabilizing driving device.

Owner:IND TECH RES INST

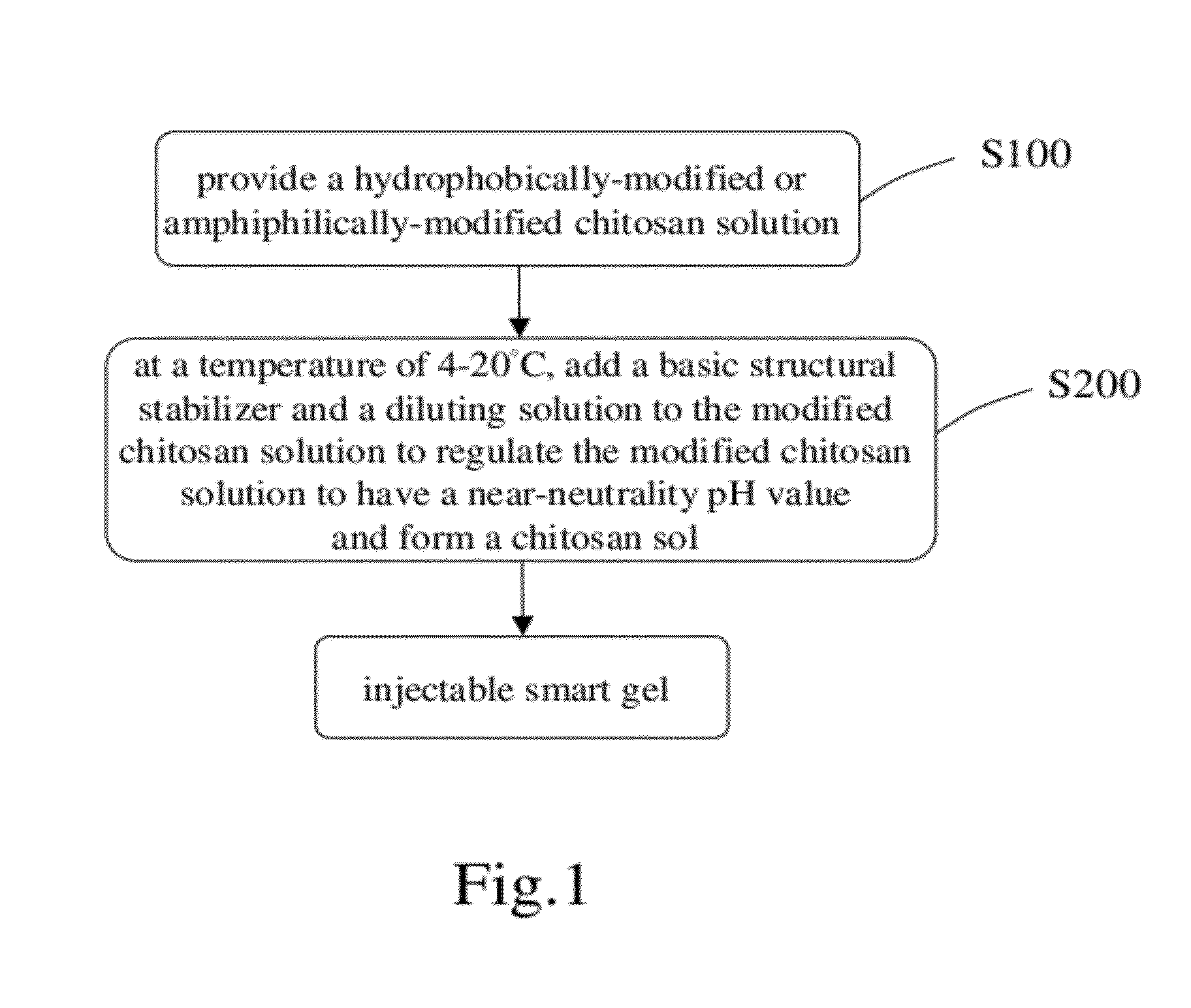

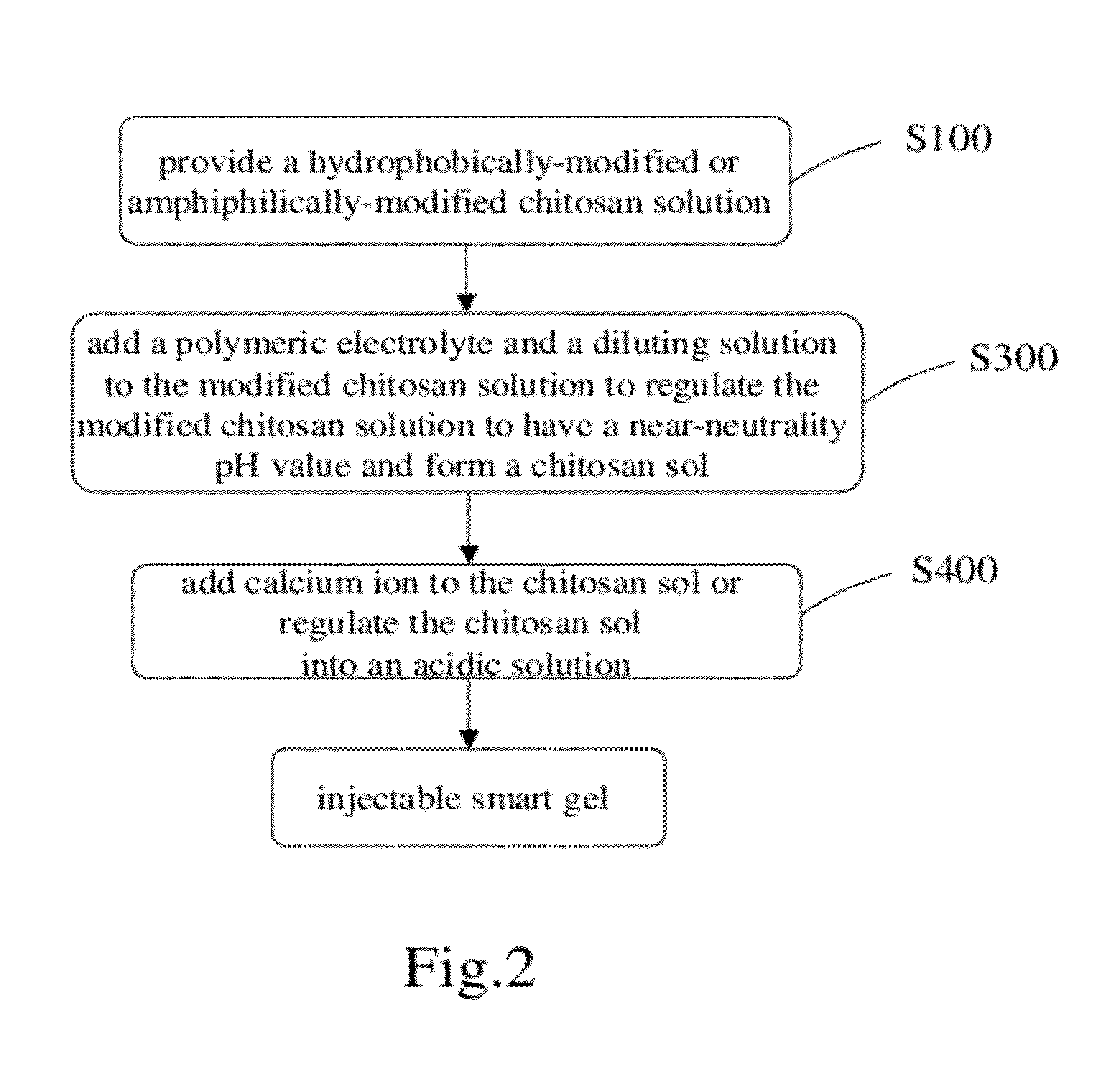

Injectable smart gel and method for fabricating the same

An injectable smart gel and a method for fabricating the same are disclosed. A basic structural stabilizer / polymeric electrolyte and a diluting solution are added to a modified chitosan to regulate the chitosan solution to have a pH value closing to that of the human body and form a flowable chitosan sol. The flowable chitosan sols formed thereby are respectively converted into inflowable chitosan gels via increasing the temperature thereof to the human body temperature, and via adding calcium ion or regulating the chitosan sol into an acidic solution. The injectable smart gel fabricated thereby is injectable and able to function as a carrier of magnetism-sensitive medicine-containing nanocapsules. The medicine can be released to the injectable smart gel with an external non-contact force, such as a magnetic field, an electric field or an ultrasonic wave, for long-acting and multi-stage medicine delivery. The present invention is very useful in biomedical engineering.

Owner:NAT CHIAO TUNG UNIV

Method and apparatus for determining dynamic deformation characteristics of an object

