Substrate positioning device and method, substrate processing device and method

The technology of a positioning device and positioning method is applied in the direction of assembling printed circuits with electrical components, rotary printing machines, printing, etc., which can solve problems such as clamping force deviation, and achieve the effect of high positioning accuracy and increased processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

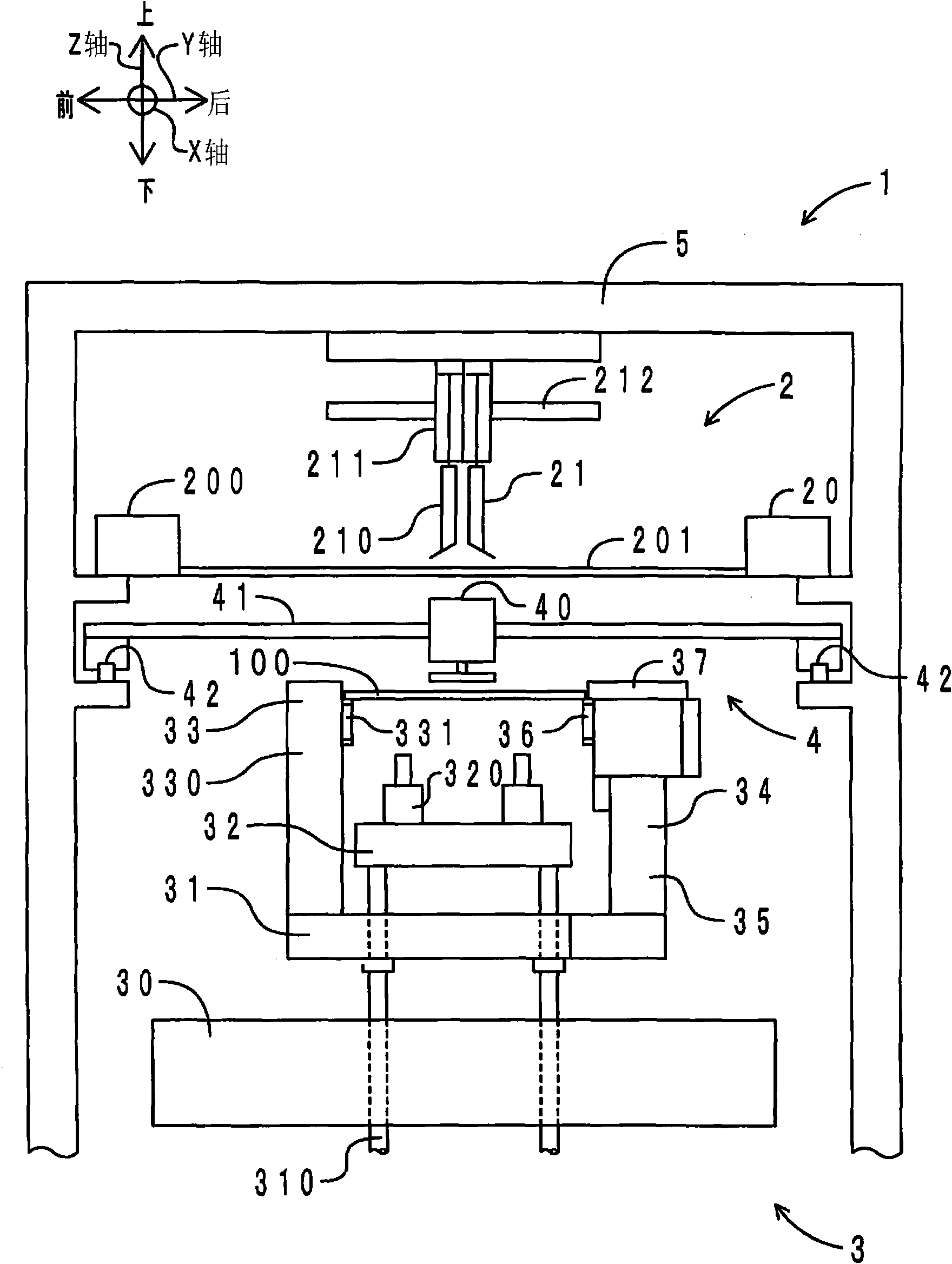

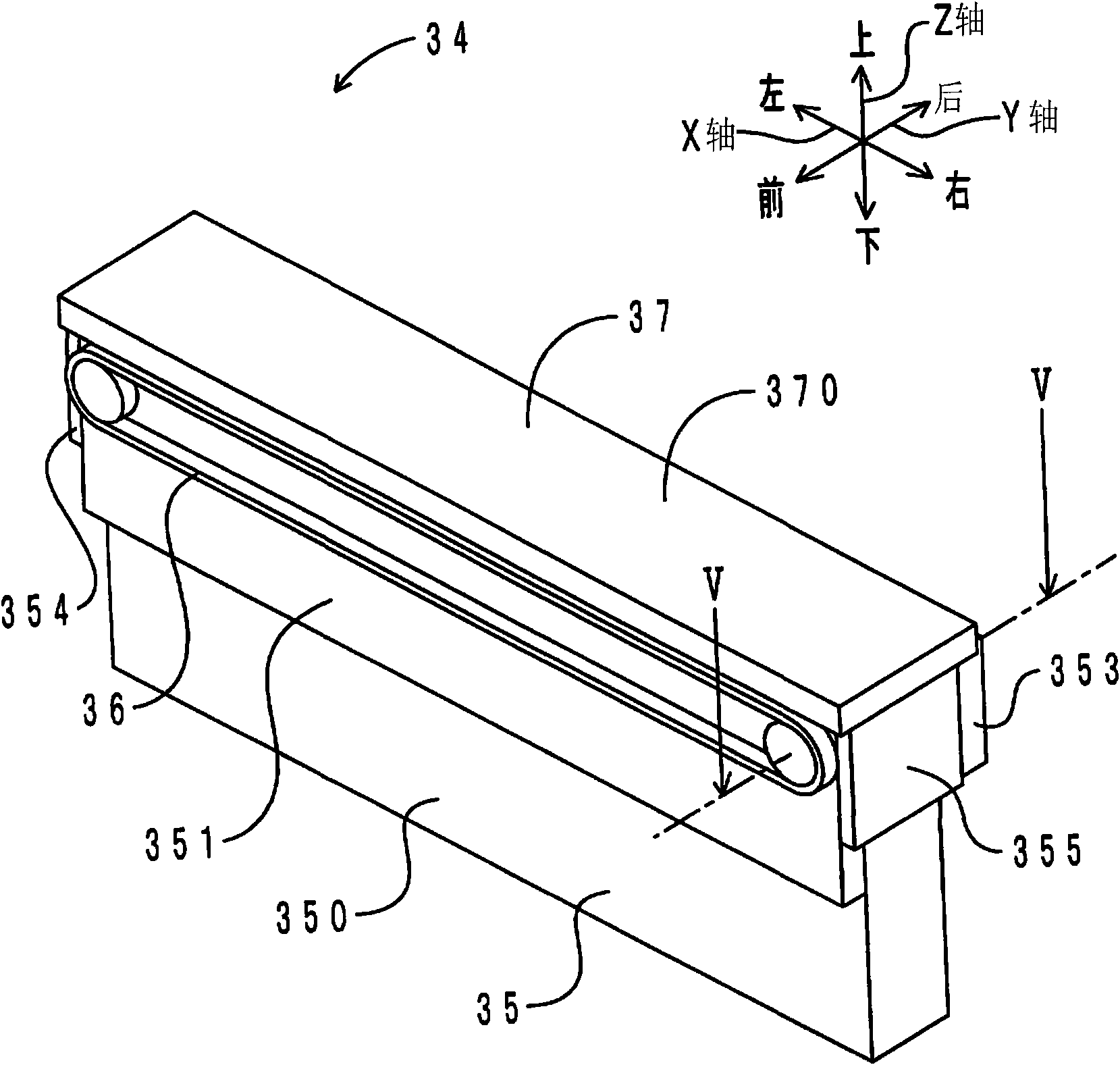