Owner:VISION OPTIMIZATION

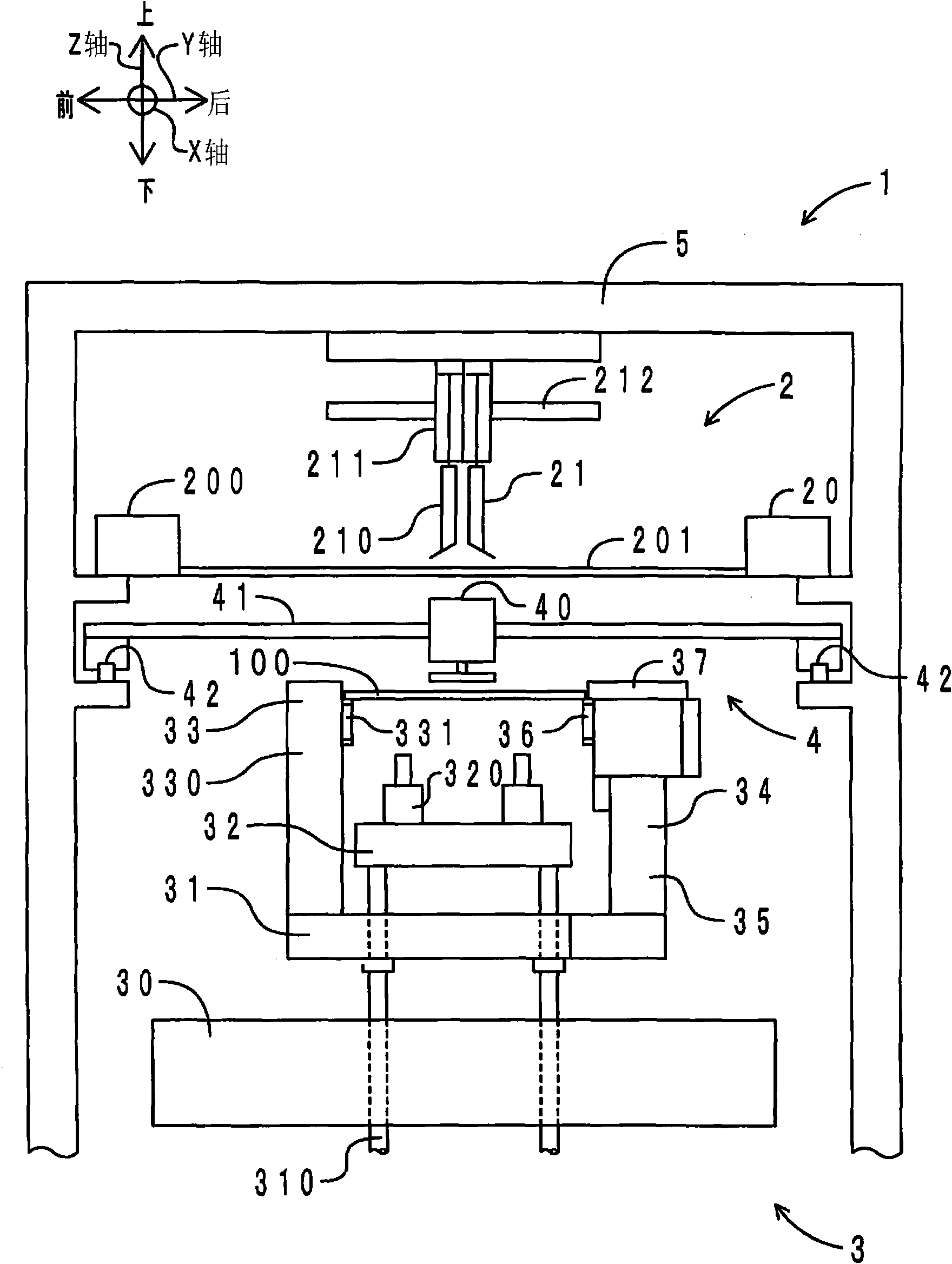

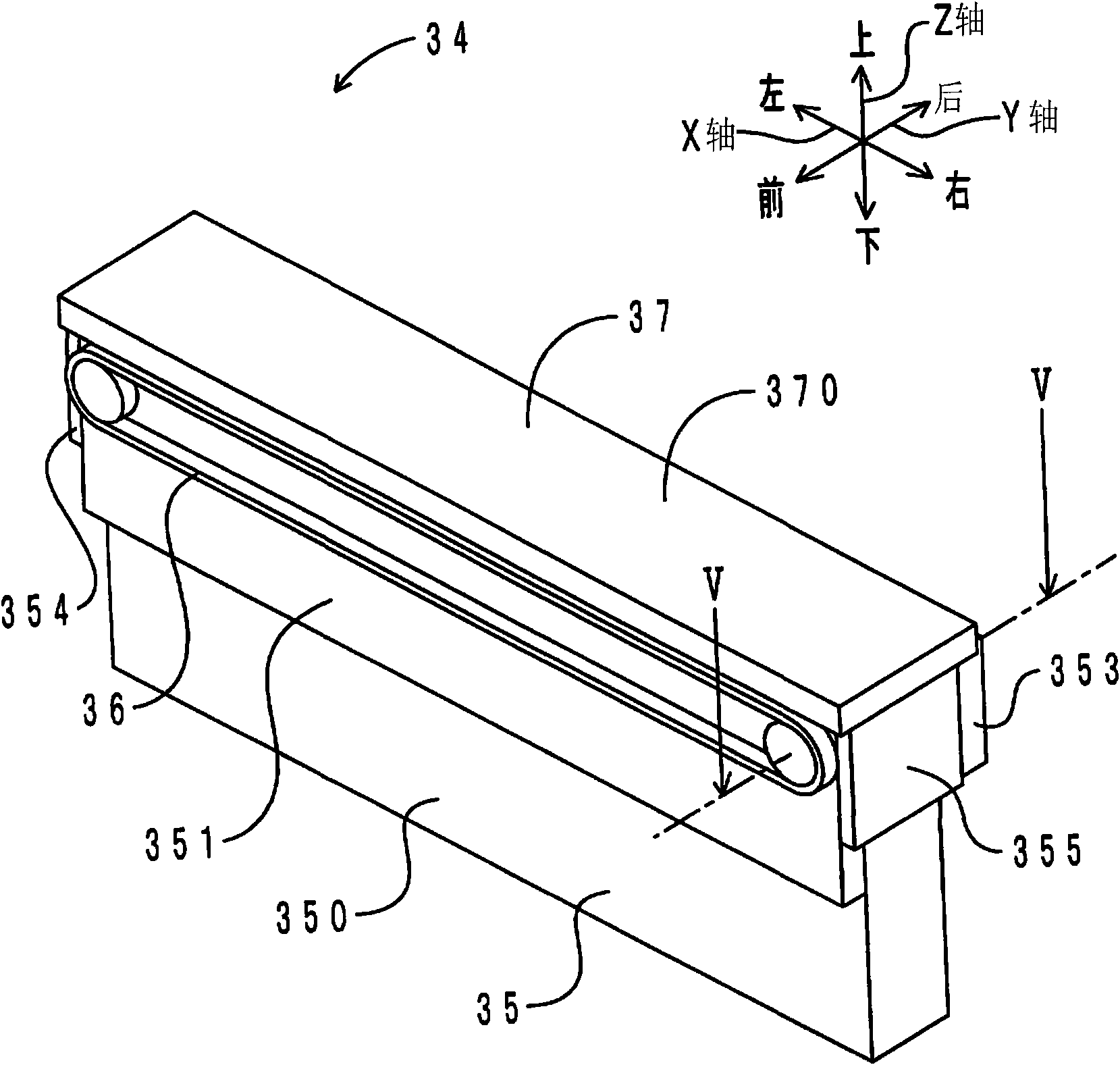

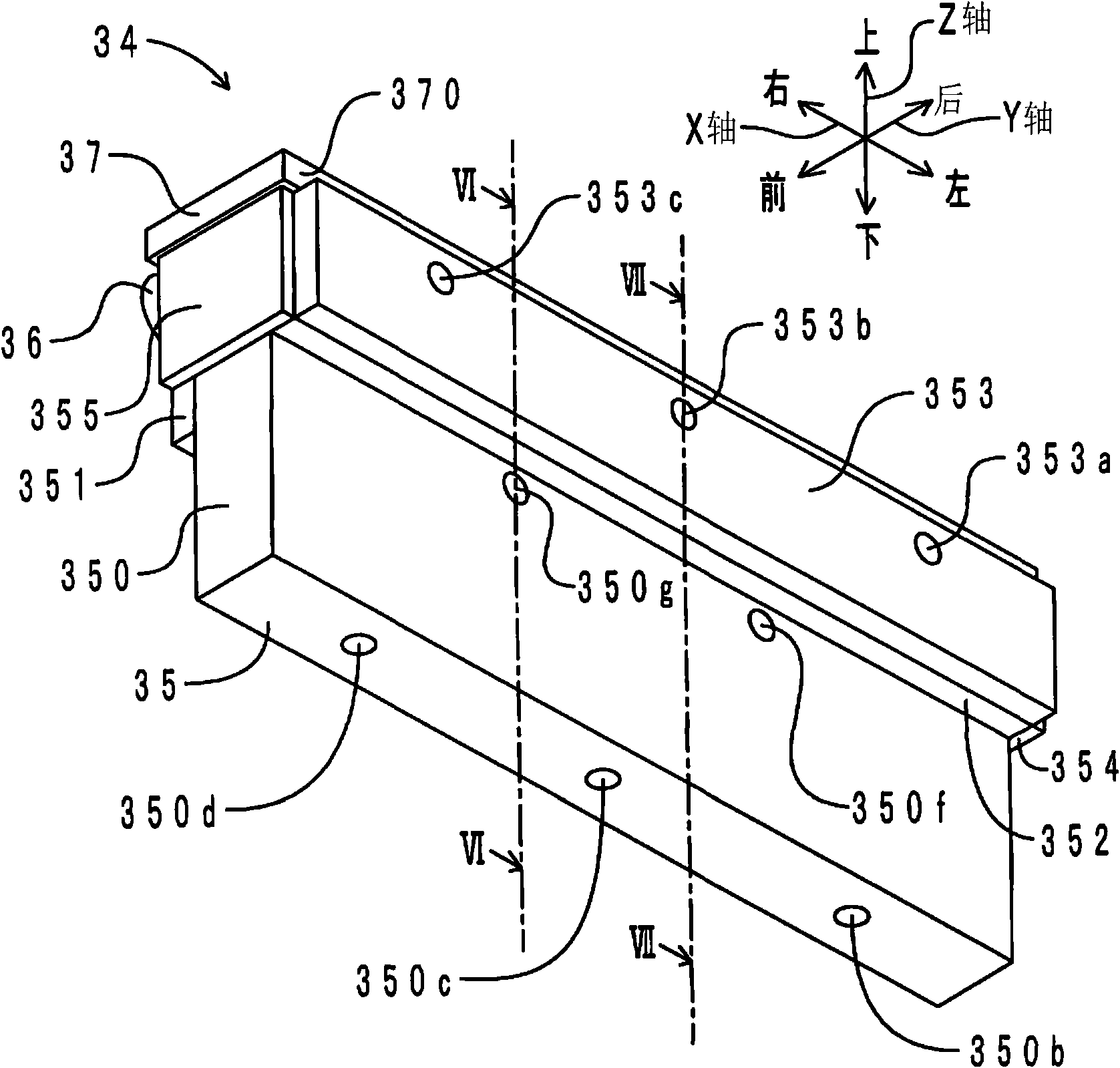

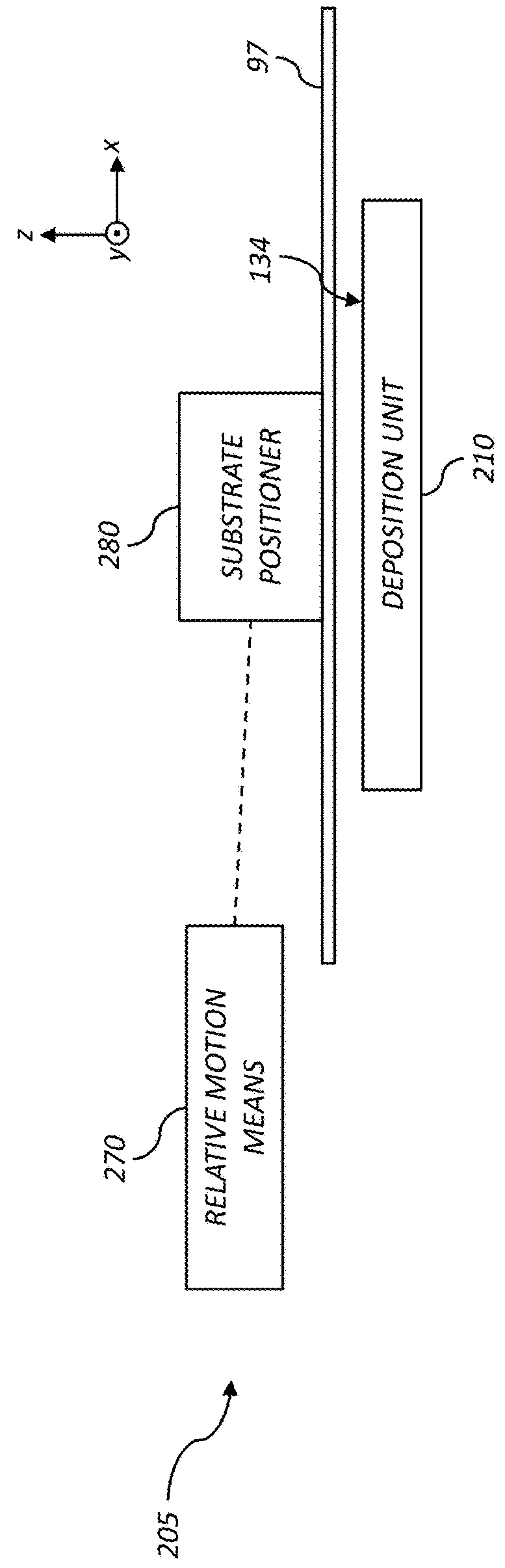

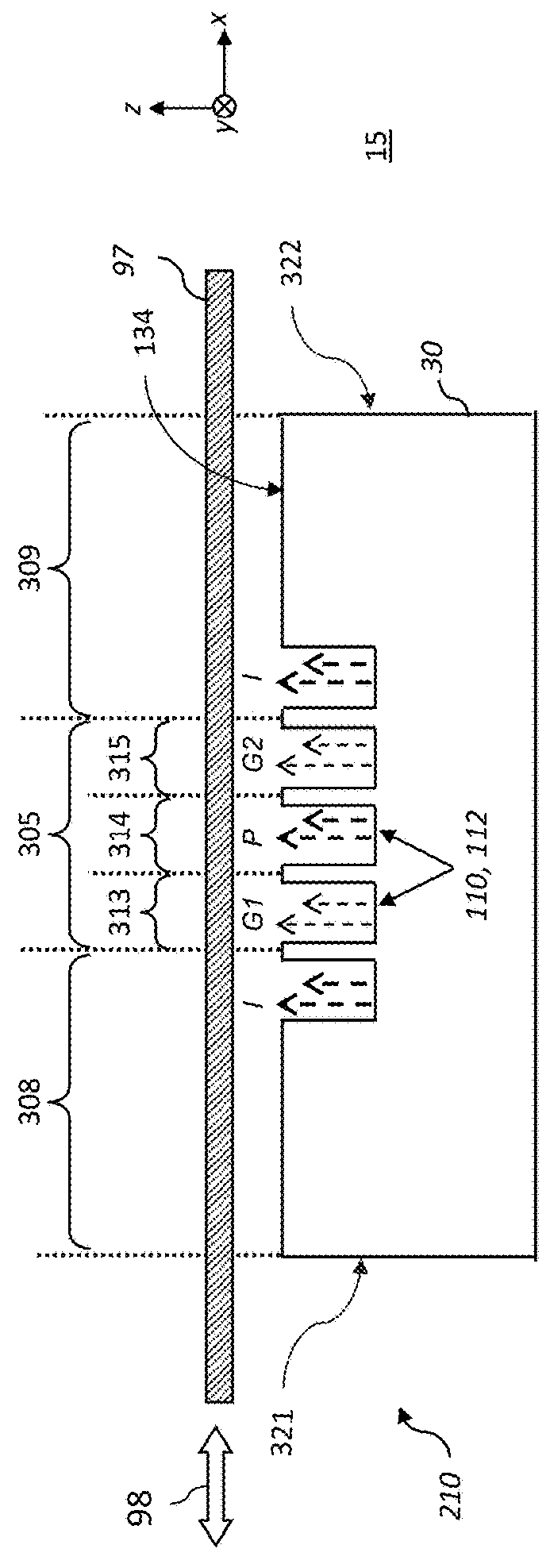

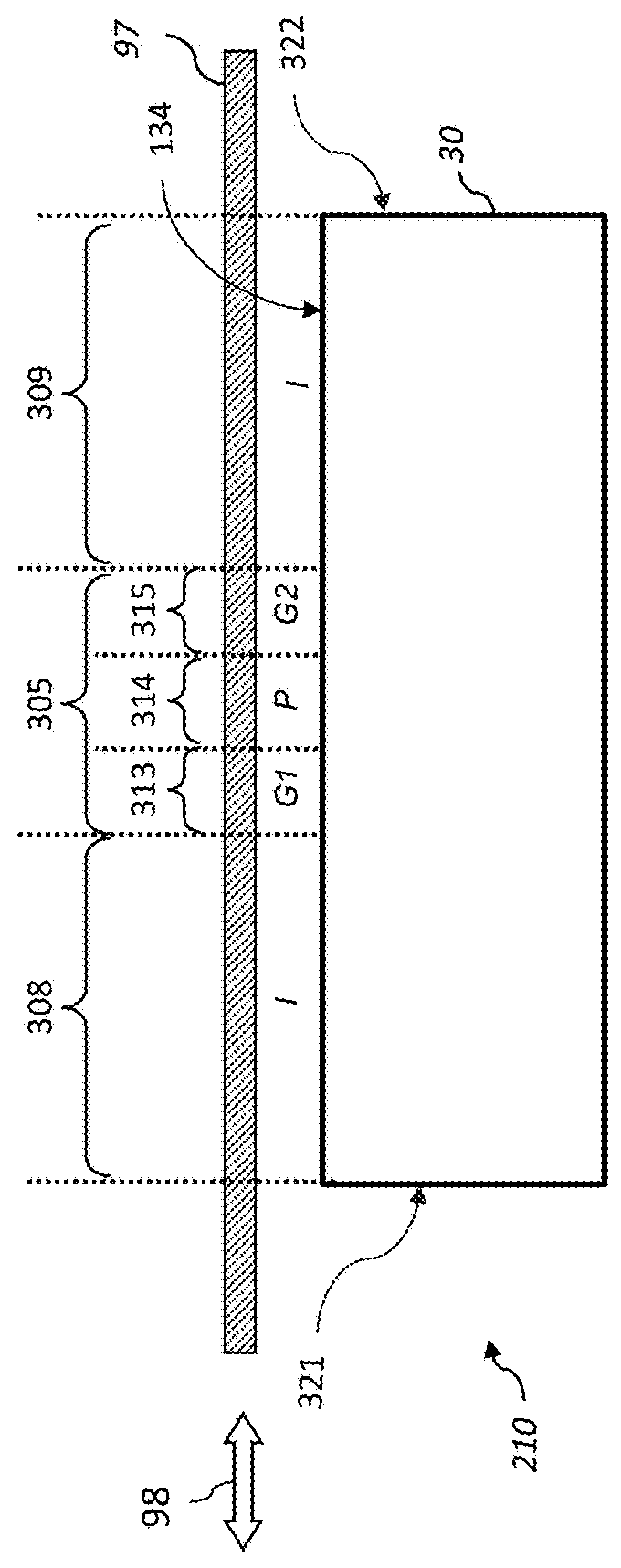

Substrate positioning device and method, substrate processing device and method

ActiveCN101564931AControl the amount of movementControl clamping forcePrinted circuit assemblingScreen printersRepulsion forceContact force

The invention provides a substrate positioning device and the method, a substrate processing device and the method which can precisely control the clamping force and cause the clamping force difficult to deviate. The substrate positioning device positions a circuit substrate by reducing the width between a pair of clamping members, is characterized in: at least one clamping member comprises a base, a movable part and a noncontact driving mechanism; the movable part can be supported by the base on bottom, can move relative to the other clamping member along the width reducing direction, and can press the circuit substrate; the noncontact driving mechanism applies more than one noncontact forces selected from the gas discharging force, gas attracting force, magnetic repulsion force and magnetic attraction force, between the base and the movable part; thereby, circuit substrate is positioned by moving the movable part relative to the base along the width reducing direction.

Owner:FUJI MASCH MFG CO LTD

Porous gas-bearing backer

InactiveUS20180265970A1Reduce quality problemsEfficient heat transferChemical vapor deposition coatingPorous membraneEngineering

Owner:EASTMAN KODAK CO

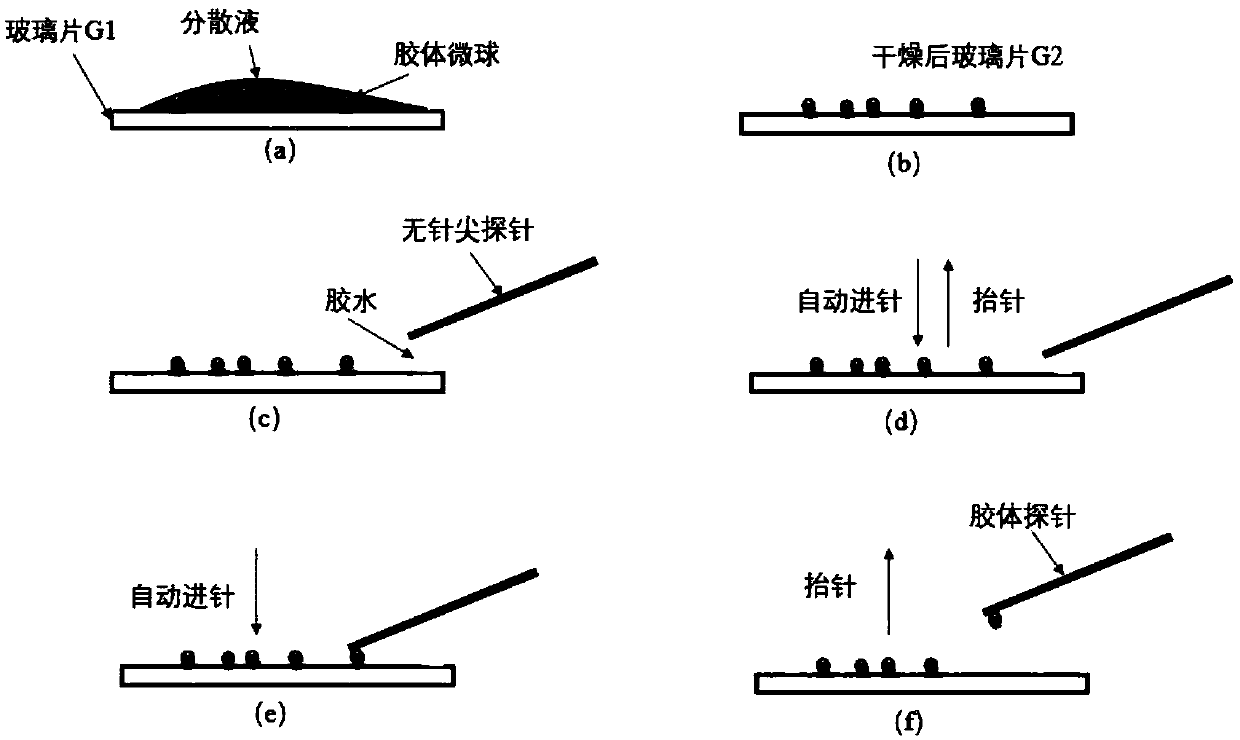

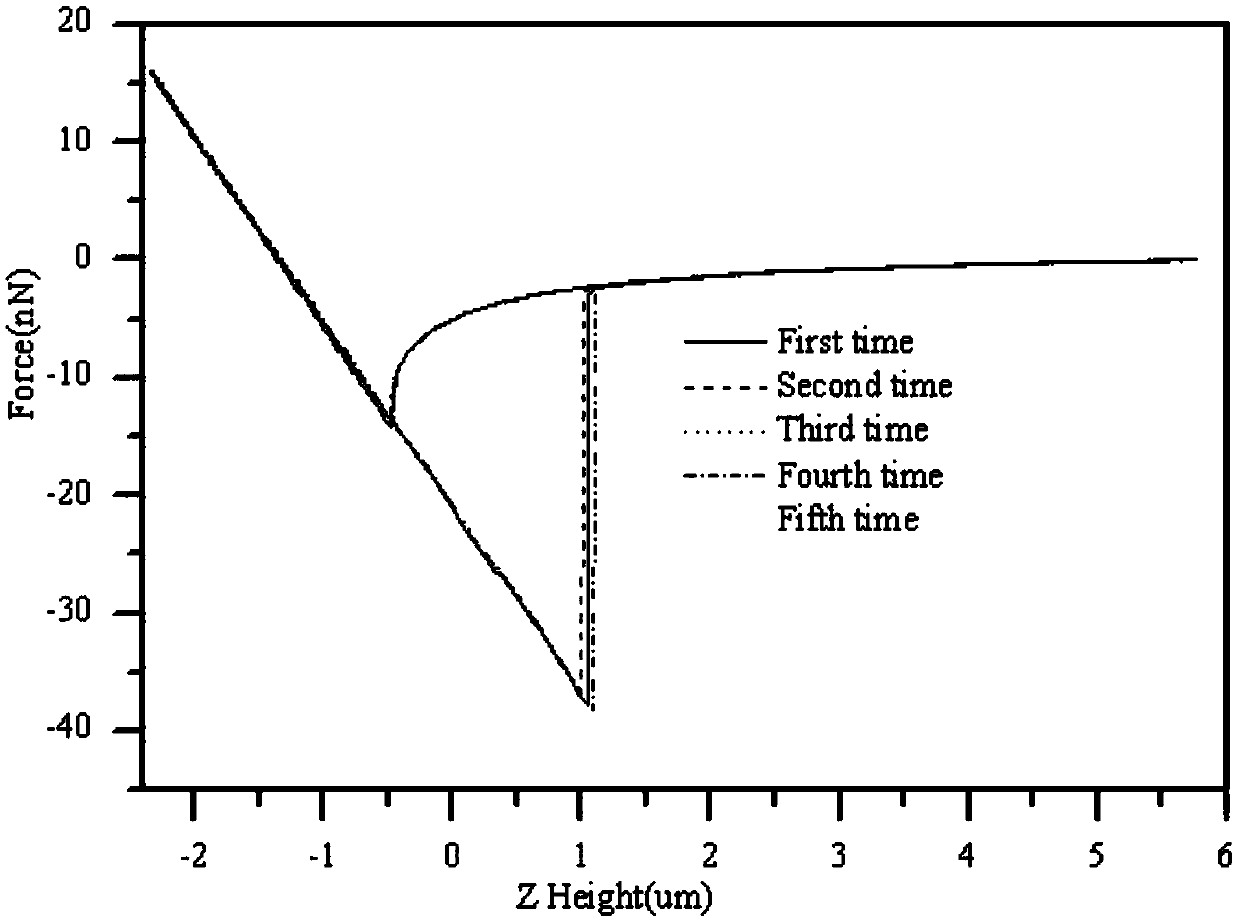

Rapid preparation method and application of colloidal probe

PendingCN109521227AHigh success rate of preparationIncrease the scope of applicationScanning probe microscopyMicrosphereColloid

The invention discloses a rapid preparation method and application of a colloidal probe. The method comprises the steps of material cleaning, colloidal ball dispersion, glue line preparation, probe glue coating and colloidal probe preparation. The colloidal probe is used for researching the non-contact force relationship between a colloidal microsphere and a glass plate to acquire the F-D curve ofthe colloidal probe and the glass plate in air. According to the invention, AFM equipped with a forward / inverted optical imaging system is used; a three-axis motion controller of AFM is combined to realize glue coating of the probe and accurate positioning and bonding of mesoscopic particles and the probe; and efficient and quick colloidal probe preparation is realized.

Owner:TIANJIN UNIV

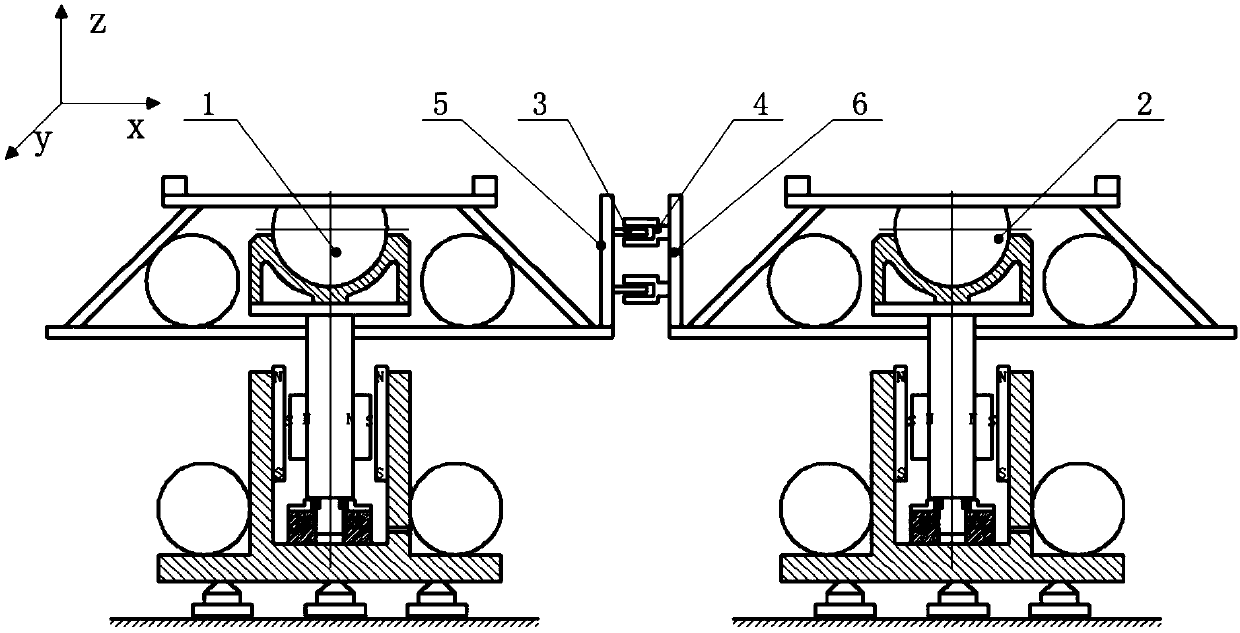

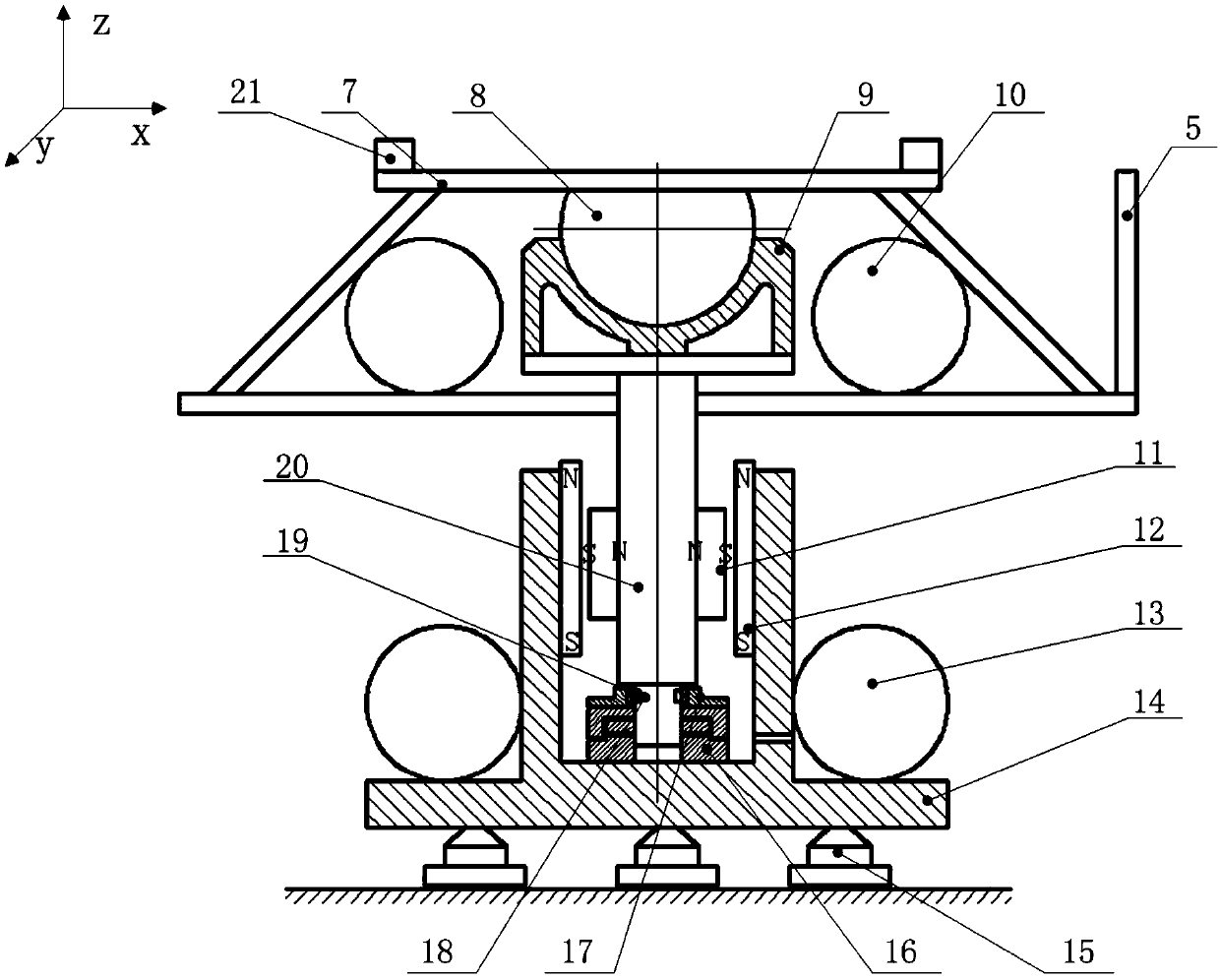

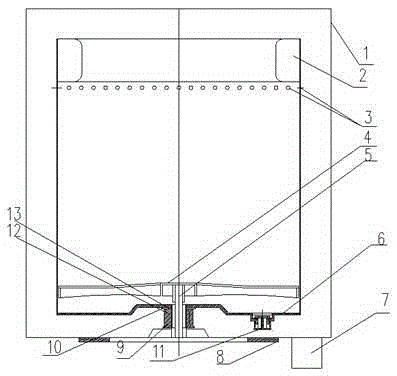

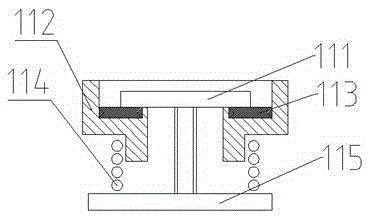

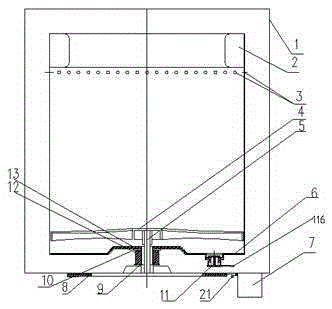

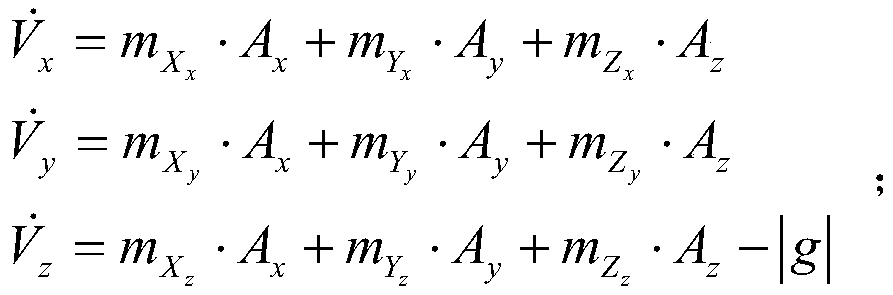

Pneumatic-magnetic combination control-based two-hypersatellite-platform attitude ground simulator

ActiveCN109599005ARealize non-contact magnetic levitation gravity compensation supportReduce frictionCosmonautic condition simulationsSimulatorsBall bearingControl engineering

The invention provides a pneumatic-magnetic combination control-based two-hypersatellite-platform attitude ground simulator, and belongs to the field of physical simulation of spacecrafts. Rx, Ry andRz degree-of-freedom motions of a rotating platform are realized through an air flotation ball bearing; X and Y degree-of-freedom motions of a load module air flotation platform and a platform moduleair flotation platform are realized through a planar air flotation bearing; non-contact gravity compensation supporting of a supporting vertical column and a horizontal moving platform is realized through magnetic suspension supporting flotation magnetic steel disposed on the supporting vertical column and magnetic suspension fixed magnetic steel disposed on the horizontal moving platform; non-contact force control and Z degree-of-freedom motion of the supporting vertical column and the horizontal moving platform are realized through a Lorentz motor consisting of Lorentz motor magnetic steel and a Lorentz motor coil; therefore, a six-degree-of-freedom motion of the rotating platform is obtained; the pneumatic-magnetic combination control-based two-hypersatellite-platform attitude ground simulator has the advantages of six-degree-of-freedom non-contact supporting, high stability, fast response and the like, and can be used to simulate attitudes of two hypersatellite platforms and realize ground verification of large-angle maneuver characteristics and dynamic imaging.

Owner:SHANGHAI SATELLITE ENG INST

Environmentally friendly water-waving washing machine and water draining method thereof

ActiveCN106811910AAvoid secondary pollutionSimple structureOther washing machinesWashing machine with receptaclesWater storagePulp and paper industry

The invention discloses an environmentally friendly water-waving washing machine and a working method. The environmentally friendly water-waving washing machine comprises an inner tub and an outer tub, wherein the inner tub is concentrically installed in the outer tub, the inner tub is a whole water storage tub, a water draining valve is arranged at the lower portion of the inner tub, and a controller for turning on and off the water draining valve is arranged at the corresponding position of a water draining valve at the lower portion of the outer tub. The controller is not in contact with the water draining valve, and the controller and the water draining valve controls turning on and off of the water draining valve under the effect of a non-contact force. The washing machine saves water by 20% or above, can also effectively prevent secondary clothes contamination and is simple in structure and good in reliability, and seal links are few.

Owner:NINGGUO JULONG IND

Active mechanical force sensor

ActiveUS20140020481A1Minimize and avoid errorEasy to detectForce measurement by measuring magnetic property varationApparatus for force/torque/work measurementNon-contact forceUltimate tensile strength

A contactless force measurement sensor for measuring an applied force onto an object is provided. The contactless force measurement sensor includes a first facing orientation which facing orientation defines an orientation pointing towards a surface of the object, a first magnetic field generating unit being adapted for generating a magnetic field towards the facing orientation, a first magnetic field detector unit being adapted for detecting a first magnetic field which field being generated by the first magnetic field generating unit and being influenced by an applied force to be measured, wherein the first magnetic field detector unit is further adapted for outputting a first signal being representative for the detected magnetic field, and an evaluating unit being adapted for evaluating a signal strength of the first signal and determining the applied force based on the first signal.