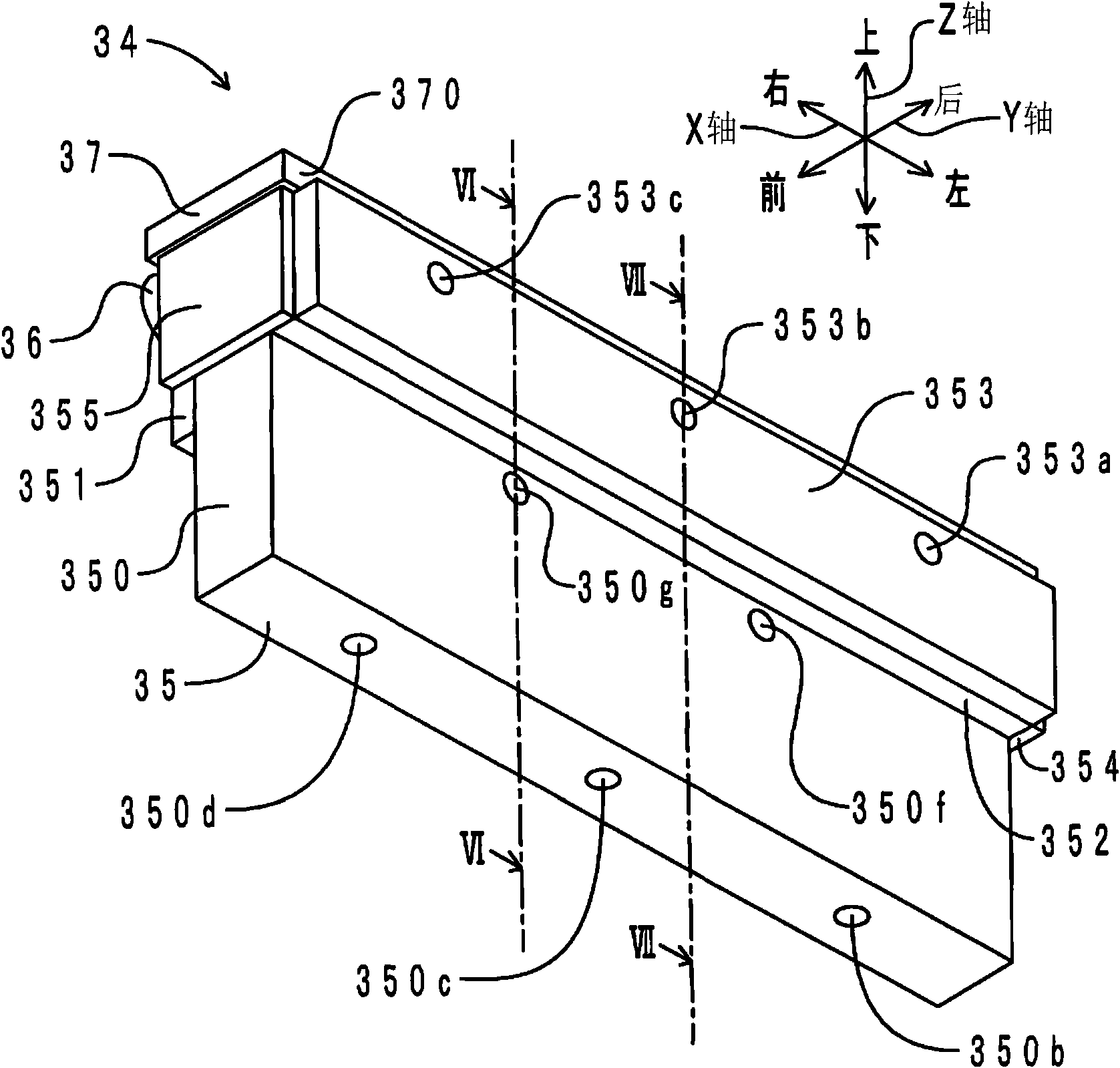

[0087] The structure of the screen printing machine

[0088] First, the structure of the screen printing machine of this embodiment is demonstrated. In the diagrams shown below, the left-right direction is defined as the X direction, the front-rear direction is defined as the Y direction, the up-down direction is defined as the Z direction, and the rotation direction in the XY plane is defined as the θ direction. In addition, the X direction corresponds to the substrate conveyance direction. figure 1 Shown is a side view of the screen printing machine of this embodiment. Such as figure 1 As shown, the screen printing machine 1 of this embodiment mainly includes a printing device 2 , a substrate positioning device 3 , a substrate pressing device 4 and a frame 5 .

[0089] Substrate positioning device

[0090] The substrate positioning device 3 is arranged inside the frame 5 . The board|substrate positioning apparatus 3 whole is supported by the support part which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com