Owner:ABAS

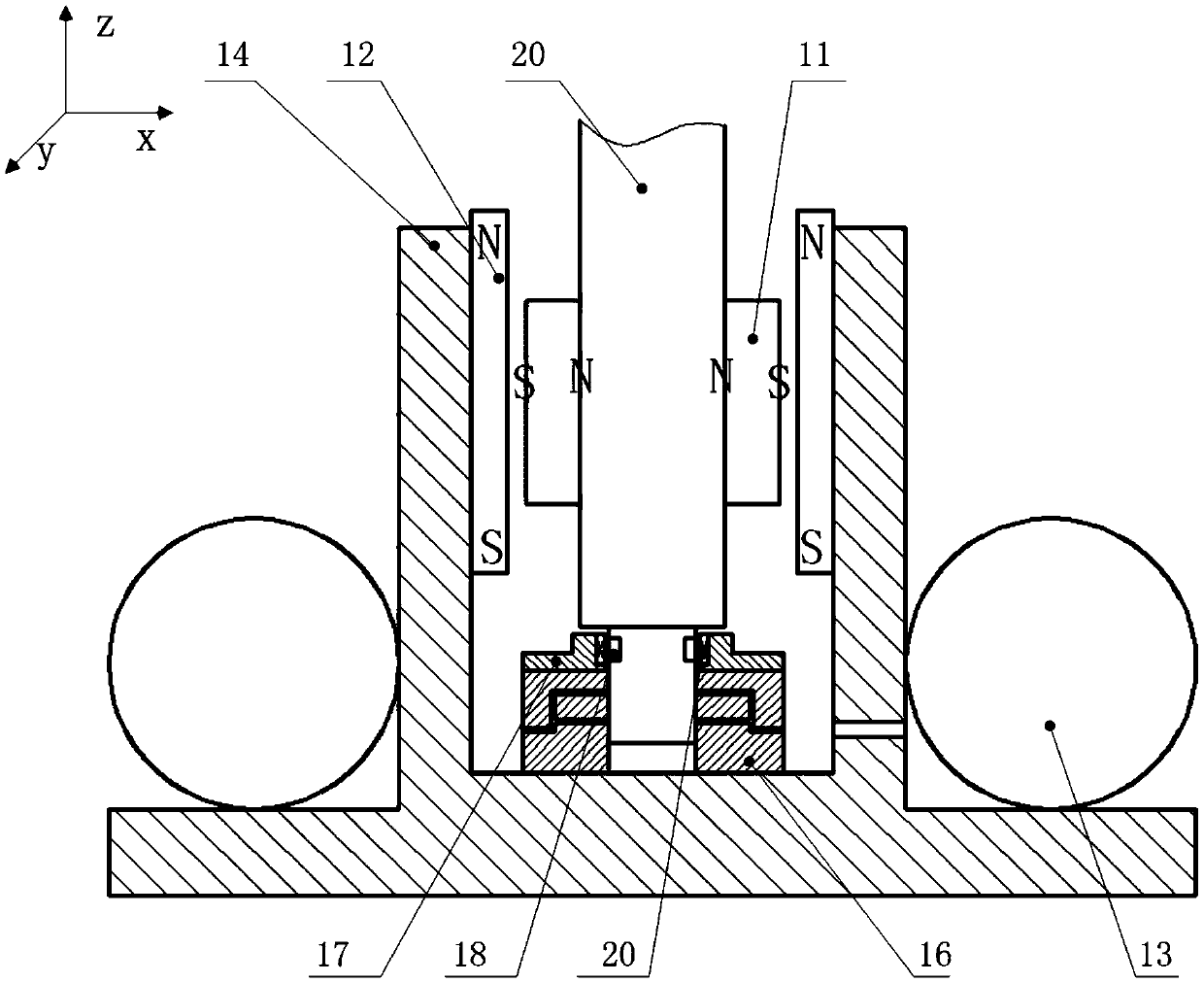

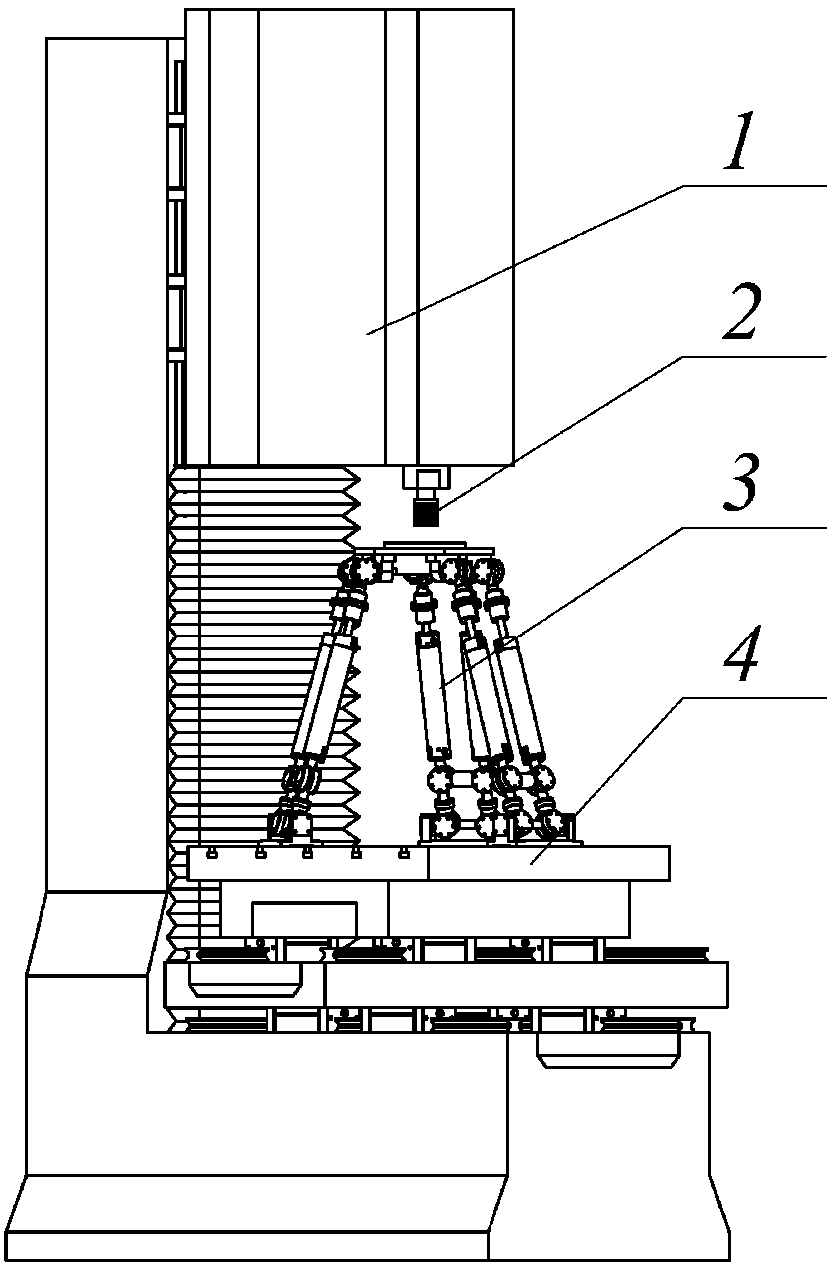

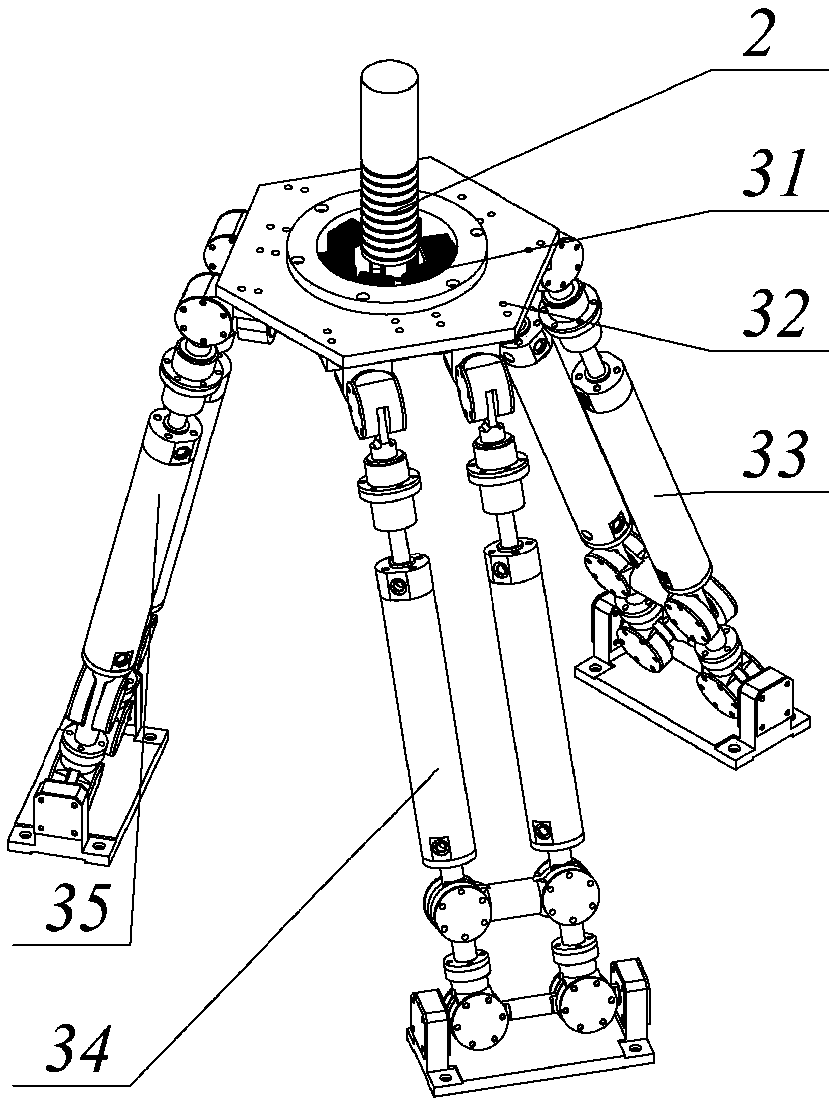

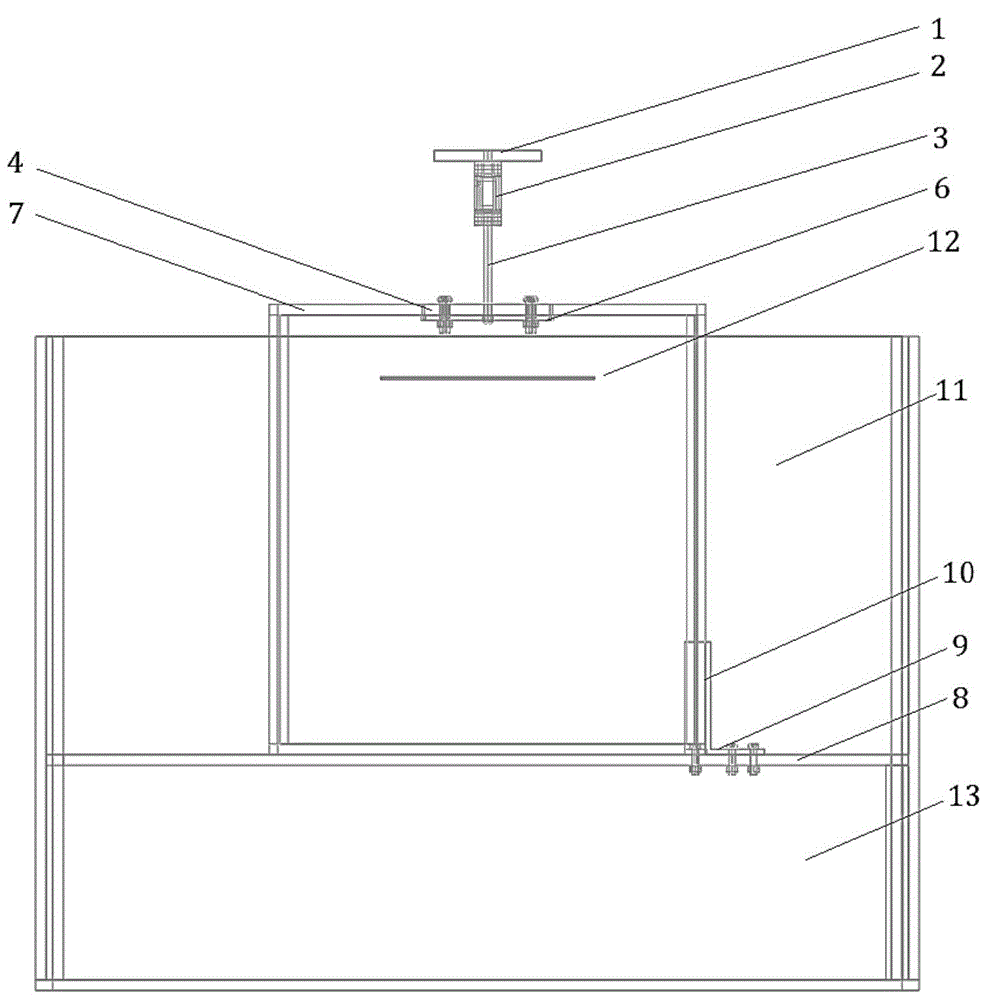

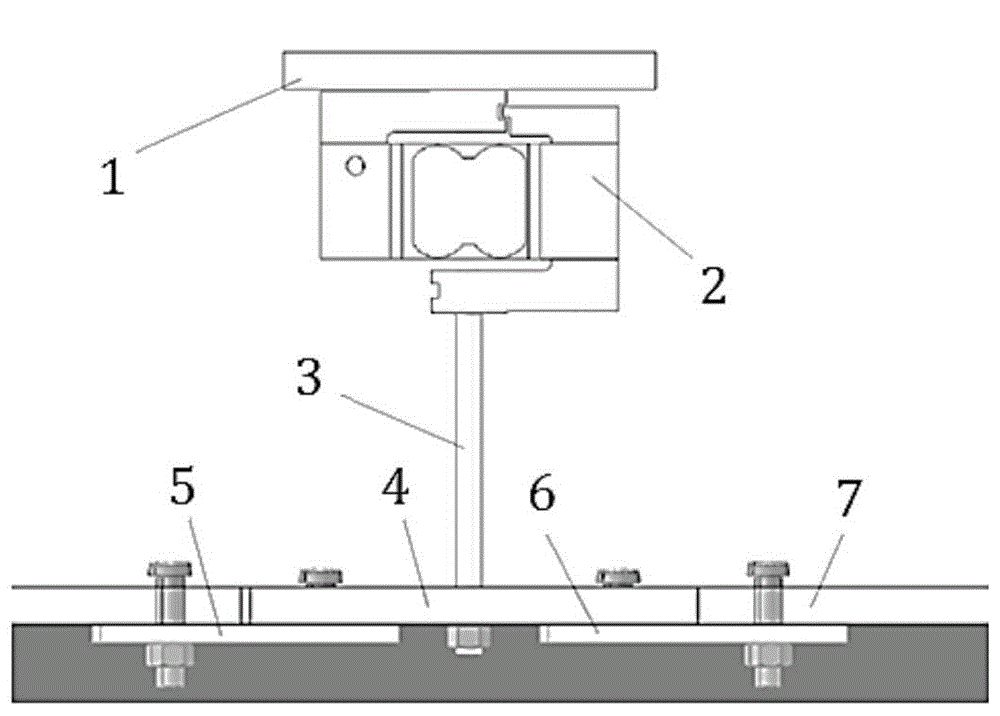

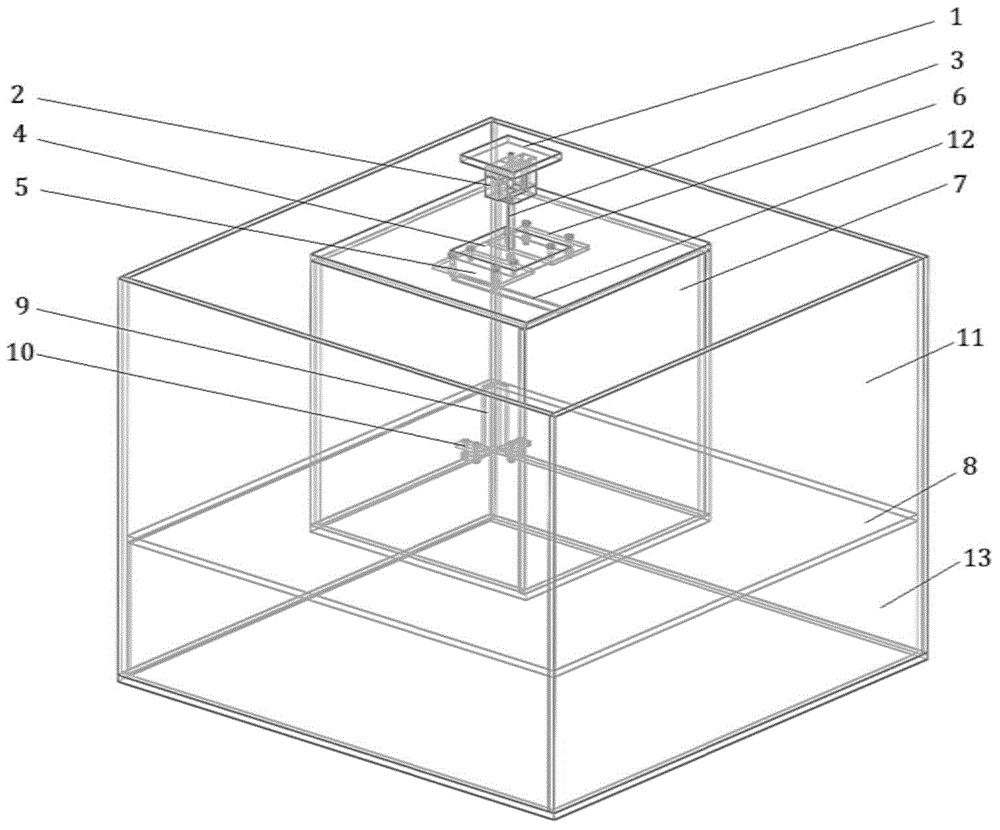

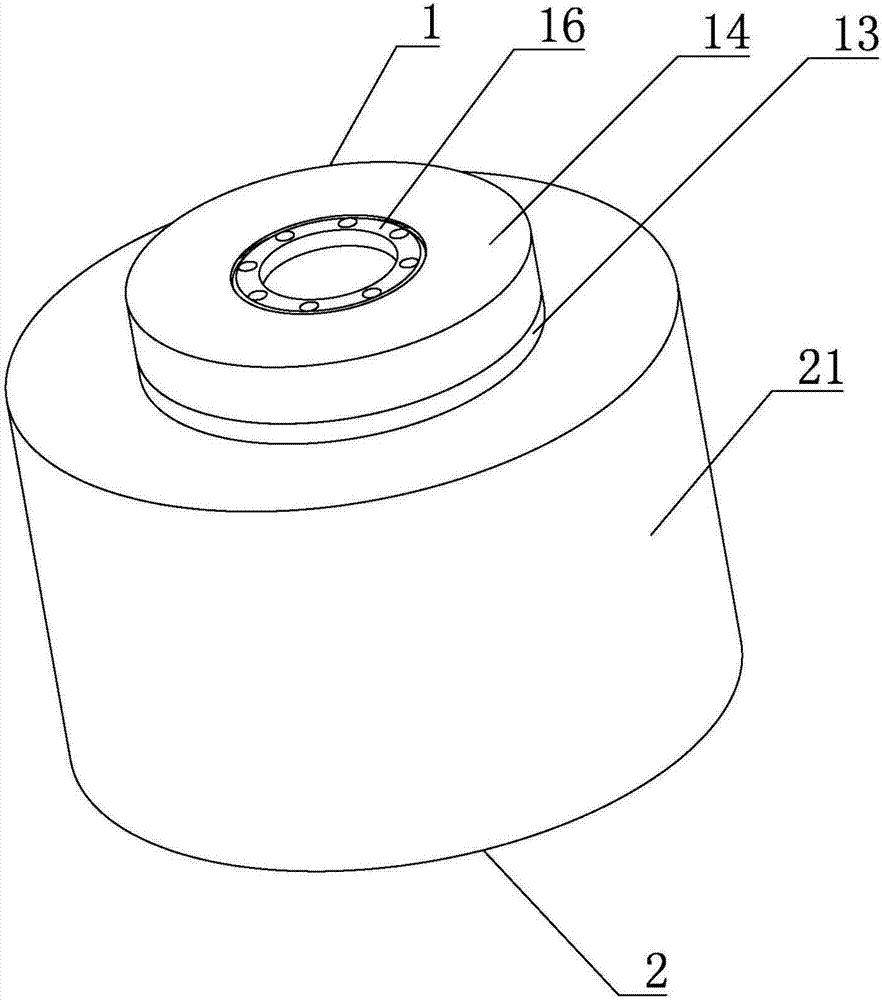

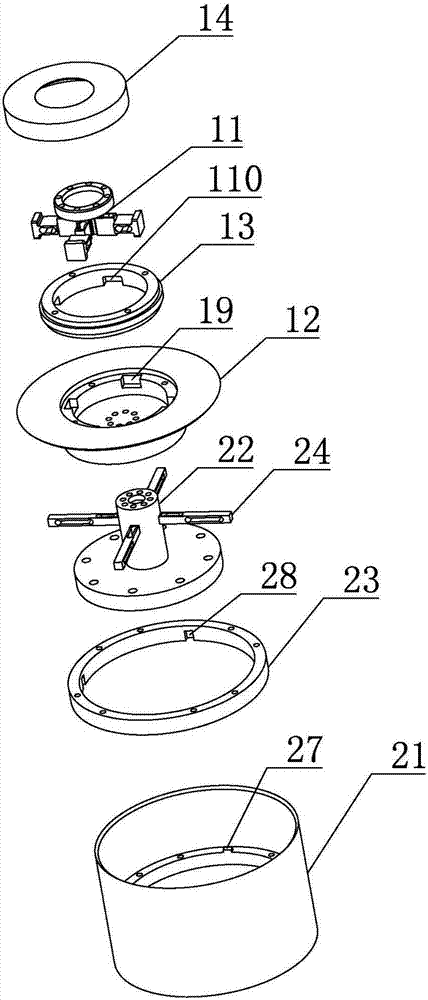

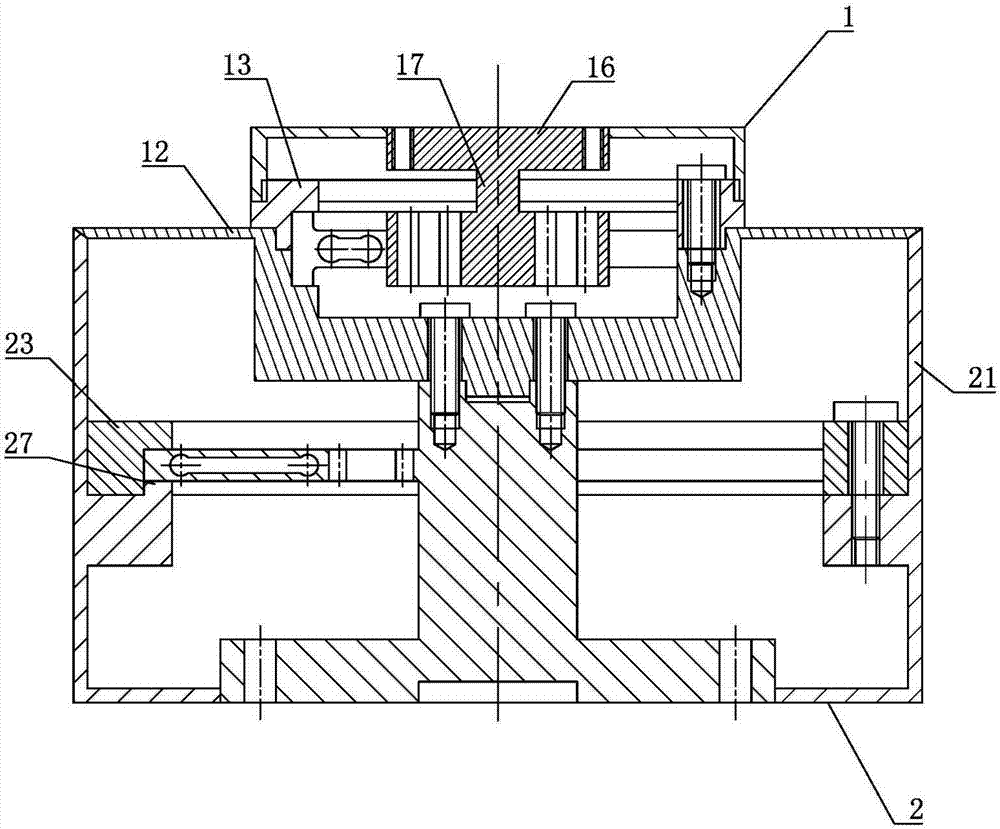

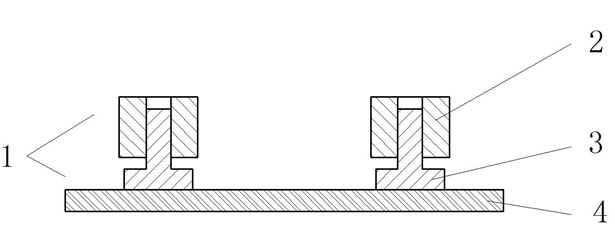

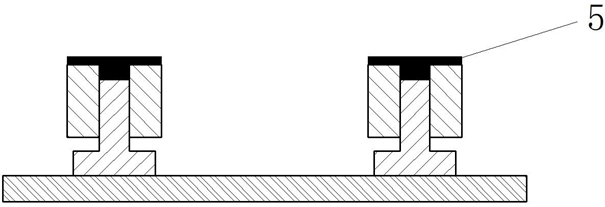

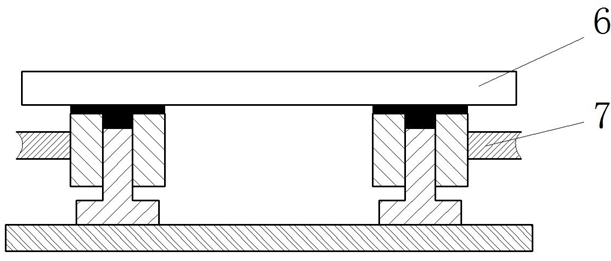

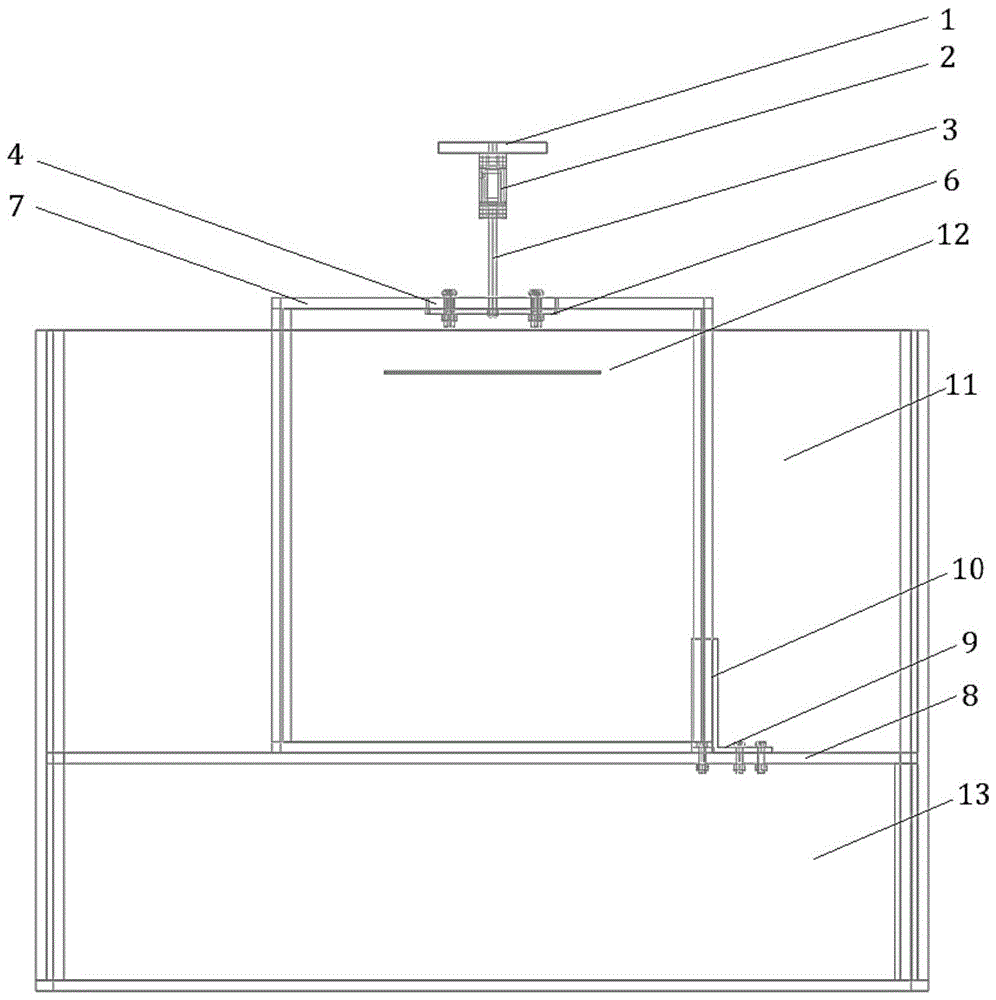

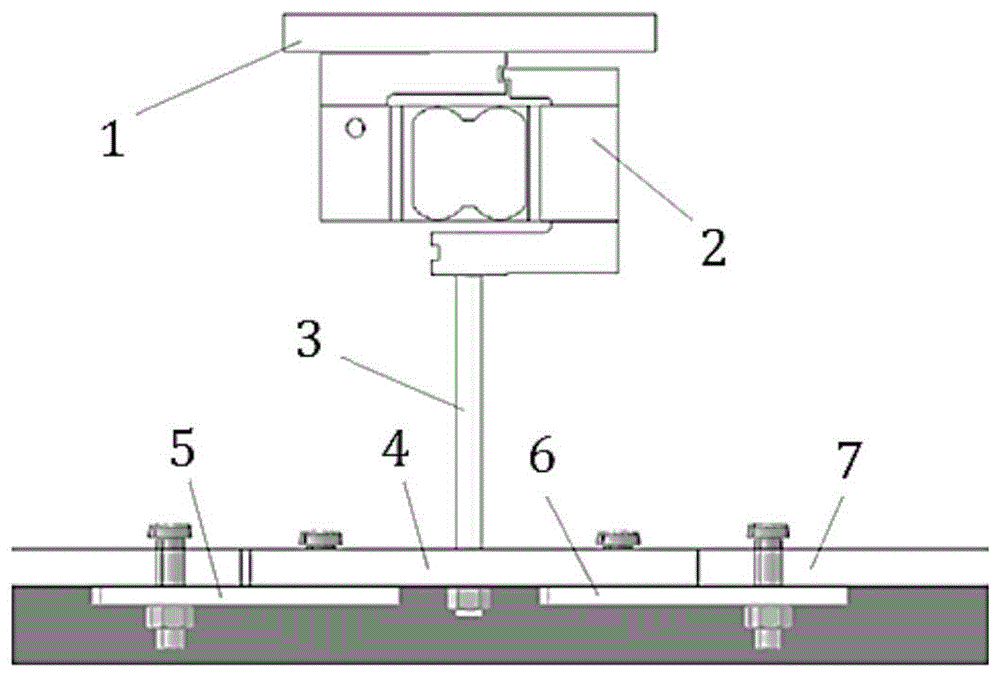

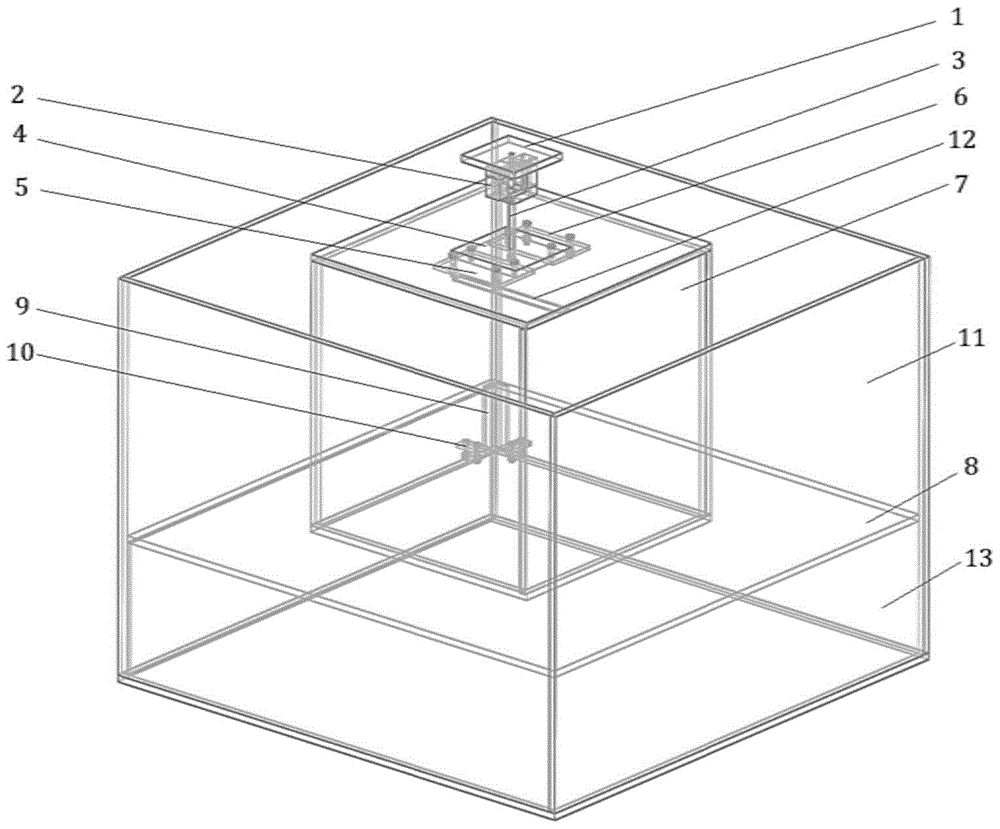

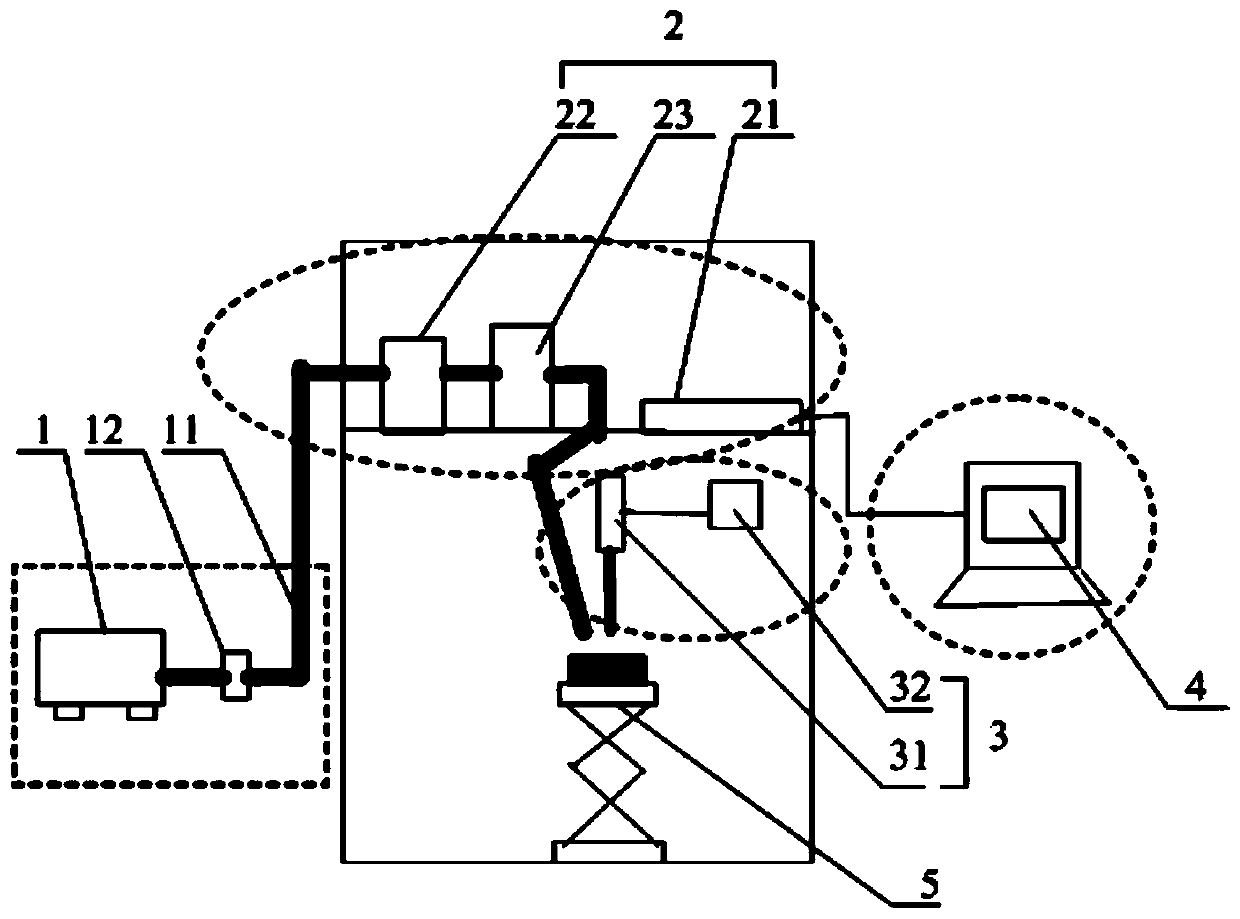

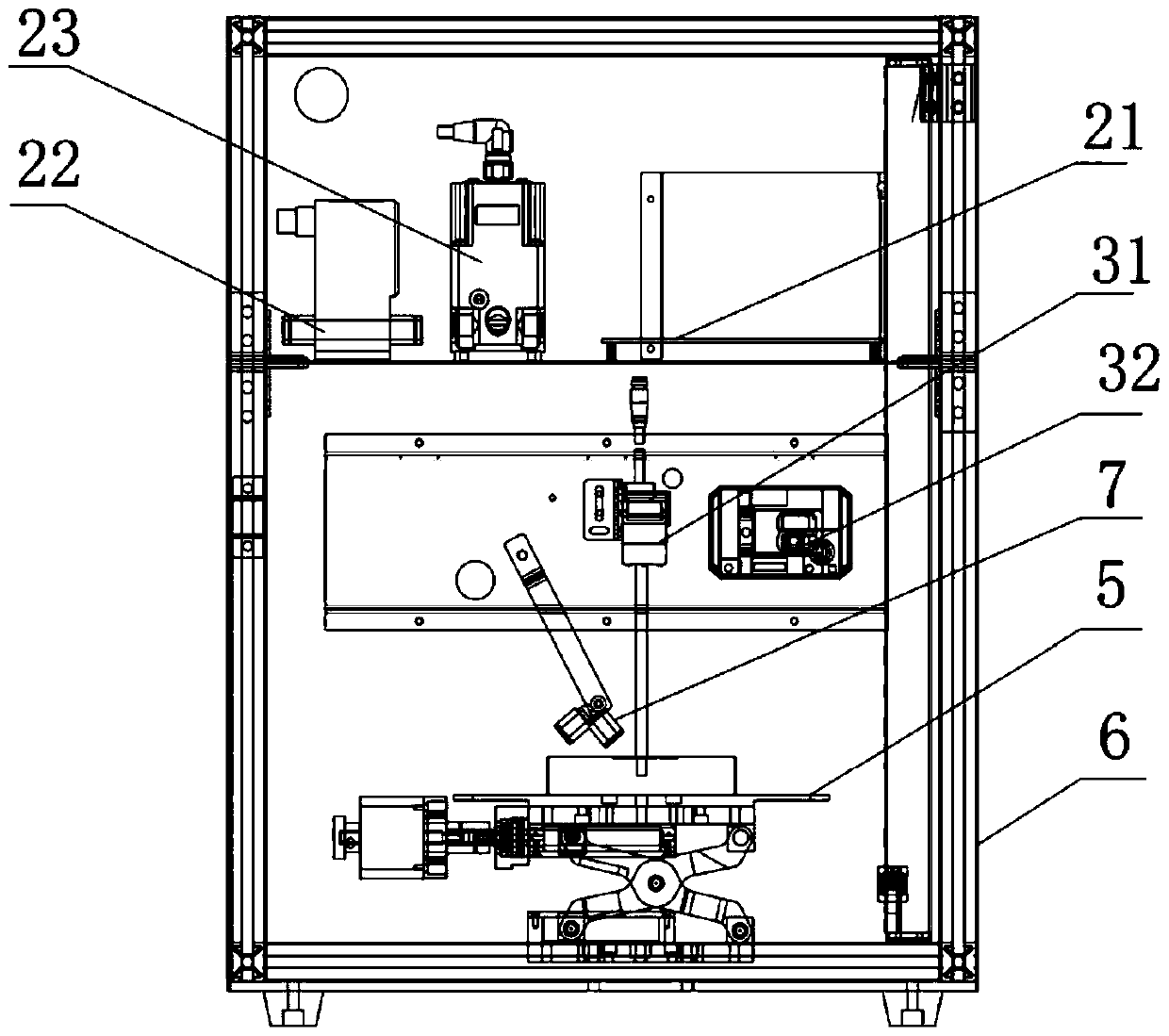

Non-contact force loading device for simulating processing of three-axis numerical control machine tool

ActiveCN108582038AEasy to manufactureEasy to controlProgramme-controlled manipulatorNumerical controlContact force

The invention relates to a non-contact force loading device for simulating the processing of a three-axis numerical control machine tool. The device mainly comprises three parts: a loading rod, a loading plate and a tri-translational parallel mechanism, wherein the loading rod is arranged at the front end of a three-axis numerical control machine tool spindle; the loading plate is arranged above the tri-translational parallel mechanism; and the tri-translational parallel mechanism is arranged on a numerical control machine tool working table. According to the non-contact force loading device for simulating the processing of the three-axis numerical control machine tool provided by the invention, through controlling the tri-translational parallel mechanism to track the movement of the three-axis numerical control machine tool, the loading rod is located in the center of the loading plate in real time; and through feeding currents with different frequencies to the loading plate, forces with different frequencies can be applied to the loading rod, and a processing process of the three-axis numerical control machine tool is further simulated, so that the performance test of the numerical control machine tool is realized. The device is simple and symmetrical in structure, easy to realize modularization, and low in manufacturing cost.

Owner:TSINGHUA UNIV

Device and method for measuring overall bulk modulus of cells based on ultrasonic standing wave sound field

InactiveCN110333286AAvoid contact damageKeep activeAnalysing fluids using sonic/ultrasonic/infrasonic wavesContinuous measurementSonification

The invention discloses a device and method for measuring the overall bulk modulus of cells based on an ultrasonic standing wave sound field. The measurement method comprises the following steps: according to Y-direction initial positions of each cell at the force start time of the standing wave sound field, calculating an ideal motion trajectory curve by using a Y-direction motion control equation of the cells in combination with field intensity parameters of the standing wave sound field, fitting the actual motion trajectory curve of the cells with the ideal motion trajectory curve of the cells through a least square method, and calculating the overall bulk modulus of the cells by combining the field intensity parameters of the standing wave sound field; due to the fact that a micro-fluidic channel chip is adopted, the cells are subjected to non-contact force motion by combining the ultrasonic standing wave sound field generated in a micro-flow channel of the piezoelectric ceramic, and the overall bulk modulus of the cells is obtained through conversion by measuring the motion trajectory of the cells, such that the problems that the local deformation amount is large and the measurement is inaccurate due to the contact type measurement method are effectively avoided, contact damage to the cells is also avoided, the activity of the cells is effectively ensured, continuous measurement is realized, and the detection flux is relatively high.

Owner:SUN YAT SEN UNIV

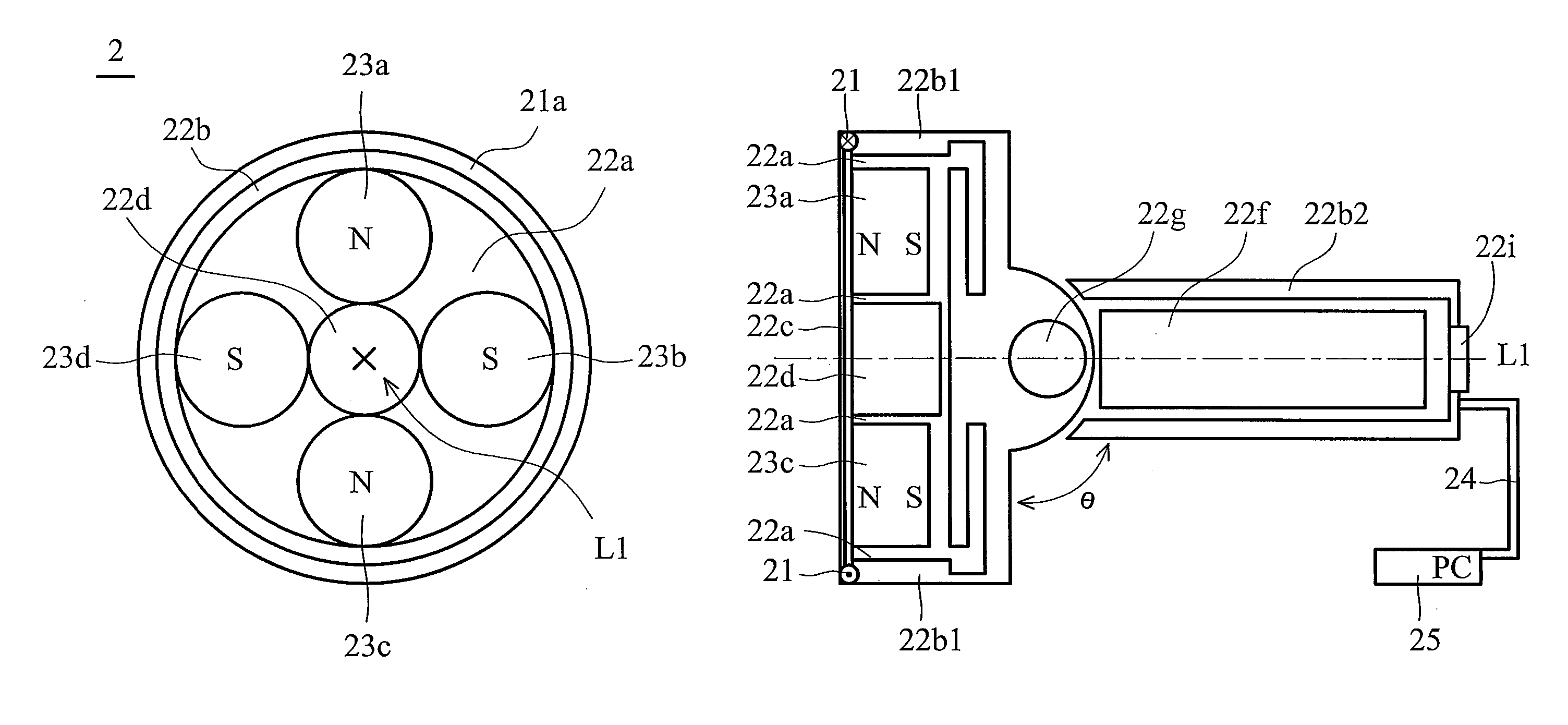

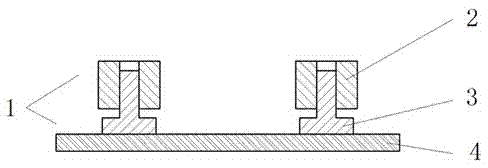

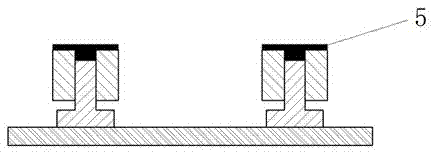

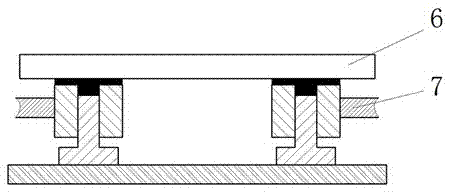

Non-contact force measuring device and non-contact force measuring method

ActiveCN104614109AHydrodynamic testingApparatus for force/torque/work measurementContact forceNon-contact force

The invention provides a non-contact force measuring device and a non-contact force measuring method in the field of fluid mechanics. The device comprises a detection cavity in a housing, wherein a supporting plate for holding the detection cavity is arranged in the housing; a detection media is put under the supporting plate; a sensing mechanism is arranged at the top of the detection cavity and the bottom of the detection cavity is fixedly connected with the supporting plate; an object to be tested is arranged in the detection cavity; the sensing mechanism comprises an upper fixed plate fixed in height, a lower fixed plate connected to the top of the detection cavity, and a sensor and a connecting rod both orderly arranged between the upper and lower fixed plates. The non-contact force measuring device is capable of measuring the fluid acting force on an object moving inside a flow field outside the flow field, and meanwhile, obtaining the corresponding flow field structure according to the related image technology.

Owner:SHANGHAI JIAO TONG UNIV

Endoscope and magnetic field control method thereof

An endoscope device is provided. The endoscope device includes a capsule sensor entering a human body for detection and sending a signal, a driving device movably disposed outside of the human body and moving and rotating the capsule sensor in the human body with non-contact force for omni-directional human body detection, a data receiving device disposed outside of the human body and receiving signals from the capsule sensor, and a power supply device providing power to the driving device and the data receiving device.

Owner:NAT TAIWAN UNIV

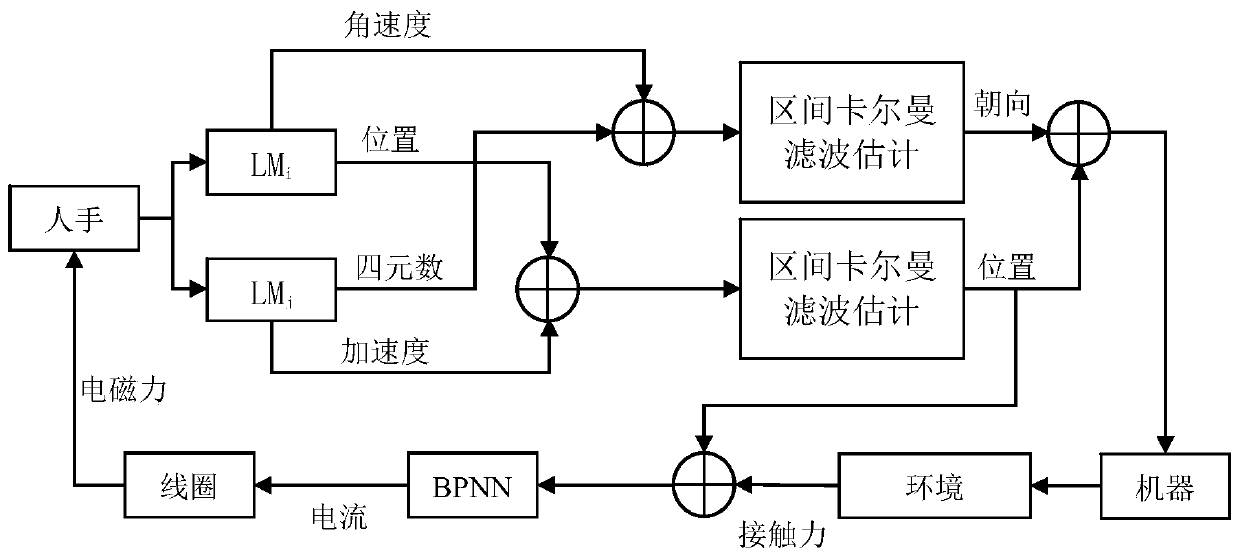

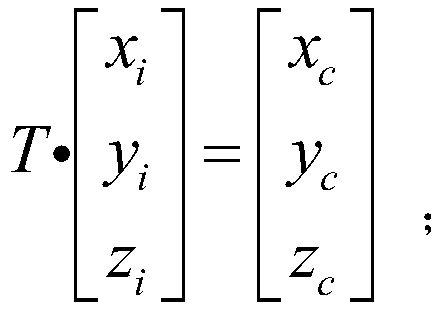

Natural man-machine interaction method for non-contact force feedback

ActiveCN110794969AStrong sense of immersionOperation real-time adjustmentInput/output for user-computer interactionProgramme-controlled manipulatorSimulationMachine

The invention provides a natural man-machine interaction method for non-contact force feedback. The method comprises the following steps: measuring a human hand by using motion sensors and carrying out coordinate registration; estimating the position and orientation of a human hand by using interval Kalman filtering according to the measured data; generating feedback electromagnetic force and feeding the force back to the human hand through a magnet on the human hand. According to the invention, the plurality of motion sensors are used for cooperatively acquiring the posture of the hand of anoperator in real time, two interval Kalman filters are used for eliminating the influence of measurement errors, and an electromagnetic force feedback mechanism is used. The problems of friction errors, connection accumulation errors, limited operation space and the like in mechanical force feedback can be solved. According to the invention, an operator not only can feel the force of a robot manipulator and obtain good immersion, but also can adjust the operation in real time, so that the control is more accurate and reliable. The method is natural and friendly, and is suitable for non-professional users.

Owner:SOUTH CHINA UNIV OF TECH

Six-dimensional force sensor capable of sensing contact force and traction force

ActiveCN107036754APromote research progressThe coupling phenomenon is not obviousMeasurement of force componentsElastomerEngineering

The invention belongs to the field of a sensor and discloses a six-dimensional force sensor capable of sensing contact force and traction force. The six-dimensional force sensor comprises a contact force sensor and a traction force sensor. The contact force sensor comprises a first elastomer, a fixation flange, a first fixation and support ring and a fixation housing. Each first support beam in the first elastomer is provided with a first detection through hole and a second detection through hole; and the outer wall of each first support beam is attached by a strain foil for measuring the contact force. The traction force sensor comprises a stress housing, a second elastomer and a second fixation and support ring, wherein the second elastomer and the second fixation and support ring are arranged in the stress housing. Each second support beam in the second elastomer is provided with a third detection through hole and a fourth detection through hole; and the outer wall of each second support beam is attached by a strain foil for measuring the traction force. The six-dimensional force sensor is capable of sensing the traction force applied to the tail end of a robot by a human as well as the contact force between a robot end effector and environment simultaneously, and can realize simultaneous accurate sensing of the sensing contact force and the traction force.

Owner:HUAZHONG UNIV OF SCI & TECH

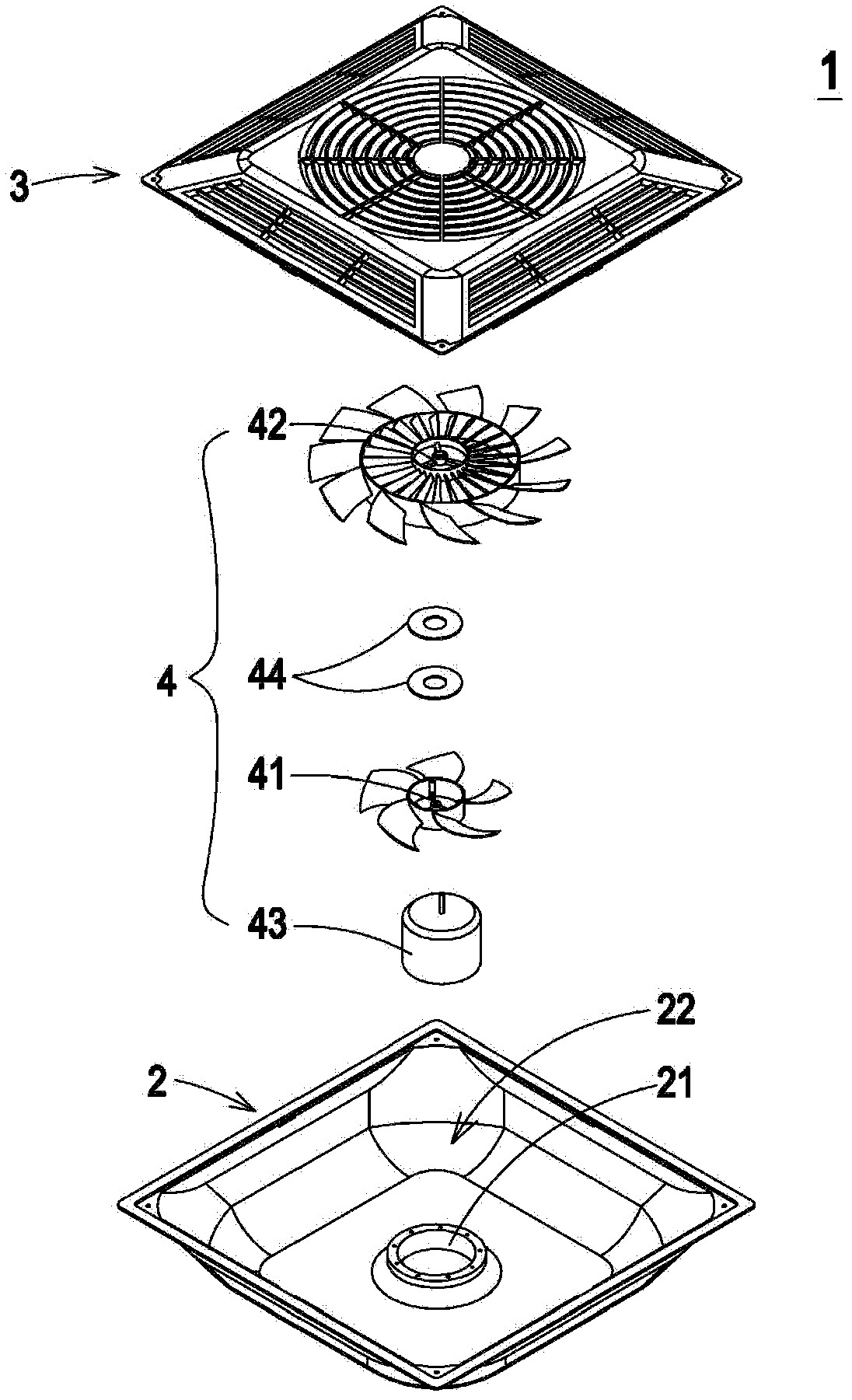

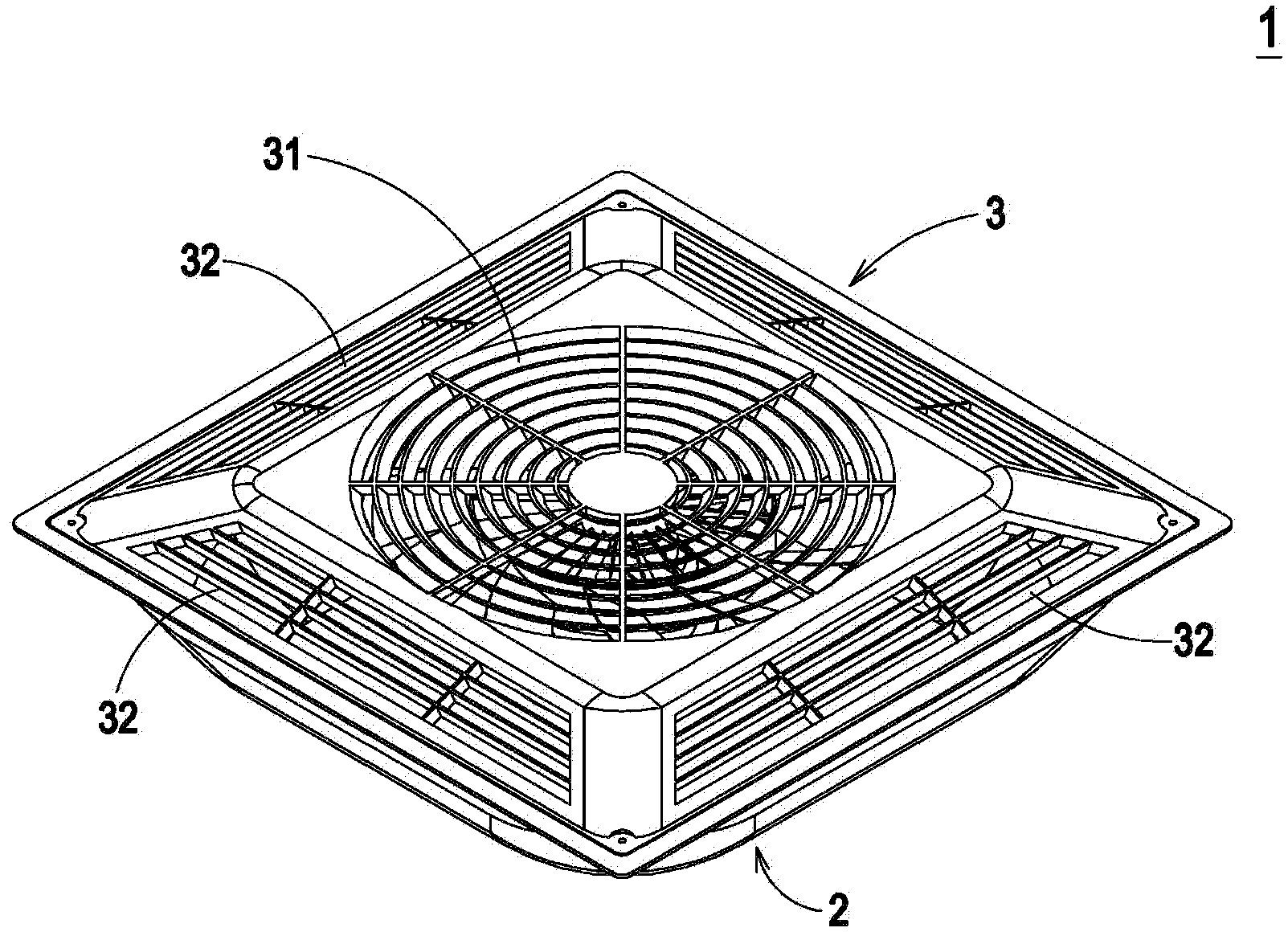

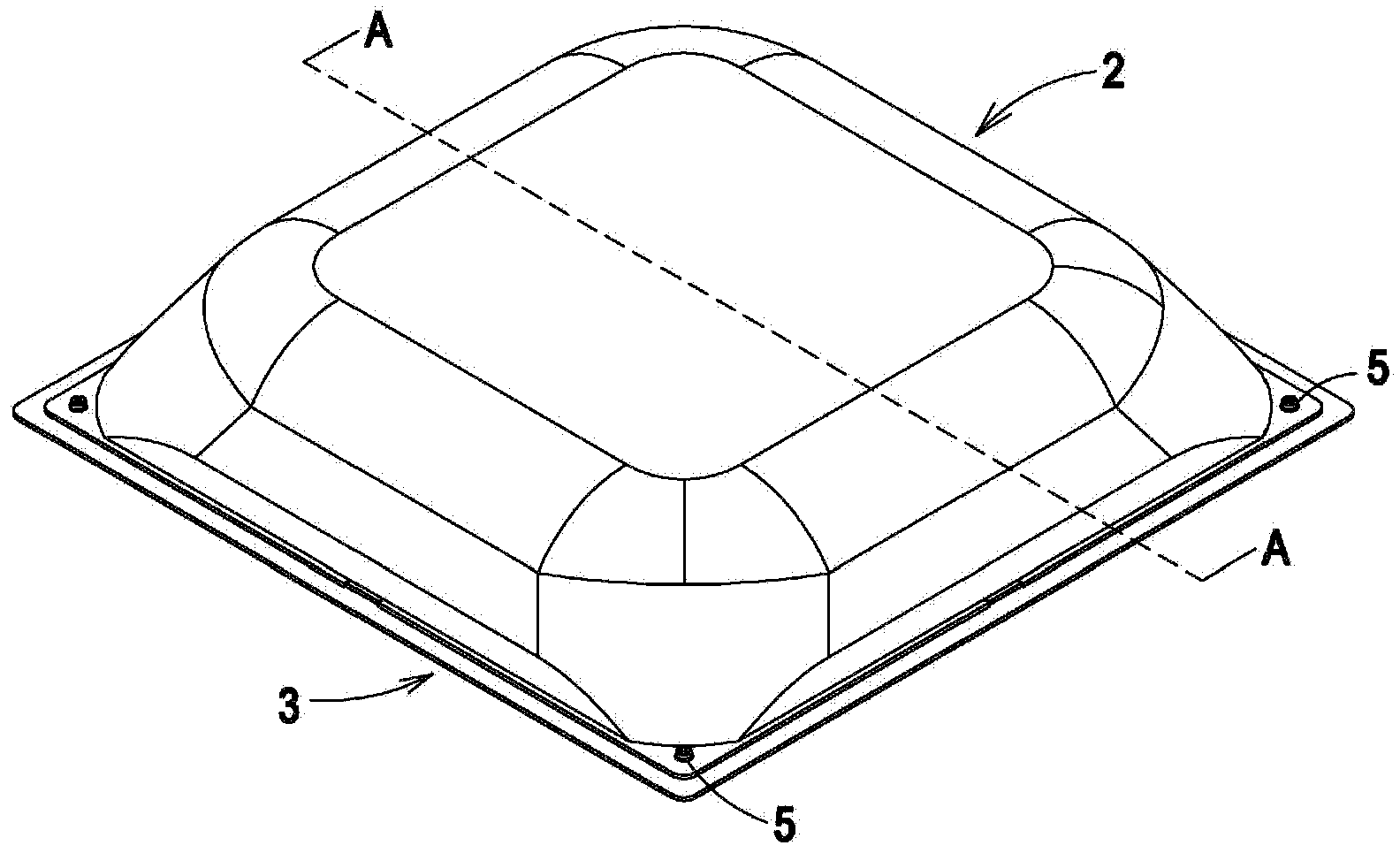

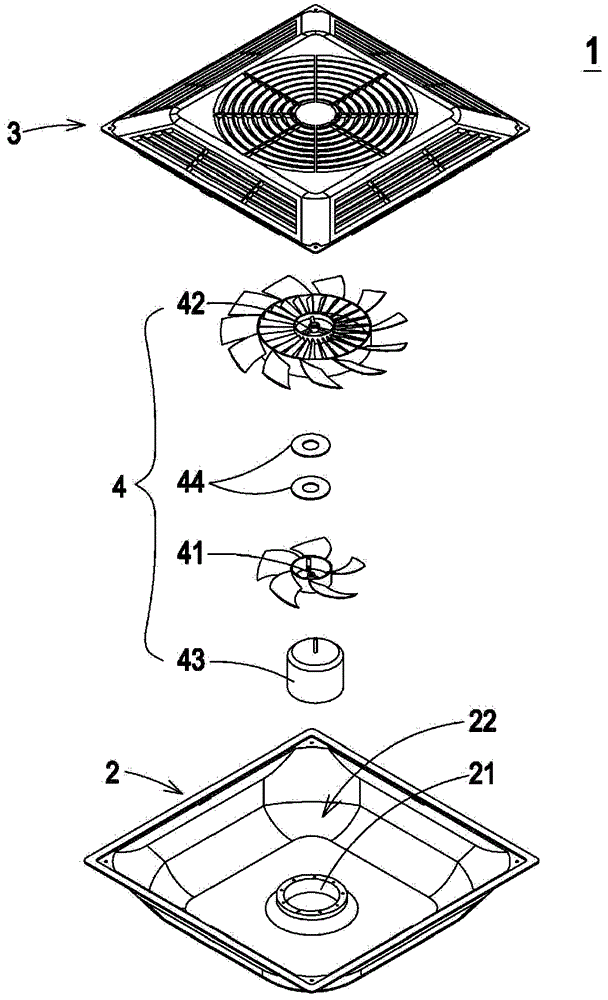

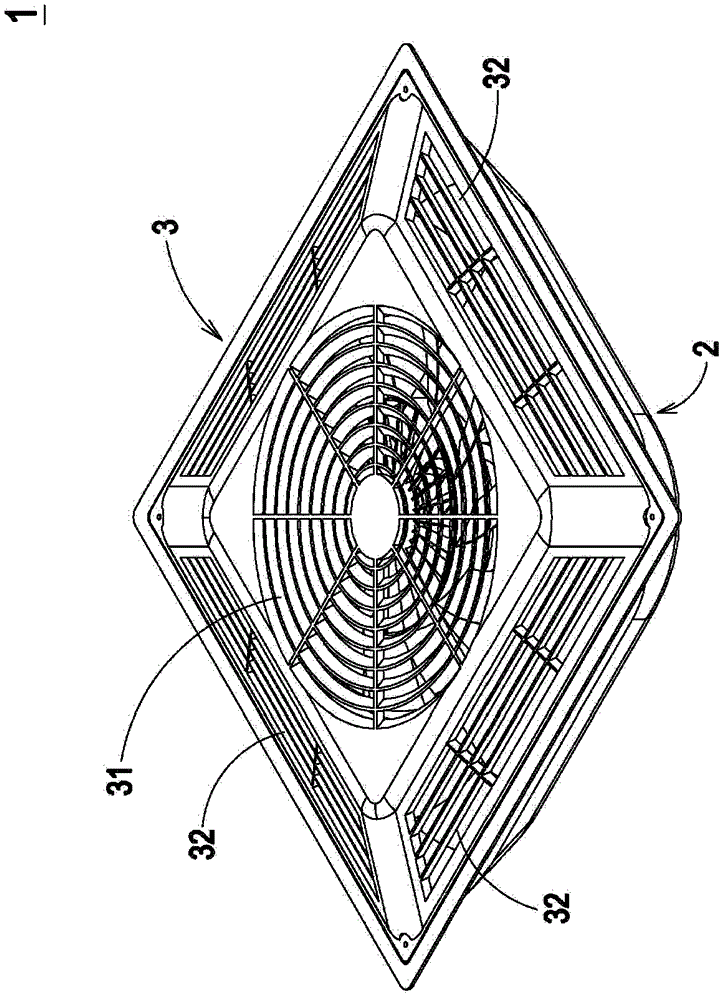

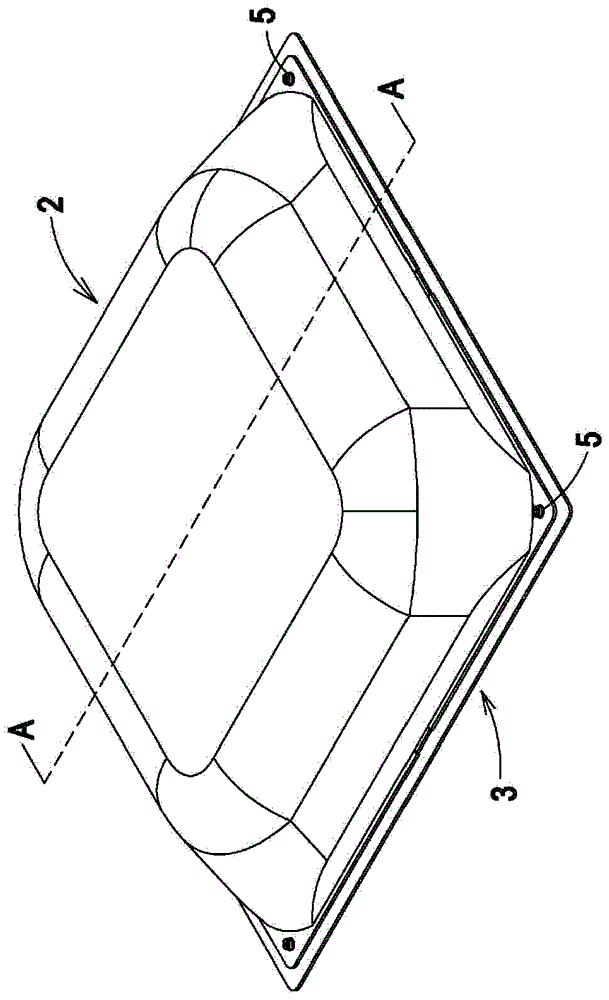

Circulating fan and fan blade group thereof

ActiveCN103161742AReduce power consumptionReduce power lossPump componentsPump installationsImpellerNon-contact force

Owner:DELTA ELECTRONICS INC

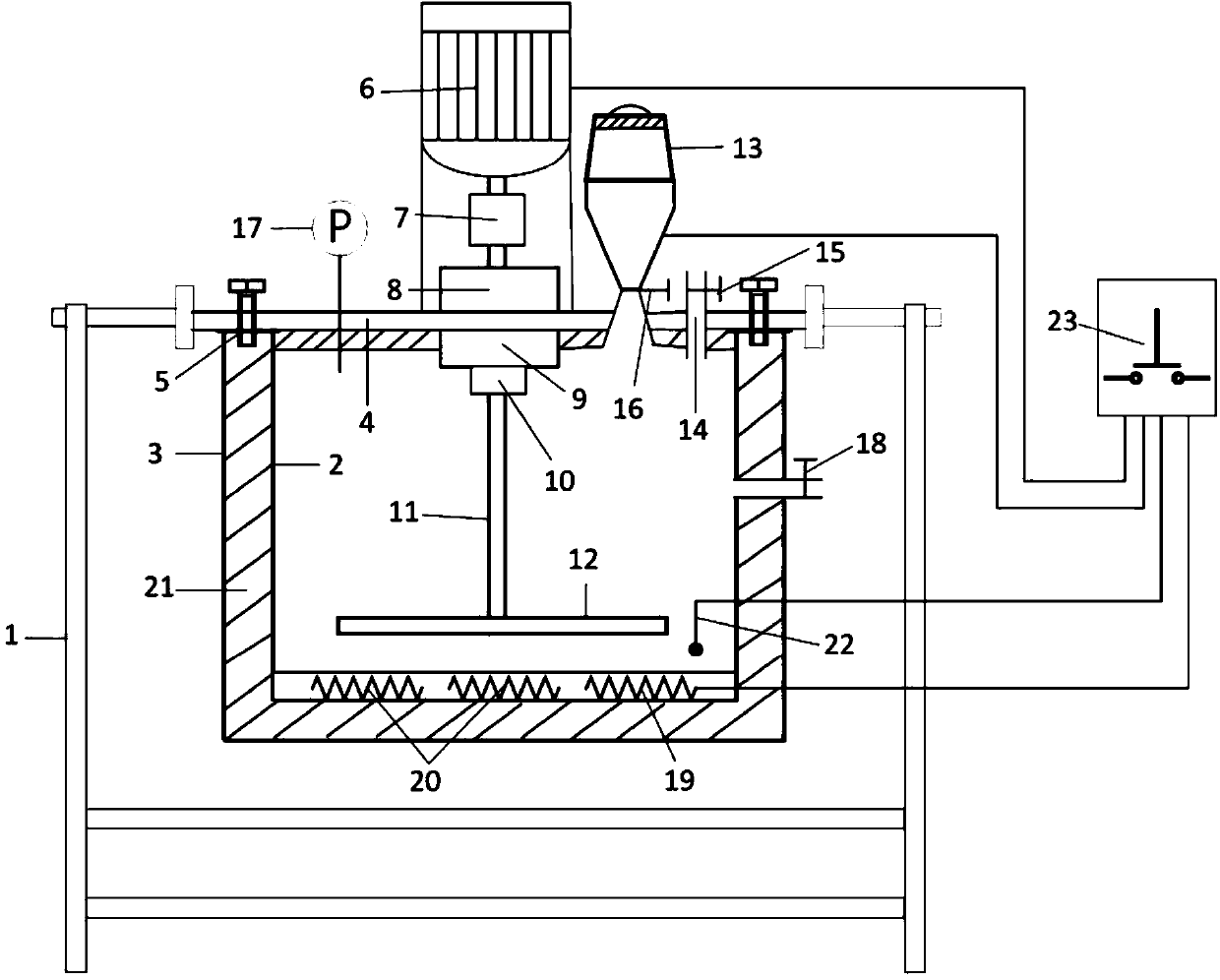

High-temperature oxygen-controlled magnetic drive liquid metal rotating corrosion experimental device and method

InactiveCN107655816AAvoid high temperature creepReduce riskWeather/light/corrosion resistanceMagnetic tension forceInsulation layer

The invention discloses a high-temperature oxygen-controlled magnetic drive liquid metal rotating corrosion experimental device and a method. The device comprises a tiltable supporting frame, an innertank body, an outer tank body, a tank lid, a sealing assembly, a motor and a reducer, an outer magnetic rotor, an isolation sleeve, an inner magnetic rotor, a clamping coupler, a transmission shaft,a disc-shaped sample holder, a smelting tank, a material inlet, a gas inlet and outlet, a pressure gauge, a pressure reducing valve, a main heater, a spare heater, an insulation layer, a temperature sensor, a main control cabinet and other parts. The motor and the reducer drive the inner magnetic rotor through a magnetic coupler to achieve the non-contact torque transmission of a static seal structure and drive the sample holder to rotate in the liquid metal. According to the principle of relative motion, the continuous flow corrosion experimentsof low activated steel and a welding seamthereofare carried out in the liquid metalto observe the surface topography of the sample and analyze the corrosion mechanism and to provide basic data for the compatibility study between the liquid metal and fusion reactor structural materials. According to the high-temperature oxygen-controlled magnetic drive liquid metal rotating corrosion experimental device and the method, the reliability and workefficiency of the device are greatly improved.

Owner:HEFEI UNIV OF TECH +2

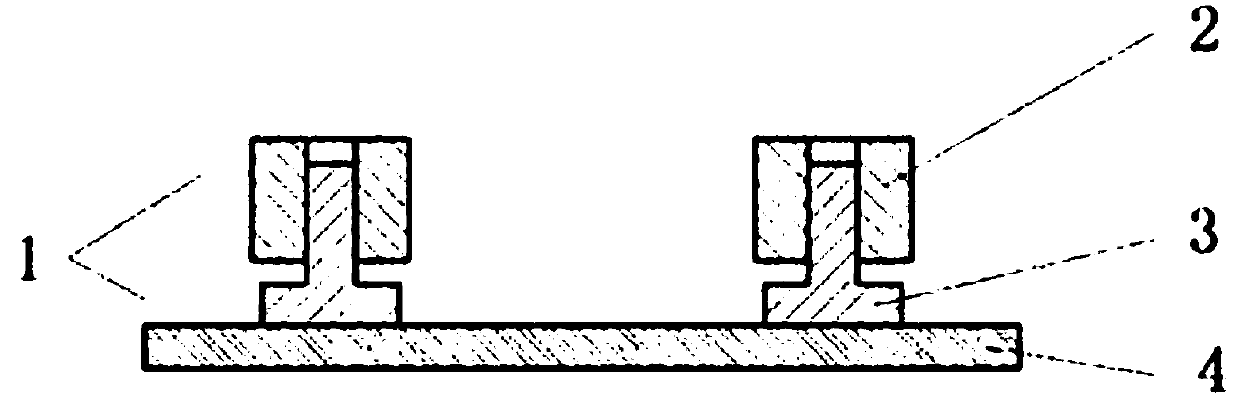

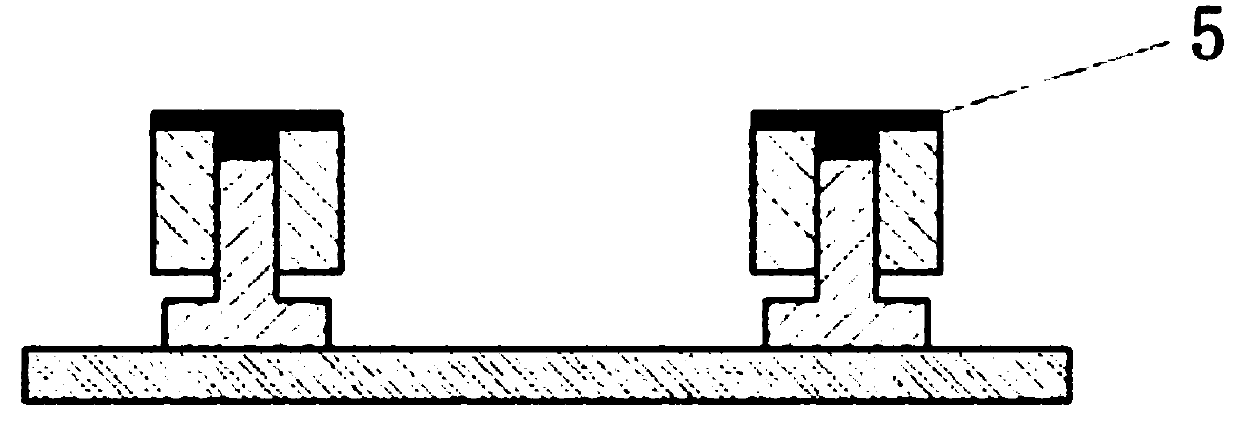

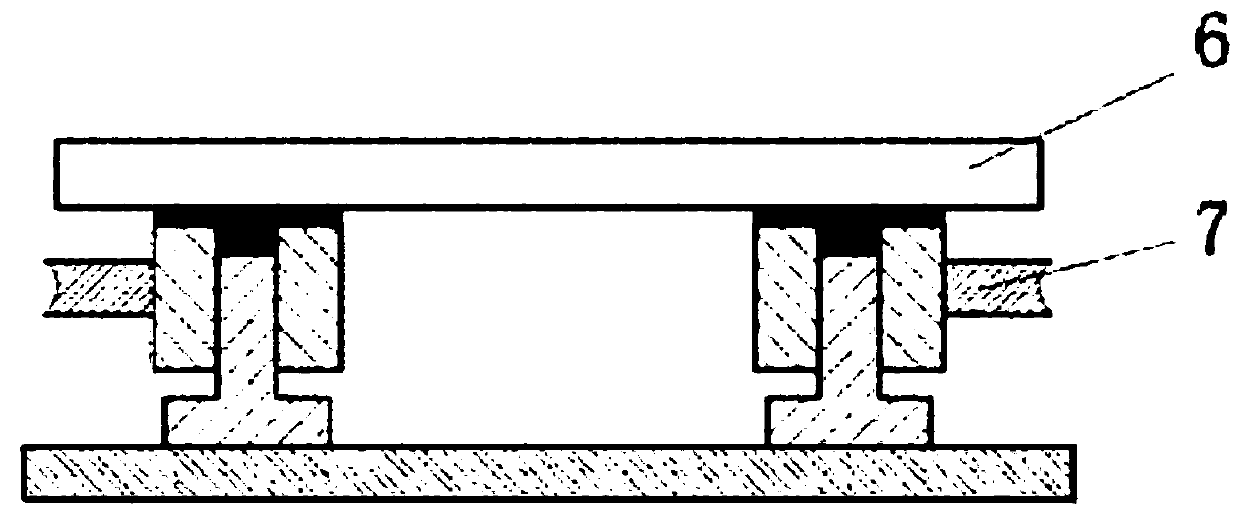

Method for disassembling micro-electro-mechanical devices under assistance of laser impact

InactiveCN102528379AAvoid contact scratchesAvoid damageDecorative surface effectsChemical vapor deposition coatingMicro nanoEngineering

The invention relates to a method for disassembling micro-electro-mechanical devices, in particular to separation of matched micro-electro-mechanical devices by using a mechanical effect of expansion and impact waves of plasmas produced by laser impact, and is suitable for disassembly and separation of the micro-electro-mechanical devices. The micro-electro-mechanical devices inside a micro-electro-mechanical system are disassembled through a non-contact force generated by an impact wave by utilizing the mechanical effect of the laser impact wave, so that the problems that contact scratches and damages of conventional operation to parts, and the parts are difficult to disassemble under a micro nano scale are solved; the micro-electro-mechanical devices are popped out by fully using the impact pressure of the laser impact wave in a laser radiation direction; and the method is a brand new method for disassembling the micro-electro-mechanical devices.

Owner:JIANGSU UNIV

Non-contact force measuring device and method

ActiveCN104614109BHydrodynamic testingApparatus for force/torque/work measurementEngineeringContact force

The invention provides a non-contact force measuring device and a non-contact force measuring method in the field of fluid mechanics. The device comprises a detection cavity in a housing, wherein a supporting plate for holding the detection cavity is arranged in the housing; a detection media is put under the supporting plate; a sensing mechanism is arranged at the top of the detection cavity and the bottom of the detection cavity is fixedly connected with the supporting plate; an object to be tested is arranged in the detection cavity; the sensing mechanism comprises an upper fixed plate fixed in height, a lower fixed plate connected to the top of the detection cavity, and a sensor and a connecting rod both orderly arranged between the upper and lower fixed plates. The non-contact force measuring device is capable of measuring the fluid acting force on an object moving inside a flow field outside the flow field, and meanwhile, obtaining the corresponding flow field structure according to the related image technology.

Owner:SHANGHAI JIAO TONG UNIV

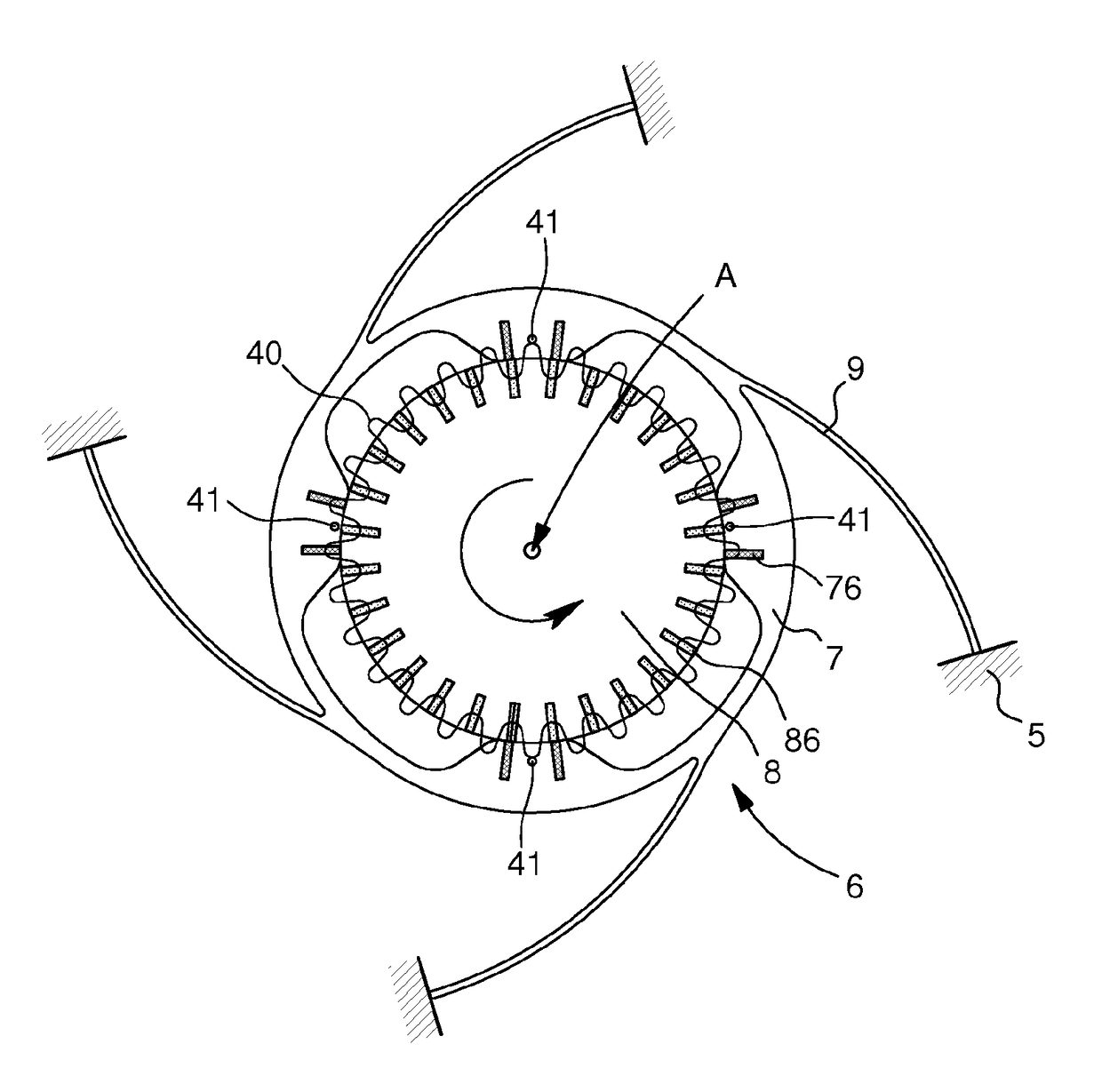

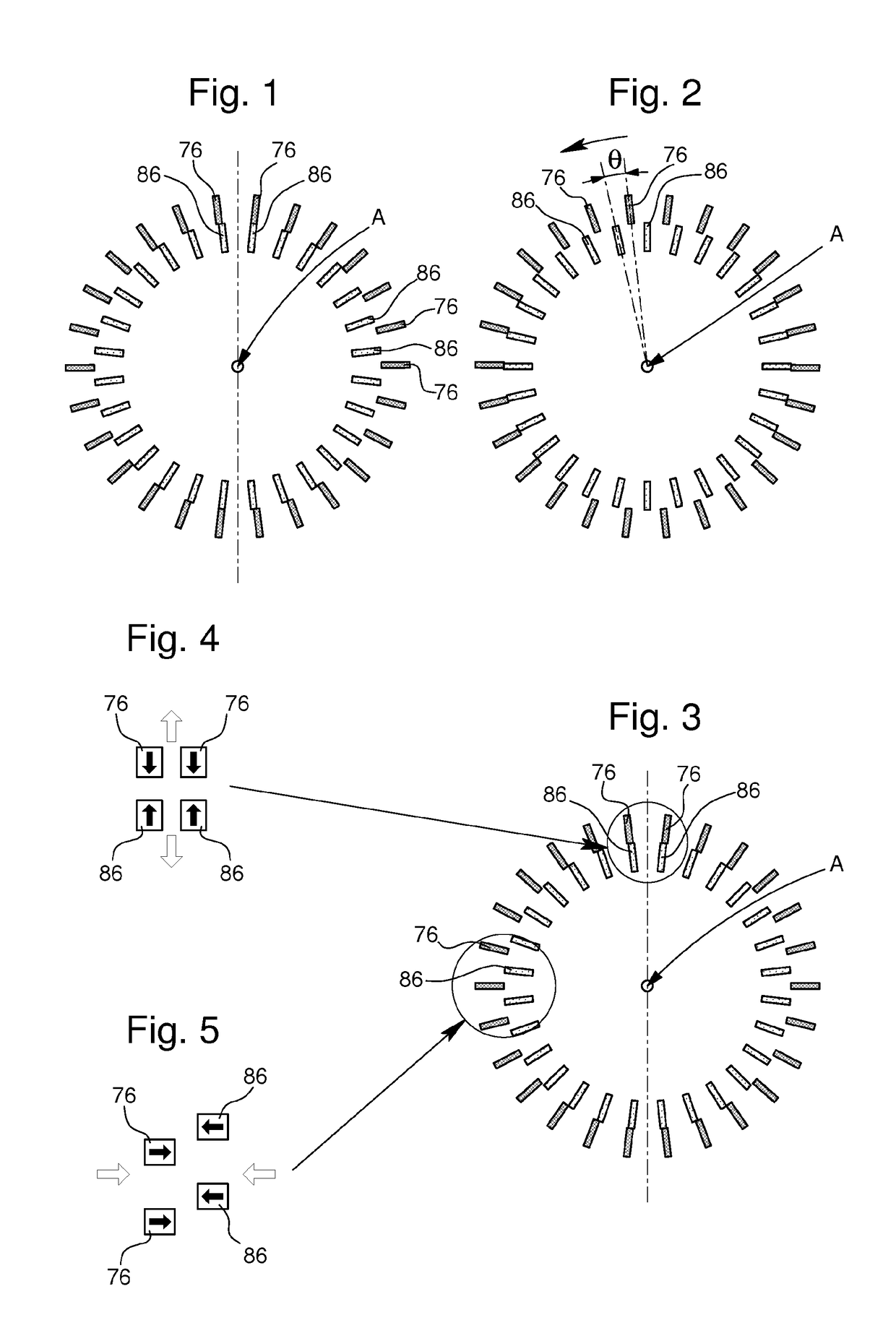

Circulation fan and its blade group

ActiveCN103161742BReduce power consumptionReduce power lossPump componentsPump installationsImpellerEddy current

The invention provides a circulating fan and a fan blade group of the circulating fan. The circulating fan at least comprises a shell body, a cover body, and a fan blade group. The shell body comprises a base seat, and the cover body and the shell body are jointed to form containing space. The fan blade group is arranged in the containing space. The fan blade group at least comprises a first impeller, a second impeller, a motor, and a plurality of magnetic components. The second impeller is arranged near the first impeller. The motor is fixedly arranged on the base seat of the shell body and connected with the first impeller to drive the first impeller to run. The magnetic components are arranged between the first impeller and the second impeller. With wind power generated by running of the first impeller and magnetic torque generated by magnetic eddy currents between the magnetic components, the second impeller is driven to run under non-contact force. According to the circulating fan and the fan blade group of the circulating fan, impellers with smaller fan blades are chosen to be used for being matched with the motor with smaller size, and thus effects that the size and power consumption are reduced, space configuration is simplified, and cost is reduced are achieved.

Owner:DELTA ELECTRONICS INC

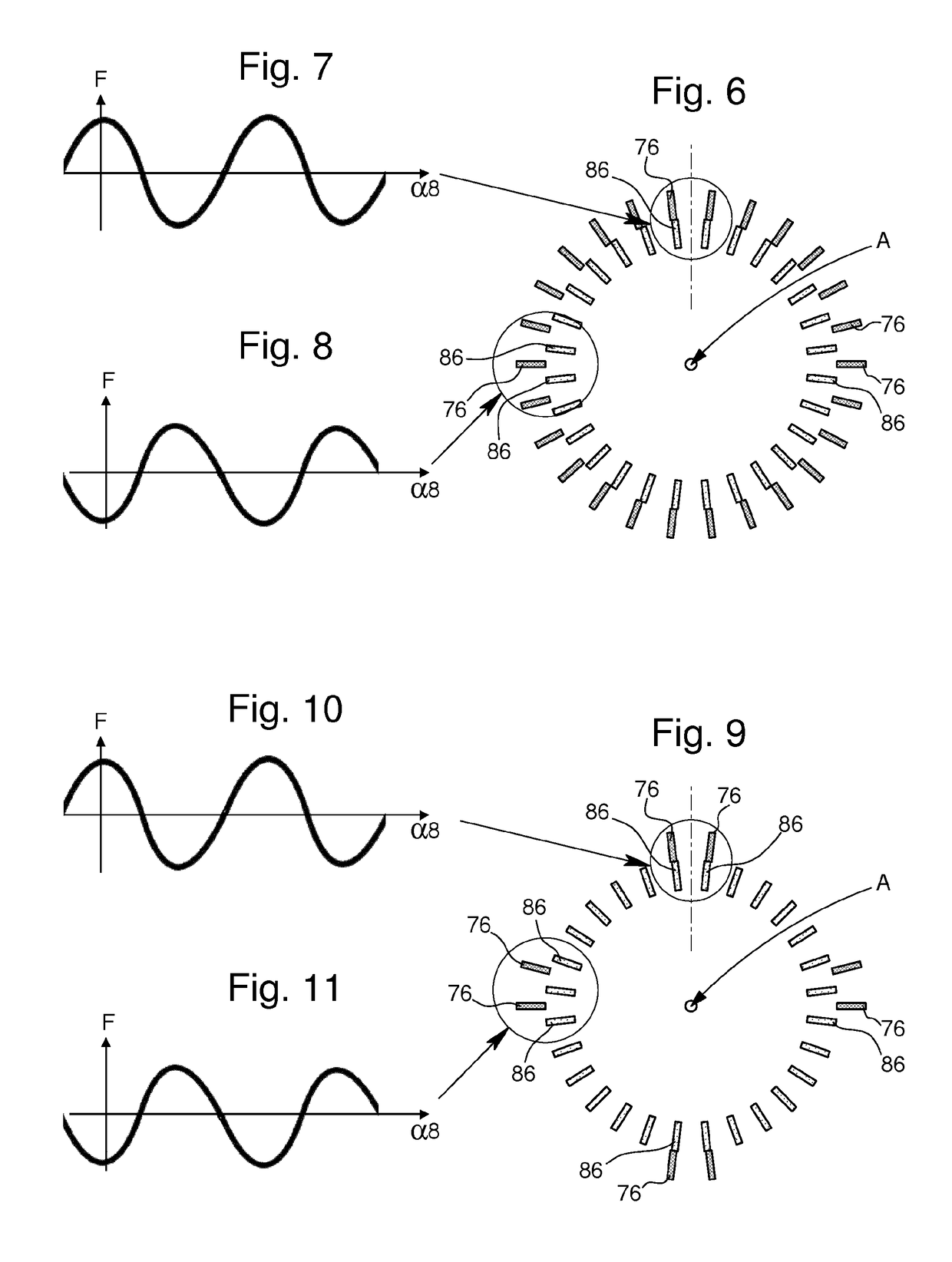

Magnetic and/or electrostatic resonator

A timepiece resonator including a mobile component ring-shaped about an axis and capable of oscillation about an axis, and a drive member subjected to a torque inside a timepiece movement. The resonator is an annular magnetic or electrostatic resonator whose mobile component is periodically excited under action induced by motion of the drive member. The drive member can exert a contactless effort on the mobile component. The mobile component includes a first quantity of first pole pieces magnetically or electrically charged at a first pitch angle, and the drive member includes a second quantity of second pole pieces magnetically or electrically charged at a second pitch angle different from the first pitch angle, arranged to cooperate in attraction or in repulsion with the first pole pieces, such that the mobile component and the drive member together form a speed reducing or increasing mechanism.

Owner:NIVAROX FAR

Method for disassembling electric device of laser shock assisted microcomputer

InactiveCN109773408AAvoid contact scratchesAvoid damageMetal working apparatusMicrocomputerShock wave

The invention relates to a disassembly method of a microcomputer electric device, specifically a method for realizing the separation between matched microcomputer electric devices by utilizing the expansion of plasma generated by laser shock and the mechanical effect of shock wave, which is suitable for the disassembly and separation of the microcomputer electric device. By using the mechanical effect of the laser shock wave, the method provided by the invention can realize the disassembly of the microcomputer electric device in the microcomputer electric system through the non-contact force generated by the shock wave, so that the problems of contact scratch and damage of components caused by conventional operation and difficulty in disassembly at the micro-nano scale are avoided, and theimpact pressure of the laser shock wave is fully utilized to eject the microcomputer electric device in the laser radiation direction, so the invnetion is a brand-new disassembling method of the microcomputer electric device.

Owner:CHENGDU HAIYI ELECTROMECHANICAL EQUIP CO LTD

Laser shock assisted dismounting method for micro electro-mechanical devices

InactiveCN106862754AAvoid contact scratchesAvoid damageLaser beam welding apparatusShock waveNon-contact force

The invention relates to a dismounting method for micro electro-mechanical devices, in particular to a laser shock assisted dismounting method which uses expansion of plasma generated by laser shock and the mechanical effect of shock waves to separate the matched micro electro-mechanical devices and is suitable for dismounting and separating of the micro electro-mechanical devices. According to the laser shock assisted dismounting method for the micro electro-mechanical devices, the mechanical effect of the laser-induced shock waves is adopted, the micro electro-mechanical devices in a micro electro-mechanical system can be dismounted through non-contact force of the shock waves, contact scratches and damage to parts by conventional operation and the problem of being hard to dismount under the micro / nano-scale condition are avoided, shock pressure of the laser-induced shock waves is fully utilized to eject the micro electro-mechanical devices in the laser radiation directions, and the method is a brand-new micro electro-mechanical device dismounting method.

Owner:重庆德秋建设工程有限公司

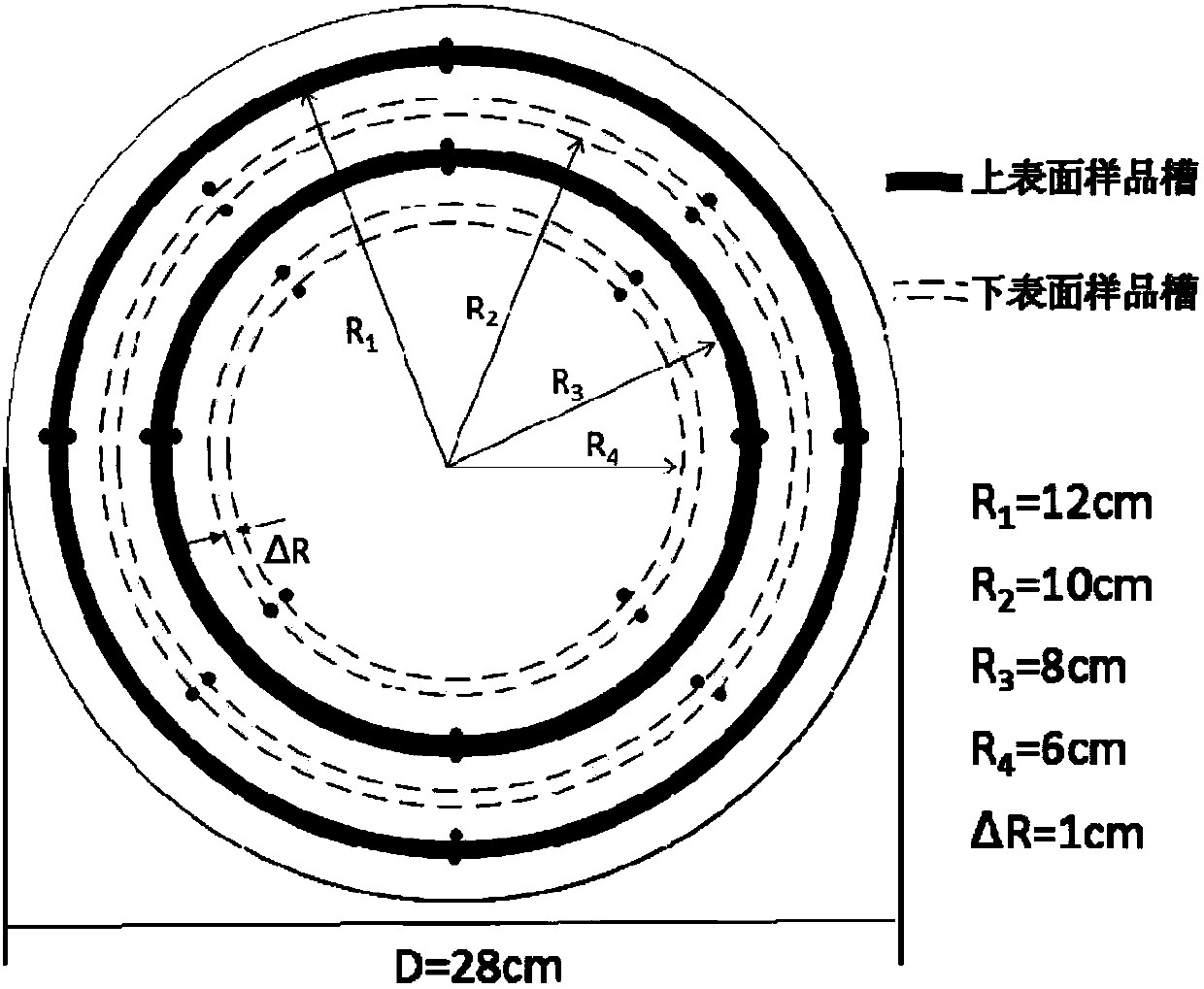

A non-destructive testing method for viscoelasticity of livestock and poultry meat

The present invention relates to the technical field of food detection, in particular to a method for viscoelasticity non-destructive detection of livestock and poultry meat, the method comprising: S1, placing the sample to be tested on a lifting platform and below the sensor head of a laser positioner; S2, The sample to be tested is driven by the lifting platform to perform a lifting movement, so that the distance between the surface of the sample to be tested and the sensor head is a preset value; S3, the air source device is used to generate airflow, and the airflow is input to the sample to be tested through the gas pipeline surface to form a non-contact force; S4, collect the displacement information of the surface of the sample to be tested during the stress process through the sensor head, and feed back the collected displacement information to the lower computer; S5, the lower computer will feedback the displacement information Send it to the host computer for viscoelastic analysis. The method effectively combines airflow pulse and laser ranging technology, so as to realize the non-contact and non-destructive detection of the viscoelasticity of livestock and poultry meat.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com